Abstract

We reported here the preparation, characterization, and catalytic ability of a Fe3O4–supported palladium–carbon (Fe3O4–Pd–C) as an efficient catalyst in disproportionation of gum rosin. The magnetic nanocatalyst was prepared by a simple method and was characterized by FTIR, XRD, TEM, N2 adsorption–desorption, VSM, and atomic absorption analysis. The prepared catalyst displayed excellent activity in disproportionation of gum rosin. The magnetic Fe3O4–Pd–C catalyst was successfully recycled three times with keeping its catalytic performance. The simplicity of the nanocatalyst production method and simple separation and recyclability, on the other hand, make possible the industrial production and application of the catalyst.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Active carbon due to high surface area, an open pore structure, excellent thermal and chemical stability, and low price is widely used as catalyst support and adsorbent, and finds extensive uses in the chemical and pharmaceutical-manufacturing industries [1,2,3]. However, carbon-supported catalysts are difficult to separate from reaction mixture and need special filtration system (Fig. 1), and then using them in large scales has been limited [4].

An attractive alternative to filtration or centrifugation is magnetic separation [5,6,7,8]. Magnetic separation method due to simplicity, high efficiency, and low cost has been widely used. In this regard, many researches are concentrating on modified active carbon [9,10,11,12]. For example, recently, Schuth et al. have reported in situ preparation of magnetic-activated carbon by formation of Fe3O4 nanoparticles in the pores of carbon [9]. More recently, preparation of activated maize cob coated with magnetic nanoparticles have been reported by Morad et al. for methylene blue (MB) adsorption [10]. Kakavandi et al. used magnetic-activated carbon for removal of aniline [11]. Mohan et al. used magnetic-activated carbon for tri-nitrophenol removal from aqueous solution [12]. However, in the most of these reports, magnetic active carbon is used as an absorbent, and research on modified carbon using magnetic nanoparticles as a support for application in catalytic reaction has not been reported before.

In our recently efforts, we have found that the activated carbon-supported palladium nanoparticles are an efficient nanocatalyst for the disproportionation of rosin [13]. Here in, the catalytic activity of magnetic palladium–carbon for disproportionation of rosin is reported.

Experimental section

Chemicals

All reagents and chemicals were purchased from the Daejung, Merck and Aldrich companies, and gum rosin was obtained as a gift from Padideh Shimi Jam Co.

Preparation of the activated carbon-supported palladium nanoparticles (Pd–NP–AC)

Twenty grams of activated carbon was dispersed in 50 ml distilled water at 80 °C. One gram of palladium metal was dissolved in aqua regia (4 ml) and added to the reaction mixture. After 2 h, the resulting black solid was filtered and washed by the use of distilled hot water for three times. The sample was dispersed in 60 ml distilled water, and using 2 M sodium hydroxide solution the pH was increased to 9. Next, 60 ml formaldehyde solution (37%) was added to the reaction. After 2 h at 80 °C, the resulting solid was filtered and washed using hot water and dried at 105 °C.

Preparation Fe3O4–palladium–active carbon (Fe3O4–Pd–C)

FeCl3·6H2O (8.7 mmol) and FeCl2·4H2O (4.3 mmol) were dissolved in distilled water at N2 atmosphere. Subsequently, at 90 °C, 15 ml ammonia (25%) and 1 g of palladium–active carbon were added to the reaction mixture. After 30 min, the formed Fe3O4–Pd–C was collected with a magnet, washed three times with distilled hot water and dried at 105 °C. Fe3O4 nanoparticles were individually prepared according to the above procedure without adding palladium–carbon.

General procedure for gum rosin disproportionation by Fe3O4–Pd–C

In a three-neck flask fitted with a stirrer, condenser, and thermometer, 100 g of gum rosin was heated under N2 atmosphere. Once temperature of reaction was reached to 280 °C, and a sample was withdrawn. Subsequently, Fe3O4–Pd–C was added to reaction flask and more samples were withdrawn every 1 h. A gas chromatography analysis was performed for a quantitative analysis of the samples [13].

Recyclability of Fe3O4–Pd–C catalyst

To recycle the Fe3O4–Pd–C catalyst, the catalyst was collected by a magnet, washed with iso-propanol, and dried at 80 °C.

Result and discussion

The Fe3O4–Pd–C catalyst was prepared by a simple co-precipitation of iron precursors (Fe2+ and Fe3+) and palladium–carbon (Fig. 2).

Figure 3 shows the FTIR spectra of the magnetic Fe3O4–Pd–C in the 400–4000 cm−1 wave number range. The IR adsorption band in 567.78 cm−1 is attributed to the Fe–O bonds. The broad band between 3000–3700 cm−1 region is attributed to the hydroxyl groups. The peaks at 1094–1571 cm−1 are ascribed to the presence of active carbon [12, 14]. Therefore, it can be concluded that Fe3O4 nanoparticles were supported successfully on the palladium–carbon.

The X-ray diffraction peaks (XRD) of the Fe3O4 (Fig. 4) and Fe3O4–Pd–C are presented in Fig. 5. Six strong diffraction peaks at 2θ = 30.3, 35.7, 43.4, 53.9, 57.8, and 63.1, which are related to the (220), (311), (400), (422), (511), and (440) phases of Fe3O4 (JCPDS Card no. 88-0315, a = 8.375 Å), were found in the XRD patterns of Fe3O4 and Fe3O4–Pd–C. In the spectra of the Fe3O4–Pd–C, narrow peaks at 2θ = 40.1° and 46.6° and 67.9° were related to the presence of Pd [15], and the mass loadings of Pd were determined to be 2.46% w/w by atomic absorption analysis. The broadening of the 2θ = 10–30° in the spectra of the Fe3O4–Pd–C is related to activated carbon.

The crystal size of the Fe3O4 nanoparticles was calculated using Scherrer’s equation [16]. The determined particle size for Fe3O4 nanoparticles in the Fe3O4 and Fe3O4–Pd–C came out to be 28 nm and 7.5 nm, respectively. This reveals that during the synthesis of the Fe3O4 nanoparticles, Pd–C prevents aggregation of these nanoparticles and because of that Fe3O4 nanoparticles loaded on activated carbon had the smallest sizes.

The lattice strain and dislocation density were 1.2 × 10−3 and 3.9 × 10−2 m−2 for Fe3O4 and 1.7 × 10−2 and 1.5 × 10−2 m−2 for Fe3O4–Pd–C, respectively, and were calculated from Eq. (1) and (2) where ‘D’ and ‘β’ are the crystallite size and the full width at half maximum (radian), respectively [16]. Small strain value indicates good crystallinity.

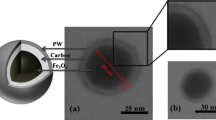

Figure 6 shows the transmission electron microscopy (TEM) images of the palladium–carbon (Pd–C) and Fe3O4 nanoparticles. In the TEM of Pd–C, palladium with high atomic number blocked partial electrons from TEM electron beam, and this made the palladium nanoparticles dark under TEM [5]. TEM images of Pd–C reveal that palladium nanoparticles are well dispersed on activated carbon and the size of Pd particles is about 10–45 nm. The TEM image of Fe3O4 clearly shows that synthesized nanoparticles are distributed uniformly and have an average size of 10–30 nm.

The N2 adsorption–desorption isotherm of the Fe3O4–Pd–C show type IV pattern with hysteresis (H3) loops at relative pressure of 0.6–1.0 (Fig. 7). Brunauer–Emmett–Teller (BET) analysis indicated that surface area of the Fe3O4–Pd–C is 487.7 m2/g, while total pore volume is 0.0407 cm3/g. The pore size diameter was calculated be 2.582 nm. The high surface area (487.7 m2/g) may be beneficial to enhancing the catalytic activity of Fe3O4–Pd–C catalyst.

The magnetically controllable aggregation behavior of Fe3O4–Pd–C was investigated by vibrating sample magnetometer (VSM) studies. Figures 8 and 9 show the VSM curves of the Fe3O4 and Fe3O4–Pd–C, respectively, measured by the Meghnatis Daghigh Kavir Company (Iran). Fe3O4 and Fe3O4–Pd–C show superparamagnetic behavior, and the saturation magnetization was determined to be 65.5 and 25.0 emu g−1, respectively.

Gum rosin is one of the important renewable forestry products and approximately 90% of the gum rosin is the abietic-type resin acid with a conjugated double bond (Fig. 10) [17]. By the use of a catalytic disproportionation reaction, the highly reactive conjugated double bond in abietic-type resin acid can be modified. Due to its advantages, i.e., high oxidation resistance, high softening point, low brittleness, and very good color stability, disproportionated rosin (DPR) has proved to be superior quietly to rosin in many applications.

Here in, the catalytic activity of Fe3O4–Pd–C in the synthesis of DPR from gum rosin was studied, and the reaction was checked by gas chromatography (GC) analysis [13]. A control experiment showed that Fe3O4 and Fe3O4–active carbon could not catalyze this disproportionation reaction, and the presence of palladium is essential. When the reaction was carried out with Fe3O4–Pd–C (0.1% w/w), dehydroabietic acid was obtained in 65% yield after 6 h. If the reaction temperature is decreased from 280 to 220 °C, dehydroabietic acid will obtain in 19.6% yield. After evaluation of the catalytic activity of Fe3O4–Pd–C, optimization shows that the best result was obtained by using of 0.25% w/w of Fe3O4–Pd–C with an optimal reaction temperature of 280 °C. In this condition, dehydroabietic acid was obtained in 74% yield after 1 h.

To recycle the Fe3O4–Pd–C catalyst, the magnetic catalyst was collected by a magnet, washed with iso-propanol for three times, and dried. At least, the Fe3O4–Pd–C catalyst was stable and reusable for three reaction runs (Table 1).

Conclusions

In conclusion, the catalytic disproportionation of gum rosin over a magnetic palladium–carbon (Fe3O4–Pd–C) was investigated. The catalyst obtained via the pathway described in this manuscript is essentially superparamagnetic, has high porosities and high surface areas, and displayed suitable activity in disproportionation of gum rosin. The Fe3O4–Pd–C catalyst was stable and reusable for at least three reaction runs. Such findings are important because the simplicity of the nanocatalyst production method and simple separation and recyclability on the other hand make possible the industrial production and application of the catalyst.

References

Marsh, H., Reinoso, F.R.: Activated carbon. Elsevier, Amsterdam (2006)

Edward, L.K., Ko, D.C., McKay, G.: Production of active carbons from waste tyres—a review. Carbon 42, 2789–2805 (2004)

Vijayakumar, P., Senthil Pandian, M., Pandikumar, A., Ramasamy, P.: A facile one-step synthesis and fabrication of hexagonal palladium-carbon nanocubes (H–Pd/C NCs) and their application as an efficient counter electrode for dye-sensitized solar cell (DSSC). Ceram. Int. 43, 8466–8474 (2017)

Holade, Y., Ege, N., Karine, S., Teko, S., Napporn, W., Kokoh, K.B.: Recent advances in carbon supported metal nanoparticles preparation for oxygen reduction reaction in low temperature fuel cells. Catalysts 5, 310–348 (2015)

Lu, A.H., Salabas, E.L., Ferdi, S.: Magnetic nanoparticles: synthesis, protection, functionalization, and application. Angew. Chem. Int. Ed. 46, 1222–1244 (2007)

Karimi, B., Mansouri, F., Mohammad Mirzaei, H.: Recent applications of magnetically recoverable nanocatalysts in C–C and C–X coupling reactions. ChemCatChem. 7, 1736–1789 (2015)

Faraji, M., Yamini, Y., Rezaee, M.: Magnetic nanoparticles: synthesis, stabilization, functionalization, characterization, and applications. J. Iran. Chem. Soc. 7, 1–37 (2010)

Arefi, M., Saberi, D., Karimi, M., Heydari, A.: Superparamagnetic Fe(OH)3@Fe3O4 nanoparticles: an efficient and recoverable catalyst for tandem oxidative amidation of alcohols with amine hydrochloride salts. ACS Comb. Sci. 17, 341–347 (2015)

Schwickardi, M., Olejnik, S., Salabas, E. L., Schmidt, W., Schuth, F.; Scalable synthesis of activated carbon with superparamagnetic properties. Chem. Commun. 3987–3989 (2006)

Tan, K.A., Morad, N., Teng, T.T., Norli, I., Panneerselvam, O.: Removal of cationic dye by magnetic nanoparticle (Fe3O4) impregnated onto activated maize cob powder and kinetic study of dye waste adsorption. APCBEE Procedia 1, 83–89 (2012)

Kakavandi, B., Jonidi, A., Rezaei, R., Nasseri, S., Ameri, A., Esrafily, A.: Synthesis and properties of Fe3O4-activated carbon magnetic nanoparticles for removal of aniline from aqueous solution: equilibrium, kinetic and thermodynamic studies. Iran. J. Environ. Health. Sci. Eng. 10, 19 (2013)

Mohan, D., Sarswat, A., Singh, V.K., Alexandre Franco, M., Pittman, C.U.: Development of magnetic activated carbon from almond shells for trinitrophenol removal from water. Chem. Eng. J. 172, 1111–1125 (2011)

Mostafalu, R., Hydari, A., Banaei, A., Ghorbani, F., Arefi, M.: The use of palladium nanoparticles supported on active carbon for synthesis of Disproportionate rosin (DPR) as a useful emulsifier in petrochemical industries. J. Nanostruct. Chem. 7, 61–66 (2016)

Ríos-Hurtado, J.C., Múzquiz-Ramos, E.M., Zugasti-Cruz, A., Cortés-Hernández, D.A.: Mechano ynthesis as a simple method to obtain a magnetic composite (activated carbon/Fe3O4) for hyperthermia treatment. J. Biomater. Nanobiotechnol. 7, 19–28 (2016)

Zamani, F., Hosseini, S.M.: Palladium nanoparticles supported on Fe3O4/amino acid nanocomposite: highly active magnetic catalyst for solvent-free aerobic oxidation of alcohols. Catal. Commun. 43, 164–168 (2014)

Vijayakumar, P., SenthilPandian, M., Su Pei, L., Pandikumar, A., Ming, H. N., Mukhopadhyay, S., Ramasamy, P.; Investigations of tungsten carbide nanostructures treated with different temperatures as counter electrodes for dye sensitized solar cells (DSSC) applications, Mater. Sci. Mater. Electron. 26, 7977–7986 (2015)

Wang, L., Chen, X., Sun, W., Liang, J., Xu, X., Tong, Z.: Kinetic model for the catalytic disproportionation of pine oleoresin over Pd/C catalyst. Ind. Crop. Prod. 49, 1–9 (2013)

Acknowledgements

We are thanks the INSF (Iran National Science Foundation), Tarbiat Modares University and Padideh Shimi Jam Co. for supporting of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mostafalu, R., Heydari, A., Arefi, M. et al. A facial, scalable, and green synthesis of superparamagnetic palladium–carbon catalyst and its use in disproportionation of gum rosin. J Nanostruct Chem 7, 201–206 (2017). https://doi.org/10.1007/s40097-017-0230-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-017-0230-9