Abstract

Organic–inorganic nanocomposite membranes of poly(vinyl alcohol) (PVA) and nanoporous silica containing sulfonic acid groups are synthesized in order to increase the proton conductivity, water retention and thermal stability of membrane. The cross-linked PVA/SBA-15-propyl-SO3H nanocomposite membrane was prepared by solution casting method. Infrared spectroscopy and scanning electron microscopy are used to characterize and confirm the structure of PVA and the cross-linked membranes. The impedance spectroscopy, water uptake and thermal stability of membranes are investigated to confirm their applicability in fuel cells. It was found that the cross-linked PVA/SBA-15-propyl-SO3H nanocomposite membrane appears to be a good candidate for using in PEM fuel cell.

Similar content being viewed by others

Introduction

There is a growing worldwide concern about energy sources and supplies. Due to the increasing worries on the diminution of fossil fuel reserves and contamination of climate, fuel cell technologies have received much attention in recent decades because of their high efficiencies and low emissions [1]. In the fuel cells, chemical energy directly converts to electrical energy. There are several kinds of fuel cells, being grouped according to their ion transport medium. This paper focuses on proton exchange membrane (PEM) fuel cells. The heart of the PEM fuel cell is membrane [2]. The traditional membranes used in PEMFC are perfluorosulfonic polymers such as Nafion, a polymer developed by DuPont de Nemours in the late 1960s [3]. Nafion has high electrochemical properties and good proton conductivity. However, the operation at temperatures below 80 °C, methanol crossover and high cost have limited its further application [4, 5].

In the last decades, several methods such as polymer blends, cross-linked polymers and organic–inorganic composite membranes have been proposed to find Nafion alternatives in proton exchange membranes (PEMs). Recent literature describes synthesizes of the organic–inorganic composite membranes by incorporations of hydrophilic inorganic phases such as silicon oxide [6], zeolite [7], metal oxide [8], zirconium phosphates [9], heteropolyacids [10], SBA-15 [11] and nano silica [12] in the commercial Nafion or different organic polymers. There is an extensive literature reporting physical, chemical, thermal, mechanical and operational data for modification of the chemical composition of polymer membranes by several groups.

Yang et al. [13] prepared the cross-linked composite membranes of PVA and MMT. It was found that the proton conductivity of membrane increases from 0.0433 to 0.0623 S cm−1 with addition of 10 % wt MMT at 60 °C. Guzman et al. [14] prepared the porous silica/Nafion composite membranes and tested under high temperature fuel cell operating conditions (140 °C). It was found that with the increase in temperature (above 100 °C), the power density and cell resistance decrease due to membrane dehydration. This organized silica enhances the proton conductivity of membrane at high temperatures up to 100 °C; this improvement is related to the aligned porous channels in the silica [14].

Presently, we introduced new type of nanocomposite membranes for application in PEMFCs. A cross-linked PVA/PSA-g-SN composite polymer membrane was synthesized and demonstrated for PEMFCs [12, 15]. It was found that grafting of sulfonated monomer onto the silica nanoparticles enhances various properties, for example, proton conductivity, water uptake and tensile strength in membranes. A cross-linked PVA and phenyl sulfonated silica were prepared and characterized as proton exchange membrane for PEMFC [16]. It was found that the composite membranes have a higher water retention and thermal stability than that of Nafion 117, perhaps because of responsibility of both acidic groups and nanoporous structure of silica additive. Nafion/Fe2TiO5 nanocomposite membranes for proton exchange membrane fuel cells (PEMFCs) were investigated and showed a higher water uptake, proton conductivity and thermal stability compared with the pure commercial Nafion membranes [17].

PVA membranes have shown relatively good properties under fuel cell circumstances such as good thermal stability, good chemical resistance, film forming ability, high hydrophilicity, high mechanical property, good water uptake and low cost [18]. With a high density of functional –OH groups, PVA also has potential for chemical cross-linking. However, PVA is highly swelling and even dissoluble in water and its properties must be improved with cross-linker. The content of added cross-linker must be controlled because if too much cross-linker is added the membrane construction becomes compact and proton conductivity decreases and if cross-linker is added less than needed, the membrane does not have enough mechanical stability to use in fuel cell. The content of added cross-linker is obtained with trial and error method.

In this work, SBA-15-propyl-SO3H was used to produce the nanocomposite membrane used in PEM fuel cells. Porous silica is one of the most commonly used fillers for proton exchange membranes. The incorporated, sulfonated nanoporous silica with high surface area in an organic polymer matrix enhances water uptake and conductivity properties [16]. The sulfonic acid groups can help to speed up proton transport through nanopore channels. Propyl sulfonic acid groups can be covalently incorporated into nanoporous silica [19]. SBA-15-propyl-SO3H has hexagonal structure, very large surface area, ordered pore structure and extremely narrow pore size distribution with easily accessible acid sites. All of the explained properties are desirable properties important for use in proton exchange membrane applications. These properties of nanoporous silica help to increase water retention in membranes. A membrane with higher water retention can offer more opportunity for protons to transfer through the membrane, leading to higher proton conductivity [20]. The conductivity of SBA-15-propyl-SO3H was above 10−2 S/cm at room temperature [21]. In this work, nanocomposite membrane composed of PVA, glutaraldehyde and SBA-15-propyl-SO3H has been prepared by solution casting method. This is an approach to add functionalized nanoporous filler into polymer for studying the water uptake, proton conductivity, morphology, and thermal stability of nanocomposite membranes.

Methods

Materials

Poly (vinyl alcohol), PVA, +99 % hydrolyzed, with an average molecular weight of 130,000, Pluronic P123 triblock copolymer and 25 wt% solution of glutaraldehyde (GLA) in water were purchased from Sigma-Aldrich. Tetraethylorthosilicate (TEOS), 3-aminopropyltrimethoxysilane (APTES), N, N′-dicyclohexylcarbodiimide, hydrochloric acid and organic solvents were obtained from Merck. These solvent were used as received without further purification.

Synthesis of SBA-15

SBA-15 was prepared according to the literature procedure [22]: 4 g of Pluronic P123 triblock copolymer surfactant (EO20PO70EO20) dissolved in HCl 2 M and tetraethylorthosilicate was added to solution. The mixture was stirred at 40 °C for 8 h. The reaction mixture was then aged for 15 h at 100 °C The mole fraction of this component was 1 TEOS:0.0168 P123:5.854 HCl:162.681 H2O. The obtained white product was filtered, washed by deionized water for several times and dried under vacuum. Calcination of product was performed in oven at 550 °C for 6 h to remove the triblock copolymer organic component.

Synthesis of SBA-15-propyl-SO3H

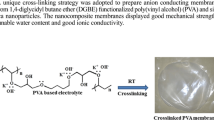

SBA-15 was dried at 100 °C for 3 h under vacuum condition. A mixture containing dry SBA-15 (5 g) and dry toluene (100 ml) reached the reflux temperature. 3-(Trimethoxysilyl)-1-propanethiol (7 ml) was added to the reaction mixture. Reflux was continued for 24 h (Scheme 1). The mixture was filtered and the white powder product (SBA-15-propyl-SH) washed with ether and dichloromethane in soxhlet extractor for 6 h. Anchored mercaptopropyl groups must be post synthetically treated to yield acid active sulfonic groups (SBA-15-propyl-SO3H). This treatment implies oxidation with a large excess of an oxidant mainly hydrogen peroxide in methanol.

Preparation of membranes

Four membranes containing PVA, PVA/GLA, PVA/SBA-15-propyl-SO3H and PVA/GLA/SBA-15-propyl-SO3H were synthesized and named M1–M4, respectively (Table 1). At first, appropriate weight of PVA and SBA-15-propyl-SO3H was dissolved in deionized water under stirring, respectively. The resulting solution was stirred for 1 h at 80–90 °C until the solution mixture became a homogeneous low viscous liquid. Then 1 ml GLA was added into the viscous mixture polymer solution to carry out the cross-linking reaction. The solution stir till the temperature of solution was slowly decreased to room temperature. Finally, 60 mg of 2 M H2SO4 was added to the solution as a catalyst for the cross-linking reaction. The resulting viscous polymer solution was casted onto a glass plate. The resultant solution underwent freeze–thaw cycles in order to enhance mechanical property and elasticity [23, 24]. The thickness of the wet nanocomposite membrane is about 250–300 μm.

Apparatus

The structures of SBA-15-propyl-SO3H-based membranes were characterized by ATR-FTIR spectra in the range of 4,000–600 cm−1 and recorded with a Bruker Equinox 55 using an attenuated total reflectance (ATR, single reflection) accessory purged with ultra dry compressed air. Thermal stability of the membranes was investigated with Mettler DSC 823 in the range −70 to 300 °C and nitrogen flow. The surfaces of the nanocomposite membranes were analyzed by high-resolution scanning electron microscopy (SEM, XL300 philips). Proton conductivity of membranes calculates by AC impedance spectroscopy over the frequency of 10–107 Hz with 50–500 mV oscillating voltage and 10 mV amplitude. Structures of nanoporous materials were investigated with N2 adsorption–desorption isotherm measurements at 77 K with a BELSORP-mini, BEL Japan.

Water uptake measurements

The membranes were dried at high temperature in oven, weighed, soaked in deionized water for 24 h at room temperature and reweighed. Water uptake of nanocomposite membrane was calculated from this formula:

In this formula, mwet is the weight of the wet membranes and mdry is weight of the dry membranes.

Conductivity measurement

Proton conductivities of nanocomposite membranes were measured by AC impedance method. At first, the membranes were soaked in deionized water for 24 h until sufficiently wet and saturated. Then, the membrane was cut into Sections 2 × 0.5 cm and sandwiched between two gold electrodes on the cell. The conductivity of membrane was calculated from the following equation: σ = L/RA, where σ is proton conductivity (S/cm), L is membrane thickness (cm), A is surface area of electrodes (cm2) and R is membrane resistance (Ω).

Results and discussion

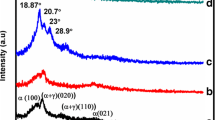

N2 Adsorption

The synthesized nanoporous silica has a high surface area. Surface area (SBET) of this nanoporous materials is determined by N2 physisorption technique (BET method). N2 adsorption isotherms of SBA-15 and SBA-15-propyl-SO3H are shown in Fig. 1 and show that nanoporous silica exhibits a well-defined step with a hysteresis loop corresponding to the filling of the nanopores by capillary condensation. Table 2 shows the surface area, pore volume and pore diameter before and after sulfonation of SBA-15 surface. The decrease in pore sizes and pore volumes confirmed a high ordering of the SO3H groups inside the pores and consequently an increase in number of the SO3H species.

Infrared spectroscopy

The structure of SBA-15-propyl-SO3H was characterized by IR spectroscopy as shown in Fig. 2. The band at around 1,600 cm−1 could be related to bending vibrations of surface O–H groups and water molecules occluded in the pores [25]. Vibrations relating to the O–H stretching in SO3H groups are also seen in spectra at 3,380 cm−1. In addition, the sample has small bands around 2950 and 1,450 cm−1 due to C–H stretching of methylene groups.

Figure 3 shows the attenuated total reflectance (ATR) spectroscopy of M1 and M4 membranes. The M1 membrane illustrates a characteristic absorbance at 3,297 cm−1 (–OH stretching), 2,921 cm−1 (symmetric –CH2–), 1,422 and 1,093 cm−1 for C–O group [16]. The bands occurring at around 3,200 cm−1 (characteristic of O–H stretching vibration) are corresponding to the O–H stretching frequency, which indicates the presence of hydroxyl groups. After cross-linking with GLA, intensity of the O–H stretching vibration band is reduced and shifted to a higher wave number [26]. The cross-linked membrane exhibits the characteristic bands at around 1,200–1,250 cm−1 due to the C–O–C group between the alcohol groups of PVA and the aldehyde groups of GLA [27]. The absorption peak at 2,870 cm−1 can confirm the free aldehyde groups [26]. The presence of sulfonic acid group in M4 membrane was confirmed by the characteristic asymmetric and symmetric S=O stretching vibrations at 1,145 and 1,030 cm−1. Also, the absorption band at ~830 cm−1 identifies existence of the S–O stretching of SO3H groups [28]. The band characteristics of the SBA-15 matrix were observed at 800 cm−1 (Si–O–Si, symmetric vibration) and 1,050 cm−1 (Si–O–Si, asymmetric vibrations). It is clear that Si–O–Si groups are results of condensation reaction between hydrolyzed silanol groups. A further characteristic stretch found in PVA/GLA/SBA-15-propyl-SO3H membrane is present at 883 cm−1 representing silanol O–H groups [29, 30].

Water uptake

It is well known that water uptake and water retention have important effect on the transport behavior and mechanical properties of a proton exchange membrane. The proton conductivity will increase by increasing water uptake because the mobility of protons in the water phase increases with increasing water content. The water uptake of the membranes was tested and the results are shown in Table 3.

From Table 3, water uptake increased with increasing the content of SBA-15-propyl-SO3H in polymer due to decreased cross-linked agent. It can be observed that an increase in sulfonated nanoporous silica content in the nanocomposite membrane leads to a substantial increase in water uptake of the membrane because of the increase in density of functional groups enhancing the porous volume and water retention in the membrane phase [31].

Sulfonation of nanocomposite membrane has a significant impact on water uptake, which in turn determines proton conductivity and mechanical properties of the membrane. The–SO3H groups of nanoporous silica increased water uptake by increasing the hydrophobic surface property. The sulfonic acid groups attracted the –OH groups of PVA to reverse the –SO3H groups to the membrane interior. The high hydrophilic character of sulfonic acid groups, the high surface area and porous volume of nanoporous silica and the stronger interactions between the absorbed water and the modified polymer contribute to increase the water uptake. The GLA decreases the water content because the membrane structure is more compact with addition of cross-linker [32].

Thermal properties

The differential scanning calorimetry (DSC) thermograms of the nanocomposite membranes are shown in Fig. 4. The endothermic peaks appeared at 120–165, 195–215, and 150–185 °C, which corresponded to the melting temperature (Tm) of the pure PVA, PVA/GLA and PVA/GLA/SBA-15-propyl-SO3H membranes. These results show that membranes have several melting points and indicate different crystal structures in nanocomposite membranes.

It was found that the melting temperature, Tm, of the cross-linked PVA/GLA membranes shifted toward higher temperature when the PVA membrane was cross-linked with GLA, which is related to the compacted structure of membrane with addition of cross-linker. The melting temperatures were shifted toward lower temperature region when the amounts of modified SBA-15 fillers were added increasingly. The Tm depression of a crystalline component means that the formation of a crystal is suppressed by the interaction between two blend components. The amorphous structure of silica-based materials can decrease the melting temperature of membranes.

Morphological studies

Figure 5 shows SEM images for the surfaces of nanocomposite membranes (M1 and M4). The effect of SBA-15-propyl-SO3H on the membrane morphology was clearly observed in these SEM images. With addition of SBA-15-propyl-SO3H in the membrane matrix, an incensement in the membrane porosity was observed. It can be clearly known that, the clear and smooth surface of M1 membrane change to uneven surface of M4 membrane which is related to SBA-15-propyl-SO3H particles.

The X-Ray mapping on the surface of M4 membranes is shown in Fig. 6. The X-Ray mapping is used to show Si dispersion on surface of membrane. It can be found that silica particles (the bright spots) are evenly distributed in the matrix.

Conductivity measurements

The water molecules exist in two different forms in nanocomposite membrane. One is the hydrated water that is bound strongly to the –SO3H groups. The other is free water that occupies the central space free from the influence of the ionic sites. It is known that the proton transport in membrane follows by two mechanisms (Fig. 7): the first one is the Grotthuss mechanism (hopping), which can be explained as the proton jump from one bound water molecule (H3O+SO3−) to the next molecule; the second one is the vehicle mechanism, which assume that the proton diffuses together with free water molecules by forming a complex (H3O+) and then diffuses intact [33, 34]. Hence, water molecules have important roles in proton conductivity.

Figure 8 shows the AC impedance spectra for different nanocomposite membranes. Descriptions of the different membrane samples used in this work are given in Table 4. Typically, the R values of the nanocomposite membranes are of the order of 11–130 Ω and are dependent on the contents of the SBA-15-propyl-SO3H and GLA. According to the results, it is clearly seen that the proton conductivity of the nanocomposite membrane decreases when the cross-linking agent is added to membrane. When GLA is added to membrane, the structure of membranes becomes compact and the proton transferring channels become narrow. Hence, the water retention and proton conductivity in the membrane decrease. The proton conductivity of the nanocomposite membrane was enhanced using the sulfonated nanoporous silica matrix. According to Fig. 7, the SO3H groups can help membrane to increase proton conductivity by Grotthuss mechanism. The high porous volume of SBA-15-propyl-SO3H can keep the water molecules and increased proton conductivity of membrane by vehicle mechanism. As a result, proton may easily enter the pores of sulfonated silica and at the interface between PVA and SBA-15-propyl-SO3H and transfer in membrane.

The thermal stability, water uptake and proton conductivity of the PVA/GLA/SBA-15-propyl-SO3H membrane, PVA/GLA/SBA-15-ph-SO3H membrane and Nafion 117 are included in Table 5 for comparison [16, 35, 36]. By considering low proton conductivity of PVA and high density of sulfonated groups in Nafion 117, proton conductivity of the nanocomposite membranes is lower than that of Nafion 117. The results show that, although the proton conductivity of the synthesized nanocomposite membrane has no significant advantage in comparison with Nafion, the water uptake and thermal stability of the nanocomposite membrane are improved. With improved physicochemical and thermal properties, these membranes will be suitable for fuel cell applications as an alternative for Nafion membrane in DMFCs. At end, the results of Table 5 show proton conductivity and Tm of SBA-15-ph-SO3H-based membrane are higher than that of SBA-15-propyl-SO3H-based membrane and the water uptake is equal for both. It was showed that the strength of acid sites of SBA-15-phenyl-SO3H is higher than that of SBA-15-propyl-SO3H [19].

Conclusions

Organic–inorganic nanocomposite membranes based on PVA/SBA-15-propyl-SO3H, in which –SO3H groups are introduced by co-condensation as hydrophilic inorganic modifier, have been investigated. Enhancement of physicochemical and thermal properties due to addition of glutaraldehyde (GLA) as cross-linking agent in a PVA matrix has been studied. Physicochemical and electrochemical properties of these nanocomposite membranes were dependent on the SBA-15-propyl-SO3H content in the membrane matrix as well as the cross-linking density. The characterizations and structure of the membranes were examined and verified by FTIR and SEM techniques. Developed membranes showed good thermal stability, proton conductivity, flexibility and water uptake. The results of differential scanning calorimetry (DSC) show that sulfonated silica decrease and glutaraldehyde can improve the thermal stability of the membrane. With addition of nanoporous silica, the nanocomposite membranes show higher water uptake and proton conductivity. This work demonstrates the promising potential of new nanocomposite membranes for the development of high-performance and high-stability proton exchange membrane fuel cells with improved water uptake and proton conductivity.

References

Wang, Y., Chen, K.S., Mishler, J., Cho, SCh., Adroher, X.C.: A review of polymer electrolyte membrane fuel cells: technology, applications, and needs on fundamental research. Appl. Energy 88, 981–1007 (2011)

Shahi, V.K.: Highly charged proton-exchange membrane: sulfonated poly (ether sulfone)-silica polyelectrolyte composite membranes for fuel cells. Solid State Ionics 177, 3395–3404 (2007)

Vinodh, R., Ilakkiya, A., Elamathi, S., Sangeetha, D.: A novel anion exchange membrane from polystyrene (ethylene butylene) polystyrene: synthesis and characterization. Mater. Sci. Eng. B 167, 43–50 (2010)

Jannasch, P.: Recent developments in high-temperature proton conducting polymer electrolyte membranes. Colloid Interface Sci 8, 96–102 (2003)

Jaafar, J., Ismail, A.F., Mustafa, A.: Physicochemical study of poly(ether ether ketone) electrolyte membranes sulfonated with mixtures of fuming sulfuric acid and sulfuric acid for direct methanol fuel cell application. Mater. Sci. Eng. A 460, 475–484 (2007)

Shao, Z.G., Joghee, P., Hsing, I.M.: Preparation and characterization of hybrid Nafion–silica membrane doped with phosphotungstic acid for high temperature operation of proton exchange membrane fuel cells. J. Membr. Sci. 229, 43–51 (2004)

Te Hennepe, H.J.C., Bargeman, D., Mulder, M.H.V., Smolders, C.A.: Zeolite-filled silicone rubber membranes part I: membrane preparation and pervaporation results. J. Membr. Sci. 35, 39–55 (1987)

Watanabe, M., Uchida, H., Emori, M.: Polymer electrolyte membranes incorporated with nanometer-size particles of Pt and/or metal-oxides: experimental analysis of the self-humidification and suppression of gas-crossover in fuel cells. J. Phys. Chem. 102, 3129–3137 (1998)

Zhou, X.Y., Weston, J., Chalkova, E., Hofmann, M.A., Ambler, C.M., Allcock, H.R., Lvov, S.N.: High temperature transport properties of polyphosphazene membranes for direct methanol fuel cells. Electrochim. Acta 48, 2173–2180 (2003)

Staiti, P., Arico, A.S., Baglio, V., Lufrano, F., Passalacqua, E., Antonucci, V.: Hybrid Nafion–silica membranes dipped with hpa for applications in DMFC. Solid State Ionics 145, 101–107 (2001)

Won, J.H., Lee, H.J., Yoon, K.S., Hong, Y.T., Lee, S.Y.: Sulfonated SBA-15 mesoporous silica-incorporated sulfonated poly(phenylsulfone) composite membranes for low-humidity proton exchange membrane fuel cells: anomalous behavior of humidity-dependent proton conductivity. Int. J. Hydrog. Energy 37, 9202–9211 (2012)

Salarizadeh, P., Javanbakht, M., Abdollahi, M., Naji, L.: Preparation, characterization and properties of proton exchange nanocomposite membranes based on poly(vinyl alcohol) and poly(sulfonic acid)-grafted silica nanoparticles. Int. J. Hydrog. Energy 38, 5473–5479 (2012)

Yang, C.C., Lee, Y.J., Yang, J.M.: Direct methanol fuel cell (DMFC) based on PVA/MMT composite polymer membranes. J. Power Sources 188, 30–37 (2009)

Guzmán, C., Alvarez, A., García, J.L., Torres, S.M.D., Arriaga, L.G.: Composite membranes based on SBA-15 and SBA-16 evaluated at high temperature and low relative humidity fuel cell conditions. Int. J. Electrochem. Sci. 6, 4787–4797 (2011)

Salarizadeh, P., Abdollahi, M., Javanbaht, M.: Modification of silica nanoparticles with hydrophilic sulfonated polymers by using surface-initiated redox polymerization. Iranian Polym J 21, 661–668 (2012)

Beydaghi, H., Javanbakht, M., Salar Amoli, H., Badiei, A., Khaniani, Y., Ganjali, M., Norouzi, P., Abdouss, M.: Synthesis and characterization of new proton conducting hybrid membranes for PEM fuel cells based on poly (vinyl alcohol) and nanoporous silica containing phenyl sulfonic acid. Int. J. Hydrog. Energy 36, 13310–13316 (2011)

Hooshyari, Kh, Javanbakht, M., Naji, L., Enhessari, M.: Nanocomposite proton exchange membranes based on Nafion containing Fe2TiO5 nanoparticles in water and alcohol environments for PEMFC. J. Membr. Sci. 454, 74–81 (2014)

Gomes, A.D.S., Filho, J.C.D.: Hybrid membranes of PVA for direct ethanol fuel cells (DEFCs) applications. Int. J. Hydrog. Energy 37, 6246–6252 (2012)

Usai, E.M., Sini, M.F., Meloni, D., Solinas, V., Salis, A.: Sulfonic acid-functionalized mesoporous silicas: microcalorimetric characterization and catalytic performance toward biodiesel synthesis. Microporous Mesoporous Mater. 179, 54–62 (2013)

Zeng, Q.H., Liu, Q.L., Broadwell, I., Zhu, A.M., Xiong, Y., Tu, X.P.: Anion exchange membranes based on quaternized polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene for direct methanol alkaline fuel cells. J. Membr. Sci. 349, 237–243 (2010)

Feng, F., Yang, Zh, Coutinho, D.H., Ferraris, J.P., Balkus Jr, K.J.: Synthesis of proton conducting tungstosilicate mesoporous materials and polymer composite membranes. Microporous Mesoporous Mater. 81, 217–234 (2005)

Zhao, D., Huo, Q., Feng, J., Chmelka, B.F., Stucky, G.D.: Nonionic triblock and star diblock copolymer and oligomeric surfactant syntheses of highly ordered, hydrothermally stable, mesoporous silica structures. J. Am. Chem. Soc. 120, 6024–6036 (1998)

Hassan, C.M., Peppas, N.A.: Advances in Polymer Science, vol. 153. Springer-Verlag, Berlin (2000)

Peppas, N.A., Stauffer, S.R.: Reinforced uncrosslinked poly (vinyl alcohol) gels produced by cyclic freezing-thawing processes: a short review. J. Control. Release 16, 305–310 (1991)

Kuznetsov, P.N., Kuznetzova, L.I., Zhyzhaev, A.M., Pashkov, G.L., Boldyrev, V.V.: Ultra fast synthesis of metastable tetragonal zirconia by means of mechanochemical activation. Appl. Catal. A Gen 227, 299–307 (2002)

Ansur, H.S., Sadahira, C.M., Souza, A.N., Mansur, A.A.P.: FTIR spectroscopy characterization of poly (vinyl alcohol) hydrogel with different hydrolysis degree and chemically crosslinked with glutaraldehyde. Mater. Sci. Eng. C 28, 539–548 (2008)

Kang, M.S., Choi, Y.J., Moon, S.H.: Water-swollen cation-exchange membranes prepared using poly (vinyl alcohol) (PVA)/poly (styrene sulfonic acid-co-maleic acid) (PSSA-MA). J. Membr. Sci. 207, 157–170 (2002)

Tseng, ChY, Ye, YSh, Kao, K.Y., Joseph, J., Shen, WCh., Rick, J., Hwang, B.J.: Interpenetrating network-forming sulfonated poly(vinyl alcohol) proton exchange membranes for direct methanol fuel cell applications. Int. J. Hydrog. Energy 36, 11936–11945 (2011)

Timofeeva, M.N., Jhung, S.H., Hwang, Y.K., Kim, D.K., Panchenko, V.N., Melgunov, M.S.: Ce-silica mesoporous SBA-15-type materials for oxidative catalysis: synthesis, characterization, and catalytic application. Appl. Catal. A Gen 317, 1–10 (2007)

Linder, N.B., Dosseh, G., Simonesco, ChA, Audonnet, F.: Imperor-Cler M. SBA-15 synthesis: are there lasting effects of temperature change within the first 10 min of TEOS polymerization. Mater. Chem. Phys. 108, 73–81 (2008)

Nagarale, R.K., Gohil, G.S., Shahi, V.K., Rangarajan, R.: Organic-inorganic hybrid membranes: thermally stable cation-exchange membrane by sol–gel method. Macromolecules 37, 10023–10030 (2004)

Kim, D.S., Park, H.B., Rhim, J., Lee, Y.M.: Preparation and characterization of crosslinked PVA/SiO2 hybrid membranes containing sulfonic acid groups for direct methanol fuel cell applications. J. Membr. Sci. 240, 37–48 (2004)

Kim, D.S., Liu, B., Guiver, M.D.: Influence of silica content in sulfonated poly(arylene ether ether ketone ketone)(SPAEEKK) hybrid membranes on properties for fuel cell application. Polymer 47, 7871–7880 (2006)

Rodriguez, C.M.B., Paleta, M.G.A.R., Marquezv, J.A.R., Delavega, J.R.G.: Effect of a rigid gas diffusion media applied as distributor of reagents in a PEMFC in operation, part II: wet gases. Int. J. Electrochem. Sci. 5, 414–428 (2010)

Pang, J., Zhang, H., Li, X., Wang, L., Liu, B., Jiang, Zh: Synthesis and characterization of sulfonated poly(arylene ether)s with sulfoalkyl pendant groups for proton exchange membranes. J. Membr. Sci. 318, 271–279 (2008)

Kim, S.O., Kim, J.S.: Preparation of hybrid proton conductor by sol–gel process from Nafion solution. Macromol. Res. 10, 174–177 (2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under license to BioMed Central Ltd. Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Beydaghi, H., Javanbakht, M. & Badiei, A. Cross-linked poly(vinyl alcohol)/sulfonated nanoporous silica hybrid membranes for proton exchange membrane fuel cell. J Nanostruct Chem 4, 97 (2014). https://doi.org/10.1007/s40097-014-0097-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40097-014-0097-y