Abstract

This study characterized and evaluated the life cycle greenhouse gas (GHG) emissions from different wind electricity generation systems by (a) performing a comprehensive review of the wind electricity generation system life cycle assessment (LCA) studies and (b) statistically evaluating the life cycle GHG emissions (expressed in grams of carbon dioxide equivalent per kilowatt hour, gCO2e/kWh). A categorization index (with unique category codes, formatted as ‘axis of rotation-installed location-power generation capacity’) was adopted for use in this study to characterize the reviewed wind electricity generation systems. The unique category codes were labeled by integrating the names from the three wind power sub-classifications, i.e., the axis of rotation of the wind turbine [horizontal axis wind turbine (HAWT), vertical axis wind turbine (VAWT)], the location of the installation [onshore (ON), offshore (OFF)], and the electricity production capacity [small (S), intermediate (I), large (L)]. The characterized wind electricity generation systems were statistically evaluated to assess the reduction in life cycle GHG emissions. A total of five unique categorization codes (HAWT-ON-S, HAWT-ON-I, HAWT-ON-L, HAWT-OFF-L, VAWT-ON-S) were designated to the 29 wind electricity generation LCA studies (representing 74 wind system cases) using the proposed categorization index. The mean life cycle GHG emissions resulting from the use of HAWT-ON-S (N = 3), HAWT-ON-I (N = 4), HAWT-ON-L (N = 58), HAWT-OFF-L (N = 8), and VAWT-ON-S (N = 1) wind electricity generation systems are 38.67, 11.75, 15.98, 12.9, and 46.4 gCO2e/kWh, respectively. The HAWT-ON-I wind electricity generation systems produced the minimum life cycle GHGs than other wind electricity generation systems.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wind energy may be defined as the energy harnessed by a wind turbine that converts the kinetic energy of the wind to mechanical energy and then to electricity. A wind turbine is comprised of different components such as the tower, the rotor blades, the yaw mechanism, the wind speed and direction monitor, and the gear box. The tower is mostly cylindrical and made of steel with heights varying from 25 to 75 m. The rotor blades are prepared with fiberglass-reinforced polyester or wood-epoxy and have a diameter varying between 30 and 80 m. As the length of the rotor blade increases, the electricity generation capacity of the wind turbine also increases. The yaw mechanism turns the turbine to face the wind. The power is automated to vary with the wind speed and stopped at very high wind speeds to prevent damage. The sensors monitor the wind direction and the tower head is turned to line up with the wind. The gear box helps increase the rotational speed from a low-speed rotor to a higher speed electrical generator.

The total electricity generation in 2012 across the world was reported to be 21.53 trillion kilowatt hours (kWh) [1]. The projected world electricity generation for 2040 is 39 trillion kWh (81%) [2]. The renewable energy sources have been projected to account for 9.6 trillion kWh (25%) of the world’s total electricity generation in 2040. With the continuing depletion of traditional non-renewable energy sources, the necessity for generating electricity through the use of renewable energy sources (wind, hydro, biomass, solar, geothermal) increased manifold. Wind energy accounted for only 0.52 trillion kWh (2.42%) of the world’s total electricity generated in 2012. Based on the 2012 statistics, wind energy was identified to be the second largest renewable energy source for electricity generation after hydro (3.646 trillion kWh) [1]. The global wind energy based electricity generation is projected to account for 25–30% of the global electricity supply in 2050 [3]. In the United States of America (USA), wind energy based electricity generation is projected to account for the largest absolute increase in renewable electricity generation to displace hydropower in becoming the largest renewable electricity generation source by 2040 [4]. These statistics indicate that there is ample scope to generate electricity on a large scale using wind energy.

Considering the projected increase in the use of wind electricity generation systems across the world, one needs to evaluate the life cycle greenhouse gas (GHG) emissions resulting from the adoption of different categories of wind electricity generation systems. The life cycle assessment (LCA) approach helps evaluate the net GHG emissions resulting from the use of wind energy as a fuel. LCA is an analytical method that provides an assessment of the environmental impacts of the considered products and technologies from a ‘cradle to grave’ systems perspective utilizing the detailed input and output parameters that operate within the designated system boundaries.

There are numerous studies that performed the LCA on wind electricity generation systems. The material production (manufacturing) stage was identified to be the primary stage that governs the life cycle GHGs emitted from wind electricity generation systems [5–12]. Approximately, 90% of the wind turbine materials were noted to be recyclable [13]. The use of recyclable materials in wind electricity generation systems considerably reduced the life cycle GHG emissions [9, 10, 14]. The GHG emissions from wind electricity generation systems were also noted to be mainly influenced by the capacity factor, the lifetime, and the rated power [15, 16]. There were less GHG emissions from wind electricity generation systems in comparison to solar [17–19], hydro [20, 21], geothermal [21], coal [17, 18, 20, 22–24] and natural gas [17, 18, 20, 22, 23] electricity generation systems. The coastal wind electricity generation systems produced less GHGs than the inland wind electricity generation systems [25]. There is no significant difference in the energy yield between the use of small and large scale wind turbines [26]. There are several other studies [19, 27–33] that quantified the GHGs by performing the LCA of real-world wind electricity generation systems.

The use of wind electricity generation systems across the world is encouraged considering that the wind is a free and an abundant energy resource that may be used for electricity generation with minimal installation, operational, and maintenance costs. The wind electricity generation systems also require less land resources and may be easily integrated into the rural infrastructure with existing farms and ranches. The use of wind electricity generation systems is inhibited by issues such as the production of noise and aesthetic pollution from wind turbines, the damage to local wildlife, and the remote location of good wind sites farther from the urban areas with high electricity demand. A more detailed description of the LCA boundary conditions, GHG emissions, and site-specific characteristics associated with each of the aforementioned wind electricity generation system studies are summarized in the “Review of wind LCA studies” section.

The majority of the wind LCA publications to date have emphasized on the determination of the life cycle GHG emissions for select site-specific wind turbine installations. There are limited studies [34, 35] that evaluated the life cycle GHG emissions on the basis of whether the wind electricity generation system was located onshore or offshore. None of the earlier studies examined the life cycle GHG emissions and characterized them across all the currently available distinct wind electricity generation classification systems. This study aims to fill this knowledge gap by performing a comprehensive review of the literature on all the currently available wind electricity generation LCA studies, followed by a statistical evaluation of the life cycle GHG emissions from the reviewed wind electricity generation system categories distinctly. The results from the statistical evaluation of the life cycle GHG emissions will assist energy policy makers and environmental professionals in identifying and encouraging the use of environmental-friendly wind electricity generation system category options to generate electricity with minimal GHG emissions.

Methodology

A review of the literature showed that the wind electricity generation systems may be categorized broadly using one of the three classification systems described in this section. The classification of wind electricity generation systems is primarily based on the axis of rotation (design) of the wind blades [36] as follows:

-

Horizontal axis wind turbine (HAWT)—the rotational axis of the wind turbine is horizontal (parallel) with the ground. These are the more widely adopted wind turbines capable of producing more electricity from a given amount of wind.

-

Vertical axis wind turbine (VAWT)—the rotational axis of the wind turbine is vertical (perpendicular) to the ground.

Of the two, the HAWTs are the most widely adopted systems due to their superior performance in generating electricity for a given amount of wind. The VAWTs are adopted for small scale electricity generation purposes in small wind projects and residential applications.

The wind electricity generation systems may further be classified on the basis of the installed location [35] as follows:

-

Onshore (ON)—wind turbines are installed over the land.

-

Offshore (OFF)—the wind turbines are installed in shallow waters off the coastal areas.

The majority of the existing wind electricity generation systems are onshore-based wind electricity generation systems located in hilly areas or open spaces. The offshore wind electricity generation systems are gaining prominence with time and have the advantage of using the relatively higher wind speeds on water bodies to generate electricity. The offshore winds tend to blow harder and more uniformly than on the land.

Depending on the electricity production capacity, wind electricity generation systems may be categorized [37] as follows:

-

Small (S)—electricity generation capacity is less than 0.1 megawatt (MW).

-

Intermediate (I)—electricity generation capacity is between 0.1 and 0.25 MW.

-

Large (L)—electricity generation capacity is between than 0.25 and 5 MW.

This study proposed and adopted the use of a new categorization index that integrated the name of all three classification systems mentioned above to generate unique category codes, represented by ‘axis of rotation-installed location-power generation capacity’ labels to characterize the wind electricity generation systems. A total of 12 unique category codes (HAWT-ON-S, HAWT-ON-I, HAWT-ON-L, HAWT-OFF-S, HAWT-OFF-I, HAWT-OFF-L, VAWT-ON-S, VAWT-ON-I, VAWT-ON-L, VAWT-OFF-S, VAWT-OFF-I, VAWT-OFF-L) may be generated using different combinations of the three classification systems. Each of the reviewed wind LCA studies was first assigned to one of the unique category codes proposed in this study. Next, the life cycle GHG emissions from the individual category coded wind electricity generation systems were evaluated using statistical metrics (sample size, mean, standard deviation, minimum, maximum, standard error of the mean, quartile 1, quartile 2 or median, quartile 3) and graphical representations (error bars representing the mean with 95% confidence intervals, box plots representing the quartiles with outliers). While the error bars demonstrate the degree of confidence in the mean GHG emissions, the box plots provide information on the degree of variation among the LCA studies characterized by different categories of wind electricity generation systems.

Results and discussion

Review of wind LCA studies

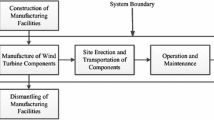

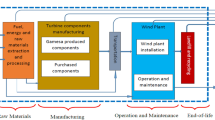

There are numerous studies [5–33] that evaluated the life cycle environmental impacts of using wind energy for electricity generation. One has to define the system boundary conditions (that includes details on the activities or processes to be considered in the analysis) and a functional unit of measure (that enables quantification of the net environmental impacts from carrying out an activity or a process as defined within the LCA system boundary conditions) when performing a LCA.

The majority of the aforementioned studies [6–14, 17–19, 21–24, 26–33] performed the conventional LCA of wind electricity generation systems by defining the system boundary conditions to include the raw material extraction, material processing, component manufacturing process, transportation, assembly and installation, operation and maintenance, and end-of-life process (decommissioning, recycling/reuse, and final disposal) activities. Two studies [15, 16] excluded the activity of end of life cycle scenario from the system boundary conditions mentioned above in relation to the majority of the wind electricity generation system LCA studies. A couple of the reviewed LCA studies [20, 25] were noted to use the input–output analysis with system boundaries varying with the material inputs considered in the respective studies. The remaining study [5] combined the conventional LCA and the input–output LCA approaches to develop a hybrid LCA approach for analyzing the life cycle impacts of wind electricity generation systems.

The common functional unit of measure adopted by the majority of the wind LCA studies is grams of carbon dioxide equivalent per kilowatt hour (gCO2e/kWh) of electricity produced. Accordingly, this study also adopts the functional unit of measure for GHG emissions to be gCO2e/kWh of electricity produced.

Table 1 provides a summary of the wind electricity generation system categorization [unique category codes generated from the combination of the three classification systems—axis of rotation (HAWT, VAWT), installed location (ON, OFF), electricity production capacity (S, I, L)] along with the corresponding GHG emissions (in gCO2e/kWh) and energy payback time (EPBT, expressed in years) periods for the reviewed wind LCA studies. Table 1 also provides additional site-specific details that included the capacity factor (CF, expressed in %), the power rating (PR, expressed in MW), and the geographical location (GL) for the installed wind electricity generation systems. The EPBT is the time period for which a wind system should operate to recover an equivalent amount of energy spent in the production and operation of the installed wind electricity generation system. CF is the ratio of the average power generated to the rated peak power. One study [15] noted that the site conditions and the characteristics of the wind turbine determine the CF, and the variation in GHG emissions of wind electricity generation systems is dependent on the CF, the lifetime of the infrastructure, and the rated power. PR is the amount of electrical power that is produced under standard operating conditions. One study [38] noted the PR to be varying proportionally with the product of the rotor area and the cube of the wind velocity at a given hub elevation.

Based on the review of 29 wind electricity generation LCA studies (refer to Table 1), one may note that the HAWT-ON-L (N = 58) wind electricity generation systems were more in number compared to HAWT-OFF-L (N = 8), HAWT-ON-I (N = 4), HAWT-ON-S (N = 3), and VAWT-ON-S (N = 1) wind electricity generation systems. There were no LCA studies on the use of HAWT-OFF-S, HAWT-OFF-I, VAWT-ON-I, VAWT-ON-L, VAWT-OFF-S, VAWT-OFF-I, and VAWT-OFF-L wind electricity generation systems. This is because the VAWTs are limited in their use to generate electricity only at a small scale (making the VAWTs inappropriate for intermediate and large scale electricity generation) and the offshore-based wind electricity generation systems require higher costs of installation and are designed for large scale electricity production to maximize the available higher wind speeds on water bodies (making the use of offshore-based HAWTs unsuitable for small and intermediate scale electricity generation). From Table 1, one may also note that the HAWT electricity generation systems (N = 73) were more in number compared to the VAWTs (N = 1), onshore-based electricity generation systems (N = 66) were more in number compared to the offshore-based electricity generation systems (N = 8), and large scale wind electricity generation systems (N = 66) were more in number compared to the small scale wind electricity generation systems (N = 4) and the intermediate scale wind electricity generation systems (N = 4).

While the life cycle stages of materials production, manufacture, and production of wind turbines accounted for approximately 90% of the total GHGs emitted, the life cycle phases of transportation, disassembly and renovation/maintenance contributed less GHG emissions of the order of approximately 5–8% [6, 34, 35]. For the small wind electricity generation systems, the life cycle processes of wind turbine production, transportation, and installation were identified to be the significant influential factors affecting GHG emissions [11]. From Table 1, one may note that the GHG emissions from wind electricity generation systems decreased with an increase in the CF [14], the life cycle time period considerations [20], and the power rating [8, 14, 17, 31]. Similar observations were made by another study [15] that noted the environmental performance of wind electricity generation systems to increase with an increase in the CF, the lifetime of the infrastructure, and the rated power. A couple of the reviewed LCA studies [14, 31] also noted that the option of recycling during decommissioning (end-of-life scenario) provided a significant positive effect on the environmental performance of wind electricity generation systems.

Statistical evaluation of wind LCA studies

Figure 1 provides a graphical representation of the (a) error bars [mean ± 95% confidence interval (CI) statistics] and (b) box plots [quartiles + outlier statistics] for GHG emissions from the different wind electricity generation systems reviewed in this study. Table 2 provides a statistical summary of the life cycle GHG emissions with details on the sample size (N), mean (X) ± standard deviation (SD), minimum (Min.), maximum (Max.), standard error of the mean (SE), quartile 1 (Q1), quartile 2 or median (Q2), and quartile 3 (Q3) for the different wind electricity generation systems reviewed in this study.

From Fig. 1a and Table 2, one may note that the mean life cycle GHG emissions obtained from the use of HAWT-ON-S, HAWT-ON-I, HAWT-ON-L, HAWT-OFF-L, and VAWT-ON-S wind electricity generation systems are 38.67, 11.75, 15.98, 12.9, and 46.4 gCO2e/kWh, respectively. The minimum GHGs are emitted from the HAWT-OFF-L and the HAWT-ON-L wind electricity generation systems. One may infer that the large wind electricity generation systems are more environmental-friendly than the intermediate and the small wind electricity generation systems. Similar observations were made by one study [15] that noted an improvement in the environmental performance of wind electricity generation systems with increasing installed electricity generation capacity, the reason being attributed to the effect of scaling (decreased material consumption per kWh of electricity produced). The use of large scale wind turbines also benefits by reducing the required footprint area per unit of rated output [26]. The mean life cycle GHG emissions were noted to be higher in the case of onshore wind electricity generation systems than the offshore wind electricity generation systems (refer to Fig. 1a; Table 2). This observation may be attributed to the variation in the scale of economies (considering offshore wind electricity generation system installations are considerably larger than the onshore wind electricity generation systems) and the possibly higher GHG emissions associated with the construction phase activities such as the destruction of forest or peat land habitats for onshore wind electricity generation systems [34, 35]. The very high average annual wind speeds occurring in offshore locations account for the superiority in the environmental performance of offshore turbines in comparison to the onshore units, despite the relatively lower environmental performance of offshore turbines than their onshore counterparts with the same CFs [15].

From Fig. 1b, one may note the degree of variation in GHG emissions was less for HAWT-ON-I wind electricity generation systems when compared to the HAWT-OFF-L, HAWT-ON-S and HAWT-ON-L wind electricity generation systems. The relatively higher variations in the GHG emissions for HAWT-ON-S wind electricity generation systems may be attributed to the considerable differences in the turbine PRs (0.005–0.02 MW) within the limited case representations (N = 3). The considerably higher variations in the HAWT-ON-L wind electricity generation system GHG emissions may be attributed to the combination of considerable differences in the turbine PRs (0.3–4.5 MW) and the CFs (11–42.5) across the ample case representations (N = 58). The reasonably higher variations in the GHG emissions for HAWT-OFF-L wind electricity generation systems may also be attributed to the combination of differences in the turbine PRs (0.5–5 MW) and the CFs (29–53) for the specified case representations (N = 8). The GHG emissions tend to generally decrease with an increase in the CF and the turbine PR [16]. The median GHG emissions were the lowest for HAWT-ON-L, followed by HAWT-ON-I, HAWT-OFF-L, and HAWT-ON-S (refer to Fig. 1b; Table 2). More LCA studies utilizing VAWT-ON-S wind electricity generation systems are to be considered before one generalizes the influence of VAWT-ON-S on the life cycle GHG emissions (note that the mean life cycle GHG emission statistics of VAWT-ON-S wind electricity generation systems in this study were based on a sample size equal to one).

Figure 2 provides a graphical representation of the (a) error bars [mean ± 95% confidence interval (CI) statistics] and (b) box plots (quartiles + outlier statistics) for EPBT periods from the different wind electricity generation system categories reviewed in this study. Table 3 provides a statistical summary of the EPBT periods for the different wind electricity generation system categories reviewed in this study. From Fig. 2a and Table 3, one may note that the mean EPBT period was the highest for VAWT-ON-S (6.5 years), followed by HAWT-ON-S (1.1 years), HAWT-ON-L (0.58 years), and HAWT-ON-I/HAWT-OFF-L (0.39 years). These results indicate that the EPBT periods followed a similar trend to that observed in GHG emissions, i.e., the EPBTs decreased with an increase in the electricity production capacity, VAWTs had the highest EPBT periods and offshore-based large scale HAWT power generation systems had the minimum EPBT period. From Fig. 2b and Table 3, one may note that the median statistic showed a different pattern to that observed in the mean EPBT periods for different wind electricity generation systems, with VAWT-ON-S being the highest (6.5 years), followed by HAWT-ON-S (1.1 years), HAWT-ON-L (0.58 years), HAWT-OFF-L (0.39 years), and HAWT-ON-I (0.33 years).

Conclusions

This paper characterized the life cycle GHG emissions from wind electricity generation systems with respect to the development of a new categorization index that integrated the names from the three classification systems based on the axis of rotation of the wind turbine (HAWT, VAWT), the location of the installation (ON, OFF), and the power generation capacity (S, I, L). A total of 29 wind electricity generation system LCA studies that summarized 74 wind system cases were identified in the literature and reviewed in this study. Each of the reviewed wind electricity generation system LCA study was assigned an unique category code in accordance with the developed categorization index. The categorization of the reviewed 29 wind electricity generation system LCA studies yielded a total of five distinct categories, namely, HAWT-ON-S, HAWT-ON-I, HAWT-ON-L, HAWT-OFF-L, and VAWT-ON-S. While the VAWTs were noted to be used for only small scale electricity production, the offshore-based wind electricity generation systems were only used for large scale electricity generation. HAWTs were used for both onshore and offshore wind electricity generation.

The mean life cycle GHG emissions from HAWT-ON-S, HAWT-ON-I, HAWT-ON-L, HAWT-OFF-L, and VAWT-ON-S wind electricity generation systems were computed to be 38.67, 11.75, 15.98, 12.9, and 46.4 gCO2e/kWh, respectively. The mean EPBT period was the highest for VAWT-ON-S (6.5 years), followed by HAWT-ON-S (1.1 years), HAWT-ON-L (0.58 years), and HAWT-ON-I/HAWT-OFF-L (0.39 years). The mean life cycle GHG emissions from wind electricity generation systems were noted to decrease with an increase in the CF, the cycle time period considerations for the infrastructure, and the power rating of the wind electricity generation systems. The HAWT-ON-I wind electricity generation systems provided the best environmental-friendly option with the lowest GHG emissions and EPBT period. The HAWT-OFF-L wind electricity generation systems performed better than the HAWT-ON-L wind electricity generation systems. All the four categories of HAWT-ON-S, HAWT-ON-I, HAWT-ON-L, and HAWT-OFF-L wind electricity generation systems had lower GHG emissions and EPBT periods than the VAWT-ON-S wind electricity generation system, thereby, indicating that HAWTs outperformed the VAWTs and are recommended for future use. There was only a single representative LCA study noted in the literature for VAWT-ON-S wind electricity generation system. More research efforts are needed to study the LCA of VAWT-ON-S wind electricity generation systems.

References

United States Energy Information Administration.: International energy statistics. http://www.eia.gov/cfapps/ipdbproject/iedindex3.cfm?tid=44&pid=44&aid=2&cid=ww,r1,&syid=2008&eyid=2012&unit=QBTU (2012). Accessed 9 November 2015

United States Energy Information Administration.: International energy outlook 2013. http://www.eia.gov/forecasts/ieo/pdf/0484(2013).pdf (2013). Accessed 9 November 2015

Global Wind Energy Council.: Global wind energy outlook 2014. http://www.gwec.net/wp-content/uploads/2014/10/GWEO2014_WEB.pdf (2014). Accessed 18 February 2016

United States Energy Information Administration.: Annual Energy Outlook 2015 with Projections to 2040. http://www.eia.gov/forecasts/aeo/pdf/0383%282015%29.pdf (2015). Accessed 9 November 2015

Lenzen, M., Wachsmann, U.: Wind turbines in Brazil and Germany: an example of geographical variability in life-cycle assessment. Appl. Energy 77, 119–130 (2004)

Rydh, C.J., Jonsson, M., Lindahl, P.: Replacement of old wind turbines assessed from energy, environmental and economic perspectives. http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.524.8291&rep=rep1&type=pdf (2004). Accessed 9 January 2016

Khan, F.I., Hawboldt, K., Iqbal, M.T.: Life cycle analysis of wind-fuel cell integrated system. Renew. Energy 30, 157–177 (2005)

Pehnt, M.: Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew. Energy 31, 55–71 (2006)

Ardente, F., Beccali, M., Cellura, M., Brano, V.L.: Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energy Rev. 12, 200–217 (2008)

Guezuraga, B., Zauner, R., Pölz, W.: Life cycle assessment of two different 2 MW class wind turbines. Renew. Energy 37, 37–44 (2012)

Kabir, MdR, Rooke, B., Dassanayake, G.D.M., Fleck, B.A.: Comparative life cycle energy, emission, and economic analysis of 100 kW nameplate wind power generation. Renew. Energy 37, 133–141 (2012)

Oebels, K.B., Pacca, S.: Life cycle assessment of an onshore wind farm located at the northeastern coast of Brazil. Renew. Energy 53, 60–70 (2013)

Schleisner, L.: Life cycle assessment of a wind farm and related externalities. Renew. Energy 20, 279–288 (2000)

Weinzettel, J., Reenaas, M., Solli, C., Hertwich, E.G.: Life cycle assessment of a floating offshore wind turbine. Renew. Energy 34, 742–747 (2009)

Jungbluth, N., Bauer, C., Dones, R., Frischknect, R.: Life cycle assessment for emerging technologies: case studies for photovoltaic and wind power. Int. J. Life Cycle Assess. 10, 24–34 (2005)

Dones, R., Bauer, C., Bolliger, R., Burger, B., Emmenegger, F.M., Frischknecht, R., Heck, T., Jungbluth, N., Röder, A., Tuchschmid, M.: Life cycle inventories of energy systems: results for current systems in Switzerland and other UCTE countries. http://ecolo.org/documents/documents_in_english/Life-cycle-analysis-PSI-05.pdf (2007). Accessed 9 January 2016

Hondo, H.: Life cycle GHG emission analysis of power generation systems: Japanese case. Energy 30, 2042–2056 (2005)

Jacobson, M.Z.: Review of solutions to global warming, air pollution, and energy security. Energy Environ. Sci. 2, 148–173 (2009)

Greening, B., Azapagic, A.: Environmental impacts of micro-wind turbines and their potential to contribute to UK climate change targets. Energy 59, 454–466 (2013)

Pacca, S.A.: Global warming effect applied to electricity generation technologies. PhD Dissertation, University of California, Berkeley, CA (2003)

Rule, B.M., Worth, Z.J., Boyle, C.A.: Comparison of life cycle carbon dioxide emissions and embodied energy in four renewable electricity generation technologies in New Zealand. Environ. Sci. Technol. 43, 6406–6413 (2009)

McCulloch, M., Raynolds, M., Laurie, M.: Life-cycle value assessment of a wind turbine. http://www.pembinafoundation.org/reports/windlcva.pdf (2000). Accessed 9 January 2016

Dolan, S.L.: Life cycle assessment and energy synthesis of a theoretical offshore wind farm for Jacksonville, Florida. MS Thesis, University of Florida, Gainesville, FL (2007)

Chen, G.Q., Yang, Q., Zhao, Y.H.: Renewability of wind power in China: a case study of nonrenewable energy cost and greenhouse gas emission by a plant in Guangxi. Renew. Sustain. Energy Rev. 15, 2322–2329 (2011)

Voorspools, K.R., Brouwers, E.A., D’haeseleer, W.D.: Energy content and indirect greenhouse gas emissions embedded in ‘emission-free’ plants: results from the low countries. Appl. Energy 67, 307–330 (2000)

Crawford, R.H.: Life cycle energy and greenhouse emissions analysis of wind turbines and the effect of size on energy yield. Renew. Sustain. Energy Rev. 13, 2653–2660 (2009)

White, S.: Net energy payback and CO2 emissions from three Midwestern wind farms: an update. Nat. Resour. Res. 15, 271–281 (2006)

Lee, Y.M., Tzeng, Y.E.: Development and life-cycle inventory analysis of wind energy in Taiwan. J. Energy Eng. ASCE 134, 53–57 (2008)

Pehnt, M., Oeser, M., Swider, D.J.: Consequential environmental system analysis of expected offshore wind electricity production in Germany. Energy 33, 747–759 (2008)

Martínez, E., Sanz, F., Pellegrini, S., Jiménez, E., Blanco, J.: Life-cycle assessment of a 2-MW rated power wind turbine: CML method. Int. J. Life Cycle Assess. 14, 52–63 (2009)

Tremeac, B., Meunier, F.: Life cycle analysis of 4.5 and 250 W wind turbines. Renew. Sustain. Energy Rev. 13, 2104–2110 (2009)

Garrett, P., Rønde, K.: Life cycle assessment of wind power: comprehensive results from a state-of-the-art approach. Int. J. Life Cycle Assess. 18, 37–48 (2012)

Rajaei, M., Tinjum, J.M.: Life cycle assessment of energy balance and emissions of a wind energy plant. Geotech. Geol. Eng. 31, 1663–1670 (2013)

Dolan, S.L., Heath, G.A.: Life cycle greenhouse gas emissions of utility-scale wind power. J. Ind. Ecol. 16, S136–S154 (2012)

Amponsah, N.W., Troldborg, M., Kington, B., Aalders, I., Hough, R.L.: Greenhouse gas emissions from renewable energy sources: a review of lifecycle considerations. Renew. Sustain. Energy Rev. 39, 461–475 (2014)

Urban Wind Engineering.: Turbine options: vertical axis vs. horizontal axis. https://sites.google.com/a/temple.edu/urbanwind/services/turbine-options-and-specifications (2015). Accessed 9 November 2015

International Renewable Energy Agency (IRENA).: Renewable energy technologies: cost analysis series—wind power. https://www.irena.org/DocumentDownloads/Publications/RE_Technologies_Cost_Analysis-WIND_POWER.pdf (2012). Accessed 3 June 2015

Lenzen, M., Munksgaard, J.: Energy and CO2 life-cycle analyses of wind turbines—review and applications. Renew. Energy 26, 339–362 (2002)

Acknowledgements

This work was supported by the US National Science Foundation through the CREST Center for Energy and Environmental Sustainability (CEES) at Prairie View A&M University, Award Number 1036593.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kadiyala, A., Kommalapati, R. & Huque, Z. Characterization of the life cycle greenhouse gas emissions from wind electricity generation systems. Int J Energy Environ Eng 8, 55–64 (2017). https://doi.org/10.1007/s40095-016-0221-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-016-0221-5