Abstract

Vertically aligned titanium dioxide (TiO2) nanotubes were synthesized by electrochemical anodic oxidation in an electrolyte solution containing 0.45 wt% ammonium fluoride (NH4F) and 2 vol% deionized water at constant potential (70 V) for various anodization time at the room temperature. The influence of the anodization time on the morphology and optical properties of the anodic TiO2 nanotubes have been studied. Field emission scanning electron microscopy results revealed that the anodic TiO2 nanotube morphology extremely depends on the anodization time. It was observed that by increasing anodization time, length of the anodic TiO2 nanotubes increased and nanotubes destroyed at the top of the tubes. After a long time of anodization process (9 h), nanotubes completely destroyed. Photoluminescence measurements showed that the anodic TiO2 nanotube band gap energy depends on the anodic TiO2 nanotube morphology. The anodic TiO2 nanotubes without any damage had a minimum band gap energy (2.9 eV).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

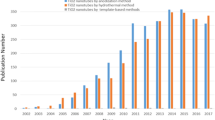

In the past decades, TiO2 nanotubes have been widely investigated due to their high interest in various applications like biomedical fields [1], photovoltaic cells [2], photocatalysts [3, 4], solar cells [5,6,7] and electrochromic devices [8]. These possible applications are due to the advantages of not-toxicity, thermal and chemical stabilities, high photocatalytic activity [9,10,11,12,13] and high surface area of the TiO2 nanotubes [14, 15]. TiO2 nanotubes could be fabricated using numerous physical or chemical methods including sol–gel [16], electrochemical anodization [17], template [18], hydrothermal [19, 20], micro-wave irradiation [21], alkaline [22] and sonoelectrochemical [23] methods.

Among these methods, electrochemical anodization is the prominent approach to prepare TiO2 nanotubes. Self-organized TiO2 nanotubes grown by an electrochemical anodization method have attracted scientific interests because these nanotubes can directly synthesize on the titanium (Ti) surface, used directly as a back-contact electrode [24]. This method also is a simple, effective, low cost especially with great ability of controlling growth parameters (potential, PH, the chemistry of electrolyte solution and time) [10, 25, 26]. The chemical and physical properties of the anodic TiO2 nanotubes are dependent on their growth conditions [27], so by changing growth parameters like anodization time, applied potential and electrolyte composition, morphological structure of the anodic TiO2 nanotubes can be modified [28] and optimum anodic TiO2 nanotubes can be obtained. For example, among the growth parameters, anodization potential is the key factor controlling the diameter of the nanotubes [29].

The aim of this work is to investigate effect of the anodization time on the morphology and physical properties of anodic TiO2 nanotubes using FESEM, XRD and PL analyses and find the optimum anodization time.

Experimental

Anodic TiO2 nanotubes were grown using the anodization method. Prior to anodizing, titanium foils (99.6% purity, 0.25 mm thick, Sigma-Aldrich) were mechanically ground with different silicon carbide paper grades and ultrasonically cleaned by acetone, deionized water (DI) and ethanol, respectively, for 20 min. The anodization process was carried out in a two-electrode system, comprised of Ti as anode and platinum as cathode with distance of 1 cm from each other, at a constant potential of 70 V and various anodization time (20 min–9 h) at room temperature. The electrolyte contained 100 ml ethylene glycol (99.5%, Merck), 2 vol% DI water and 0.45 wt% NH4F (98%, Merck). After anodization, as-prepared anodic TiO2 nanotubes were immersed in methanol for few minutes and dried in air. In order to improve crystal structure and physical properties of the as-grown TiO2 nanotubes, they annealed at 400 °C for 1 h in air (heating/cooling rate 10 °C/min). The current density was measured during the anodization process. Anodic TiO2 nanotube morphology was characterized via field emission scanning electron microscope (FESEM, JEOL, 7610f). The structural and optical properties of the anodic TiO2 nanotubes were evaluated by X-ray diffraction (XRD) using Cu-Kα radiation (λ = 1.5418 Å) and photoluminescence (PL) spectra using a PL module using an excitation laser with 380 nm wavelength (helium–cadmium laser) associated with a spectrophotometer (FL0906M003, Cary Eclipse).

Results and discussion

Study of the formation mechanism of the TiO2 nanotubes has been of interest for the researchers that among all the theories two important theories including oxygen bubble [30] and field-assistant are challenging [31,32,33]. Field-assistant theory about TiO2 nanotubes growth is based on 3 significant processes [34]:

-

1.

oxidation by field-assistant at the metal/oxide interface, given by Eq. (1):

$$ {\text{Ti}} + 2{\text{H}}_{2} {\text{O}} \to {\text{TiO}}_{2} + 4{\text{H}}^{ + } + 4{\text{e}}^{ - } $$(1) -

2.

dissolution by field-assistant at the oxide/electrolyte interface at the bottom of the nanotubes.

-

3.

chemical etching at the top of the nanotubes. Chemical interactions of these two last cases is given by Eq. (2):

$$ {\text{TiO}}_{2} + 6{\text{F}}^{ - } + 4{\text{H}}^{ + } \to {\text{TiF}}_{6}^{2 - } + 2{\text{H}}_{2} {\text{O}} . $$(2)

The collective effects of them will decide the final morphologies of the TiO2 nanotubes. Figure 1 shows the current density–time curves obtained during anodization process. Regardless of the anodization time, the curves show approximately same behavior. At the first stage, the sharp drop in the current density is due to the oxide layer formation on the Ti surface [35], which decreases the conduction resulting in sharp drop in the current density. At the second stage, current density is increased, indicating the pore formation. At the next stage, current density is decreased and remains constant. At this stage, oxide growth rate in the oxide/metal interface and oxide dissolution rate at the electrolyte/nanotube bottom are in equilibrium [35]. See inset of Fig. 1, which shows the current density–time curve for the 9 h anodization time in detail; at the last stage after 7 h, the curve is slightly increased and again remains constant. It may due to the temperature increment of the solution during the anodization process, which is occurred after a long time of anodization process and could increase conductivity of the solution.

The influence of anodization time on the anodic TiO2 nanotube morphologies is shown in Fig. 2. The anodization process at the different anodization time but 9 h resulted in vertically oriented TiO2 nanotube arrays. Differences were observed between the anodic TiO2 nanotube morphologies grown at the different anodization time. By increasing anodization time from 20 min to 3 h, an increase in nanotube length from 7.5 to 34 µm was observed. Length of the TiO2 nanotube grown for 1 h reached to about 22 µm without any significant collapse of the nanotubes. The top of the anodic TiO2 nanotubes for the 3 h, as shown in Fig. 1c, was destroyed. The significant collapse of the anodic TiO2 nanotubes for 3 h is due to the nanotube top dissolution by fluoride ions [36, 37]. The 9 h anodization time resulted in destroying the nanotubes and forming the nanograss (Fig. 1d). Nanograss structures form when the growth rate of the nanotubes at the oxide/metal interface is smaller than the chemical dissolution rate at the tubes top/electrolyte interface. In other words, chemical dissolution rate at the tubes top/electrolyte interface is higher than at tubes bottom [38].

In order to study the crystal phase, X-ray diffraction analysis had been conducted. Figure 3 shows the XRD patterns of the anodic TiO2 nanotubes grown at 1 h condition. The presence of Ti peaks and anatase TiO2 is observed. Other peaks such as rutile and brookite peaks were not detected, that is due to the annealing temperature. Similar results were observed for other samples grown at different anodization time (not included in Fig. 3).

Figure 4 presents the PL spectra of the TiO2 nanotubes for different anodization time at 380 nm excitation wavelength. Peak of the all samples appeared within the visible range from 400 to 450 nm, so the samples have a narrow band gap energy. All samples’ PL shapes are similar; however, peak locations and peak intensities are different. As it is known, PL intensity reflects the recombination rate of the electron–hole, that is lower PL intensity reflects a lower electron–hole recombination rate [39]. Maximum intensity of the PL peaks belongs to the TiO2 nanotubes grown for 3 h, which could be due to the fact that it is significant damage compare to the other samples. Well-aligned TiO2 nanotubes without any damage can enable a convenient and rapid pathway for charge transport, decreasing the carrier path length so as a consequence can reduce recombination losses and in the other words results in reduced number of the recombination centers [40]. However, in the damaged TiO2 nanotubes the carrier path length can increase and as a result the number of recombination centers increases. So the PL peaks intensity of the damaged nanotubes can be higher than that of nanotubes without any damage. It is known that band gap energy of the anodic TiO2 nanotubes decreases with increasing anodization time [40]; it could be due to tube length increase. Therefore, it is expected that the TiO2 nanotubes grown for 3 h had the minimum band gap energy, but the tubes grown for 1 h have the minimum band gap energy (about 2.9 eV). The redshift in the peak of TiO2 nanotubes grown for 1 h as compared with the 3 h may be due to the tube wall thickness decrease of the nanotubes grown for 3 h compare to the 1 h, which is in good agreement with the previous work [41].

Conclusion

Anodic TiO2 nanotubes were synthesized by anodization method at different anodization time. Influence of the anodization time on the TiO2 nanotube physical properties was investigated. Anodization time significantly affected the morphology of the nanotubes. By increasing anodization time, length of the nanotubes increased. At 3 h anodization time, the anodic nanotubes were destroyed at the top of the tubes and nanotubes grown for 9 h completely destroyed. Morphology differences could change the value of the band gap energy which the nanotubes with the length of 22 μm and without any damage had a minimum band gap energy. Therefore, the morphology and optical properties of the TiO2 nanotubes could be optimized by proper anodization time.

References

Kim, W.T., Lee, J.K., Jang, I.S., Choi, D.S., Choi, W.Y.: Surface improvement of TiO2 nanotube arrays for dental implant. Appl. Mech. Mater. 864, 78–83 (2017)

Li, D., Chang, P.C.H., Chien, C.J., Lu, J.G.: Applications of tunable TiO2 nanotubes as nanotemplate and photovoltaic device. Chem. Mater. 22, 5707–5711 (2010)

Paramasivam, I., Jha, H., Liu, N., Schmuki, P.: A review of photocatalysis using self-organized TiO2 nanotubes and other ordered oxide nanostructures. Small 8, 3073–3103 (2012)

Nischk, M., Mazierski, P., Gazda, M., Zaleska, A.: Ordered TiO2 nanotubes: the effect of preparation parameters on the photocatalytic activity in air purification process. Appl. Catal. B Environ. 144, 674–685 (2014)

Roy, P., Albu, S.P., Schmuki, P.: TiO2 nanotubes in dye-sensitized solar cells: higher efficiencies by well-defined tube tops. Electrochem. Commun. 12, 949–951 (2010)

Mor, G.K., Varghese, O.K., Paulose, M.: A review on highly ordered, vertically oriented TiO2 nanotube arrays: fabrication, material properties, and solar energy applications. Sol. Energy Mater. Sol. Cells 90, 2011–2075 (2006)

Qiuling, M., Yuqi, C., Xiaoyong, D., Xiuwen, C., Qingfeng, C., Bo, L.: Controllable fabrication of TiO2 nanobelts/nanotubes photoelectrode for dye sensitized solar cells. J. Nanosci. Nanotechnol. 17, 2072–2078 (2017)

Song, Y.Y., Gao, Z.D., Wang, J.H., Xia, X.H., Lynch, R.: Multistage coloring electrochromic device based on TiO2 nanotube arrays modified with WO3 nanoparticles. Adv. Funct. Mater. 21, 1941–1946 (2011)

Pishkar, N., Ghoranneviss, M., Ghorannevis, Z., Akbari, H.: Study of the highly ordered TiO2 nanotubes physical properties prepared with two-step anodization. Results Phys. (2018). https://doi.org/10.1016/j.rinp.2018.02.009

Indira, K., Mudali, U.K., Nishimura, T., Rajendran, N.: A review on TiO2 Nanotubes: influence of anodization parameters, formation mechanism, properties, corrosion behavior, and biomedical applications. J. Bio Tribo Corros. 1, 28 (2015)

Wang, X., Li, Z., Shi, J., Yu, Y.: One-dimensional titanium dioxide nanomaterials: nanowires, nanorods, and nanobelts. Chem. Rev. 114, 9346–9384 (2014)

Roy, P., Berger, S., Schmuki, P.: TiO2 nanotubes: synthesis and applications. Angew. Chem. Int. Ed. 50, 2904–2939 (2011)

Liu, W., Su, P., Chen, S., Wang, N., Wang, J., Liu, Y., Ma, Y., Li, H., Zhang, Z., Webster, T.J.: Antibacterial and osteogenic stem cell differentiation properties of photoinduced TiO2 nanoparticle-decorated TiO2 nanotubes. Nanomedicine 10, 713 (2015)

Lu, Y., Yu, H., Chen, Sh, Quan, X., Zhao, H.: Integrating plasmonic nanoparticles with TiO2 photonic crystal for enhancement of visible-light-driven photocatalysis. Environ. Sci. Technol. 46, 1724–1730 (2012)

MacakH, J.M., Tsuchiya, A., Ghicov, K., Yasuda, R., Hahn, S., Bauer, P.Schmuki: TiO2 nanotubes: self-organized electrochemical formation, properties and applications. Curr. Opin. Solid State Mater. Sci. 11, 3–18 (2007)

Lee, C.H., Rhee, S.W., Choi, H.W.: Formation of a crystalline nanotube–nanoparticle hybrid by post water-treatment of a thin amorphous TiO2 layer on a TiO2 nanotube array as an efficient photoanode in dye-sensitized solar cells. Nanoscale Res. Lett. 48, 4370–4375 (2012)

Narayanan, R., Lee, J.H., Kwon, T.Y., Kim, K.J.: Anodic TiO2 nanotubes from stirred baths: hydroxyapatite growth & osteoblast responses. Mater. Chem. Phys. 125, 510–517 (2011)

Sitler, S.J., Raja, K.S.: Self-ordering dual-layered honeycomb nanotubular titania: a study in formation mechanisms. RSC Adv. 6, 11991–12002 (2016)

Choi, M.G., Lee, Y.G., Song, S.W., Kim, K.M.: Lithium-ion battery anode properties of TiO2 nanotubes prepared by the hydrothermal synthesis of mixed (anatase and rutile) particles. Electrochim. Acta 55, 5975–5983 (2010)

Lee, K., Mazare, A., SchmukI, P.: One-dimensional titanium dioxide nanomaterials: nanotubes. Chem. Rev. 114, 9385–9454 (2014)

Ribbens, S., Meynen, V., Tendeloo, G.V., Ke, X., Mertens, M., Maes, B.U.W., Cool, P., Vansant, E.F.: Development of photocatalytic efficient Ti-based nanotubes and nanoribbons by conventional and microwave assisted synthesis strategies. Microporous Mesoporous Mater. 114, 401–409 (2008)

Arruda, L.B., Santos, C.M., Orlandi, M.O., Schreiner, W.H., Lisboa-Filho, P.N.: Formation and evolution of TiO2 nanotubes in alkaline synthesis. Ceram. Int. 41, 2884–2891 (2015)

Wang, C., Sun, L., Yun, H., Li, J., Lai, Y., Lin, C.: Sonoelectrochemical synthesis of highly photoelectrochemically active TiO2 nanotubes by incorporating CdS nanoparticles. Nanotechnology 20, 295601 (2009)

Nah, YCh., Shrestha, N.K., Kim, D., Schmuki, P.: Electrochemical growth of self-organized TiO2–WO3 composite nanotube layers: effects of applied voltage and time. J. Appl. Electrochem. 43, 9–13 (2013)

Jarosz, M., Kapusta-KoBodziej, J., Jasku, M, Sulka, G.D.: Effect of different polishing methods on anodic titanium dioxide formation. J. Nanomater. Article ID 295126 (2015)

Chong, B., Yu, D.L., Gao, M.Q., Fan, H.W., Yang, C.Y., Ma, W.H., Zhang, S.Y., Zhua, X.F.: Formation mechanism of gaps and ribs around anodic TiO2 nanotubes and method to avoid formation of ribs. J. Electrochem. Soc. 162, H244–H250 (2015)

Li, D.G., Chen, D.R., Wang, J.D., Liang, P.: Effect of acid solution, fluoride ions, anodic potential and time on the microstructure and electronic properties of self-ordered TiO2 nanotube arrays. Electrochem Acta 207, 152–163 (2016)

Kulkarni, M., Mazare, A., Schmuki, P., Iglic, A.: Biomaterial surface modification of titanium and titanium alloys for medical applications. Adv. Mater. Lett. 7, 23–28 (2016)

Macak, J.M., Tsuchiya, H., Ghicov, A., Yasuda, K., Hahn, R., Bauer, S., Schmuki, P.: TiO2 nanotubes: self-organized electrochemical formation, proper ties and applications. Curr. Opin. Solid State Mater. Sci. 11, 3–18 (2007)

Zhao, S., Li, C., Wei, T., Li, C., Yua, M., Cui, H., Zhu, X.: A mathematical model for initiation and growth of anodic titania nanotube embryos under compact oxide layer. Electrochem. Commun. 91, 60–65 (2018)

Yu, M., Chen, Y., Li, C., Yan, S., Cui, H., Zhu, X., Kong, J.: Studies of oxide growth location on anodization of Al and Ti provide evidence against the field-assisted dissolution and field-assisted ejection theories. Electrochem. Commun. 87, 76–80 (2018)

Yu, M., Cui, H., Ai, F., Jiang, L., Kong, J., Zhu, X.: Terminated nanotubes: evidence against the dissolution equilibrium theory. Electrochem. Commun. 86, 80–84 (2018)

Yu, M., Li, C., Yang, Y., Xu, S., Zhang, K., Cui, H., Zhu, X.: Cavities between the double walls of nanotubes: evidence of oxygen evolution beneath an anion-contaminated layer. Electrochem. Commun. 90, 34–38 (2018)

Zhang, Q., Ma, L., Xu, X., Shao, M., Huang, J., Han, L., Li, W.: The influence of oxidation time on the morphologies of TiO2 nanostructures. J. Nanosci. Nanotechnol. 14, 3262–3265 (2014)

Regonini, D., Bowen, C.R., Jaroenworaluck, K., Stevens, R.: A review of growth mechanism, structure and crystallinity of anodized TiO2 nanotubes. Mater. Sci. Eng. R 74, 377–406 (2013)

Li, Y., Ma, Q., Han, J., et al.: Controllable preparation, growth mechanism and the properties research of TiO2 nanotube arrays. Appl. Surf. Sci. 297, 103–108 (2014)

Regonini, D., Clemens, F.J.: Anodized TiO2 Nanotubes: effect of anodizing time on film length, morphology and photoelectrochemical properties. Mater. Lett. 142, 97–101 (2015)

Mohammad pour, F., Moradi, M.: Double-layer TiO2 nanotube arrays by two-step anodization: used in back and front-side illuminated dye-sensitized solar cells. Mater. Sci. Semicond. Process. 39, 255–264 (2015)

Ansari, S.A., Khan, M.M., Ansari, M.O., Cho, M.H.: Gold nanoparticles-sensitized wide and narrow band gap TiO2 for visible light applications: a comparative study. New J. Chem. 39, 4708–4715 (2015)

Mazierski, P., Nischk, M., Gołkowska, M., Lisowski, W., Gazda, M., Winiarski, M.J., Klimczuk, T., Zaleska-Medynska, A.: Photocatalytic activity of nitrogen doped TiO2 nanotubes prepared by anodic oxidation: the effect of applied voltage, anodization time and amount of nitrogen dopant. Appl. Catal. B 196, 77–88 (2016)

Chang, Y.H., Liu, C.M., Cheng, H.E., Chen, Chih: Effect of geometric nanostructures on the absorption edges of 1-D and 2-D TiO2 fabricated by atomic layer deposition. ACS Appl. Mater. Interfaces 5, 3549–3555 (2013)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Jedi-soltanabadi, Z., Pishkar, N. & Ghoranneviss, M. Enhanced physical properties of the anodic TiO2 nanotubes via proper anodization time. J Theor Appl Phys 12, 135–139 (2018). https://doi.org/10.1007/s40094-018-0290-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40094-018-0290-3