Abstract

The influence of monoethanolamine (MEA) and piperazine added into methyldiethanolamine (MDEA) aqueous solution on the desulfurization of natural gas was investigated by the method of equilibrium data determination in this paper. Four kinds of equilibrated systems, i.e. H2S-NG-MEA-water, H2S-NG-MDEA-water, H2S-NG-(MEA-MDEA)-water, H2S- NG-(MEA-MDEA-PZ)-water at the temperature ranging from 298.15 to 333.15 K were measured in a glass-jacketed gas absorption cell with a double-drive impeller device. The results show that the H2S partial pressure increases with the increase of H2S loading in liquid phase along an isotherm. The addition of MEA and PZ is beneficial for improving the desulfuration ability of MDEA. The ability of H2S absorption for the four mixed alkanolamine systems is MEA > (MEA-MDEA-PZ) > (MEA-MDEA) > MDEA according to the order of size. The four equilibrium data can be well correlated with the Soave–Redlich–Kwong equation of state and electrolyte-NRTL activity coefficient model. The overall mean relative errors of total pressure and H2S partial pressure between the calculated and experimental data of the four systems are 3.30 and 3.07 %, respectively. The experimental and calculated results are very useful for desulfuration and purification process of natural gas or other industrial gases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The desulfuration of natural gas (NG), and the gas streams in petroleum refinery and chemical plant is of a great importance concerning energy efficiency and environment safety. The main method for these industries is the absorption of acid gases (mainly CO2 and H2S) by using aqueous alkanolamine solutions followed by the desorption from solutions by using steam stripping [1]. The monoethanolamine (MEA), methyldiethanolamine (MDEA) and their blends are the commonly used absorbents, and piperazine is often widely used as an additive.

MEA is the common gas treating alkanolamine solvent due to its high reactivity, low cost, ease of reclamation, and low solubility of hydrocarbons. The disadvantage of MEA is the large enthalpy of reaction with carbon dioxide, as well as the formation of stable carbamate which limits its absorption capability [2]. MDEA is difficult to react directly with CO2 to form carbamate. That is to say, the selectivity of MDEA absorption for H2S is higher than that of MEA when H2S and CO2 are both present. Moreover, the regeneration cost for MDEA is lower than that of MEA [3]. A kind of solvent with aqueous blend alkanolamine by adding an additive is widely used to enhance the loading of acid gas. Piperazine is most commonly used as a chemical activator. It is reported that PZ is more effective than the other conventional activators. The major advantages of PZ are its high reaction rate, and high resistance of thermal and oxidative degradation. Besides, the blends of PZ and amines exhibit low amine volatility due to the non-ideality of the mixed amine solution [4, 5]. The advantages and disadvantages of MEA, MDEA and PZ have been summarized in literatures [6–10].

The gas–liquid equilibria data of H2S in the aqueous MEA, MDEA and the blends of MEA and MDEA solution are reported in a lot of literatures with different concentration, temperature, H2S loading and partial pressure. Lee et al. [11] measured the gas–liquid equilibrium of H2S-MEA-H2O system under the conditions of MEA concentration from 2.5 to 5.0 N, temperature at 298.15, 313.15, 333.15, 353.15, 373.15 and 393.15 K, and the H2S partial pressure from 0.15 to 2317 kPa. Isaacs et al. [12] reported the solubilities of H2S, CO2 and their mixture in the 2.5 mol/L aqueous solution of MEA at 373.15 K and acid gases partial pressure from 0.03 kPa to 3.36 kPa. Jou et al. [13] determined the solubilities of H2S and CO2 dissolved in the aqueous MDEA solution under the conditions of temperature from 313.15 to 393.15 K and partial pressure of acid gas up to 6600 kPa. The experimental data were correlated with the procedure presented by Kent and Eisenberg. They [14, 15] also measured the solubilities of H2S, CO2, and H2S + CO2 in 35 %wt. aqueous MDEA solution at temperature from 313.15 to 373.15 K, and the experimental data were regressed by the Deshmukh-Mather correlation. Kuranov et al. [16] investigated the solubilities of single gas CO2 and H2S in the aqueous MDEA solution under the conditions of temperature from 313.15 to 413.15 K, and the total pressure up to 5 MPa. A mathematical model of taking into account contributions of chemical reaction and physical interaction was prosposed to correlate the experimental data. Kamps [17] reported the experimental data of solubilities of CO2 and H2S in 8 mol/kg aqueous MDEA solution under the conditions of temperature from 313.15 to 393.15 K, and the total pressure up to 7.6 MPa. Li et al. [18] investigated solubilities of H2S in aqueous MEA and MDEA blend under the conditions of temperatures from 313.15 to 373.15 K, and at H2S partial pressure up to 450 kPa.

Unlike the previous works, the NG was introduced as a makeup gas herein to actualize the industrial desulfuration process of natural gas, and the gas–liquid equilibrium of aqueous H2S-(MEA-MDEA-PZ)-water solution was determined experimentally in this work. The gas–liquid equilibria data of the four systems of H2S-NG-MEA-water, H2S-NG-MDEA-water, H2S-NG-(MEA-MDEA)-water and H2S-NG-(MEA-MDEA-PZ)-water were measured in a homemade equilibrium apparatus under the conditions of the temperature from 298.15 to 333.15 K, and the H2S partial pressure up to 60 kPa. And a thermodynamic model was used to correlate the experimental data.

Experimental section

Reagents and materials

Monoethanolamine (MEA, ≥99.0 %wt.), methyldiethanolamine (MDEA, ≥99.0 %wt.), piperazine (PZ, ≥99.0 %wt.), sodium thiosulfate (Na2S2O3, ≥99.0 %wt.), soluble starch, kalium iodide (KI, ≥98.5 %wt.) and sodium sulfide (Na2S, ≥98.0 %wt.) were purchased from Shanghai Ling Feng Chemical Reagent Co., Ltd., China. Iodine (I2, ≥99.8 %wt.) was bought from Zhejiang Lingfu fine chemicals plant, China. Sulfuric aicd (H2SO4, ≥98.0 %wt.) and hydrochloric acid (HCl, ≥36 %wt.) were bought from Jiangsu Yonghua Fine Chemicals Co., Ltd., China. Zinc acetate [Zn(CH3COO)2, ≥99 %wt.] was supplied by Sinopharm Chemical Reagent Co., Ltd., China.

The natural gas in this work was obtained from laboratory natural gas pipeline which consists of 96.266 % CH4 (vol, the same below), 1.770 % C2H6, 0.300 % C3H8, 0.062 % i-C4H10, 0.075 % n-C4H10, 0.125 % C5H12 and 1.442 % N2.

Apparatus and experimental method

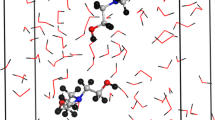

A static-analytic method was used to measure the gas–liquid equilibrium data of these systems stated above, and the experimental apparatus is shown in Fig. 1.

Flow chart of the measurement equipment for gas–liquid equilibria 1 dropping funnel containing H2SO4, 2 H2S generator vessel, 3 H2S outlet valve, 4 NG inlet pipeline, 5 leveling bottle, 6 alkanolamines inlet pipeline and valve, 7 H2S and NG mixture inlet valve, 8 mercurial thermometer, 9 glass-jacketed equilibrium cell, (10-1, 10-2) electromagnet driving double agitator blades, 11 liquid sampling valve, (12-1, 12-2)-direct current motor, 13 two pieces of stainless steel flange, 14 constant temperature circulating water inlet, 15 constant temperature circulating water outlet, 16 eudiometer, 17 gas sampling valve, 18 glass U-tube manometer, 19 leveling bottle, 20 vacuum pump valve, 21 vacuum air pump

The apparatus in Fig. 1 consists of three parts. The first is a H2S generator. The second one is an equilibrium cell, and the third one is the measurements of equilibrium temperature and pressure, as well as the samplings.

The H2S generator is composed of a dropping funnel (1) containing 1 mol/L aqueous H2SO4 solution and the H2S generator vessel (2) with 10 %wt. Na2S solution. The equilibrium cell (9) is a glass-jacketed gas liquid absorber with two double drive impellers. The rotating speeds of the gas phase impeller (10-2) and liquid phase impeller (10-1) are controlled by its own direct current motor (12-1), (12-2), respectively. And the speed is displayed on the screen of revolution counter. The absorption temperature is measured by a mercurial thermometer (8) with a sensitivity of 0.1 °C, which is adjusted by the constant temperature circulating water (14), (15) with a water thermostat. The pressure difference was determined by a glass U-tube manometer (18) with the minimum resolution of 0.1 mmHg (0.013 kPa). The absorption pressure equates the pressure difference plus the atmosphere pressure measured by a Fortin Barometer. Liquid sampling is undertaken with a 2 mL injection syringe connected with the liquid sampling valve (11), and analyzed by the methods of weighing and chemical iodine titration. Gas sampling is done quantitatively with a eudiometer (16).

Operation procedures The absorption alkanolamines agent is firstly added into the equilibrium cell (9) from the leveling bottle (5) and valve (6). Then the whole absorption unit including the pipelines is vacuumized and degassed by a vacuum air pump (21). Afterward the stopcock of dropping funnel (1) is opened and then let the aqueous sulfuric acid reacts with sodium sulfide to generate hydrogen sulfide. The gas of hydrogen sulfide is mixed with NG derived from the pipeline and its valve (4). The gas mixture is introduced into the equilibrium cell (9) and absorbed by the alkanolamines agent under a specified pressure and temperature. The system could be thought to reach the equilibration when the absorption time is about 1–1.5 h by preliminary test.

Analysis method The method of iodine quantity is used for determining the content of hydrogen sulfide in the liquid phase. About 1 mL liquid sample drawn from the equilibrium cell with a 2 mL injection syringe, and weighted by an electric analytical balance with accuracy of 0.0001 g. Then it is slowly injected underneath the liquid interface of a 250 mL volumetric flask containing 25 mL aqueous 0.1 mol/L zinc acetate. The injection syringe is washed with this aqueous zinc acetate for three times, and for another two times washed with pure water. All of the cleaning water should be collected and mixed with the aqueous zinc acetate. Afterwards, the pH value of the aqueous solution is adjusted to 6.5 ~ 7.0 with 0.01 mol/L HCl solution. Add appropriate amount of iodine standard solution into the liquid, sealed and preserved under a dark place for at least 5 min. The mixture is titrated with 0.01 mol/L sodium thiosulfate standard solution to the color of buff; successively by added starch indicator, continuing titrated with the sodium thiosulfate standard solution to the color of blue disappearing as the titration end point [19]. The reactions included in this procedure can be written as from Eqs. (1–3).

L value represents the molar loading quantity of hydrogen sulfide per molar alkanolamines in liquid aqueous solution, which reflects the absorption ability of absorbents for H2S. It is calculated as

where \(V_{{{\text{I}}_{2} }}\), \(c_{{{\text{I}}_{2} }}\) are the volume consumed and molar concentration of iodine standard solution. \(V_{{{\text{Na}}_{ 2} {\text{S}}_{ 2} {\text{O}}_{ 3} }}\), \(c_{{{\text{Na}}_{ 2} {\text{S}}_{ 2} {\text{O}}_{ 3} }}\) are the volume titration demanded and molar concentration of sodium thiosulfate standard solution. n amines is molar quantity of the mixed alkanolamines calculated by:

In Eq. (5), m i and M i are the quality and molecular weight of the mixed alkanolamines component i.

The analysis method of gas phase: Firstly, 50 mL 0.1 mol/L zinc acetate solution is added into the leveling bottle (19). Keep the liquid interface of eudiometer (16) and leveling bottle (19), and record the initial scale value. Open the gas sampling valve (17) and let the gas phase into the eudiometer, then close the sampling valve and record the end reading. The difference of the ending and the initial readings is the gas sampling volume. Shake the eudiometer and let the sampling gas mix completely with the solution of zinc acetate. The reaction liquid is transferred to a clean 250 mL volumetric flask. Washing the eudiometer with pure water two times, and the washed water is also added into the volumetric flask. Afterwards, an adequate quantity of iodine standard solution is added, and then sealed and preserved under a dark place for at least 5 min. Then, titration of sodium thiosulfate is adopted as described above for analyzing the containing of hydrogen sulfide. The Eq. (6) is used for calculation the molar fraction of hydrogen sulfide in the gas phase.

In Eq. (6), T and V are the equilibrium temperature and volume of the sampling gas phase. R is the universal gas constant, 8.3145 J/(mol K). p is the equilibrium total pressure,and calculated as

where Δh is the reading difference of the glass U-tube manometer (18), p a is the atmosphere pressure measured by a Fortin Barometer. For Shanghai, it is calculated as

In the Eq. (8), p read is the reading value of the Fortin Barometer, and t is the room temperature during the experiments.

The reliability of the apparatus

In order to check the reliability of the apparatus and experimental method, gas–liquid equilibrium data of hydrogen sulfide dissolved in 2.5 mol/L MEA aqueous solution under 313.15 K and atmosphere pressure were measured and compared with the literature data [11]. The results are shown in Fig. 2.

The results shown in Fig. 2 indicate that the experimental value is agreed very well with the literature data, and the maximum relative error is less than 5 %. It shows that the apparatus is suitable for determination the gas–liquid equilibrium of hydrogen sulfide dissolved in alkanolamines solutions.

Correlation of experimental data with thermodynamics model

Hydrogen sulfide dissolved in aqueous alkanolamines is a system of electrolyte solution. Non-idealities of species in gas phase and liquid phase should be taken into account in the thermodynamic computation of multicomponent complex aqueous solution like H2S-NG-(MEA-MDEA-PZ)-water system. In this work, the Soave–Redlich–Kwong (SRK) equation of state [20] is used to account for the non-ideality of gas phase, and the electrolyte-NRTL equation [21, 22] is adopted to describe that of the liquid phase. Herein, a brief description is made as follows.

Chemical equilibrium relationship of species in the liquid aqueous solution

The chemical equilibrium relationship of the species in the liquid phase can be written in the form of chemical dissociation [3, 23, 24] as follows.

The chemical equilibrium constants from Eqs. (R1–R6) can be written as:

where K j is the chemical equilibrium constant of the above Eqs. (R1–R6), \(\hat{a}_{ji}\) and ν ji are the activity and stoichiometric coefficient of component i of the reaction j, respectively. The mass balance equations for the sulfur element and alkanolamine molecules can be expressed by

Another restriction is the condition of liquid phase electroneutrality, and can be written as

In Eq. (14), n i and z i are the molar quantity and charge number of ions (including ions of H3O+, HS−, S2−, MEAH+, MDEAH+, PZH+,OH+, etc.).

The relationship of equilibrium constant for Eq. (9) and Henry’s constant of hydrogen sulfide with temperature can be expressed in Eq. (15), and the parameters are listed in Table 1.

Gas–liquid equilibria for molecules

The Henry’s Law is adopted to express the gas–liquid equilibrium of H2S:

where \(y_{{{\text{H}}_{ 2} {\text{S}}}}\), \(x_{{{\text{H}}_{ 2} {\text{S}}}}\) are the molar fraction of hydrogen sulfide in gas phase and liquid phase. \(\hat{\varphi }_{{{\text{H}}_{ 2} {\text{S}}}}\), \(\gamma^{ * }_{{{\text{H}}_{ 2} {\text{S}}}}\) are the fugacity coefficient and activity factor of hydrogen sulfide in gas phase and liquid phase, respectively. \(H_{{{\text{H}}_{ 2} {\text{S}}}}^{\infty }\), \(v_{{{\text{H}}_{ 2} {\text{S}}}}^{\infty }\) and p ∅are the Henry’s constant, molar volume of hydrogen sulfide and reference pressure under the condition of infinite dilute concentrations. For the components of solvent, like water, MEA, MDEA and PZ, the relationship of gas–liquid equilibrium can be written in

In Eq. (17), y i , x i are the molar fraction of component i in gas phase and liquid phase. \(\hat{\varphi }_{i}\), γ i are the fugacity coefficient and activity factor of component i in gas phase and liquid phase, respectively. p s i , v i are the saturated gas pressure and molar volume of component i under the equilibrium temperature T.

Activity coefficient of component i

The electrolyte-NRTL equation [25], which is composed of three contributions of excess Gibbs free energy counted by the Pitzer long-range interaction (PDH), corrected Born term (Born) and short-range solvation effect (NTRL), is used to calculate the activity coefficient of liquid phase components. For similar weak electrolyte solutions, this model had been widely used to correlate the gas–liquid equilibrium in literatures [16, 22, 26–28]. The parameters, including relevant coefficients and interaction parameters in the model could be also obtained in the literatures. Table 2 lists the dielectric constant for solvent components, like MEA, MDEA, PZ and water. Table 3 collects the binary interaction parameters of components, which are used to calculate the activity coefficient of components by the electrolyte-NRTL model.

Fugacity coefficient for component i

The fugacity coefficients of components in the gas phase are calculated by the SRK equation of state. Table 4 lists the molecular properties of pure components of this gas–liquid equilibrium [19], which are used in the calculation with SRK equation of state.

Calculation procedure

The activity coefficient of components for liquid phase and fugacity coefficient for gas phase can be calculated by the electrolyte-NRTL equation and SRK equation of state, respectively. The total pressure for the equilibrated system can be calculated by the following Eq. (18), which ignored the partial pressure of other components excluding H2S, solvent components and CH4 in the gas phase.

The Bubble point method was adopted to calculate the gas–liquid equilibria. Ordinarily, the known variables are the temperature T, concentration of hydrogen sulfide in the liquid phase \(x_{{{\text{H}}_{ 2} {\text{S}}}}\), initial molar quantity of solvent components, like MEA, MDEA, PZ and water, by solving the equation set of Eqs. (9–14), as well as Eq. (16) and Eq. (17), the total pressure of the equilibrated system p cal. and molar fraction of hydrogen sulfide \(y_{{{\text{H}}_{ 2} {\text{S}}}}\) can be evaluated by the objective function approaching to minimum, i.e., \(OBJ =\sqrt{(\sum\limits_{j} {(p_{{{\text{cal}} .}} - p_{\exp .} )^{2} } + \sum\limits_{j} {(y_{{{\text{H}}_{ 2} {\text{S, cal}} .}} - y_{{{\text{H}}_{ 2} {\text{S,}}\exp .}} )^{2}}) /2N} \to \hbox{min}.\)Where N is the number of experimental points.

Results and discussions

Experimental data of H2S dissolved in a single alkanolamine aqueous solution

Comparisons of the calculated partial pressures of hydrogen sulfide with the experimental data, which is dissolved in a different aqueous MEA solution at absorption isotherms of 298.15, 313.15 and 333.15 K, are shown in Fig. 3. As seen from Fig. 3, with the increasing of H2S loading in liquid phase, the partial pressure of H2S in the gas phase increases under any an isotherm. While, the increment of H2S partial pressure shows a small value under the condition of relatively lesser H2S loading along an isotherm at first; then it sharply increases at the higher H2S loading along the same isotherm. For an example, at the isotherm of aqueous H2S-NG-8.5 %wt. MEA-water solution at 333.15 K (Line 9 in Fig. 3), the H2S partial pressure increases from 1.462 to 3.997 kPa by the difference value of 2.535 kPa when H2S loading in the aqueous solution changes from 0.100 to 0.325 (the difference value of 0.225). But it increases rapidly from 11.578 to 36.914 kPa when H2S loading varies from 0.627 to 0.874 (the difference value of 0.247). The reason is that the desulfuration of H2S by aqueous alkanolamine solutions has the features of both chemical absorption and physical absorption. The chemical reaction of hydrogen sulfide with MEA is to be equilibrium with a larger H2S loading in liquid. And then the chemical absorption is transferred into physical absorption, so the H2S partial pressure in the gas phase increases theatrically sharply at the larger H2S loading.

Meanwhile, the H2S partial pressure increases with the rising of absorption temperature at the conditions of a constant H2S loading and the same component concentrations of the aqueous absorption solution. The H2S loading in liquid phase decreases with the rising of absorption temperature under the same H2S partial pressure and the same component concentrations. These behaviors are the universal phenomena of the influence of temperature on the H2S partial pressure under the conditions of the constant H2S loading and the same component concentrations.

The average relative errors of total pressure and H2S partial pressure between the theoretical values and the experimental data for the system of aqueous H2S-NG-MEA-water are 3.01 and 3.26 %, respectively.

The H2S partial pressure calculated by the electrolyte-NRTL model is compared with the experimental value at 333.15 K under different isoconcentration of aqueous MEA solution as shown in Fig. 4. The results show that the calculated values are in good consistent with the experimental ones. The H2S partial pressure increases with the higher concentration of aqueous MEA solution at a constant H2S loading; the loading of H2S in the liquid phase decreases with higher concentration of the aqueous MEA solution at a constant H2S partial pressure.

The relationship of H2S partial pressure with H2S loading in aqueous solution of the system consisting of H2S-NG-MDEA-water is presented in Figs. 5 and 6. These two Figures have very similar features as the aqueous MEA solutions shown in Figs. 3 and 4, respectively. And the calculated results are also in agreement with the experimental data. Compared two H2S absorption isotherms lines, for instance numbered as line 1, shown in Figs. 3 and 4, the H2S loading is 1.02 in Fig. 3 under the condition of 20.0 kPa H2S partial pressure and 298.15 K, which is larger than that of 0.742 in Fig. 4 at the same conditions. The result shows that the desulfuration ability of aqueous MEA solution is stronger than that of MDEA, although the concentration of aqueous MDEA is higher than that of MEA solution.

The average relative errors of total pressure and H2S partial pressure between the calculated values and the experimental data for the system of aqueous H2S-NG-MDEA-water are 3.46 and 2.91 %, respectively.

Influence of MEA and piperazine added into the MDEA aqueous solutions

Comparison of calculated H2S partial pressure with the experimental data of H2S-NG-(MEA-MDEA)-water system at different isotherms and different equi-compositions is shown in Fig. 7. The blends of MEA and MDEA for H2S absorption have the similar performance with the signal MEA or MDEA. It also can be seen in Fig. 7 that the total content of the mixed aqueous MEA-MDEA solution has little effect on the relationships between H2S loading and H2S partial pressure at lower temperatures, i.e., 298.15 and 313.15 K, but has significantly influence at higher temperature, i.e. 333.15 K. And the deviations become significant at high temperatures for the MEA-MDEA solutions. The reason is that the MEA-MDEA solutions have a higher absorption capacity for H2S, and the influences of total content of MEA-MDEA become more and more important with the increasing of temperature.

The average relative errors of total pressure and H2S partial pressure between the calculated values and the experimental data for the system of aqueous H2S-NG-(MEA-MDEA)-water are 3.12 and 3.00 %, respectively.

By comparing H2S loading in liquid phase under a certain H2S partial pressure and absorption temperature shown in Figs. 3, 5 and 7, the size order of H2S absorption ability for the three systems, i.e. MEA, MDEA and the mixed MEA-MDEA, is MEA > (MEA-MDEA) > MDEA, which indicates that the addition of MEA into aqueous MDEA solution can improve the desulfuration ability of MDEA.

The relationship of the H2S partial pressure with its loading in the liquid phase of the mixed aqueous (MEA-MDEA-PZ) solutions containing PZ is shown in Fig. 8. As discussed above, the H2S partial pressure increases with the higher of H2S loading along the isotherms shown in Fig. 8. The addition of the PZ into the mixed aqueous MEA-MDEA solution is beneficial for increasing its ability of desulfuration. The size order of H2S absorption ability for the above four systems, i.e. MEA, MDEA, mixed (MEA-MDEA), and mixed (MEA-MDEA-PZ), is MEA > (MEA-MDEA-PZ) > (MEA-MDEA) > MDEA, which indicates that the addition of MEA and PZ into aqueous MDEA solutions can well enhance the desulfuration ability of MDEA.

The influence of PZ content on the relationship of H2S partial with its loading in the liquid phase along the four iso-concentration curves of component MEA and MDEA at 313.15 K is shown in Fig. 9. As seen in Fig. 9, the more content of PZ, the greater H2S loading in the liquid phase under the condition of a constant H2S partial pressure. And the more quantity of PZ containing, the lower H2S partial pressure under the condition of a constant H2S loading in the liquid phase. Especially, the four curves tend to be closer at the low H2S loadings about from 0.3 to 0.6. The reason is that almost identical desulfuration ability for these four aqueous absorption systems at this range.

The average relative errors of total pressure and H2S partial pressure between the calculated values and the experimental data for the system of aqueous H2S-NG-(MEA-MDEA-PZ)-water are 3.47 and 3.08 %, respectively.

Comparison of calculated results by model and experimental data

The comparison of H2S partial pressure calculated by the SRK equation of state and electrolyte-NRTL model with the experimental data for the four systems above is shown in Fig. 10. The overall average relative errors of total pressure and H2S partial pressure are 3.30 and 3.07 %, respectively. It shows that the calculated results are very well consistent with the experimental data, and the selected models can well describe the non-idealities of the gas phase and the liquid phase containing aqueous weak electrolytes of hydrogen sulfide dissolved in a kind of mixed alkanolamine solution.

Conclusions

The gas–liquid equilibrium data for desulfuration of natural gas (NG) by using a mixed aqueous alkanolamine solution was investigated and the results were used for evaluating their ability of removing hydrogen sulfide. The apparatus was a glass-jacketed gas absorption cell with a double-drive impeller device. Four gas–liquid equilibria systems, i.e. H2S-NG-MEA-water, H2S-NG-MDEA-water, H2S-NG-(MEA- MDEA)- water, H2S-NG-(MEA-MDEA-PZ)-water at the temperature ranging from 298.15 to 313.15 K were experimentally investigated in this work. The equilibrium data were correlated with SRK equation of state and electrolyte-NRTL activity coefficient model, which describe the non-idealities of the gas phase and the aqueous weak electrolyte solution. The results show that the H2S partial pressure increases with the higher of H2S loading along an isotherm. The quantity of H2S loading in the aqueous phase decreases when the temperature increases under the condition of constant H2S partial pressure. The addition of MEA and PZ is beneficial for improving the desulfuration ability of MDEA. The size order of H2S absorption ability for the four systems, i.e. MEA, MDEA, the mixed (MEA-MDEA), and the mixed (MEA-MDEA-PZ), is MEA > (MEA-MDEA-PZ) > (MEA-MDEA) > MDEA. The four sets of gas–liquid equilibria data can be well correlated with the SRK equation of state and electrolyte-NRTL activity coefficient model. The overall average relative errors of total pressure and H2S partial pressure between the calculated and experimental results of the above four absorption systems are 3.30 and 3.07 %, respectively. The experimental and calculated results are very useful for desulfuration and purification process of natural gas or other industrial gases.

Abbreviations

- wt.:

-

Abbreviation of weight

- vol.:

-

Abbreviation of volume

- NG:

-

Abbreviation of natural gas

- MEA:

-

Abbreviation of monoethanolamine

- MDEA:

-

Abbreviation of methyldiethanolamine

- PZ:

-

Abbreviation of piperazine

- n amines :

-

The total mole numbers of (MEA + MDEA + PZ), mol

- L :

-

H2S loading in liquid phase, mol/mol

- n :

-

The mole number of each species, mol

- \(V_{{{\text{I}}_{2} }}\) :

-

The volume of I2 standard solution consumed with titration, mL

- \(c_{{{\text{I}}_{2} }}\) :

-

The concentration of I2 standard solution, mol/L

- R :

-

Universal gas constant, 8.3145 J/(mol K)

- m :

-

Weight of MEA, MDEA and PZ, g

- V :

-

Volume of gas sample, m3

- p a :

-

Atmosphere pressure, kPa

- Δh :

-

Reading difference of the glass U-tube manometer, kPa

- p :

-

The equilibrium total pressure, kPa

- p read :

-

Fortin Barometer reading, kPa

- t :

-

Room temperature when testing, °C

- M :

-

Molecular weight, g/mol

- N :

-

Number of experimental points

- H :

- p exp., p lit.:

-

Experimental and literature data of H2S partial pressure, kPa

- T :

-

Absolute temperature, K

- K :

-

Equilibrium constants for R1-R6

- a i :

-

Activity of component i

- z i :

-

Valency of an ion i

- x :

-

Liquid phase mole fraction

- y :

-

Gas phase mole fraction

- A 1, A 2, A 3, A 4 :

-

Parameters of Eq. 15

- D:

-

Dielectric constants

- A, B :

-

Parameters in Table 4

- a, b :

-

Parameters of Eq. 18

- T c :

-

Critical temperature, K

- p c :

-

Critical pressure, kPa

- V c :

-

Critical volume, m3/kmol

- Z c :

-

Critical compressibility factor

- I :

-

Component i

- J :

-

W, 1, 2, 3, 4, 5

- exp.:

-

Experimental

- lit.:

-

Literature

- cal.:

-

Calculated

- ∞:

-

Infinite dilution in pure water

- ø:

-

Reference state, standard state

- ω :

-

Parameter of Eq. 18

- υ i :

-

Stoichiometric coefficient of component i

- γ i :

-

Activity coefficient of component i

- \(\hat{\varphi }_{i}\) :

-

Fugacity coefficient of component i in a mixture

References

Lemoine B, Li YG, Cadours R, Bouallou C, Richon D (2000) Partial vapor pressure of CO2 and H2S over aqueous methyldiethanolamine solutions. Fluid Phase Equilib 172:261–277

Haghtalab A, Dehghani Tafti M (2007) Electrolyte UNIQUAC-NRF model to study the solubility of acid gases in alkanolamines. Ind Eng Chem Res 46:6053–6060

Vrachnos A, Kontogeorgis G, Voutsas E (2006) Thermodynamic modeling of acidic gas solubility in aqueous solutions of MEA, MDEA and MEA-MDEA blends[J]. Ind Eng Chem Res 245:5148–5154

Dash SK, Samanta AN, Bandyopadhyay SS (2011) Solubility of carbon dioxide in aqueous solution of 2-amino-2-methyl-1-propanol and piperazine. Fluid Phase Equilib 307:166–174

Haghtalab A, Izadi A (2014) Simultaneous measurement solubility of carbon dioxide + hydrogen sulfide into aqueous blends of alkanolamines at high pressure. Fluid Phase Equilib 375:181–190

Chakravarty T, Phukan UK, Weiland RH (1985) Reaction of acid gases with mixtures of amines. Chem Eng Prog 81:32–36

Bishnoi S, Rochelle GT (2000) Absorption of carbon dioxide into aqueous piperazine: reaction kinetics, mass transfer and solubility. Chem Eng Sci 55:5531–5543

Sun WC, Yong CB, Li MH (2005) Kinetics of the absorption of carbon dioxide into mixed aqueous solutions of 2-amino-2-methyl-1-propanol and piperazine. Chem Eng Sci 60:503–516

Bishnoi S, Rochelle GT (2002) Absorption of carbon dioxide in aqueous piperazine/methyldiethanolamine. AIChE J 48:2788–2799

Xu X, Cai ZY, Liang K (2010) A study on flue gas desulfurization using aqueous piperazine. Environ Chem 29:450–454 (in Chinese)

Lee JI, Otto FD, Mather AE (1976) Equilibrium in hydrogen sulfide-monoethanolamine-water system. J Chem Eng Data 21:207–208

Isaacs EE, Otto FD, Mather AE (1980) Solubility of mixtures of hydrogen sulfide and carbon dioxide in a monoethanolamine solution at low partial pressures. J Chem Eng Data 25:118–120

Jou FY, Mather AE, Otto FD (1982) Solubility of H2S and CO2 in aqueous methyldiethanolamine solutions. Ind Eng Chem Process Des Dev 21:539–544

Jou FY, Carroll JJ, Mather AE, Otto FD (1993) The solubility of carbon dioxide and hydrogen sulfide in a 35 wt% aqueous solution of methyldiethanolamine. Can J Chem Eng 71:264–268

Jou FY, Carroll JJ, Mather AE, Otto FD (1993) Solubility of mixtures of hydrogen sulfide and carbon dioxide in aqueous N-methldiethanolmine solutions. J Chem Eng Data 38:75–77

Kuranov G, Rumpf B, Smirnova NA, Maurer G (1996) Solubility of single gases carbon dioxide and hydrogen sulfide in aqueous solutions of N-methyldiethanolamine in the temperature range 313–413 K at pressure up to 5 MPa. Ind Eng Chem Res 35:1959–1966

Kamps ÁP-S, Balaban A, Jödecke M, Kuranov G, Smirnova NA, Maurer G (2001) Solubility of single gases carbon dioxide and hydrogen sulfide in aqueous solutions of N-methyldiethanolamine at temperatures from 313 to 393 K and pressures up to 7.6 MPa: new experimental data and model extension. Ind Eng Chem Res 40:696–706

Li M-H, Shen K-P (1993) Solubility of hydrogen sulfide in aqueous mixtures of monoethanolamine with N-methldiethanolamine. J Chem Eng Data 38:105–108

Perry RH, Green DW, Maloney JO (1997) Perry’s chemical engineers’ handbook, 7th edn. McGraw-hill, New York

Soave G (1972) Equilibrium constants from a modified Redlich-Kwong equation of state. Chem Eng Sci 27:1197–1203

Austgen DM, Rochelle GT, Peng X, Chen CC (1989) Model of vapor-liquid equilibria for aqueous acid gas-alkanolamine systems using the Electrolyte-NRTL equation. Ind Eng Chem Res 28:1060–1073

Austgen DM, Rochelle GT, Chen CC (1991) Model of vapor-liquid equilibria for aqueous acid gas-alkanolamine systems. 2. Representation of hydrogen sulfide and carbon dioxide solubility in aqueous MDEA and carbon dioxide solubility in aqueous mixtures of MDEA with MEA or DEA. Ind Eng Chem Res 30:543–555

Li Y, Mather AE (1997) Correlation and prediction of the solubility of CO2 and H2S in aqueous solutions of methyldiethanolamine. Ind Eng Chem Res 36:2760–2765

Bishnoi S, Rochelle GT (2002) Thermodynamics of piperazine/methyldiethanolamine/water/carbon dioxide. Ind Eng Chem Res 41:604–612

Mock B, Evans LB, Chen CC (1986) Thermodynamic representation of phase equilibria of mixed-solvent electrolyte systems. AIChE J 32:1655–1664

Hetzer HB, Robinson RA, Bates RG (1968) Dissociation constants of piperazinium ion and related thermodynamic quantities from 0° to 50°. J Phys Chem C 72:2081–2086

Vrachnos A, Voutsas E, Magoulas K, Lygeros A (2004) Thermodynamics of acid gas-MDEA-water systems. Ind Eng Chem Res 43:2798–2804

Masih HJ, Majid AA, Seyed SH, Medhi V, Naser SM (2005) Solubility of carbon dioxide in aqueous mixtures of N-methyldiethanolamine + piperazine + sulfolane. J Chem Eng Data 50:583–586

Derks PWJ, Dijkstra HBS, Hogendoorn JA, Versteeg GF (2005) Solubility of carbon dioxide in aqueous piperazine solutions. AIChE J 51:2311–2327

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Yunhai, S., Shan, L., Wei, L. et al. Influence of MEA and piperazine additives on the desulfurization ability of MDEA aqueous for natural gas purification. Int J Ind Chem 7, 297–307 (2016). https://doi.org/10.1007/s40090-016-0072-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40090-016-0072-1