Abstract

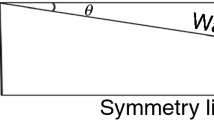

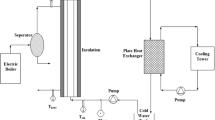

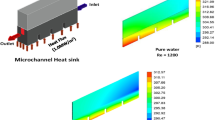

Optimization of thermal systems requires higher heat transfer rate and lower entropy production rate. The review of literature shows that there are limited works on entropy production rate of nanofluids flowing through a converging pipe as the available ones only considered entropy production rate in a linear converging pipe. In this study, a 2D-computational fluid dynamic model is set up to investigate entropy production rate of Al2O3 nanofluid flowing through novel Bessel-like convergent pipes in laminar flow regime. The effect of Reynolds number \(\left( {300 \le {\text{Re}} \le 1200} \right)\), nanoparticle concentration \(\left( {0 \le \varphi \le 0.1} \right)\), and convergent index \(\left( {n = 0 - 3} \right)\) on the entropy production rate, heat transfer effectiveness number, and irreversibility distribution ratio were considered. The results obtained revealed that increase in convergent index enhances viscous entropy production rate, but diminishes thermal entropy production rate. For instance, the reduction in thermal entropy production rate at \({\text{Re}} = 900\) between pipe corresponds to \(n = 0\) and \(n = 3\) was 51.98% while the increase in viscous entropy production rate was 753.65%. Furthermore, a new correlation was developed using response surface methodology to estimate the entropy production rate as a function of the Reynolds number, nanoparticle concentration, and convergence index. The overall result shows that the usage of converging pipe in place of straight pipe is more advantageous.

Similar content being viewed by others

Abbreviations

- \(A_{{\text{s}}}\) :

-

Surface area (m2)

- Be:

-

Bejan number

- \(c_{{\text{p}}}\) :

-

Specific heat capacity at constant pressure (J/kg K)

- Dh :

-

Diameter of the pipe (m)

- \(f\) :

-

Friction factor

- \(h\) :

-

Coefficient of heat transfer (W/m2 K)

- \(I_{{\text{a}}}\) :

-

Thermal effectiveness number

- \(\dot{m}\) :

-

Mass flow rate

- \(N_{{\text{s}}}\) :

-

Dimensionless entropy production rate

- \({\text{Nu}}\) :

-

Nusselt number

- \(\Pr\) :

-

Prandtl number of base fluid

- Re:

-

Reynolds number

- \(S\) :

-

Entropy production

- \(T_{{}}\) :

-

Temperature of base fluid (K)

- u r, u x :

-

Component velocity (m/s)

- \(u_{{{\text{in}}}}\) :

-

Inlet velocity

- \(r\left( x \right)\) :

-

Axial radius

- \(R\) :

-

Radius

- \(\alpha\) :

-

Thermal diffusivity (m2/s)

- \(\lambda\) :

-

Thermal conductivity (W/m K)

- \(\mu\) :

-

Dynamic viscosity (kg/ms)

- \(\varphi\) :

-

Nanoparticle volume fraction (%)

- \(\rho\) :

-

Density of base fluid (kg/m3)

- \(\emptyset\) :

-

Irreversibility distribution function

- \(\delta_{{{\text{th}}}}\) :

-

Thickness of thermal boundary layer

- \(\Delta P\) :

-

Pressure drop

- bulk:

-

Bulk

- f:

-

Base fluid

- gen:

-

Total

- in:

-

Inlet

- out:

-

Outlet

- nf:

-

Nanofluid

- p:

-

Nanoparticle

- con:

-

Convergent

- str:

-

Straight

- ther:

-

Thermal

- vis:

-

Viscous

References

Choi, S.U., Eastman, J.A.: Enhancing thermal conductivity of fluids with nanoparticles (No. ANL/MSD/CP-84938; CONF-951135–29). Argonne National Lab, Lemont (1995)

Moradi, A., Toghraie, D., Isfahani, A.H.M., Hosseinian, A.: An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J. Therm. Anal. Calorimetry 137(5), 1797–1807 (2019)

Anjibabu, D., Nayeem, S.: Heat transfer phenomenon of fluids in corrugated plate heat exchangers. Int. J. Eng. Adv. Technol. 8(5), 2249–8958 (2019)

Eshgarf, H., Kalbasi, R., Maleki, A., Shadloo, M.S.: A review on the properties, preparation, models and stability of hybrid nanofluids to optimize energy consumption. J. Therm. Anal. Calorimetry (2020). https://doi.org/10.1007/s10973-020-09998-w

Fadodun, O.G., Amosun, A.A., Salau, A.O., Ogundeji, J.A.: Numerical investigation of thermal performance of single-walled carbon nanotube nanofluid under turbulent flow conditions. Eng. Rep. 1, e12024 (2019)

Sharif, A., Bağcı, Ö., Ameel, B., De Paepe, M., Bokisova, L.: Parametric study of a triangular cross corrugated plate. In: 13th International Conference on Heat Transfer, Fluid Mechanics and Thermodynamics (2016)

Lakshmans, K., Rajesh, D.: Fluid flow and heat transfer analysis in a converging pipe using Al2O3–water nanofluid. J. Emerg. Technol. Innov. Res. 5(5), 1–8 (2018)

Al-Sammarraie, A.T., Vafai, K.: Heat transfer augmentation through convergence angles in a pipe. Num. Heat Transf. Part A Appl. 72(3), 197–214 (2017)

Al-Sammarraie, A.T., Al-Jethelah, M., Salimpour, M.R., Vafai, K.: Nanofluids transport through a novel concave/convex convergent pipe. Num. Heat Transf. Part A Appl. 75(2), 91–109 (2019)

Rashidi, A.T., Akbarzadeh, M., Karimi, N., Masoodi, R.: Combined effects of nanofluid and transverse twisted-baffles on the flow structures, heat transfer and irreversibilities inside a square duct. J. Appl. Therm. Eng. 130, 315 (2018)

Davood, T., Omid, A.A., Ali, K., Ramin, M.: Numerical investigation of turbulent nanofluid flow and two-dimensional forced-convection heat transfer in a sinusoidal converging-diverging channel. Heat Transf. Res. 50(7), 671–695 (2019)

Muhammed, N., Sidik, C.A.: Utilization of nanofluids in minichannel for heat transfer and fluid flow augmentation. Concise Res. Des. 1(1), 18–29 (2018)

Khan, M.S., Zou, R., Yu, A.: Computational simulation of air-side heat transfer and pressure drop performance in staggered mannered twisted oval tube bundle operating in crossflow. Int. J. Therm. Sci. 161, 106748 (2021)

Pourfattah, F., Akbari, O.A., Jafrian, V., Toghraie, D., Pourfattah, E.: Numerical simulation of turbulent flow and forced heat transfer of water/CuO nanofluid inside a horizontal dimpled fin. J. Therm. Anal. Calorimetry 139, 1–14 (2019)

Xie, Y., Zheng, L., Zhang, D., Xie, G.: Entropy generation and heat transfer performances of Al2O3-water nanofluid transitional flow in rectangular channels with dimples and protrusions. Entropy 18(4), 148 (2016)

Alshare, A., Al-Kouz, W., Khan, W.: Cu–Al2O3 water hybrid nanofluid transport in a periodic structure. Processes 8(3), 2–14 (2020)

Bejan, A., Tsatsaronis, G., Moran, M., Moran, M.J.: Thermal Design and Optimization. Wiley, Oxford (1996)

Owojori, A.A., Olokuntoye, B.A., Fadodun, O.G.: Numerical investigation of second law analysis of PGGNP/H2O nanofluid in various converging pipes. Int. Nano Lett. 11, 43–57 (2021)

Kurnia, J.C., Sasmito, A.P.: Numerical evaluation of heat transfer and entropy generation of helical tubes with various cross-sections under constant heat flux condition. In: MATEC Web of Conferences, vol. 225. EDP Sciences, p. 03017 (2018)

Wang, W., Zhang, Y., Liu, J., Wu, Z., Li, B., Sundén, B.: Entropy generation analysis of fully-developed turbulent heat transfer flow in inward helically corrugated tubes. Num. Heat Transf. Part A Appl. 73(11), 788–805 (2018)

Fadodun, O.G., Amosun, A.A., Okoli, N.L., Olaloye, D.A., Ogundeji, J.A., Durodola, S.S.: Numerical investigation of entropy production in SWCNT/H2O nanofluid flowing through inwardly corrugated tube in turbulent flow regime. J. Therm. Anal. Calorimetry (2020). https://doi.org/10.1007/s10973-020-09589-9

Nakhchi, M.E., Esfahani, J.A.: Entropy generation of turbulent Cu–water nanofluid flow in a heat exchanger tube fitted with perforated conical rings. J. Therm. Anal. Calorimetry 138, 1–14 (2018)

Azadi, M., Hosseinirad, E., Hormozi, F., Rashidi, S.: Second law analysis for nanofluid flow in mini-channel heat sink with finned surface: a study on fin geometries. J. Therm. Anal. Calorimetry 140, 1–13 (2019)

Nayak, R.K., Bhattacharyya, S., Pop, I.: Heat transfer and entropy generation in mixed convection of a nanofluid within an inclined skewed cavity. Int. J. Heat Mass Transf. 102, 596–609 (2016)

Behera, T.R.: Computational Study on Entropy Generation Minimization of Pipe Bending. Doctoral dissertation (2015)

Majid, S., Mohammad, J.: Optimal selection of annulus radius ratio to enhance heat transfer with minimum entropy generation in developing laminar forced convection of water-Al2O3 nanofluid flow. J. Cent. South Univ. 24(8), 1850–1865 (2017)

Shadlaghani, A., Barhemmati-Rajab, N., Zhao, W.: Exergy analysis of the alumina nanofluid through a ribbed annular channel. In: ASTFE Digital Library. Begel House Inc., Danbury (2019)

Mumtaz, M.W., Adnan, A., Mukhtar, H., Rashid, U., Danish, M.: Biodiesel production through chemical and biochemical transesterification: trends, technicalities, and future perspectives. In: Clean Energy for Sustainable Development, pp. 465–485. Academic Press, New York (2017)

Bharath, K.N., Manjunatha, G.B., Santhosh, K.: Failure analysis and the optimal toughness design of sheep–wool reinforced epoxy composites. In: Failure Analysis in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, pp. 97–107. Woodhead Publishing, Sawston (2019)

Fadodun, O.G., Amosun, A.A., Okoli, N.L., Olaloye, D.A., Ogundeji, J.A., Durodola, S.S.: Sensitivity analysis of entropy production in Al2O3/H2O nanofluid through converging pipe. J. Therm. Anal. Calorimetry 143, 431 (2019)

Fadodun, O.G., Amosun, A.A., Ogundeji, J.A., Olaloye, D.O.: Numerical investigation of thermal efficiency and pumping power of Al2O3/H2O nanofluid in pipe using response surface methodology. J. Nanofluids 8(7), 1566–1576 (2019)

Fadodun, O.G., Olokuntoye, B.A., Salau, A.O., Amosun, A.A.: Numerical investigation and sensitivity analysis of entropy production in Al2O3/H2O Nanofluid in straight pipe using response surface methodology. Arch. Thermodyn. 41, 1–12 (2020)

Ahmadi, A.A., Arabbeiki, M., Ali, H.M., Goodarzi, M., Safaei, M.R.: Configuration and optimization of a minichannel using water-alumina nanofluid by non-dominated sorting genetic algorithm and response surface method. Nanomaterials 10(5), 901 (2020)

Danish, M., Yahya, S.M., Saha, B.B.: Modelling and optimization of thermophysical properties of aqueous titania nanofluid using response surface methodology. J. Therm. Anal. Calorim. 139(5), 3051–3063 (2020)

Montazer, E., Salami, E., Yarmand, H., Kazi, S.N., Badarudin, A.: The RSM approach to develop a new correlation for density of metal-oxide aqueous nanofluids. In: IOP Conference Series: Materials Science and Engineering, vol. 210, p. 12071. IOP Publishing, Bristol (2017)

Rejeb, O., Ghenai, C., Jomaa, M.H., Bettayeb, M.: Statistical study of a solar nanofluid photovoltaic thermal collector performance using response surface methodology. Case Stud. Therm. Eng. 21, 100721 (2020)

Hatami, M., Kheirkhah, A., Ghanbari-Rad, H., Jing, D.: Numerical heat transfer enhancement using different nanofluids flow through venturi and wavy tubes. Case Stud. Therm. Eng. 13, 100368 (2019)

Kays, W.M.: Convective Heat and Mass Transfer. Tata McGraw-Hill Education, Pennsylvania (2012)

Buongiorno, J.: Convective transport in nanofluids. J. Heat Transf. 128, 240–250 (2006)

Xuan, Y., Roetzel, W.: Conceptions for heat transfer correlation of nanofluids. Int. J. Heat Mass Transf. 43(19), 3701–3707 (2000)

Corcione, M.: Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers. Manag. 52(1), 789–793 (2011)

Ji, Y., Zhang, H.C., Yang, X., Shi, L.: Entropy generation analysis and performance evaluation of turbulent forced convective heat transfer to nanofluids. Entropy 19(3), 108–116 (2017)

Ratts, E.B., Raut, A.G.: Entropy generation minimization of fully developed internal flow with constant heat flux. J. Heat Transf. 126(4), 656–659 (2004)

Lior, N., Sarmiento-Darkin, W., Al-Sharqawi, H.S.: The exergy fields in transport processes: their calculation and use. Energy 31, 553–578 (2006)

Fadodun, O.G., Salau, A.O., Amosun, A.A., Ibitoye, F.I.: Sensitivity analysis and evaluation of critical size of reactor using response surface methodology. Int. J. Emerg. Technol. 10(4), 184–190 (2019)

Aydar, A.Y.: Utilization of response surface methodology in optimization of extraction of plant materials. In: Statistical Approaches with Emphasis on Design of Experiments Applied to Chemical Processes, pp. 157–169. Intech, London (2018)

Kleijnen, J.P.: Response surface methodology. In: Handbook of Simulation Optimization, pp. 81–104. Springer, New York (2015)

Al-Rashed, A.A.: Optimization of heat transfer and pressure drop of nano-antifreeze using statistical method of response surface methodology. Phys. A 521, 531–542 (2019)

Rashidi, S., Bovand, M., Esfahani, J.A.: Sensitivity analysis for entropy generation in porous solar heat exchangers by RSM. J. Thermophys. Heat Transf. 31(2), 390–402 (2016)

Khuri, A.I., Mukhopadhyay, S.: Response surface methodology. Wiley Interdiscip. Rev. Comput. Stat. 2(2), 128–149 (2010)

Design expert 8.0.7. Stat-Ease Inc., Minneapolis

Andreozzi, A., Manca, O., Nardini, S., Ricci, D.: Forced convection enhancement in channels with transversal ribs and nanofluids. Appl. Therm. Eng. 98, 1044–1053 (2016)

Fluent Inc.: Fluent 14.0 Theory Guide. Fluent Inc., Pittsburgh (2012)

Wen, D., Ding, Y.: Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int. J. Heat Mass Transf. 47(24), 5181–5188 (2004)

Shah, R.K., London, A.L.: Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical Data. Academic press, New York (2014)

Heris, S.Z., Etemad, S.G., Esfahany, M.N.: Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat Mass Transf. 33(4), 529–535 (2006)

Vigdorovich, I.I.: Turbulent thermal boundary layer on a plate. Reynolds analogy and heat transfer law over the entire range of Prandtl numbers. Fluid Dyn. 52(5), 631–645 (2017)

Shari, K.: How to Get Started with Design Expert Software. Stat-Ease Inc, Minneapolis (2013)

Richard, B.: Design Expert 7. Introduction. Mathematics Learning Support Centre, London (2007)

Campolongo, F., Braddock, R.: The use of graph theory in the sensitivity analysis of the model output: a second order screening method. Reliab. Eng. Syst. Saf. 64(1), 1–12 (1999)

Whitcomb, P.J., Anderson, M.J.: RSM Simplified: Optimizing Processes Using Response Surface Methods for Design of Experiments. CRC, Boca Raton (2004)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fadodun, O.G., Amosun, A.A. & Olaloye, D.O. Numerical modeling of entropy production in Al2O3/H2O nanofluid flowing through a novel Bessel-like converging pipe. Int Nano Lett 11, 159–178 (2021). https://doi.org/10.1007/s40089-021-00333-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40089-021-00333-1