Abstract

The report presents the operation status of and upgrade plan for the 100-MeV proton linac at the Korea Multi-purpose Accelerator Complex (KOMAC). First, an operation history of the 100-MeV linac since its commissioning in 2013, such as operation hours, user services, machine availabilities, and downtimes, is discussed. Second, the status of the beamlines in service or under development is described in a detailed manner. Finally, the Korea Spallation Neutron Source (KSNS), which is part of the upgrade plan for the 100-MeV proton linac to expand its utilization fields, is discussed.

Similar content being viewed by others

1 Introduction

The Korea Multi-purpose Accelerator Complex (KOMAC) 100-MeV proton linac was developed through the Proton Engineering Frontier Project, which was launched in 2002 as a twenty-first Century Frontier Project and completed in 2012, with the primary goal to support cutting-edge research and development in various disciplines. The following philosophy was reflected in the development of the KOMAC 100-MeV proton linac to satisfy that goal. First, the proton accelerator should be able to supply characterized proton beams with specific conditions to satisfy user demands. Second, it should support as many users as possible effectively and efficiently. Third, it should be capable of delivering a sufficient number of proton beams for mass irradiation processing. Finally, it should have future upgradability to a GeV-class accelerator.

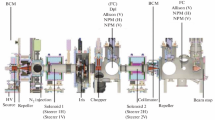

The 100-MeV proton linac is designed to deliver a high-intensity proton beam to be utilized in a wide range of R&D fields, including industrial applications, and for effective support in various R&D projects with characterized beam requirements, it is designed with the specifications summarized in Table 1. The 100-MeV proton linac is composed of a 50-keV injector; a 3-MeV radio frequency quadrupole (RFQ); a 20-MeV drift tube linac (DTL)-I; a 100-MeV DTL-II; and a medium energy beam transport (MEBT) between DTL-I and DTL-II, which extracts 20-MeV proton beams in the middle of the accelerator. A detailed description of the proton accelerator can found elsewhere [1].

For effective user support on maximum operational efficiency of the accelerator, five 20-MeV beamlines (TR21–TR25) and five 100-MeV beamlines (TR101–TR105) have been designed, as shown in Fig. 1. Each beamline is assigned a specific application field with characterized beam energy, current, repetition rate, pulse length, and so on to support user requirements. The details of the beamlines are discussed elsewhere [2].

Since having obtained its operation license from the Nuclear Safety and Security Commission in 2013, the 100-MeV proton linac was commissioned with two general-purpose beamlines to deliver proton beams to users from various R&D fields. Since then, a number of beamlines have been implemented, and the machine availability of the 100-MeV proton linac has been stabilized at about 95% as the time of operation hour and experience have accumulated. During the period, more than 2000 users have utilized the 100-MeV proton linac in about 780 R&D programs.

This report summarizes the operation history of the KOMAC 100-MeV proton linac, such as number of hours of operations, user services, and machine availabilities and downtimes, since its commissioning in 2013. In addition, beamlines in service or under development to expand its application fields are described in a detailed manner. Finally, KSNS, the upgrade plan of the 100-MeV linac to widen its utilization fields is discussed.

2 Operation status of the 100-MeV proton linac

Since the pilot user service in 2013 and official user service in 2014, the 100-MeV proton linac has been operated to support users from various research and industrial application fields, including material science, bio-science, basic science, nuclear science, and semiconductor science and others. The annual operation time is about 3000 h, and the total accumulated operation time reached 23,800 h at the end of 2020, as shown in Fig. 2.

In the initial user service phase, we focused on increasing the number of users and experiments to promote our facility. After 3 years of official user service, the Program Advisory Committee (PAC) changed the policy and weighted the quality of the experiments more when it reviewed the proposals and allocated the beam-time. That is why, the trend in Fig. 3 shows a decrease after 2016. The global COVID-19 pandemic is the reason behind the sharp decrease in 2020.

The evolution of the machine availability, defined as the actual beam service hours over planned beam service hours, is shown in Fig. 4. It has continually increased since the commissioning in 2013 and reached about 95% in recent 5 years. We analyzed the impact of the downtime on the machine availability in 2020, and we summarized the result in Fig. 5. In 2020, the total number of downtime event was 33 (~ 103 h), excluding the number of failures, which had no impact on user beam service. Troubles related with the drift tube linac are the most frequent events and accounted for about 30% of the total downtime. The drift tube linac in the 100-MeV machine consists of 11 tanks, one of which had a minor vacuum problem. Other troubles included water leakage in the cooling circuit of the DTL, damage to the power cable for the electromagnet in a drift tube, and several erroneous interlock events in the machine protection system. We had several events in the klystron/modulator system, mainly due to high-voltage breakdown in the cable connecting the modulator to the klystron. For the ion source, we have operated the 2.45-GHz microwave ion source at ground potential without a high-voltage deck using a waveguide DC break. The only high-voltage part is the plasma chamber, and high-voltage breakdown occurred several times in the insulating part isolating the plasma chamber from the solenoid magnet. When a breakdown happens, it permanently damages the insulator, which has to be replaced with new one. In addition to those mentioned above, we had a few minor troubles in utilities and in the resonant frequency control cooling system (RCCS), which usually took less than 3 h to regain normal operation. Continuously, we have been making efforts to increase the machine availability through pre-emptive maintenance and procurement of spares for major components.

3 Beamline status

The required beam parameters from users are very wide in beam energy, fluence, and size. For example, some users from bio-science or space science require very low-intensity beams with large uniform areas, whereas users studying radiation-resistant materials want as high-intensity beam as possible. In addition, the user-required beam energies range from 3 to 100 MeV, depending on the application fields and specimen types. At KOMAC, we can provide beams with energies ranging from 10 to 100 MeV continuously by both controlling the DTL tank RF timing and using an energy degrader. We started the pilot user service in 2013 with two beamline/target rooms, which we call general-purpose beamlines, and now, we are operating a radio-isotope (RI) production beamline (TR101), a low-flux beamline (TR102), a beamline for secondary RI beam study (TR104), and a neutron production beamline (dump), as well as two general-purpose beamlines (TR23, TR103). In addition, we were certified under the International Organization for Standardization ISO9001 in 2016 to control the quality of beam service.

1. General-purpose beamlines

Since 2013, we have operated two general-purpose beamlines: one for 20 MeV and the other for 100 MeV. The beam power at the target is 10 kW, and a typical irradiation fluence is about 1011 proton/cm2/pulse; however, it can be modulated to meet user requirement. We guarantee an irradiation uniformity of better than 10% with a sample size smaller than 30 mm in diameter, and we can irradiate large samples up to 300 mm in diameter with reduced uniformity (Fig. 6 lower right). We provide an external beam using a beam window made of a 0.5-mm-thick aluminum–beryllium alloy. The target room is equipped with a beam shutter, a sample holder, a remote sample loading system, and a hot cell for irradiated sample manipulation, as shown in Fig. 6. The beamline is mainly used for materials/nanoscience, bio-life science, and semiconductor irradiation.

2. RI production beamline

One of main applications of a high-intensity proton linac is radio-isotope production. Therefore, in 2016, we developed and commissioned a beamline dedicated to the production of proton-enrich RIs, such as 67Cu (cancer therapy) and 82Sr (PET imaging) [3]. The beam power at the target position is 30 kW, and the irradiation area is tuned for the RI production target with a 50-mm diameter. The target room is highly activated during irradiation, so it is equipped with a hot cell for target handling, as well as a target transportation system and a target cooling system with a separate closed loop. We have demonstrated the production of Cu-67 (68Zn(p, 29)67Cu) and Rb-82 (natRb(p, x)82Sr), but in small amounts due to limited a chemical processing capability, as shown in Fig. 7. The chemical processing facility for RI separation and refining is being installed and will be available in 2021.

3. Low-flux beamline

Recently, the demand for electronic devices used in space applications has been increasing with the growth of space industry. Because protons are the dominant source of radiation in the space environment, and cause radiation effects such as single-event effects (SEEs), proton beam from an accelerator can be used for accelerated ground testing of radiation effects on electronic devices to predict their performance in space. The test for space environment simulation usually requires a very-low-intensity beam, especially for determining the threshold of SEEs precisely. To meet the requirements of users from the space industry, we developed a low-flux beamline (Fig. 8) with features such as easy access and real-time data acquisition capabilities, which are essential for SEE tests [4]. To reduce the beam intensity by more than three orders of magnitude (minimum average current ~ 0.1 nA), we installed a locally shielded collimator. Two octupole magnets were installed to provide a uniform beam with a uniformity better than 10% in a 100 mm-by-100 mm area at the sample position (Fig. 8 lower right). The low-flux beam can be further collimated using an in-air collimator to restrict the irradiation to a specific electronic component mounted on a large board. We can reliably provide a proton beam with an intensity as low as 105 proton/cm2/pulse. Even a lower intensity is possible, but precise dose monitoring is very difficult. The low-flux beamline has been in operation since 2017, and the majority of users utilized that beamline during recent 3 years.

4.8Li production beamline

To expand the utilization fields of the KOMAC accelerator, we have conducted a development program to study secondary beams such as 8Li and neutron generated by bombarding a target with primary proton beam. Especially, a 8Li beam is very useful and can be used in beta-detected nuclear magnetic resonance (β-NMR) for advanced surface analysis. Therefore, we allocated one of the beamlines with a 1-kW beam power as a test beamline for studying 8Li beam generation and for developing a target/ion source (TIS). For the development of the TIS, we performed various numerical studies to estimate the rate of 8Li production, the ionization efficiency, and the operation temperature. The main components of the TIS include a beryllium oxide (BeO) disk-shaped target, a graphite target container, a target heater, and a surface ion source made of rhenium. A prototype of the TIS was fabricated and tested at temperatures above 2000 ℃, as shown in Fig. 9 [5, 6]. In addition to the TIS, beam optical components, such as a beam steerer, an electrostatic focusing lens, and a Wien filter, were installed to transport the generated 8Li beam, and a high-energy beta detector was mounted to detect the beta decay of 8Li. We verified the production of a 8Li beam at a rate of 106 particle/s by measuring the characteristic decay curve (Fig. 9 lower right). Additional studies to improve the production and transport of a 8Li beam, along with a detection technique, will be conducted to realize β-NMR capability at KOMAC.

5. Neutron production beamline

In addition to the proton beam, demands for neutron beams from groups in various fields, such as the semiconductor industry, nuclear fusion society, and nuclear data evaluation groups, have been strong. Especially, the terrestrial radiation (mainly neutrons produced by cosmic rays) effects on the semiconductor devices used for aviation, massive data storage system, and autonomous vehicle systems have been important, because the soft error induced by terrestrial radiation can be critical in those systems; neutron tests on semiconductor devices have been gaining interest in recent years. We have provided users with a pilot service using by-product neutrons generated at a beam dump and with a limited primary beam power (~ 1 kW), as shown in Fig. 10. The estimated neutron fluxes based on a numerical simulation at a reference sample position were 8.1 × 106 neutron/cm2/s for neutron energy above 1 keV and 3.64 × 106 neutron/cm2/s with neutron energy above 10 MeV [7]. Currently, the neutron user service is not so user-friendly, and neutron flux is limited; however, we have a plan to improve the neutron beamline by replacing the beam dump with a dedicated neutron generation target and installing user-friendly equipment to meet the increasing user demands for neutron beams.

4 Future upgrade plan

Various upgrade options of the KOMAC 100-MeV proton linac had been considered and reviewed, such as a spallation neutron source, a high-energy or nuclear physics facility, an accelerator-driven reactor experimental system, and so on [8,9,10]. After considering the performance, upgrade budget, and supporting application fields, we chose a 2-GeV, 600-kW proton rapid-cycling synchrotron (RCS)-based spallation neutron source for the future upgrade of the KOMAC 100-MeV proton linac [11,12,13]. The project’s name is the Korea Spallation Neutron Source (KSNS), and one possible facility layout is shown in Fig. 11.

The KSNS facility consists of four main components: the KOMAC linac, which will be converted to 100-MeV (~ 250 MeV at the upgrade phase-II) H− linac to inject proton beams into the 2-GeV RCS ring; a 2-GeV RCS ring, which can boost the proton beam energy from 100 MeV to 2 GeV; the first experimental building to deliver high-energy (≥ 500 MeV) protons for proton beam irradiation to test radiation effects on space parts, semiconductors, and electronic devices; the second experimental building to deliver high-energy (≥ 500 MeV) neutrons for neutron beam irradiation to test the effects of terrestrial radiation on space parts, semiconductors, and electronic devices. In addition, the second experimental building can also deliver low-energy (≤ 25 meV), high-flux (≥ 1017 neutron/cm2/sec) thermal and cold neutrons for neutron analyses.

After considering two on-going large accelerator construction projects in Korea (RAON heavy ion accelerator project at Daejeon and the fourth-generation synchrotron light source project at Ochang), we will perform a basic design of the KSNS facility for the years 2021–2024, detailed engineering design from 2025 to 2027, facility construction from 2028 to 2033, commissioning in 2034, and finally user service from 2035. At the beginning, we will construct at least three beamlines [high-energy (≥ 500 MeV) proton and neutron beamlines for proton and neutron irradiation, and a low-energy high-flux neutron beamline for neutron analyses]. Later, by installing further beamlines step by step, we will increase the total number of operating beamlines to 20.

The main application fields of the KSNS facility will be research and developments on space parts, semiconductors, future vehicles (self-driving cars, flying cars, drone-taxis, etc.), artificial satellites, sixth-generation wireless communications (6G) network, battery and energy materials, vaccines and drugs, new materials for extreme environments, and almost all advanced science and technology fields. For the realization of the KSNS project, detailed planning, as well as underlying R&D efforts, to develop a superconducting RF linac, a rapid-cycling synchrotron, neutron production target, beamlines, instrumentations, and so on is in progress.

5 Conclusion

Since commissioning in 2013, the operation of the KOMAC 100-MeV proton linac has become stabilized with an annual operational time of more than 3,000 h and a machine availability of greater than 95%. The number of user experiments supported by the linac has reached its limit through a number of beamlines, such as a RI production beamline, a low-flux beamline, and a pilot neutron production beamline, providing normal user services.

However, if more users are to be supported with greater beam quality, more sophisticated care of the 100-MeV linac is required, which is essential to maintain the annual number of operating hours, as well as a machine availability of greater than 95%. In addition, if the application fields of the 100-MeV linac are to be widened and specialized, more specialized beamlines, such as beta-NMR, need to be developed. Especially, the underlying R&D required to realize the upgrade plan of the KOMAC 100-MeV linac to the Korea Spallation Neutron Source should be performed as soon as possible.

References

K.Y. Kim, Y.-S. Cho, J.Y. Kim, K.-R. Kim, B.-H. Choi, J. Korean Phys. Soc. 56, 1937 (2010)

K.-R. Kim, K.Y. Kim, Y.-S. Cho, J.Y. Kim, J.-W. Park, B.-H. Choi, J. Korean Phys. Soc. 59, 521 (2011)

H.-S. Kim, J. Korean Phys. Soc. 69, 1115 (2016)

Y.-M. Kim, S.-P. Yun, H.-S. Kim, H.-J. Kwon, Nucl. Instrum. Methods A 950, 162971 (2020)

J.-J. Dang, J. Korean Phys. Soc. 73, 1103 (2018)

P. Lee, J.-J. Dang, W.-H. Jung, D.-H. Kim, H.-J. Kwon, H.-S. Kim, S. Lee, Y.-S. Cho, AIP Conf. Proc. 2319, 080014 (2021)

P. Lee, J.-J. Dang, H.-S. Kim, H.-J. Kwon, S.H. Lee, Y.-S. Cho, J. Phys. Conf. Ser. 1350, 012066 (2019)

Long-term Planning for Proton Engineering Frontier Project (in Korean), STEPI (2009)

National large research facilities roadmap, National Science & Technology Commission, p. 92 (2012)

Long-term roadmap and operation strategy of large accelerators (in Korean), Ministry of Science and ICT (2020)

Y. Kim, Korea Spallation Neutron Source (KSNS), NFEC survey of demand to make a plan on Korea Long-term planning on basic research infrastructure (in Korean) (2021)

Y. Kim, M. Moon, J.-S. Lee, Phys. High Technol. 30(5), 2 (2021)

Y. Kim, Korea Spallation Neutron Source (KSNS), invited oral talk at 2021 Korean Physical Society (KPS) fall meeting (2021)

Acknowledgements

This work has been supported through the KOMAC (Korea Multi-purpose Accelerator Complex) operation fund of the Korea Atomic Energy Research Institute (KAERI) supported by the MSIT (Ministry of Science and ICT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, HS., Kwon, HJ., Kim, KY. et al. Operational status of and upgrade plan for the 100-MeV proton linac at the Korea multi-purpose accelerator complex. J. Korean Phys. Soc. 80, 799–807 (2022). https://doi.org/10.1007/s40042-022-00396-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40042-022-00396-z