Abstract

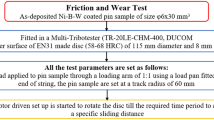

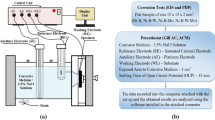

The coatings are utilised on any materials as a protective layer. The coating characteristics are dependent on their composition, phase structure and surface morphology. In this current investigation, the coated specimens are developed by chemical deposition method with the incorporation of tungsten (W) and molybdenum (Mo) either alone or jointly into Ni–B matrix. The coatings are studied to make a comparative analysis on mechanical behaviours of the as-deposited coatings to understand the impact of bath parameters. Steel made square samples are coated with borohydride reduced coatings with various compositions. The coating characterisations are carried out for the elemental analysis of the coated specimens as well as their surface morphology. The coated layer thicknesses are found to rise due to rise in concentration for all types of coatings under study. The nanoindentation tests are conducted to determine elastic modulus and nanohardness. The scratch hardness tests are carried out using a micro-scratch tester. The boron concentration is found to increase with chemical solution element concentrations which contribute to increase the nanohardness. The nanohardness of Ni–B–W–Mo coatings is found to be better than untreated binary and ternary coatings at higher compositions. The scratch hardness of untreated Ni–B–W coatings is observed to possess its maximum value across the examined range due to the presence of boron and tungsten. The nanohardness and scratch hardness of untreated Ni–B–Mo coatings increase with concentration level in the coating bath but remained lower than other variants.

Similar content being viewed by others

Abbreviations

- BM:

-

Electroless Ni–B–Mo coating

- BW:

-

Electroless Ni–B–W coating

- BWM:

-

Electroless Ni–B–W–Mo coating

- EDAX:

-

Energy dispersive X-ray analysis

- HL:

-

Higher level

- LL:

-

Lower level

- ML:

-

Middle level

- NB:

-

Electroless Ni–B coating

- SEM:

-

Scanning electron microscopy

- XRD:

-

X-ray diffraction

References

F. Bülbül, H. Altun, V. Ezirmik, Ö. Küçük, Investigation of structural, tribological and corrosion properties of electroless Ni–B coating deposited on 316L stainless steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 227(6), 629–639 (2013). https://doi.org/10.1177/1350650112464928

Y. Wan, Y. Yu, L. Cao, M. Zhang, J. Gao, C. Qi, Corrosion and tribological performance of PTFE-coated electroless nickel boron coatings. Surf. Coat. Technol. 307, 316–323 (2016). https://doi.org/10.1016/j.surfcoat.2016.09.001

T. Miri, D. Seifzadeh, Z. Rajabalizadeh, Electroless Ni–B-MMT nanocomposite on magnesium alloy. Surf. Eng. 37(9), 1194–1205 (2021). https://doi.org/10.1080/02670844.2021.1959287

P. Sahoo, S.K. Das, Tribology of electroless nickel coatings—a review. Mater. Des. 32(4), 1760–1775 (2011). https://doi.org/10.1016/j.matdes.2010.11.013

M. Barman, T.K. Barman, P. Sahoo, Effect of borohydride concentration on tribological and mechanical behavior of electroless Ni–B coatings. Mater. Res. Express 6(12), 126575 (2019). https://doi.org/10.1088/2053-1591/ab58b7

S. Sürdem, C. Eseroğlu, R. Çitak, A parametric study on the relationship between NaBH4 and tribological properties in the nickel–boron electroless depositions. Mater. Res. Express 6(12), 125085 (2019). https://doi.org/10.1088/2053-1591/ab5beb

M. Barman, T.K. Barman, P. Sahoo, Effect of heat-treatment temperature and borohydride concentration on corrosion behaviour of ENB coating. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 237(1), 183–200 (2023). https://doi.org/10.1177/09544062221117677

M. Barman, T.K. Barman, P. Sahoo, Tribo-mechanical characterisation of borohydride reduced Ni–B–W coatings. J. Inst. Eng. India Ser. 1, 1 (2023). https://doi.org/10.1007/s40033-023-00471-0

S. Pal, N. Verma, V. Jayaram, S.K. Biswas, Y. Riddle, Characterization of phase transformation behaviour and microstructural development of electroless Ni–B coating. Mater. Sci. Eng. A 528(28), 8269–8276 (2011). https://doi.org/10.1016/j.msea.2011.07.060

E. Correa, A.A. Zuleta, L. Guerra, M.A. Gómez, J.G. Castaño, F. Echeverría, G.E. Thompson, Tribological behavior of electroless Ni–B coatings on magnesium and AZ91D alloy. Wear 305(1–2), 115–123 (2013). https://doi.org/10.1016/j.wear.2013.06.004

V. Vitry, L. Bonin, Increase of boron content in electroless nickel–boron coating by modification of plating conditions. Surf. Coat. Technol. 311, 164–171 (2017). https://doi.org/10.1016/j.surfcoat.2017.01.009

J.N. Balaraju, A. Priyadarshi, V. Kumar, N.T. Manikandanath, P.P. Kumar, B. Ravisankar, Hardness and wear behaviour of electroless Ni–B coatings. Mater. Sci. Technol. 32(16), 1654–1665 (2016). https://doi.org/10.1080/02670836.2015.1137683

V. Vitry, A. Sens, A.F. Kanta, F. Delaunois, Experimental study on the formation and growth of electroless nickel–boron coatings from borohydride-reduced bath on mild steel. Appl. Surf. Sci. 263, 640–647 (2012). https://doi.org/10.1016/j.apsusc.2012.09.126

R.A. Yildiz, K. Genel, T. Gulmez, Effect of heat treatments for electroless deposited Ni–B and Ni–WB coatings on 7075 Al alloy. Int. J. Mater. Mech. Manufact. 5(2), 83–86 (2017). https://doi.org/10.18178/ijmmm.2017.5.2.295

V. Vitry, A.F. Kanta, F. Delaunois, Mechanical and wear characterization of electroless nickel–boron coatings. Surf. Coat. Technol. 206(7), 1879–1885 (2011). https://doi.org/10.1016/j.surfcoat.2011.08.008

C. Domínguez-Ríos, A. Hurtado-Macias, R. Torres-Sanchez, M.A. Ramos, J. Gonzalez-Hernandez, Measurement of mechanical properties of an electroless Ni–B coating using nanoindentation. Ind. Eng. Chem. Res. 51(22), 7762–7768 (2012). https://doi.org/10.1021/ie201760g

M. Barman, T.K. Barman, P. Sahoo, Tribo-mechanical characterization of ENB alloy coatings: effect of heat-treatment temperature and sodium borohydride concentration. Facta Univ. Ser. Mech. Eng. 1, 1 (2022). https://doi.org/10.22190/FUME220814041B

I.G. Serin, A. Göksenli, B. Yüksel, R.A. Yildiz, Effect of annealing temperature on the corrosion resistance of electroless Ni–B–Mo coatings. J. Mater. Eng. Perform. 24, 3032–3037 (2015). https://doi.org/10.1007/s11665-015-1568-0

I.G. Serin, A. Göksenli, Effect of annealing temperature on hardness and wear resistance of electroless Ni–B–Mo coatings. Surf. Rev. Lett. 22(05), 1550058 (2015). https://doi.org/10.1142/S0218625X15500584

M.G. Hosseini, S. Ahmadiyeh, A. Rasooli, S. Khameneh-Asl, Pulse plating of Ni–WB coating and study of its corrosion and wear resistance. Metall. Mater. Trans. A 50, 5510–5524 (2019). https://doi.org/10.1007/s11661-019-05444-1

A. Mukhopadhyay, T.K. Barman, P. Sahoo, Effect of heat treatment on tribological behavior of electroless Ni–B–Mo coatings at different operating temperatures. SILICON 10, 1203–1215 (2018). https://doi.org/10.1007/s12633-017-9594-1

A. Mukhopadhyay, T.K. Barman, P. Sahoo, Tribological characteristics of electroless Ni–B–Mo coatings at different operating temperatures. Surf. Rev. Lett. 26(04), 1850175 (2019). https://doi.org/10.1142/S0218625X18501755

V. Nemane, S. Chatterjee, Scratch and sliding wear testing of electroless Ni–B–W coating. J. Tribol.Tribol. 142(2), 021705 (2020). https://doi.org/10.1115/1.4045165

A.I. Aydeniz, A. Göksenli, G. Dil, F. Muhaffel, C. Calli, B. Yüksel, Electroless Ni–BW coatings for improving hardness, wear and corrosion resistance. Mater. Tehnol. 47(6), 803–806 (2013)

R.A. Yildiz, A. Göksenli, B.H. Yüksel, F. Muhaffel, A. Aydeniz, Effect of annealing temperature on the corrosion resistance of electroless produced Ni–BW coatings. Adv. Mater. Res. 651, 263–268 (2013). https://doi.org/10.4028/www.scientific.net/AMR.651.263

A.B. Radwan, R.A. Shakoor, A. Popelka, Improvement in properties of Ni–B coatings by the addition of mixed oxide nanoparticles. Int. J. Electrochem. Sci.Electrochem. Sci. 10(9), 7548–7562 (2015). https://doi.org/10.1016/S1452-3981(23)17370-6

V. Niksefat, M. Ghorbani, Mechanical and electrochemical properties of ultrasonic-assisted electroless deposition of Ni–B–TiO2 composite coatings. J. Alloy. Compd. 633, 127–136 (2015). https://doi.org/10.1016/j.jallcom.2015.01.250

M. Barman, T.K. Barman, P. Sahoo, Corrosion behaviour of borohydride reduced Ni–B, Ni–B–W, Ni–B–Mo, Ni–B–W–Mo coatings with varying composition: a comparison. J. Inst. Eng. Ser. D (2023). https://doi.org/10.1007/s40033-023-00574-8

M. Barman, T.K. Barman, P. Sahoo, Tribological behavior of electroless Ni–B ternary and quaternary coatings with inclusion of W and Mo. PhysicaScripta. 99, 025924 (2023). https://doi.org/10.1088/1402-4896/ad19bc

A. Mukhopadhyay, T.K. Barman, P. Sahoo, J.P. Davim, Comparative study of tribological behavior of electroless Ni–B, Ni–B–Mo, and Ni–B–W coatings at room and high temperatures. Lubricants 6(3), 67 (2018). https://doi.org/10.3390/lubricants6030067

M. Barman, T.K. Barman, P. Sahoo, Tribo-mechanical behaviour of electroless Ni–B–Mo coatings with varying bath composition. Eng. Res. Express 5, 025072 (2023). https://doi.org/10.1088/2631-8695/acdd52

V. Vitry, J. Hastir, A. Mégret, S. Yazdani, M. Yunacti, L. Bonin, Recent advances in electroless nickel–boron coatings. Surf. Coat. Technol. 429, 127937 (2022). https://doi.org/10.1016/j.surfcoat.2021.127937

F. Madah, C. Dehghanian, A.A. Amadeh, Investigations on the wear mechanisms of electroless Ni–B coating during dry sliding and endurance life of the worn surfaces. Surf. Coat. Technol. 282, 6–15 (2015). https://doi.org/10.1016/j.surfcoat.2015.09.003

V. Vitry, A. Sens, & F. Delaunois. (2014). Comparison of various electroless nickel coatings on steel: structure, hardness and abrasion resistance. in Materials Science Forum (Vol. 783, pp. 1405–1413). Trans Tech Publications Ltd. https://doi.org/10.4028/www.scientific.net/msf.783-786.1405

J.N. Balaraju, N. Raman, N.T. Manikandanath, Nanocrystalline electroless nickel poly-alloy deposition: incorporation of W and Mo. Trans. IMF 92(3), 169–176 (2014). https://doi.org/10.1179/0020296713Z.000000000123

V. Nemane, V. Sharma, S. Chatterjee, Tribological electroless ternary Ni–BW coatings: a suitable alternative to hard chromium coatings. J. Tribol.Tribol. 144(12), 121401 (2022). https://doi.org/10.1115/1.4055409

R. Agrawal, A. Mukhopadhyay, Development of Ni–B electroless coating from stabilizer free bath and characterization of high temperature tribological behaviour, scratch and corrosion resistance. Surf. Topogr. Metrol. Prop.Topogr. Metrol. Prop. 10(4), 045028 (2022). https://doi.org/10.1088/2051-672X/aca784

A. Mukhopadhyay, T.K. Barman, P. Sahoo, Effect of heat treatment on the characteristics of electroless Ni–B, Ni–BW and Ni–B–Mo coatings. Mater. Today Proc. 5(2), 3306–3315 (2018). https://doi.org/10.1016/j.matpr.2017.11.573

A. Mukhopadhyay, T.K. Barman, P. Sahoo, Effect of heat treatment on microstructure and corrosion resistance of Ni–BW–Mo coating deposited by electroless method. Surf. Rev. Lett. 25(08), 1950023 (2018). https://doi.org/10.1142/S0218625X19500239

S. Yazdani, F. Mahboubi, Comparison between microstructure, wear behavior, and corrosion resistance of plasma-nitrided and vacuum heat-treated electroless Ni–B coating. J. Bio Tribo-Corros. 5, 1–11 (2019). https://doi.org/10.1007/s40735-019-0264-2

A. Mukhopadhyay, T.K. Barman, P. Sahoo, J.P. Davim, Tribological characteristics of electroless Ni–BW–Mo coatings under dry sliding condition. J. Manuf. Technol. Res. 11(1/2), 13–23 (2019)

M. Lekka, R. Offoiach, A. Lanzutti, M.Z. Mughal, M. Sebastiani, E. Bemporad, L. Fedrizzi, Ni–B electrodeposits with low B content: effect of DMAB concentration on the internal stresses and the electrochemical behaviour. Surf. Coat. Technol. 344, 190–196 (2018). https://doi.org/10.1016/j.surfcoat.2018.03.018

L. Bonin, V. Vitry, Mechanical and wear characterization of electroless nickel mono and bilayers and high boron-mid phosphorus electroless nickel duplex coatings. Surf. Coat. Technol. 307, 957–962 (2016). https://doi.org/10.1016/j.surfcoat.2016.10.021

A. Mukhopadhyay, T.K. Barman, P. Sahoo, Tribological behavior of electroless Ni-B-W coating at room and elevated temperatures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 232(11), 1450–1466 (2018). https://doi.org/10.1177/1350650118755781

X. Liu, F. Yuan, Y. Wei, Grain size effect on the hardness of nanocrystal measured by the nanosize indenter. Appl. Surf. Sci. 279, 159–166 (2013). https://doi.org/10.1016/j.apsusc.2013.04.062

S. Arias, J.G. Castaño, E. Correa, F. Echeverría, M. Gómez, Effect of heat treatment on tribological properties of Ni–B coatings on low carbon steel: wear maps and wear mechanisms. J. Tribol.Tribol. 141(9), 091601 (2019). https://doi.org/10.1115/1.4043906

S. Pal, R. Sarkar, V. Jayaram, Characterization of thermal stability and high-temperature tribological behavior of electroless Ni–B coating. Metall. Mater. Trans. A 49, 3217–3236 (2018). https://doi.org/10.1007/s11661-018-4599-y

A. Mukhopadhyay, T.K. Barman, P. Sahoo, Wear and friction characteristics of electroless Ni–BW coatings at different operating temperatures. Mater. Res. Express 5(2), 026526 (2018). https://doi.org/10.1088/2053-1591/aaae5a

L. Bonin, V. Vitry, F. Delaunois, Inorganic salts stabilizers effect in electroless nickel–boron plating: stabilization mechanism and microstructure modification. Surf. Coat. Technol. 401, 126276 (2020). https://doi.org/10.1016/j.surfcoat.2020.126276

M. Yunacti, A. Mégret, M.H. Staia, A. Montagne, V. Vitry, Characterization of electroless nickel–boron deposit from optimized stabilizer-free bath. Coatings 11(5), 576 (2021). https://doi.org/10.3390/coatings11050576

L. Bonin, V. Vitry, F. Delaunois, The tin stabilization effect on the microstructure, corrosion and wear resistance of electroless Ni–B coatings. Surf. Coat. Technol. 357, 353–363 (2019). https://doi.org/10.1016/j.surfcoat.2018.10.011

L. Bonin, V. Vitry, F. Delaunois, Replacement of lead stabilizer in electroless nickel–boron baths: synthesis and characterization of coatings from bismuth stabilized bath. Sustain. Mater. Technol. 23, e00130 (2020). https://doi.org/10.1016/j.susmat.2019.e00130

S. Banerjee, P. Sarkar, P. Sahoo, Improving corrosion resistance of magnesium nanocomposites by using electroless nickel coatings. Facta Univ. Ser. Mech. Eng. 20(3), 647–663 (2022). https://doi.org/10.22190/FUME210714068B

Funding

There are no funding sources to conduct this study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barman, M., Barman, T.K. & Sahoo, P. Effects of W and Mo Concentrations on Mechanical Behaviour of Ni–B Based Coatings—A Comparative Study. J. Inst. Eng. India Ser. D (2024). https://doi.org/10.1007/s40033-024-00696-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-024-00696-7