Abstract

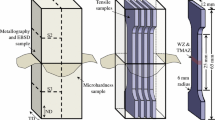

Friction welding of Ti-6Al-4V alloy is gaining considerable interest in the biomedical field for various applications. Ti-6Al-4V alloy is used to make biomedical equipment for a variety of uses, such as orthopaedic implants, dental implants, cardiovascular devices, and surgical instruments. The outstanding strength-to-weight ratio and biocompatibility of this alloy make it highly suitable for medical applications. In the present investigation, Ti-6Al-4V alloy rods were subjected to rotary friction welding. Prior to welding, pre-heat treatments were conducted in α + β and β conditions, followed by stress relieving on the Ti-6Al-4V rods. Additionally, some rods underwent stress relieving after the welding process. After multiple experimental trials, it was determined that friction welding at a rotational speed of 1500 rpm and an upset force of 5kN yielded defect-free joints. With the exception of a small difference in intensities, the XRD pattern shows that all conditions are quite similar. The existence of martensite and α colonies indicates that the transformation is a mixed phase. The tensile fracture behaviour of Ti-6Al-4V alloy welds were influenced by heat treatment. In as-received and stress-relieved welds, various characteristics were observed below the fractured surface, including changes in grain orientation, the presence of micro-voids, and discontinuous β grain boundaries. The α + β weld and α + β weld with stress-relieving conditions displayed high-density micro-voids, secondary void development, blunt cracks, and voids at the cusp of β grain boundaries. In β welds crack at prior beta grain boundaries, micro-voids in prior beta grains and kinking of α/β lamellae were observed. In β weld with stress-relieving micro-voids at the prior beta grain boundary and coarse slip bands within the prior β grains were observed. Scanning electron microscopy provided evidence of correlation among all features.

Similar content being viewed by others

References

S. Karna, M. Cheepu, D. Venkateswarulu, V. Srikanth, Recent developments and research progress on friction stir welding of titanium alloys: an overview. IOP Conf. Ser. Mater. Sci. Eng. (2018). https://doi.org/10.1088/1757-899X/330/1/012068

M.M. Kasaei, R. Beygi, R.J.C. Carbas, E.A.S. Marques, L.F.M. da Silva, A review on mechanical and metallurgical joining by plastic deformation. Discov. Mech. Eng. 2(1), 5 (2023). https://doi.org/10.1007/s44245-023-00012-9

A.I. Gulyaev, S.Y. Smolenskii, A.A. Preobrazhenskii, A.V. Sinitsyn, N.A. Sosin, R.N. Feofilov, Manufacturing medical instruments by friction welding. Biomed. Eng. (NY) 11(1), 34–35 (1977). https://doi.org/10.1007/BF00556011

B. Skowrońska, T. Chmielewski, W. Pachla, M. Kulczyk, J. Skiba, W. Presz, Friction weldability of UFG 316L stainless steel. Arch. Metall. Mater. (2019). https://doi.org/10.24425/amm.2019.129494

A. Jabbar Hassan, T. Boukharouba, D. Miroud, Friction welding of AISI 304: effect of friction time on micro-structure, micro-hardness and tension-compression properties. Acta Metall. Slovaca 26, 78–83 (2020). https://doi.org/10.36547/ams.26.3.631

A. Jabbar Hassan, T. Boukharouba, D. Miroud, N. Titouche, S. Ramtani, Direct drive friction welding joint strength of AISI 304. Int. J. Eng. Trans. B Appl. (2021). https://doi.org/10.5829/ije.2021.34.03c.16

A.K. Nasution, P. Nawangsari, A. Junaidi, H. Hermawan, Friction welding of AZ31-SS316L for partially-degradable orthopaedic pins. IOP Conf. Ser. Mater. Sci. Eng. 532(1), 012014 (2019). https://doi.org/10.1088/1757-899X/532/1/012014

M.S. Gogheri, M. Kasiri-Asgarani, H.R. Bakhsheshi-Rad, H. Ghayour, M. Rafiei, Mechanical properties, corrosion behavior and biocompatibility of orthopedic pure titanium−magnesium alloy screw prepared by friction welding. Trans. Nonferrous Met. Soc. China 30(11), 2952–2966 (2020). https://doi.org/10.1016/S1003-6326(20)65434-6

A.U. Rehman, N.K. Babu, M.K. Talari, Y.S. Usmani, H. Al-Khalefah, Microstructure and mechanical properties of dissimilar friction welding Ti-6Al-4V alloy to nitinol. Metals (Basel) (2021). https://doi.org/10.3390/met11010109

K.S.R. Vikas, K.S. Rao, Rahul, G.M. Reddy, V.S.N. Venkata Ramana, Influence of heat treatments on microstructural and mechanical properties of Grade 5 titanium friction welds. Eng. Res. Express 4, 025053 (2022). https://doi.org/10.1088/2631-8695/ac7a0a

S. Daqian, Zhenan, Microstructural features of friction-welded Ti-6Al-4V joint. Mater. Sci. Technol. English Ed. 16(1), 59–62 (2000)

W. A. Backofen, “Fracture of engineering materials,” ASM Int. Mater. Park. OH, pp. 107–126, 1964.

T.J. Lienert, W.A. Baeslack, J. Ringnalda, H.L. Fraser, Inertia-friction welding of SiC-reinforced 8009 aluminium. J. Mater. Sci. 31(8), 2149–2157 (1996). https://doi.org/10.1007/BF00356639

R. Rahul, K.V. Rajulapati, G.M. Reddy, T. Mohandas, K. Bhanu Sankara Rao, Studies on effect of parent metal condition on the room temperature mechanical properties of Ti6Al4V friction welds. Trans. Indian Inst. Met. 70, 2277–2291 (2017). https://doi.org/10.1007/s12666-017-1084-z

Antonio Augusto Monaco da Silva, “An investigation on the structure/property relationships of solid states welding processes in a titanium matrix composite alloy (Ti-6Al-4V),” PhD Thesis, University of Duisburg, Germany, 2006.

R. Palanivel, R.F. Laubscher, I. Dinaharan, D.G. Hattingh, Microstructure and mechanical characterization of continuous drive friction welded grade 2 seamless titanium tubes at different rotational speeds. Int. J. Press. Vessel. Pip. (2017). https://doi.org/10.1016/j.ijpvp.2017.06.005

M. C. Zulu and P. M. Mashinini, “The influence of rotational speed and pressure on the properties of rotary friction welded titanium alloy (Ti-6Al-4V),” in 11th South African Conference on Computational and Applied Mechanics, SACAM 2018, 2018.

M.C. Zulu, P.M. Mashinini, Process optimization of rotary friction welding of Ti-6Al-4V alloy rods. IOP Conf. Ser. Mater. Sci. Eng. (2018). https://doi.org/10.1088/1757-899X/430/1/012012

M. Avinash, G.V.K. Chaitanya, D.K. Giri, S. Upadhya, B.K. Muralidhara, Microstructure and mechanical behaviuor of rotary friction welded titanium alloys. Int. J. Mech. Aerospace, Ind. Mechatron. Manuf. Eng. 1, 641–643 (2007)

K.S.R. Vikas, Rahul, V.S.N.V. Ramana, G.M. Reddy, K.S. Rao, Influence of heat treatments on corrosion behavior of Ti64 friction welds. Chem. Data Collect. 42, 100940 (2022). https://doi.org/10.1016/j.cdc.2022.100940

O.G. Klimova-Korsmik, G.A. Turichin, S.A. Shalnova, M.O. Gushchina, V.V. Cheverikin, Structure and properties of Ti-6Al-4V titanium alloy products obtained by direct laser deposition and subsequent heat treatment. J. Phys. Conf. Ser. 1109, 012061 (2018). https://doi.org/10.1088/1742-6596/1109/1/012061

S.L.R. da Silva, L.O. Kerber, L. Amaral, C.A. dos Santos, X-ray diffraction measurements of plasma-nitrided Ti-6Al-4V. Surf. Coatings Technol. 116–119, 342–346 (1999). https://doi.org/10.1016/S0257-8972(99)00204-2

M. Esmaily, S. Nooshin Mortazavi, P. Todehfalah, M. Rashidi, Microstructural characterization and formation of α′ martensite phase in Ti-6Al-4V alloy butt joints produced by friction stir and gas tungsten arc welding processes. Mater. Des. 47, 143–150 (2013). https://doi.org/10.1016/J.MATDES.2012.12.024

Y. Ko, K. Lee, K. Baik, Effect of tool rotational speed on mechanical properties and microstructure of friction stir welding joints within Ti-6Al-4V alloy sheets. Adv. Mech. Eng. 9(8), 168781401770970 (2017). https://doi.org/10.1177/1687814017709702

S. Malinov, W. Sha, Z. Guo, C.C. Tang, A.E. Long, Synchrotron X-ray diffraction study of the phase transformations in titanium alloys. Mater. Charact. 48(4), 279–295 (2002). https://doi.org/10.1016/S1044-5803(02)00286-3

M.T. Jovanović, S. Tadić, S. Zec, Z. Mišković, I. Bobić, The effect of annealing temperatures and cooling rates on microstructure and mechanical properties of investment cast Ti-6Al-4V alloy. Mater. Des. 27(3), 192–199 (2006). https://doi.org/10.1016/J.MATDES.2004.10.017

H. Matsumoto et al., Room-temperature ductility of Ti-6Al-4V alloy with α′ martensite microstructure. Mater. Sci. Eng. A 528(3), 1512–1520 (2011). https://doi.org/10.1016/J.MSEA.2010.10.070

B. Li, Y. Shen, W. Hu, L. Luo, Surface modification of Ti-6Al-4V alloy via friction-stir processing: microstructure evolution and dry sliding wear performance. Surf. Coatings Technol. 239, 160–170 (2014). https://doi.org/10.1016/J.SURFCOAT.2013.11.035

W. Xu, E.W. Lui, A. Pateras, M. Qian, M. Brandt, In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 125, 390–400 (2017). https://doi.org/10.1016/j.actamat.2016.12.027

J.P. Hirth, F.H. Froes, Interrelations between fracture toughness and other mechanical properties in titanium alloys. Metall. Trans. A (1977). https://doi.org/10.1007/BF02667402

G. Thomas, V. Ramachandra, R. Ganeshan, R. Vasudevan, Effect of pre- and post-weld heat treatments on the mechanical properties of electron beam welded Ti-6Al-4V alloy. J. Mater. Sci. (1993). https://doi.org/10.1007/BF00361152

Y. Xu, Y. Lu, J. Liang, R.D. Sisson, Microstructure and corrosion behaviour of additively manufactured Ti-6Al-4V with various post-heat treatments. Mater. Sci. Technol. 35(1), 89–97 (2019). https://doi.org/10.1080/02670836.2018.1542052

R.D. Thomson, J.W. Hancock, Ductile failure by void nucleation, growth and coalescence. Int. J. Fract. 26(2), 99–112 (1984). https://doi.org/10.1007/BF01157547

V. Tvergaard, “Material Failure by Void Growth to Coalescence,” in Advances in Applied Mechanics, Elsevier, 1989, pp. 83–151. doi: https://doi.org/10.1016/S0065-2156(08)70195-9.

J.S. Jha, S.P. Toppo, R. Singh, A. Tewari, S.K. Mishra, Deformation behavior of Ti-6Al-4V microstructures under uniaxial loading: Equiaxed Vs. transformed-β microstructures. Mater. Charact. 171, 110780 (2021). https://doi.org/10.1016/J.MATCHAR.2020.110780

J.M. York, A metallographic study of the variation of fracture morphology of Ti-6Al-4V with solution-treating temperature. Metallography 12(1), 33–55 (1979). https://doi.org/10.1016/0026-0800(79)90017-X

D.D. Makel, D. Eylon, Effect of microstructure on localized melting at separation in Ti-6Al-4V tensile samples. Metall. Trans. A Phys. Metall. Mater. Sci. 21, 3127–3136 (1990). https://doi.org/10.1007/BF02647309/METRICS

T.S. Balasubramanian, M. Balakrishnan, V. Balasubramanian, M.A.M. Manickam, Influence of welding processes on microstructure, tensile and impact properties of Ti-6Al-4V alloy joints. Trans. Nonferrous Met. Soc. China 21(6), 1253–1262 (2011). https://doi.org/10.1016/S1003-6326(11)60850-9

Y.C. Lin et al., Effects of initial microstructures on hot tensile deformation behaviors and fracture characteristics of Ti-6Al-4V alloy. Mater. Sci. Eng. A (2018). https://doi.org/10.1016/j.msea.2017.11.044

M.H.I. Alluaibi, E.M. Cojocaru, A. Rusea, N. Șerban, G. Coman, V.D. Cojocaru, Microstructure and Mechanical Properties Evolution during Solution and Ageing Treatment for a Hot Deformed, above β-transus, Ti-6246 Alloy. Metals (Basel) 10(9), 1114 (2020). https://doi.org/10.3390/met10091114

S.A. Etesami, B. Fotovvati, E. Asadi, Heat treatment of Ti-6Al-4V alloy manufactured by laser-based powder-bed fusion: process, microstructures, and mechanical properties correlations. J. Alloys Compd. 895, 162618 (2022). https://doi.org/10.1016/j.jallcom.2021.162618

X. Zhang, S. Zhang, Q. Zhao, Y. Zhao, R. Li, W. Zeng, In-situ observations of the tensile deformation and fracture behavior of a fine-grained titanium alloy sheet. J. Alloys Compd. (2018). https://doi.org/10.1016/j.jallcom.2018.01.009

S.L. Dong, Y.C. Xin, G. Lu, D.Z. Yang, S.Y. He, E.H. Han, Tensile properties and deformation-fracture behavior of Ti-6Al-4V alloy at cryogenic temperature. Mater. Sci. Forum 561–565, 207–210 (2007). https://doi.org/10.4028/www.scientific.net/MSF.561-565.207

J. Bustillos, A. Moridi, Uncovering the deformation pathways of additive manufactured Ti-6Al-4V with engineered duplex microstructure. Materialia 25, 101545 (2022). https://doi.org/10.1016/j.mtla.2022.101545

Y. Xiao, L. Lan, S. Gao, B. He, Y. Rong, Mechanism of ultrahigh ductility obtained by globularization of αGB for additive manufacturing Ti-6Al-4V. Mater. Sci. Eng. A 858, 144174 (2022). https://doi.org/10.1016/j.msea.2022.144174

J. Koike et al., Stress-induced phase transformation during superplastic deformation in two-phase Ti–Al–Fe alloy. Acta Mater. 48(9), 2059–2069 (2000). https://doi.org/10.1016/S1359-6454(00)00049-5

L. Li, M. Li, Further mechanism of α/β interphase boundary evolution and dynamic globularization of Ti–5Al–2Sn–2Zr–4Mo–4Cr at elevated temperature deformation. Prog. Nat. Sci. Mater. Int. 32(4), 490–497 (2022). https://doi.org/10.1016/J.PNSC.2022.07.007

F.S. Lin, E.A. Starke, S.B. Chakrabortty, A. Gysler, The effect of microstructure on the deformation modes and mechanical properties of Ti-6Al-2Nb-1Ta-0.8Mo: Part I. Widmanstätten structures. Metall. Mater. Trans. A 15(6), 1229–1246 (1984). https://doi.org/10.1007/BF02644717

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, Y.V.R.K. Prasad, Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure. Mater. Sci. Eng. A 325(1–2), 112–125 (2002). https://doi.org/10.1016/S0921-5093(01)01448-4

Y. Chong, T. Bhattacharjee, J. Yi, S. Zhao, N. Tsuji, Achieving bi-lamellar microstructure with both high tensile strength and large ductility in Ti-6Al-4V alloy by novel thermomechanical processing. Materialia 8, 100479 (2019). https://doi.org/10.1016/j.mtla.2019.100479

T. Seshacharyulu, S. Medeiros, J. Morgan, J. Malas, W. Frazier, Y.V.R. Prasad, Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti-6Al-4V. Mater. Sci. Eng. A 279(1–2), 289–299 (2000). https://doi.org/10.1016/S0921-5093(99)00173-2

Y.V.R.K. Prasad, T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, J.C. Malas III., Hot deformation mechanisms in Ti-6Al-4V with transformed β starting microstructure: commercial v. extra low interstitial grade. Mater. Sci. Technol. 16(9), 1029–1036 (2000). https://doi.org/10.1179/026708300101508829

Y.M. Ren, X. Lin, X. Fu, H. Tan, J. Chen, W.D. Huang, Microstructure and deformation behavior of Ti-6Al-4V alloy by high-power laser solid forming. Acta Mater. 132, 82–95 (2017). https://doi.org/10.1016/j.actamat.2017.04.026

Acknowledgements

The authors gratefully acknowledge Visakha Institute of Engineering and Technology, Narava, Visakhapatnam, Andhra Pradesh, India, and the Department of Metallurgical Engineering, Andhra University, Visakhapatnam, Andhra Pradesh, India, for their continuous support in completing this work.

Funding

The authors did not receive support from any organization for the submitted work. No funding was received to assist with the preparation of this manuscript. No funding was received for conducting this study. No funds, grants, or other support was received.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vikas, K.S.R., Rahul, Ramana, V.S.N.V. et al. Effect of Heat Treatments on Tensile Fracture Behaviour of Ti-6Al-4V Alloy Friction Welds. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00549-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-023-00549-9