Abstract

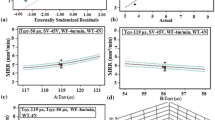

Cu–Al–Mn ternary shape memory alloys (SMAs) were synthesized and investigated for their surface roughness (Ra). Cu–Al–Mn SMAs were prepared through the ingot metallurgy method with aluminium (Al) content of 10–15 wt.% and manganese (Mn) content of 0-10wt.% and the rest is copper. After the heat treatment process, the alloy which exhibited an excellent shape memory effect was subjected to machinability studies in Wire EDM (Electrical Discharge Machining). In the context of Wire EDM, experiments were carried out using Taguchi's L9 orthogonal array (OA). Taguchi's method was used to obtain the optimum value of surface roughness. The effects of pulse duration, pulse interval, and peak current on surface roughness were studied using a technique that combined orthogonal array (OA) and analysis of variance (ANOVA). The obtained results revealed that peak current is the most significant factor affecting the Ra. From the Taguchi method, the best machining parameters combination settings are pulse duration (100 µs), pulse interval (32 µs), and peak current (1A) to meet the optimum value of surface roughness. The main purpose of the present investigation is to check for its machinability by identifying the machining performance, material behaviour and finally to optimise wire EDM machining parameters for Cu–Al–Mn SMAs using Taguchi’s optimization technique.

Similar content being viewed by others

References

S. Balasubramani, T. Vigraman, Effect of Cu and Ti addition in Fe–Mn–Si shape memory alloy. Int. J. Sci. Eng. Res. 5(5), 183–186 (2014)

I. Journal, O.F. Engineering, A.R. On, O. Detection, a review on obstacle detection and vision. Int. J. Eng. Sci. Res. Technol. 4(1), 1–11 (2015)

U.S. Mallik, V. Sampath, Influence of quaternary alloying additions on transformation temperatures and shape memory properties of Cu–Al–Mn shape memory alloy. J. Alloys Compd 469, 156–163 (2009)

U.S. Mallik, V. Sampath, Influence of aluminum and manganese concentration on the shape memory characteristics of Cu–Al–Mn shape memory alloys. J. Alloys Compd. 459(1–2), 142–147 (2008)

U.S. Mallik, V. Sampath, Effect of composition and ageing on damping characteristics of Cu–Al–Mn shape memory alloys. Mater. Sci. Eng. A 478, 48–55 (2008)

D. Gajjar, J. Desai, Optimization of MRR, surface roughness and KERF width in wire EDM using Molybdenum wire. Int. J. Res. Educ. 4(2), 9–17 (2015)

P.V.D. Patel, R.V. Vaghmare, A Review of recent work in wire electrical discharge machining. IJERA 3(3), 805–816 (2013)

F. Kausar, S. Kumar, M. Azam, S. Suman, A. Sharma, A. Sethi, Optimization of machining parameter for surface roughness on Wedm of En36 alloy steel. IOSR J. Mech. Civ. Eng. Ver. II 12(6), 2278–2684 (2015)

P. Bharathi, T. Gouri, L. Priyanka, G.S. Rao, B.N. Rao, Optimum WEDM process parameters of SS304 using taguchi method. Int. J. Ind. Manuf. Syst. Eng. 1(3), 69–72 (2016)

M.D. Prakash, R.S. Narayanan, Prediction of machining parameters on tool steel in wire EDM. Int. J. Innov. Res. Sci. Eng. Technol. 27, 10618–10624 (2016)

G. Archana, K. Dharma Reddy, P. Venkataramaiah, Study on machining response in wire EDM OF Inconel 625. Int. J. Appl. Eng. Res. 13(21), 15270–15277 (2018)

M.S. Hewidy, T.A. El-Taweel, M.F. El-Safty, Modelling the machining parameters of wire electrical discharge machining of Inconel 601 using RSM. J. Mater. Process. Technol. 169, 328–336 (2005)

B. Hwa Yan, H.C. Tsai, F. Yuan Huang, L. Chorng Lee, Examination of wire electrical discharge machining of Al2O3p/6061Al composites. Int. J. Mach. Tools Manuf. 45(3), 251–259 (2005)

P.N. Singh, K. Raghukandan, B.C. Pai, Optimization by Grey relational analysis of EDM parameters on machining Al-10%SiC P composites. J. Mater. Process. Technol. 155–156(1–3), 1658–1661 (2004)

M.H. El-Axir, M.M. Elkhabeery, M.M. Okasha, Modeling and parameter optimization for surface roughness and residual stress in dry turning process. Eng. Technol. Appl. Sci. Res. 7(5), 2047–2055 (2017)

S. Hammed, V.N. Najm, Surface Roughness Evaluation in WEDM Using Taguchi Parameter Design Method. Eng. Technol. J. 36(1), 10–1102 (2018). https://doi.org/10.30684/etj.36.1A.9

H.T.T. Alloy, Revealing the WEDM process parameters for the machining of. pp. 1–15 (2021)

A. Pramanik, A.K. Basak, Effect of wire electric discharge machining (EDM) parameters on fatigue life of Ti–6Al–4V alloy. Int. J. Fatigue 128, 105186 (2019)

M. Manjaiah, S. Narendranath, J. Akbari, Optimization of wire electro discharge machining parameters to achieve better MRR and surface finish. Procedia Mater. Sci. 5, 2635–2644 (2014)

M. Subrahmanyam, T. Nancharaiah, Optimization of process parameters in wire-cut EDM of Inconel 625 using Taguchi’s approach. Mater. Today Proc. 23, 642–646 (2020)

K. Hareesh, K.V. Nalina Pramod, N.K. Linu Husain, K.B. Binoy, R. Dipin Kumar, N.K. Sreejith, Influence of process parameters of wire EDM on surface finish of Ti6Al4V. Mater. Today Proc. 47, 5017–5023 (2021)

A. Goyal, A. Garimella, P. Saini, Optimization of surface roughness by design of experiment techniques during wire EDM machining. Mater. Today Proc. 47, 3195–3197 (2021)

N. Tata, R.K. Pacharu, S.K. Devarakonda, Multi response optimization of process parameters in wire-cut EDM on INCONEL 625. Mater. Today Proc. 47, 6960–6964 (2021)

S. Paliwal, P. Solanki, M. Soni, A.K. Chanda, Parameter optimization of wire electrical discharge machining for minimum surface roughness and Kerf width using Taguchi method. Int. J. Ind. Electron. Electr. Eng. 2(7), 36–39 (2014)

A. Goyal, A. Pandey, P. Sharma, Investigation of surface roughness for Inconel 625 using wire electric discharge machining. IOP Conf. Ser. Mater. Sci. Eng. 377, 1 (2018)

A.M. Takale, N.K. Chougule, R.L. Patil, A.S. Awate, Analysis and optimization of wire electro discharge machining parameters of TiNi shape memory alloy using Taguchi technique. SSRN Electron. J. (2018). https://doi.org/10.2139/ssrn.3101586

C.J. Manjunatha, C. Durga Prasad, H. Hanumanthappa, A. Rajesh Kannan, D.G. Mohan, B.K. Shanmugam, C. Venkategowda. Influence of microstructural characteristics on wear and corrosion behaviour of Si3N4 reinforced Al2219 composites. Adv. Mater. Sci. Eng. Hindawi, vol. 2023, Article ID 1120569, (2023) https://doi.org/10.1155/2023/1120569

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Characterization and wear behavior of NiCrMoSi microwave cladding. J. Mater. Eng. Perform. (2023). https://doi.org/10.1007/s11665-023-07998-z

H. Sharanabasva, C. Durga Prasad, M.R. Ramesh, Effect of Mo and SiC reinforced NiCr microwave cladding on microstructure, mechanical and wear properties. J. Inst. Eng. (India) Series D (2023). https://doi.org/10.1007/s40033-022-00445-8

K.H. Ho, S.T.Ã. Newman, S. Rahimifard, R.D. Allen, State of the art in wire electrical discharge machining (WEDM). Int. J. Mach. Tools Manuf. 44, 1247–1259 (2004)

F. Ghanem, C. Braham, H. Sidhom, Influence of steel type on electrical discharge machined surface integrity. J. Mater. Process. Technol. 142, 163–173 (2003)

H.S. Nithin, K.M. Nishchitha, D.G. Pradeep, C. Durga Prasad, M. Mathapati, Comparative analysis of CoCrAlY coatings at high temperature oxidation behavior using different reinforcement composition profiles. Weld. World 67, 585–592 (2023). https://doi.org/10.1007/s40194-022-01405-2

D.C. Naveen, N. Kakur, B.S. Keerthi Gowda, G. Madhu Sudana Reddy, C. Durga Prasad, R. Shanmugam, Effects of polypropylene waste addition as coarse aggregate in concrete: experimental characterization and statistical analysis. Adv. Mater. Sci. Eng. Hindawi, vol. 2022, Article ID 7886722, 11 pages (2022) https://doi.org/10.1155/2022/7886722.

V. Gowda, H. Hanumanthappa, B. Kumar Shanmugam, C. Durga Prasad, T.N. Sreenivasa, M.S. Rajendra Kumar, High-temperature tribological studies on hot forged Al6061-Tib2 in-situ composites. J. Bio Tribo-Corros. 8, 101 (2022). https://doi.org/10.1007/s40735-022-00699-5

G. Madhusudana Reddy, C. Durga Prasad, P. Patil, N. Kakur, M.R. Ramesh, Elevated temperature erosion performance of plasma sprayed NiCrAlY/TiO2 coating on MDN 420 steel substrate. Surf. Topogr.: Metrol. Prop. 10, 025010 (2022). https://doi.org/10.1088/2051-672X/ac6a6e

K.K. Jangra, An experimental study for multi-pass cutting operation in wire electrical discharge machining of WC-5.3% Co composite. Int. J. Adv. Manuf. Technol. 76(5), 971–982 (2015)

R. Magabe, N. Sharma, K. Gupta, J.P. Davim. Modeling and optimization of Wire-EDM parameters for machining of Ni 55.8 Ti shape memory alloy using hybrid approach of Taguchi and NSGA-II. pp. 1703–1717 (2019)

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T. Nageswara Rao, P. Patil, Investigation of thermally sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermet composite coatings on titanium alloys. Eng. Res. Express 4, 025049 (2022). https://doi.org/10.1088/2631-8695/ac7946

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T. Nageswara Rao, P. Patil, High temperature oxidation behavior of plasma sprayed NiCrAlY/TiO2 & NiCrAlY /Cr2O3/YSZ coatings on titanium alloy. Weld World 66, 1069–1079 (2022). https://doi.org/10.1007/s40194-022-01268-7

T. Naik, M. Mathapathi, C. Durga Prasad, H.S. Nithin, M.R. Ramesh, Effect of laser post treatment on microstructural and sliding wear behavior of HVOF sprayed NiCrC and NiCrSi coatings. Surf. Rev. Lett. 29(1), 225000 (2022). https://doi.org/10.1142/S0218625X2250007X

G. Madhusudana Reddy, C. Durga Prasad, G. Shetty, M.R. Ramesh, T. Nageswara Rao, P. Patil, High temperature oxidation studies of plasma sprayed NiCrAlY/TiO2 & NiCrAlY /Cr2O3/YSZ cermet composite coatings on MDN-420 special steel alloy. Metallogr. Microstruct. Anal. 10, 642–651 (2021). https://doi.org/10.1007/s13632-021-00784-0

M. Mathapati, C. Kiran Amate, C. Durga Prasad, M.L. Jayavardhana, T. Hemanth Raju, A review on fly ash utilization. Mater. Today Proc. 50(Part 5), 1535–1540 (2022)

R. Dinesh, S. Rohan Raykar, T.L. Rakesh, M.G. Prajwal, M. Shashank Lingappa, C. Durga Prasad, Feasibility study on MoCoCrSi/WC-Co cladding developed on austenitic stainless steel using microwave hybrid heating. J. Mines Metals Fuels 69(12A), 260 (2021). https://doi.org/10.18311/jmmf/2021/30113

N. Sharma, K. Gupta, J. Paulo, ScienceDirect on wire spark erosion machining induced surface integrity of Ni 55.8 Ti shape memory alloys. Arch. Civ. Mech. Eng. 19(3), 680–693 (2019)

H. Bisaria, P. Shandilya, The machining characteristics and surface integrity of Ni-rich NiTi shape memory alloy using wire electric discharge machining. J. Mech. Eng. Sci. 233(3), 1068–1078 (2019). https://doi.org/10.1177/0954406218763447

M. Azam, M. Jahanzaib, J.A. Abbasi, M. Abbas, A. Wasim, S. Hussain, Parametric analysis of recast layer formation in wire-cut EDM of HSLA steel. Int. J. Adv. Manuf. Technol. 87, 713–722 (2016)

M. Sudana Reddy, C. Durga Prasad, P. Patil, M.R. Ramesh, N. Rao, Hot corrosion behavior of plasma sprayed NiCrAlY/TiO2 and NiCrAlY/Cr2O3/YSZ cermets coatings on alloy steel. Surf. Interfaces 22, 100810 (2021). https://doi.org/10.1016/j.surfin.2020.100810

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, S. Srinath, Microstructure and tribological resistance of flame sprayed CoMoCrSi/WC-CrC-Ni and CoMoCrSi/WC-12Co composite coatings Remelted by microwave hybrid heating. J. Bio Tribo-Corros. 6, 124 (2020). https://doi.org/10.1007/s40735-020-00421-3

T.R. Newton, S.N. Melkote, T.R. Watkins, R.M. Trejo, L. Reister, Investigation of the effect of process parameters on the formation and characteristics of recast layer in wire-EDM of Inconel 718. Mater. Sci. Eng. A 513–514(C), 208–215 (2009)

V. Lalwani, P. Sharma, C.I. Pruncu, D.R. Unune. Response surface methodology and artificial neural network-based models for predicting performance of wire electrical discharge machining of inconel 718 alloy. J. Manufact. Mater. Process. 4(2), 44 (2020). https://doi.org/10.3390/jmmp4020044

C. Durga Prasad, A. Jerri, M.R. Ramesh, Characterization and sliding wear behavior of iron based metallic coating deposited by HVOF process on low carbon steel substrate. J. Bio and Tribo-Corros. (2020). https://doi.org/10.1007/s40735-020-00366-7

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Comparison of high temperature wear behavior of microwave assisted HVOF sprayed CoMoCrSi-WC-CrC-Ni/WC-12Co composite coatings. SILICON 12, 3027–3045 (2020). https://doi.org/10.1007/s12633-020-00398-1

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Effect of microwave heating on microstructure and elevated temperature adhesive wear behavior of HVOF deposited CoMoCrSi-Cr3C2 composite coating. Surf. Coat. Technol. 374, 291–304 (2019)

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Development and sliding wear behavior of Co–Mo–Cr–Si cladding through microwave heating. SILICON 11, 2975–2986 (2019). https://doi.org/10.1016/j.surfcoat.2019.05.056

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Microstructure and tribological behavior of flame sprayed and microwave fused CoMoCrSi/CoMoCrSi-Cr3C2 coatings. Mater. Res. Express 6, 026512 (2019). https://doi.org/10.1088/2053-1591/aaebd9

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, B.H. Channabasappa, Influence of microwave hybrid heating on the sliding wear behaviour of HVOF Sprayed CoMoCrSi Coating. Mater. Res. Express 5, 086519 (2018). https://doi.org/10.1088/2053-1591/aad44e

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, A. Sarkar, High temperature gradient cobalt based clad developed using microwave hybrid heating. Am. Inst. Phys. 1943, 020111 (2018). https://doi.org/10.1063/1.5029687

K.G. Girisha, C. Durga Prasad, K.C. Anil, K.V. Sreenivas Rao, Dry sliding wear behaviour of Al2O3 coatings for AISI 410 grade stainless steel. Appl. Mech. Mater. 766–767, 585–589 (2015). https://doi.org/10.4028/www.scientific.net/AMM.766-767.585

K.G. Girisha, R. Rakesh, C. Durga Prasad, K.V. Sreenivas Rao, Development of corrosion resistance coating for AISI 410 grade steel. Appl. Mech. Mater. 813–814, 135–139 (2015). https://doi.org/10.4028/www.scientific.net/AMM.813-814.135

R.R. Kolhapure, Study of Machining Characteristics of Non-Conventional Methods, vol. 2 (Atlantis Press International, Amsterdam, 2023)

Acknowledgements

The authors would like to take this opportunity to extend their appreciation to the Siddaganga Institute of Technology for the research assistantship support that was provided in order to carry out this research work.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Praveen, N., Mallik, U.S., Shivasiddaramaih, A.G. et al. Synthesis and Wire EDM Characteristics of Cu–Al–Mn Ternary Shape Memory Alloys Using Taguchi Method. J. Inst. Eng. India Ser. D (2023). https://doi.org/10.1007/s40033-023-00501-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40033-023-00501-x