Abstract

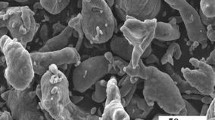

Al4032/Bimodal-B4C composites were synthesized via different milling methods, namely low speed ball milling (SLBM), high speed ball milling (SHBM) and two speed ball milling (TSBM). The Al4032 powder particles were shifted to flakes and some agglomerated B4C were slowly dispersed in flakes during SLBM. SHBM generated severe cold welding of Al4032 flakes and stronger collision, resulting in agglomerated zones within the Al matrix grain. While, TSBM processed samples showed the well coordination of bimodal B4C dispersion in matrix material and better interfacial bonding between Al4032/B4C. The composite powders synthesized at varying concentration of B4C (2.5, 5 and 7.5 wt.%) were hot pressed at 620 °C for 60 min in a vacuum furnace.The results demonstrated that the Al4032 composite with the dispersion of 5 wt.% of bimodal B4C through long term SLBM followed by short term SHBM achieved better hardness and tensile strength values of 87.32 HV and 219.36 MPa.

Similar content being viewed by others

References

Z.Y. Xu et al., Improving the mechanical properties of carbon nanotubes reinforced aluminum matrix composites by heterogeneous structural design. Compos. Commun. (2022). https://doi.org/10.1016/j.coco.2021.101050

D. Katundi, P. Ferreira, E. Bayraktar, M.-H. Robert, Design and microstructural evolution, mechanical and physical properties of fine particles reinforced aluminium matrix composites. Adv. Mater. Process. Technol. 2, 566–577 (2016). https://doi.org/10.1080/2374068X.2016.1247244

D.K. Das et al., Fabrication and heat treatment of ceramic-reinforced aluminium matrix composites-a review. Int. J. Mech. Mater. Eng. (2014). https://doi.org/10.1186/s40712-014-0006-7

L.-M.-P. Ferreira, E. Bayraktar, I. Miskioglu, H. Robert, New magnetic aluminum matrix composites (Al-Zn-Si) reinforced with nano magnetic Fe3O4 for aeronautical applications. Adv. Mater. Process. Technol. 4(3), 358–369 (2018). https://doi.org/10.1080/2374068X.2018.1432940

V. Oddone, B. Boerner, S. Reich, Composites of aluminum alloy and magnesium alloy with graphite showing low thermal expansion and high specific thermal conductivity. Sci. Technol. Adv. Mater. 18(1), 180–186 (2017). https://doi.org/10.1080/14686996.2017.1286222

A. Canakci, F. Arslan, T. Varol, Effect of volume fraction and size of B4C particles on production and microstructure properties of B4C reinforced aluminium alloy composites. Mater. Sci. Technol. 29(8), 954–960 (2013). https://doi.org/10.1179/1743284713Y.0000000232

D. Zhou, F. Qiu, H. Wang, Q. Jiang, Manufacture of nano-sized particle-reinforced metal matrix composites: a review. Acta Metall. Sin. (Engl. Lett.) 27, 798–805 (2014). https://doi.org/10.1007/s40195-014-0154-z

B. Sadeghi et al., Microstructural and mechanical behavior of bimodal reinforced Al-based composites produced by spark plasma sintering and FSP. Int. J. Adv. Manuf. Technol. 94, 3903–3916 (2018). https://doi.org/10.1007/s00170-017-1144-x

Q. Li, L. Guo, Y. Ma, Fabrication and characterization of bimodal size Al2O3p reinforced 7075 aluminium matrix composites. Mater. Sci. (Medžiag) (2017). https://doi.org/10.5755/j01.ms.23.4.16956

K. Moheimani, A. Keshtgar, S. Khademzadeh, M. Tayebi, A. Rajaee, A. Saboori, Tribological behaviour of AZ31 magnesium alloy reinforced by bimodal size B4C after precipitation hardening. J. Magnes. Alloys 10, 3267–3280 (2022). https://doi.org/10.1016/j.jma.2021.05.016

M.J. Shen, M.F. Zhang, W.F. Ying, Processing, microstructure and mechanical properties of bimodal size SiCp reinforced AZ31B magnesium matrix composites. J. Magnes. Alloys 3, 162–167 (2015). https://doi.org/10.1016/j.jma.2015.05.002

S. Suresh, G.H. Gowd, M.L.S. Deva Kumar, Mechanical properties of AA 7075/Al2O3/SiC nano-metal matrix composites by stir-casting method. J. Inst. Eng. India Ser. D 100, 43–53 (2019). https://doi.org/10.1007/s40033-019-00178-1

V. Abbasi Chianeh, H.R. Madaah Hosseini, M. Nofar, Micro structural features and mechanical properties of Al–Al3Ti composite fabricated by in-situ powder metallurgy route. J. Alloys Compd. 473, 127–132 (2009). https://doi.org/10.1016/j.jallcom.2008.05.068

J. Huang, Y. Zhang, D. Wang, P. Bo Ren, G.Z. Song, B. Cai, Z. Liu, Effect of ball milling process on the mechanical and thermal properties of the nanodiamond/2024Al composites. Micron (2021). https://doi.org/10.1016/j.micron.2021.103104

S.K. Pabi, B.S. Murty, Mechanism of mechanical alloying in NiAl and CuZn systems. Mater. Sci. Eng., A 214, 146–152 (1996). https://doi.org/10.1016/0921-5093(96)10224-0

H. Ahamed, V. Senthilkumar, Role of nano-size reinforcement and milling on the synthesis of nano-crystalline aluminium alloy composites by mechanical alloying. J. Alloy. Compd. 505, 772–782 (2010). https://doi.org/10.1016/j.jallcom.2010.06.139

J.B. Fogagnolo, F. Velasco, M.H. Robert, J.M. Torralba, Effect of mechanical alloying on the morphology, microstructure and properties of aluminium matrix composite powders. Mater. Sci. Eng. A 342, 131–143 (2003). https://doi.org/10.1016/S0921-5093(02)00246-0

Z. Asghar, M.A. Latif, Z.N. Rafi-ud-Din, F. Ali, S. Abdul Basit, T.S. Badshah, Effect of distribution of B4C on the mechanical behaviour of Al-6061/B4C composite. Powder Metall. 61, 293–300 (2018). https://doi.org/10.1080/00325899.2018.1501890

M. Gürbüz, SM Can E Koç, The effect of sintering time, temperature, and graphene addition on the hardness and microstructure of aluminum composites. J. Compos. Mater. 52(4), 553–563 (2018)

E. Salur, A. Aslan, M. Kuntoğlu, M. Acarer, Effect of ball milling time on the structural characteristics and mechanical properties of nano-sized Y2O3 particle reinforced aluminum matrix composites produced by powder metallurgy route. Adv. Powder Technol. 32, 3826–3844 (2021). https://doi.org/10.1016/j.apt.2021.08.031

M. Chen, G. Fan, Z. Tan, D. Xiong, Q. Guo, Y. Su, J. Zhang, Z. Li, MDi. NaitoZhang, Design of an efficient flake powder metallurgy route to fabricate CNT/6061Al composites. Mater. Des. 142, 288–296 (2018). https://doi.org/10.1016/j.matdes.2018.01.044

P.K. Kumar et al., Influence of sintering conditions on microstructure and mechanical properties of alloy 218 steels by powder metallurgy route. Arab J. Sci. Eng. 43, 4659–4674 (2018). https://doi.org/10.1007/s13369-017-3015-z

Z. Zheng et al., High-content graphene nanoplatelet reinforced aluminum composites produced by ball milling and hot extrusion. Sci. China Technol. Sci. 63, 1426–1435 (2020). https://doi.org/10.1007/s11431-020-1670-4

M. Gowrishankar, P. Hiremath, M. Shettar, S. Sharma, S. Rao, Experimental validity on the casting characteristics of stir cast aluminium composites. J. Market. Res. 9, 3340–3347 (2020). https://doi.org/10.1016/j.jmrt.2020.01.028

J. Vairamuthu, A. Senthil Kumar, B. Stalin, M. Ravichandran, Optimization of powder metallurgy parameters of TiC and B4C-reinforced aluminium composites by Taguchi method. Trans. Can. Soc. Mech. Eng. 45(2), 249–261 (2020). https://doi.org/10.1139/tcsme-2020-0091

P.K. Kumar et al., Effect of Y2O3 addition and cooling rate on mechanical properties of Fe-24Cr-20Ni-2Mn steels by powder metallurgy route. Compos. Commun. 10, 116–121 (2018)

Z. Asghar, M.A. Latif, Z. Rafi-ud-DinNazar, F. Ali, A. Basit, T. Subhani, Effect of distribution of B4C on the mechanical behaviour of Al-6061/B4C composite. Powder Metall. 61(4), 293–300 (2018)

G.A. Kumar, J. Satheesh et al., Optimization of wear properties of b4c nanoparticle-reinforced Al7075 nanocomposites using Taguchi approach. J. Inst. Eng. India Ser. D (2022). https://doi.org/10.1007/s40033-022-00385-3

R.A. Penchal Reddy, G.P. Shakoor, F. Vyasaraj Manakari, A.M.A.M. Ubaid, M. Gupta, Enhanced performance of nano-sized SiC reinforced Al metal matrix nanocomposites synthesized through microwave sintering and hot extrusion techniques. Prog. Nat. Sci. Mater. Int. 27, 606–614 (2017). https://doi.org/10.1016/j.pnsc.2017.08.015

K. Halil, O. İsmail, D. Sibel, Ç. Ramazan, Wear and mechanical properties of Al6061/SiC/B4C hybrid composites produced with powder metallurgy. J. Market. Res. 8, 5348–5361 (2019). https://doi.org/10.1016/j.jmrt.2019.09.002

Z. Ling et al., B4C-Al composites fabricated by the powder metallurgy process. Appl. Sci. 7, 1009 (2017). https://doi.org/10.3390/app7101009

H. Kaser et al., Development of an aluminum/amorphous nano-SiO2 composite using powder metallurgy and hot extrusion processes. Ceram. Int. 43, 14582–14592 (2017). https://doi.org/10.1016/j.ceramint.2017.06.057

Y. Jiang et al., Tailoring the structure and mechanical properties of graphene nanosheet/aluminum composites by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. Manuf. 111, 73–82 (2018). https://doi.org/10.1016/j.compositesa.2018.05.022

E. Amal, Nassar, properties of aluminum matrix nano composites prepared by powder metallurgy processing. J. King Saud Univ. Eng. Sci. 29, 295–299 (2017). https://doi.org/10.1016/j.jksues.2015.11.001

C.H.S. Vidyasagar, D.B. Karunakar, Effects of Nano yttrium and spark plasma sintering on the mechanical properties of AA2024 matrix composites. Met. Mater. Int. 27, 4626–4637 (2021). https://doi.org/10.1007/s12540-020-00727-4

Funding

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Author information

Authors and Affiliations

Contributions

Authors Contribution

G. Arumugam: Conceptualization, Methodology, Investigation, Writing - original draft. S. Saravanan: Revising the manuscript critically for important intellectual content, Supervision. S. Mohamed Iqbal: Review & Manuscript editing. P. Kishorekumar: Writing -review & editing, Interpretation of data.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arumugam, G., Saravanan, S., Iqbal, S.M. et al. Effect of Two-Step Ball Milling on Microstructure and Mechanical Properties of Al4032/Bimodal-B4C Composites. J. Inst. Eng. India Ser. D 105, 285–295 (2024). https://doi.org/10.1007/s40033-023-00479-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40033-023-00479-6