Abstract

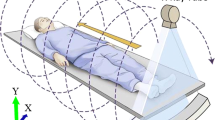

Additive Manufacturing (AM) is the swift manufacturing process, in which input data can be provided from various sources like 3-Dimensional (3D) Computer Aided Design (CAD), Computed Tomography (CT), Magnetic Resonance Imaging (MRI) and 3D scanner data. From the CT/MRI data can be manufacture Biomedical Additive Manufacturing (Bio-AM) models. The Bio-AM model gives a better lead on preplanning of oral and maxillofacial surgery. However manufacturing of the accurate Bio-AM model is one of the unsolved problems. The current paper demonstrates error between the Standard Triangle Language (STL) model to Bio-AM model of dry mandible and found correction factor in Bio-AM model with Fused Deposition Modelling (FDM) technique. In the present work dry mandible CT images are acquired by CT scanner and supplied into a 3D CAD model in the form of STL model. Further the data is sent to FDM machine for fabrication of Bio-AM model. The difference between Bio-AM to STL model dimensions is considered as dimensional error and the ratio of STL to Bio-AM model dimensions considered as a correction factor. This correction factor helps to fabricate the AM model with accurate dimensions of the patient anatomy. These true dimensional Bio-AM models increasing the safety and accuracy in pre-planning of oral and maxillofacial surgery. The correction factor for Dimension SST 768 FDM AM machine is 1.003 and dimensional error is limited to 0.3 %.

Similar content being viewed by others

References

ASTM F2792-12a, Standard Terminology for Additive Manufacturing Technologies, ASTM International, (West Conshohocken, PA, 2012)

T.T. Wohler, Additive Manufacturing and 3D Printing State of the Industry, Annual Worldwide Progress Report, (Wohlers Associates, Colorado, USA, 2013)

T.P. Farias, F.L. Dias, B.A. Sousa, M.S. Galvao, D. Bispo, A.C. Past, Prototyping: major advance in surgical planning and customizing prostheses in patients with bone tumors of the Head and neck. Int. J. Clin. Med. 4, 1–7 (2013)

M.C. Goiato, M.R. Santos, A.A. Pesqueira, A. Moreno, D.M. Santos, M.F. Haddad, Prototyping for surgical and prosthetic treatment. J. Craniofac. Surg. 22, 914–917 (2011)

R.S. Gil, A.M. Roig, C.A. Obispo, A. Morla, C.M. Pages, J.L. Perez, Surgical planning and microvascular reconstruction of the mandible with a fibular flap using computer-aided design, rapid prototype modelling, and precontoured titanium reconstruction plates: a prospective study. Br. J. Oral Maxillofac. Surg. 53, 49–53 (2015)

O.S. Carneiro, A.F. Silva, R. Gomes, Fused deposition modeling with polypropylene. Mater. Des. 83, 768–776 (2015)

F.P.W. Melchels, J. Feijen, D.W. Grijpma, A, Review on stereolithography and its applications in biomedical engineering. Biomaterials 31, 6121–6130 (2010)

A.T. Sidambe, Biocompatibility of advanced manufactured titanium implants—A review. Materials 7, 8168–8188 (2014)

www.sciaky.com/additive-manufacturing/electron-beam-additive-manufacturing-technology

M. Sugavaneswaran, G. Arumaikkannu, Modelling for randomly oriented multi material additive manufacturing component and its fabrication. Mater. Des. 54, 779–785 (2014)

K. Myers, M. Juhasz, P. Cortes, Mechanical modeling based on numerical homogenization of an Al2O3/Al composite manufactured via binder jet printing. Comput. Mater. Sci. 108, 128–135 (2015)

D. Ahn, J. Kweon, J. Choi, S. Lee, Quantification of surface roughness of parts processed by laminated object manufacturing. J. Mater. Process Technol. 212, 339–346 (2012)

D. Ibrahim, T.L. Broilo, C. Heitz, M.G. Deoliveira, H.W. Oliveira, S.M.W. Nobre, J.H.G.D.S.A. Filho, D.N. Silva, Dimensional error of selective laser sintering, three-dimensional printing and PolyJet models in the reproduction of mandibular anatomy. J. Cranio-Maxillofac. Surg. 37, 167–173 (2009)

M. Salmi, K.T. Paloheimo, J. Tuomi, J. Wolff, A. Makitie, Accuracy of medical models made by additive manufacturing (rapid manufacturing). J. Craniomaxillofac. Surg. 41, 603–609 (2013)

D.N. Silva, M.G.D. Oliveira, E.M.M. Meurer, J.V.L.D. Silva, A.S. Rbara, Dimensional error in selective laser sintering and 3D-printing of models for craniomaxillary anatomy reconstruction. J. Cranio-Maxillofac. Surg. 36, 443–449 (2008)

K. Murugesan, P.A. Anandapandian, S.K. Sharma, M.V. Kumar, Comparative evaluation of dimension and surface detail accuracy of models produced by three different rapid prototype techniques. J. Indian Prosthodont. Soc. 12, 16–20 (2012)

D.T. Pham, R.S. Gault, A comparison of rapid prototyping technologies. Int. J. Mach. Tools Manuf 38, 1257–1287 (1998)

A.K. Sood, R.K. Ohdar, S.S. Mahapatra, Improving dimensional accuracy of fused deposition modelling processed part using grey Taguchi method. Mater. Des. 30, 4243–4252 (2009)

Acknowledgments

This paper is a revised and expanded version of an article entitled, ‘‘Finding of Correction Factor and Dimensional Error in Bio-AM Model by FDM Technique’’ presented in “International Conference on Additive Manufacturing and 3D Printing (ICAM3D 2015)” held at Chennai, India, during February 6–7, 2015. The authors also would like to thank Department of Oral and Maxillofacial Surgery, Panineeya Institute of Dental Science and Research Center, Hyderabad, India for providing CT images and perform a mock surgery on Bio-AM model in their hospital.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manmadhachary, A., Ravi Kumar, Y. & Krishnanand, L. Finding of Correction Factor and Dimensional Error in Bio-AM Model by FDM Technique. J. Inst. Eng. India Ser. C 99, 293–300 (2018). https://doi.org/10.1007/s40032-016-0294-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-016-0294-1