Abstract

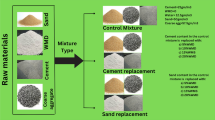

An experimental program was performed to check the efficacy of stone slurry powder on durability performance of hybrid engineered cementitious composite (ECC). For developing the hybrid ECC, three different types of fibers: PVA, PET and MSE fiber were dispersed in cementitious composite. SSL was employed as alternate substitution of fine aggregates to conserve the natural resources and reduce the demand of expensive MSS. In this work, to design the cost-effective and sustainable HECC, total 12 mixes were prepared into two groups utilizing SSL and hybrid fibers. The viability of designed mixtures has been reported via flexural response, air permeability, electrical resistivity (ER), sorptivity, sustainability aspects and economic index. The performance index of designed mixes was evaluated to facilitate the selection process of constituents and to produce most suitable mix proportion as per the required parameters criteria. Recorded parameters revealed that the incorporation of SSL as fine aggregates improved the flexural response and transport properties and also reduced the cost up to 43.2%. Sustainability aspects and cost evaluation of matrices revealed that the developed mixes are beneficial for eco-friendly environment and widespread applications of ECC.

Similar content being viewed by others

Abbreviations

- PVA:

-

Polyvinyl alcohol fiber

- PET:

-

Polyester fiber

- MSE:

-

Micro-steel fiber

- MSS:

-

Micro-silica sand

- FRS:

-

Fine river sand

- BFS:

-

Blast furnace slag

- SSL:

-

Stone slurry powder

- SPW:

-

Stone processing waste

- ER:

-

Electrical resistivity

- FS:

-

Flexural strength

- MD:

-

Mid-span deflection

- API:

-

Air permeability index

- ST:

-

Sorptivity index

- EE:

-

Embodied energy

- GWP:

-

Global warming potential

- PI:

-

Performance index

References

A.M. Neville, Properties of concrete (Pearson, San Francisco, CA, 2012)

Mehta PK, Monteiro PJM. Concrete: microstructure, properties, and materials, 3rd edn. (McGraw Hill, 2006)

B. Van Belleghem, R. Montoya, J. Dewanckele, N. Van den Steen, I. De Graeve, J. Deconinck, V. Cnudde, K. Van Tittelboom, N. De Belie, Capillary water absorption in cracked and uncracked mortar – A comparison between experimental study and finite element analysis. Const. Buil. Mater. 110, 154–162 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.027

Ali Akbar Ramezanianpour, Practical evaluation of relationship between concrete resistivity, water penetration, rapid chloride penetration and compressive strength. Constr. Build. Mater, 25 (2011) 2472–2479

H.S. Wong, R.W. Zimmerman, N.R. Buenfeld, Estimating the permeability of cement pastes and mortars using image analysis and effective medium theory. Cem. Concr. Res. 42, 476–483 (2012)

S. Varadharajan, Determination of mechanical properties and environmental impact due to inclusion of flyash and marble waste powder in concrete. Structures 25, 613–630 (2020). https://doi.org/10.1016/j.istruc.2020.03.040

V. Kumar, A. Kumar, B. Prasad, Mechanical behavior of non-silicate-based alkali-activated ground granulated blast furnace slag. Constr.Build. Mater. 198, 494–500 (2019)

K. Kapoor, S.P. Singh, B. Singh, Durability of self-compacting concrete made with recycled concrete aggregates and mineral admixtures. Constr. Build. Mater. 128, 67–76 (2016)

A. Bentur, S. Mindess, Fiber reinforced cementitious composite (CRC Press, Boca Raton, USA, 2006)

M. Singh, B. Saini, H.D. Chalak, Performance and composition analysis of engineered cementitious composite (ECC) – A review. J. Build. Eng. 26, 100851 (2019a). https://doi.org/10.1016/j.jobe.2019.100851

T. Kanda, V.C. Li, Interface property and apparent strength of high-strength hydrophilic fiber in cement matrix. J. Mater. Civ Eng. 10, 5–13 (1998)

M Singh, B Saini, HD Chalak, Properties of engineered cementitious composites: A Review. ICSWMD 2018, LNCE 21. pp. 1–11, (2019) https://doi.org/10.1007/978-3-030-02707-0_54

M Singh, B Saini, HD Chalak, Appraisal of hybrid fiber reinforced engineered cementitious composite. In: Proceedings of the 4th international conference on civil, structural and transportation engineering (ICCSTE'19) Ottawa, Canada, (2019) DOI: https://doi.org/10.11159/iccste19.192

M. Singh, B. Saini, H.D. Chalak, Flexural response and durability aspects of ECC containing stone slurry powder. Asian J. Civ. Eng. 22, 369–379 (2020)

Li VC, Engineered cementitious composites - tailored composites through micromechanical modeling. Fiber reinforced concrete: present and the future. In: Canadian Society for Civil Engineering, N. Banthia, A. Bentur, A. A. Mufti (eds.), Montreal, pp. 64–97 (1998)

V.C. Li, T. Kanda, Engineered cementitious composites for structural applications. J. Mater.Civ. Eng 10, 66–69 (1998)

M. Singh, B. Saini, H.D. Chalak, Long term evaluation of engineered cementitious composite containing stone slurry powder. Constr. Build. Mater. 264, 120183 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120183

Li VC, Engineered cementitious composites (ECC) – Material, structural, and durability performance. In: Concrete construction engineering handbook, Nawy E (Eds.), CRC Press, (2008)

H.R. Pakravan, M. Jamshidi, M. Latifi, Study on fiber hybridization effect of engineered cementitious composite with low and high-modulus polymeric fibers. Constr. Build. Mater. 112, 739–746 (2016)

V.C. Li, E.N. Herbert, Self-healing of microcracks in engineered cementitious composites (ECC) under a natural environment. Materials 6(7), 2831–2845 (2013)

M. Sahmaran, H.E. Yücel, S. Demirhan, M.T. Arık, V.C. Li, Combined effect of aggregate and mineral admixtures on tensile ductility of engineered cementitious composites. ACI Mater. J. 109, 627–638 (2012)

M. Singh, A. Srivastava, D. Bhunia, An investigation on effect of partial replacement of cement by waste marble slurry. Constr. Build. Mater. 134, 471–488 (2017)

M Singh, B Saini, HD Chalak, An overview on utilization of stone waste in construction industry. In: 3rd International conference on innovative technologies for clean and sustainable development. (2021) https://doi.org/10.1007/978-3-030-51485-3_38

A. Rana, P. Kalla, L.J. Csetenyi, Sustainable use of marble slurry in concrete. J. Clean. Prod. 94, 304–311 (2015)

S. Singh, R. Nagar, V. Agrawal, A. Rana, A. Tiwari, Sustainable utilization of granite cutting waste in high strength concrete. J. Clean. Prod. 116, 223–235 (2016)

D.K. Ashish, Feasibility of waste marble powder in concrete as partial substitution of cement and sand amalgam for sustainable growth. J. Build. Eng. 15, 236–242 (2018)

J.D. Rathod, S.C. Patodi, Interface tailoring of polyester-type fiber in engineered cementitious composite matrix against pullout. ACI Mater. J. 107, 114–122 (2010)

R. Siddique, K. Kapoor, E.H. Kadri, R. Bennacer, Effect of polyester fibres on the compressive strength and abrasion resistance of HVFA concrete. Constr. Build. Mater. 29, 270–278 (2012)

IS-8112. Specification for 43 grade ordinary Portland cement, Bureau of Indian Standards. New Delhi, (2013)

BIS 456. Plain and Reinforced Concrete - Code of Practice (4th ed.). Bureau of Indian Standards. (2000). https://www.iitk.ac.in/ce/test/IS-codes/is.456.2000. Pdf

BIS 516-1959 Methods of tests for strength of concrete (18th Ed.). New Delhi: Bureau of Indian Standards, (2006)

BS-EN-12390–5 Testing hardened concrete, Flexural strength of test specimens. British Standard Institution, (2009)

J.P. Broomfield, Corrosion of steel in concrete, 2nd edn. (Taylor and Francis, New York, 2007)

ACI 222R-01, (2010) Protection of metals in concrete against corrosion.

American Association of State Highway and Transport Officials, AASHTO T358- 15, Standard test method for surface resistivity indication of concretes ability to resist chloride ion penetration, Washington, USA (2015)

Autoclam permeability system operating manual, department of civil engineering, Queen’s University, Belfast, U.K, (1994)

B.J. Mathew, M. Sudhakar, C. Natarajan, Strength, economic and sustainability characteristics of coal ash-GGBS based geopolymer concrete. Int. J. Comput. Eng. Res. 3, 207–212 (2013)

R. Sharma, R.A. Khan, Sustainable use of copper slag in self-compacting concrete containing supplementary cementitious materials. J. Clean. Prod. 151, 179–192 (2017)

W.C. Choi, H.D. Yun, J.W. Kang, S.W. Kim, Development of recycled strain-hardening cement-based composite (SHCC) for sustainable infrastructures. Compos. B Eng. 43, 627–635 (2012)

K.H. Yang, J.K. Song, K. Song, Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 39, 265–272 (2013)

J. Yu, J. Yao, X. Lin, H. Li, J.Y.K. Lam, C.K.Y. Leung, I.M.L. Sham, K. Shih, Tensile performance of sustainable strain-hardening cementitious composites with hybrid PVA and recycled PY fibers. Cem. Concr. Res. 107, 110–123 (2018)

D. Zhang, J. Yu, H. Wu, B. Jaworska, B.R. Ellis, V.C. Li, Discontinuous micro-fibers as intrinsic reinforcement for ductile engineered cementitious composites (ECC). Compos. B Eng. 184, 107741 (2020)

H.L. Wu, J. Yu, D. Zhang, J.X. Zheng, V.C. Li, Effect of morphological parameters of natural sand on mechanical properties of engineered cementitious composites. Cement Concr. Compos. 100, 108–119 (2019)

A.S. El-Dieb, D.M. Kanaan, Ceramic waste powder an alternative cement replacement – Characterization and evaluation. Sustain. Mater. Technol. 17, e00063 (2018)

Z. Pan, C. Wu, J. Liu, W. Wang, J. Liu, Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 78, 397–404 (2015)

A.R. Sakulich, V.C. Li, Nanoscale characterization of engineered cementitious composite (ECC). Cem. Concr. Res. 41, 169–175 (2011)

B. Suryanto, H. Takaoka, W.J. McCater, D. Saraireh, H. Taha, Impedance measurements on an engineered cementitious composite: A critical evaluation of testing protocols. Measurement 129, 445–456 (2018)

N. Banthia, S. Djeridane, M. Pigeon, Electrical resistivity of carbon and steel micro-fiber reinforced cements. Cem. Concr. Res. 22, 804–814 (1992)

Acknowledgements

The authors would like to acknowledge the financial assistance of University Grants Commission, New Delhi.

Funding

The authors feel obliged to the University Grants Commission, New Delhi vide letter no. F1 17.1/2017–18/MANF-2017–18-HAR-78129 for the financial assistance for research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, M., Saini, B. & Chalak, H.D. Durability and Ecological Performance of Hybrid Engineered Cementitious Composite Containing Stone Industry Waste. J. Inst. Eng. India Ser. A 103, 747–765 (2022). https://doi.org/10.1007/s40030-022-00658-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40030-022-00658-w