Abstract

Plant microbial fuel cells (PMFC) have attracted great scholarly attention as a renewable energy source. These cells have three main components: anode, cathode chambers, and a proton exchange membrane. In this study, a dual-chamber plant microbial fuel cell system was designed using Cyperus papyrus and Shewanella oneidensis. The effects of various factors, including the size of the electrodes, the distance between the electrodes, and the inoculation volume of Shewanella oneidensis, on the ability of electricity generation, were scrutinized. The results indicated that increasing the size area of the electrodes from 2 × 2 to 4 × 4 and 6 × 6 cm2 caused an increase in the output voltage by 43% and 58%, respectively. The PMFC produced a maximum power of 240 mW, with a Coulombic efficiency ranging from 0.66 to 0.75%. The plant microbial fuel cell designed in this study seemed to have a high potential to remove wastewater contaminants. Based on the results, during five days of setting up the system, COD and BOD decreased by 61.75% and 93.16%, respectively, which shows that in addition to generating power, the designed PMFC had a high potential to remove wastewater contaminants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fuel cells are a new technology for generating energy, which generates eco-friendly high-efficiency electrical energy from a direct combination of fuel and oxidant without causing pollution. During the last two decades, microbial fuel cell (MFC) technology has rapidly grown due to the direct conversion of chemical energy into electrical energy. This technology is important for treating wastewater due to the inexpensive and accessible resources for supplying raw materials for these reactors and producing valuable energy and fuel such as hydrogen gas (Fan et al. 2008).

The MFC consists of the anode and cathode electrodes separated by a proton exchange membrane. The fuel and the oxidant enter the anode and cathode chambers in these cells, respectively. Oxidation and reduction reactions will then occur at the anode and cathode chambers, correspondingly (Logan 2008). Bacteria in the anode decompose the substrate into positive and negative ions, and an ion-conducting electrolyte transfers ions from the anode to the cathode. Afterward, the electrons move through an external circuit to the cathode, where the combination of the positive and negative ions causes the production of water and carbon dioxide (Kirubakaran et al. 2009). Under aerobic conditions, microorganisms produce carbon dioxide and water by consuming the substrate, but protons and electrons are produced under anaerobic conditions. Since microbes must be kept far from oxygen to generate electricity, the anode chamber must be isolated against oxygen infiltration. By using acetate as the substrate, the reactions in the cathode and anode chambers are done as follows.

Anodic reaction: CH3COO– + 2H2O → 2CO2 + 7H+ + 8e −

Cathodic reaction: O2+ 4H+ + 4e− → 2H2O.

Among various types of MFCs, single-chamber, dual-chamber, tubular, and upflow are considered the most important MFCs. However, single-chamber MFCs are superior to other types due to their simple design, flexibility, and low internal resistance (Rabaey et al. 2003).

The main component of an MFC is the bacteria with electrical activity or biocatalysts. Different microorganisms such as Geobacter sulfurreducens, Shewanella oneidensis, Rhodoferax ferrireducens, and Aeromonas hydrophila, mostly gram-negative, have been used for generating electricity in the cells (Logan et al. 2019). The performance of an MFC is highly dependent on the substrate, electron transformation (from bacteria to the electrodes), ion diffusion, salinity, temperature, and pH (Mishra et al. 2017; Tremouli et al. 2017).

Bacteria transfer electrons from the cell surface to the electrode surface in two ways, described as follows. The first method is the direct electron transfer using active redox proteins such as cytochromes located on the outer surface of bacterial cell membranes and microbial nanowires. The second method is the mediated electron transfer using electron shuttles such as Flavin’s or shuttles added to the environment (Logan and Regan 2006; Kumar et al. 2016; Prathiba et al. 2022).

Many studies reveal that microorganisms and anode materials transmit electrons through direct electron transfer and mediated electron transfer modes of electron transfer processes (Prathiba et al. 2022). Electrons are transmitted directly from biological substances to electrode materials in direct electron transfer. This method, therefore, requires enough direct physical contact between the electrode material and the microbial membrane (Lovley 2006a). Research-based evidence has confirmed Geobacter sp., Shewanella sp., and Rhodoferax sp. as efficient microbial treatments in direct electron transfer mechanism ((Lovley 2006b; Lovley and Nevin 2013; Prathiba et al. 2022). Redox proteins, called C-type cytochromes, facilitate electron transport to the external section of the terminal electron acceptor (Busalmen et al. 2008). Mediated electron transfer, also called the indirect mode of electron transfer, employs a redox carrier as a transporter to move electrons from a source to a destination. Redox mediators of this type often collect electrons from the microbial cell delivered in the reduced state and transfer these electrons to anode materials oxidized in the microbial fuel cells. The electrons in these oxidized phases were, then, free to begin the subsequent process of electron transfers (Prathiba et al. 2022).

The nutrients in the culture medium, the cellular structure of the cell, bacterial genetics and the membrane's permeability, and the electrodes' potential are considered as some solutions used for increasing the efficiency of the MFC (Leong et al. 2013). MFCs are widely used for removing pollution from municipal and industrial wastewater. In addition to these systems' ability to oxidize and decompose organic matter in wastewater, they have a high potential to generate electricity. In the decomposition process of organic matter, plants can also be effective in addition to microorganisms, among which Arundinella anomala and Spartina anglica are considered the most important plants (Strik et al. 2008). Recently, the electricity generation by Pachira macrocarpa and Populus alba in the plant microbial fuel cell (PMFC) was reported (Lu et al. 2020). Moreover, Cyperus papyrus has been used in municipal wastewater treatment and has shown a high potential for contaminant removal (Perbangkhem and Polprasert 2010). Development of knowledge and technology on MFC is still progressing, but there has been a need to review the recent knowledge of the bio-electrochemical treatment's electron transfer processes, microbial community, variety of substrates, and design to understand the future directions and Parthiba et al. (2022) has recently filled this research gap.

The present study aimed to evaluate the effect of factors including distance and size of the electrode and inoculation volume on the amount of electricity generation in the plant MFCs fed from the municipal wastewater of Mashhad. The intended system was designed and commissioned based on the plants of the Poaceae family and Shewanella sp. bacteria, the role of which is known in wastewater treatment and electricity generation. Considering the effective function of bacteria and plants in removing pollution, it is obvious that using a combination of microbes and plants not only can solve a significant part of the problems caused by pollution of municipal and industrial wastewater but also can be efficient in generating electricity.

Materials and methods

In this study, Cyperus papyrus was obtained from Zeribar Lake, located in Kurdistan province, and transferred to the microbiology laboratory of the biology department of Ferdowsi University of Mashhad.

Cyperus

Cyperus papyrus plant belongs to the Cyperus family, which is abundant in Europe. This plant is morphologically classified in the narrow-leaved group (Poaceae). Cyperus papyrus photosynthetically belongs to C4 plants. Due to the rhizosphere's release of significant photosynthetic products, this plant can supply the hydrocarbons required to the electrogenic bacteria existing in the plant MFCs (Gulamhussein and Randall 2020).

Bacteria strains

Due to the high potential of Shewanella bacteria in generating electricity, the lyophilized sample of Shewanella oneidensis strain (Identification code IBRC-M10991 2018.02.04) was obtained from the Iranian National Center for Genetic Resources, cultured and regenerated in Tryptic Soy Broth (TSB), and ensured its purity. It was then cultured in the required amount in TSB medium and incubated at 30 °C and 200 rpm for 24 h to use in the fuel cell (Juliastuti et al. 2018). A 10-L bacterial suspension was made from the McFarland standard for investigating the effects of all experimental parameters.

Sampling

This study obtained samples from Khin Arab municipal wastewater treatment plant located in Mashhad, Khorasan-e Razavi province. The samples were then transferred to the laboratory and stored at room temperature (25 °C) to conduct the research.

Designing the plant microbial fuel cells

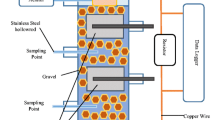

This study used dual-chamber PMFCs, the chambers of which were made of Plexiglass with a 2 mm thickness. In this cell, the anode and cathode chambers were separated by Plexiglas Spacers and completely sealed. PTFE membrane (FiltraTECH-France) with a diameter of 4 cm was used for the anion-cation exchange. Graphite plates fabricated the electrode with a thickness of 0.2 mm with 99% purity (made in Taiwan). Moreover, copper wires were used as the connector between the electrode and the electrical circuit to close the electrical circuit and measure the current and generated voltage (Abdel-Hady et al., 2010). In the next step, 500 ml of 1 mM sodium acetate solution buffer (pH = 7) was equally injected into different locations of the anode region using a syringe (Kaku et al. 2008) (Fig. 1).

A A schematic representation of the plant bacterial fuel cell packs; B a zoomed section of the cellular pack; C a section view of (B). 1: mesh basket plant holder; 2: the location where the PTFE proton exchange membrane is installed; 3: graphite-based half-cell cathode; 4: graphite-based half-cell anode

Effect of different factors on the amount of electricity generation and wastewater treatment

Various impacts of factors, including electrode surface area (2 × *2, 4 × *4, and 6 × *6 cm2), the distance of anode electrodes (2, 4, and 6 cm), and bacterial inoculation volume (2.5 L and 5 L), were examined on the voltage, electric current, and reduction of BOD and COD of PMFCs. Voltage and electric current were measured using DOC digital multimeter with the accuracy of 0.0001 A and 0.01 V, respectively (Khudzari et al. 2018). The effect of the parameters was analyzed by Design-Expert version 10, and all the experiments were conducted with three replicates.

Measurement of COD and BOD of wastewater samples

COD and BOD were measured using the COD and BOD meters (Intelligent-China). Shewanella oneidensis was inoculated into a reservoir containing the wastewater sample and worked for five days. After 5 days, BOD and COD were measured. All steps of the test were replicated three times.

Coulombic efficiency

The MFC's Coulombic efficiency (CE) is an indicator that can be used to evaluate the efficiency of fuel cells. This index is the ratio of the total electrons transferred from the anode to the cathode to the total number of electrons produced from sodium acetate's oxidation (Logan 2008).

In this equation, Qx is the total current, V is the liquid volume (5 L), F is Faraday’s constant (96,485 C/mol of e−), b is mol of e− produced per mol of O2 (4 mol/mol), and M is the mole mass of O2 (32 g/mol).

Loading the plant microbial fuel cell

In this system, 27 PMFCs (3 electrode distances × 3 electrode areas × 3 replicates) were used successively in the series in three separate transparent chambers. The place of Cypress plants in the cell was designed using four plastic nets per cell with a diameter of 4 cm (Fig. 2).

Implementing the system of the plant microbial fuel cell

After designing and fabricating the desired PMFCs, the sample of municipal wastewater and Shewanella oneidensis bacteria were loaded in the anodic chamber with a ratio of 7:3 (wastewater/bacteria suspension). Next, the plant samples were sterilized using bleach 5% for 3 min and ethanol 70% for 1 min and transferred to the anodic chamber (Fig. 3).

Results and discussion

The Effect of the electrode size on output voltage of the system

The evaluation of the effect of electrode size on the output voltage in this study showed that the output voltage increased by 43% and 58% by increasing the size of the electrodes (area) from 2 × 2 to 4 × 4 and 6 × 6 cm2, respectively. Our results are consistent with the findings of the previous researchers (e.g., Oliot et al. 2017; Wang et al. 2010) in that evaluation of the electricity generation in various bacteria, such as Shewanella sp. demonstrated these bacteria not only generated the highest amount of electricity, but they also had significant roles in reducing environmental risks (Logan et al. 2019). Increasing the electrode's size enhanced electricity generation, and these results are consistent with our study (Oliot et al. 2017). While Wang et al. (2010) and Oliot et al. (2017) have reported the positive impacts of electrode size on generating electricity, there have been other research afterward that have not confirmed such effects for anode size (e.g., Rossie et al. 2019) or further developed the knowledge on cathode and anode performance during the electrical generation (e.g., Ueoka et al. 2016). Ueoka et al. (2016) demonstrate that anodes are the limiting element for generating electricity when the operation starts. However, cathodes become the limiting factor once anode performances are sufficiently raised. Rossie et al. (2019) also revealed that the anode's performance was unaffected when the anode brushes' diameter was decreased from 5.1 to 2.5 cm.

Moreover, other research showed that increasing the size of the electrodes caused an increase in electricity generation (Wang et al. 2010). Studies have shown that increasing the surface area of the anode electrode (electrode size) results in increasing the absorption of electrons from the bacteria and increasing the generation of electricity, which may be related to the accumulation of more bacteria on the surface of the electrode. In other words, more surface is provided to the bacteria for electron transfer. In the present study, electricity generation decreased by increasing the distance since increasing the distance of the anode electrodes caused a decrease in electron transfer due to the formation of nanowires by Shewanella oneidensis bacteria. The generated nanowires have variable lengths and increasing the distance between the electrodes increases the number of these nanowires in the electron transfer path. Therefore, it caused a decrease in the rate of electron transfer and an increase in the time of electron transfer.

Effect of electrode distance on output voltage

The effects of 2, 4, and 6 cm distances between the electrodes were evaluated on the system's output voltage. The findings of this study showed that the electrode distance did not have a significant impact on the output voltage (P-value > 0.05), while previous studies such as Sajana et al. (2013) suggested that the increasing the distance between the electrodes decrease the amount of soluble COD and increasing in electricity generation.

Effect of volume on output voltage

The effect of 2.5 and 5 L inoculation volumes on the system's output voltage was evaluated. The results demonstrated that the inoculated volume failed to significantly affect the output voltage (P-value > 0.05). Figure 4 displays the effect of changing the factors tested in this study on the output voltage of a dual-chamber plant microbial fuel cell.

Effect of combining the parameters on the output voltage of dual-chamber plant microbial fuel cell, a effect of electrode distance and electrode surface on the output voltage, b effect of inoculation volume and electrode surface on the output voltage, and c effect of electrode distance and inoculation volume

Effect of the plant microbial fuel cell on COD and BOD

The experimental results indicate a positive correlation between the duration of electricity generation and the reduction in chemical oxygen demand (COD) and biochemical oxygen demand (BOD) levels in the wastewater sample (Table 1). In a similar study, the plants of the Poaceae family have been used for treating wastewater and affecting the process of removing pollutants. The results demonstrated that these plants stored organic matter in their organs and removed them from water or the plant culture medium (Bui et al. 2018). Recent reports have shown that Shewanella sp. plays a significant role in generating electricity and reducing the COD of wastewater by 62% (Hassan et al. 2018). Logan et al. (2019) also showed that evaluation of the electricity generation in various bacteria, such as Shewanella sp., demonstrated these bacteria not only generated the highest amount of electricity but they also had important roles in reducing environmental risks. In the present study, using the dual chamber, PMFC decreased the COD and BOD of urban wastewater by 61.75% and 93.16%, respectively. Further, Escherichia coli and Shewanella oneidensis bacteria in MFC during 12 days have shown great potential for reducing the BOD of wastewater from sugar factory about 84.53% and 73.77%, respectively (Juliastuti et al. 2018). The Coulombic efficiency of these PMFCs in our study was measured to be 0.66–0.75%.

Various methods are used to remove contaminants, the most harmless of which is the biological method which uses microorganisms and plants. As mentioned, different factors, such as the composition of the culture medium, the structure of the fuel cell, bacterial genetics, and an increase in the membrane permeability and electrode potential, considerably influence the performance and efficiency of the MFC. The electrogenic bacteria Shewanella oneidensis released electrons by decomposing the hydrocarbons. These electrons were then collected by a graphite electrode embedded in the MFC in the next stage and were transferred to an electrical circuit to generate electricity. In the MFC, electrons accumulate in the anode electrode. Shewanella oneidensis bacteria transferred the electrons obtained from the decomposition of hydrocarbons to the anode electrode through the nanowires generated in the wastewater. Afterward, the electrons moved through an electrical circuit to the cathode electrode, where the electrons were transferred to the final electron acceptor. The electrons produced in this process were eventually transferred to oxygen or other acceptors through the cathode electrode. The results of previous studies in the literature proved the efficient role of MFC, microorganisms, and various plants such as Poaceae and Euphorbiaceae in the removal and treatment of wastewater and electricity generation (Bui et al. 2018; Adekunle et al. 2017). Therefore, the plant MFC designed in this study is based on the Shewanella oneidensis and Cyperus papyrus. Increasing the size of the electrodes has excellent potential for generating electricity and removing wastewater.

Conclusion

The successful removal of industrial and municipal pollutants from wastewater remains a significant challenge, despite advancements in various scientific and technological approaches. Among the available techniques, biological processes involving microorganisms and plants have emerged as the most environmentally friendly and sustainable solutions. In this research, we designed a dual-chamber plant microbial fuel cell (PMFC) utilizing the electrical-generating capabilities of Shewanella oneidensis bacteria and the purification efficiency of Cyperus papyrus. Through comprehensive experimentation, we thoroughly evaluated the impact of key factors, such as electrode size, electrode spacing, and inoculation volume, on the electricity generation in the PMFC.

One of the key findings of our research is the significant role of electrode size in enhancing the power output of the PMFC. This observation suggests that careful consideration of electrode dimensions can lead to improved electricity production, making this parameter an essential factor in the design and optimization of PMFC systems.

Additionally, we assessed the effects of electrode spacing and inoculation volume, which, interestingly, did not exhibit discernible impacts on the electricity production in our PMFC setup. Furthermore, the PMFC system exhibited an impressive capability to reduce COD and BOD levels in the wastewater samples. This further highlights the potential of PMFCs as a dual-purpose technology, not only for sustainable energy generation but also for efficient wastewater treatment. These findings not only underscore the significance of employing biological approaches in pollution abatement but also emphasize the potential of PMFCs as a sustainable and versatile technology for energy generation and wastewater treatment. By harnessing the bioelectricity generation abilities of Shewanella oneidensis and the pollutant-removing capabilities of Cyperus papyrus, PMFCs present a promising eco-friendly and sustainable solution for environmental remediation. Further research and optimization of PMFC systems can pave the way for sustainable and efficient solutions in the realm of clean energy production and wastewater treatment.

References

Adekunle A, Raghavan V (2017) Evaluation of the suitability and performance of cassava waste (peel) extracts in a microbial fuel cell for supplementary and sustainable energy production. Waste Manag Res 35(1):47–55. https://doi.org/10.1177/0734242X16670487

Bui XT, Nguyen DD, Nguyen VT, Ngo HH, Guo W, Nguyen PD, Nguyen CN, Lin C (2018) Wastewater treatment and biomass growth of eight plants for shallow bed wetland roofs. Bioresour Technol 247:992–998. https://doi.org/10.1016/j.biortech.2017.09.194

Busalmen JP, Esteve-Núnez A, Berna A, Feliu JM (2008) C-type cytochromes wire electricity-producing bacteria to electrodes. Angew Chem Int Ed 47(26):4874–4877. https://doi.org/10.1002/anie.200801310

Fan Y, Sharbrough E, Liu H (2008) Quantification of the internal resistance distribution of microbial fuel cells. Environ Sci Technol 42(21):8101–8107. https://doi.org/10.1021/es801229j

Gulamhussein M, Randall DG (2020) Design and operation of plant microbial fuel cells using municipal sludge. J Water Process Eng 38:101653. https://doi.org/10.1016/j.jwpe.2020.101653

Hassan H, Jin B, Donner E, Vasileiadis S, Saint C, Dai S (2018) Microbial community and bioelectrochemical activities in MFC for degrading phenol and producing electricity: microbial consortia could make differences. Chem Eng J 332:647–657. https://doi.org/10.1016/j.cej.2017.09.114

Juliastuti SR, Darmawan R, Ayuningtyas A, Ellyza N (2018) The utilization of Eschericia coli and Shewanella oneidensis for microbial fuel cell. In: IOP conference series: materials science and engineering. vol 334(1), p 012067. httsp://doi:https://doi.org/10.1088/1757-899X/334/1/012067

Kaku N, Yonezawa N, Kodama Y, Watanabe K (2008) Plant/microbe cooperation for electricity generation in a rice paddy field. Appl Microbiol Biotechnol 79(1):43–49. https://doi.org/10.1007/s00253-008-1410-9

Khudzari JM, Kurian J, Gariépy Y, Tartakovsky B, Raghavan GS (2018) Effects of salinity, growing media, and photoperiod on bioelectricity production in plant microbial fuel cells with weeping alkaligrass. Biomass Bioenerg 109:1–9

Kirubakaran A, Jain S, Nema RK (2009) A review on fuel cell technologies and power electronic interface. Renew Sustain Energy Rev 13(9):2430–2440. https://doi.org/10.1016/j.rser.2009.04.004

Kumar R, Singh L, Zularisam AW (2016) Exoelectrogens: recent advances in molecular drivers involved in extracellular electron transfer and strategies used to improve it for microbial fuel cell applications. Renew Sustain Energy Rev 56:1322–1336. https://doi.org/10.1016/j.rser.2015.12.029

Lovley DR (2006a) Microbial fuel cells: novel microbial physiologies and engineering approaches. Curr Opin Biotechnol 17(3):327–332. https://doi.org/10.1016/j.copbio.2006.04.006

Lovley DR (2006b) Bug juice: harvesting electricity with microorganisms. Nat Rev Microbiol 4(7):497–508. https://doi.org/10.1038/nrmicro1442

Lovley DR, Nevin KP (2013) Electrobiocommodities: powering microbial production of fuels and commodity chemicals from carbon dioxide with electricity. Curr Opin Biotechnol 24(3):385–390. https://doi.org/10.1016/j.copbio.2013.02.012

Leong JX, Daud WR, Ghasemi M, Liew KB, Ismail M (2013) Ion exchange membranes as separators in microbial fuel cells for bioenergy conversion: a comprehensive review. Renew Sustain Energy Rev 28:575–587. https://doi.org/10.1016/j.rser.2013.08.052

Logan BE (2008) Microbial fuel cells. John Wiley & Sons, New Jersey. https://doi.org/10.1002/9780470258590

Logan BE, Regan JM (2006) Electricity-producing bacterial communities in microbial fuel cells. TREN in Microbiology 14(12):512–518. https://doi.org/10.1016/j.tim.2006.10.003

Logan BE, Rossi R, Saikaly PE (2019) Electroactive microorganisms in bioelectrochemical systems. Nat Rev Microbiol 17(5):307–319. https://doi.org/10.1038/s41579-019-0173-x

Lu Z, Yin D, Chen P, Wang H, Yang Y, Huang G, Cai L, Zhang L (2020) Power-generating trees: direct bioelectricity production from plants with microbial fuel cells. Appl Energy 268:115040. https://doi.org/10.1016/j.apenergy.2020.115040

Mishra B, Awasthi SK, Rajak RK (2017) A review on electrical behavior of different substrates, electrodes and membranes in microbial fuel cell. Int J En Pow Eng 11(9):983–988. https://doi.org/10.5281/zenodo.1132290

Oliot M, Chong P, Erable B, Bergel A (2017) Influence of the electrode size on microbial anode performance. Chem Eng J 327:218–227. https://doi.org/10.1016/j.cej.2017.06.044

Prathiba S, Kumar PS, Vo DN (2022) Recent advancements in microbial fuel cells: a review on its electron transfer mechanisms, microbial community, types of substrates and design for bio-electrochemical treatment. Chemosphere 286:131856

Perbangkhem T, Polprasert C (2010) Biomass production of papyrus (Cyperus papyrus) in constructed wetland treating low-strength domestic wastewater. Bioresour Technol 101(2):833–835. https://doi.org/10.1016/j.biortech.2009.08.062

Rabaey K, Lissens G, Siciliano SD, Verstraete W (2003) A microbial fuel cell capable of converting glucose to electricity at high rate and efficiency. Biotechnology Let 25(18):1531–1535. https://doi.org/10.1023/A:1025484009367

Rossi R, Evans PJ, Logan BE (2019) Impact of flow recirculation and anode dimensions on performance of a large-scale microbial fuel cell. J Pow Sour 412:294–300

Sajana TK, Ghangrekar MM, Mitra A (2013) Effect of pH and distance between electrodes on the performance of a sediment microbial fuel cell. Water Sci Technol 68(3):537–543. https://doi.org/10.2166/wst.2013.271

Strik DP, Hamelers HV, Snel JF, Buisman CJ (2008) Green electricity production with living plants and bacteria in a fuel cell. Int J Energy Res 32(9):870–876. https://doi.org/10.1002/er.1397

Tremouli A, Martinos M, Lyberatos G (2017) The effects of salinity, pH and temperature on the performance of a microbial fuel cell. Waste Biomass Valoriz 8(6):2037–2043. https://doi.org/10.1007/s12649-016-9712-0

Ueoka N, Sese N, Sue M, Kouzuma A, Watanabe K (2016) Sizes of anode and cathode affect electricity generation in rice paddy-field microbial fuel cells. J Sustain Bioenerg Syst 6:10–15

Wang Y, Jiang Y, Guo DP, Luo S, Wang XB, Li YF (2010) The influence of the electrode anode sizes of the microbial fuel cell (MFC) on the electrical property and COD removal with the electroplating wastewater to be the cathode. Adv Mater Res 113:2189–2192. https://doi.org/10.4028/www.scientific.net/AMR.113-116.2189

Acknowledgements

This work was partially supported by Ferdowsi University of Mashhad. The authors would like to thank Dr Farhad Ghiasvand for his time reading and editing the manuscript.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest in this work.

Additional information

Editorial responsibility: S. Mirkia.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Golzarian, M., Ghiasvand, M., Shokri, S. et al. Performance evaluation of a dual-chamber plant microbial fuel cell developed for electricity generation and wastewater treatment. Int. J. Environ. Sci. Technol. 21, 5947–5954 (2024). https://doi.org/10.1007/s13762-023-05415-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05415-5