Abstract

The objective of the study was to maximize the liquid yield by hydrocracking a waste plastic mixture (by weight 24.76% low-density polyethylene, 29.85% high-density polyethylene, 10.57% polypropylene and 34.82% polystyrene) over different hierarchical (containing both micro- and mesosized pores) zeolite catalysts. Two optimizations were performed, i.e., catalyst synthesis optimization followed by the process parameter optimization to maximize the liquid yield and oil yield, respectively. Response surface methodology with central composite design approach was used for both the optimizations. Preliminary experiments were carried out using mesoporous ZSM-5 and Beta Zeolite by desilication/dealumination approaches, where desilicated alumina impregnated Beta Zeolite showed the best results in terms of liquid yield. Alumina loading and synthesis temperature were considered as the significant factors for the catalyst optimization. The experiments were carried out at catalyst-to-plastic ratio of 1:20 and a temperature of 400 °C in an atmospheric pressure setup. For the process parameter optimization, a high-pressure (parr autoclave) setup was used. The parameters selected were temperature (360‒440 °C), pressure (1‒40 bar) and catalyst-to-plastic ratio (1:5–1:40 wt/wt). The results indicated that pressure and catalyst-to-plastic ratio were not as statistically significant in comparison with temperature. At optimized conditions of 420 °C, 20 bar and catalyst-to-plastic ratio of 1:30 wt/wt, 11.27 g (37.57 wt%) of oil yield was achieved. Two quadratic regression models were developed for each optimization, i.e., process optimization (R2 ~ 91%) and catalyst optimization (R2 ~ 95%) that show good fit with the experimental data.

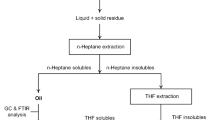

Graphical abstract

Similar content being viewed by others

References

Ahmed MHM (2017) Effect of multi-step desilication and dealumination treatments on the performance of hierarchical EU-1 zeolite for converting methanol to olefins. J Heterocycl Chem 54:375–383

Anene AF, Fredriksen SB, Saetre KA, Tokheim LA (2018) Experimental study of thermal and catalytic pyrolysis of plastic waste components. Sustainability 10:3979–3991

Cejka J, van Bekkum H (eds) (2005) Zeolites and ordered mesoporous materials: progress and prospects: the 1st FEZA School on Zeolites, Prague, Czech Republic, August 20–21, 2005, vol 157. Gulf Professional Publishing

Cui Q, Zhou Y, Wei Q, Tao X, Yu G, Wang Y, Yang J (2012) Role of the zeolite crystallite size on hydrocracking of vacuum gas oil over NiW/Y-ASA catalysts. Energy Fuels 26:4664–4670

Davis ME (2015) Mesoporous zeolites: preparation, characterization and applications. Wiley

Delkash M, Bakhshyesh BE, Kazemian H (2015) Using zeolitic adsorbents to cleanup special wastewater streams: a review. Microporous Mesoporous Mater 214:224–241

Feliczak-Guzik A (2018) Hierarchical zeolites: synthesis and catalytic properties. Microporous Mesoporous Mater 259:33–45

Gao N, Xie S, Liu S, An J, Zhu X, Hu L, Wei H, Li H (2014) Catalytic degradation of LDPE and PP over MCM-49 based micro–mesoporous composites. Catal Lett 144:1296–1304

Gonzalez G, Sagarzazu A, Zoltan T (2013) Influence of microstructure in drug release behavior of silica nanocapsules. J Drug Deliv 2013:1–8

Hoff TC, Gardner DW, Thilakaratne R, Proano-Aviles J, Brown RC, Tessonnier JP (2017) Elucidating the effect of desilication on aluminum-rich ZSM-5 zeolite and its consequences on biomass catalytic fast pyrolysis. Appl Catal A Gen 529:68–78

Hossain SMZ, Sultana N, Irfan MF, Elkanzi EMA, Al-Aali YAM, Taha A, Haque SKM (2016) Optimization of biodiesel production from spent palm cooking oil using fractional factorial design combined with the response surface methodology. Am J Appl Sci 13:1255

Irfan MF, Goo JH, Kim SD (2008) Co3O4 based catalysts for NO oxidation and NOx reduction in fast SCR process. Appl Catal B Environ 78:267–274

Irfan MF, Hossain SMZ, Khalid H, Sadaf F, Al-Thawadi S, Alshater A, Hossain MM, Razzak SA (2019) Optimization of bio-cement production from cement kiln dust using microalgae. Biotechnol Rep 23:e00356

Irfan MF, Hossain SMZ, Tariq I, Khan NA, Tawfeeqi A, Goeva A, Wael M (2020) Modeling and optimization of aqueous mineral carbonation for cement Kiln dust using response surface methodology integrated with Box-Behnken and central composite design approaches. Min Metall Explor 37:1367–1383

Joglekar AM, May AT (1987) Product excellence through design of experiments. Cereal Foods World 32:857–868

Kanai J, Martens JA, Jacobs PA (1992) On the nature of the active sites for ethylene hydrogenation in metal-free zeolites. J Catal 133:527–543

Kumar S, Singh RK (2014) Optimization of process parameters by response surface methodology (RSM) for catalytic pyrolysis of waste high-density polyethylene to liquid fuel. J Environ Chem Eng 2:115–122

Lei XG, Jockusch S, Ottaviani MF, Turro NJ (2003) In situ EPR investigation of the addition of persistent benzyl radicals to acrylates on ZSM-5 zeolites. Direct spectroscopic detection of the initial steps in a supramolecular photopolymerization. Photochem Photobiol Sci 2:1095–1100

Lerici LC, Renzini MS, Pierella LB (2015) Chemical catalyzed recycling of polymers: catalytic conversion of PE, PP and PS into fuels and chemicals over H-Y. Procedia Mater Sci 8:297–303

Li Y, Yu J (2014) New stories of zeolite structures: their descriptions, determinations, predictions, and evaluations. Chem Rev 114:7268–7316

Lin Q, Bu X, Mao C, Zhao X, Sasan K, Feng P (2015) Mimicking high-silica zeolites: highly stable germanium- and tin-rich zeolite-type chalcogenides. J Am Chem Soc 137:6184–6197

Mante OD, Agblevor FA, McClung R (2013) A study on catalytic pyrolysis of biomass with Y-zeolite based FCC catalyst using response surface methodology. Fuel 108:451–464

Mayers RH, Montgomery DC (2002) Response surface methodology: process and product optimization using designed experiments. Wiley, New York, p 79

Meusinger J, Corma A (1995) Activation of hydrogen on zeolites: kinetics and mechanism of n-heptane cracking on H-ZSM-5 zeolites under high hydrogen pressure. J Catal 152:189–197

Miandad R, Barakat MA, Aburiazaiza MS, Rehan M, Ismail IM, Nizami AS (2017) Effect of plastic waste types on pyrolysis liquid oil. Int Biodeterior Biodegrad 119:239–252

Miandad R, Rehan M, Barakat MA, Aburiazaiza AS, Khan H, Ismail IM, Nizami AS (2019) Catalytic pyrolysis of plastic waste: Moving towards pyrolysis based biorefineries. Front Energy Res 7:1–17

Miranda M, Pinto F, Gulyurtlu I, Cabrita I, Nogueira CA, Matos A (2010) Response surface methodology optimization applied to rubber tyre and plastic wastes thermal conversion. Fuel 89:2217–2229

Mostowicz R, Testa F, Crea F, Aiello R, Fonseca A, Nagy JB (1997) Synthesis of zeolite beta in presence of fluorides: influence of alkali cations. Zeolites 18:308–324

Munir D, Piepenbreier F, Usman MR (2017) Hydrocracking of a plastic mixture over various micro-mesoporous composite zeolites. Powder Technol 316:542–550

Munir D, Irfan MF, Usman MR (2018) Hydrocracking of virgin and waste plastic: a detailed review. Renew Sust Energy Rev 90:490–515

Ni P, Sun A, Wu X, Hai G, Hu J, Li T, Li G (2011) Preparation of hierarchical mesoporous Zn/HZSM-5 catalyst and its application in MTG reaction. J Nat Gas Chem 20:237–242

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel: a suitable method for plastic waste management and manufacture of value-added products—a world prospective. Renew Sustain Energy Rev 14:233–248

Pérez-Page M, Makel J, Guan K, Zhang S, Tringe J, Castro RH, Stroeve P (2016) Gas adsorption properties of ZSM-5 zeolites heated to extreme temperatures. Ceram Int 42:15423–15431

Perez-Pariente J, Martens JA, Jacobs PA (1987) Crystallization mechanism of zeolite beta from (TEA)2O, Na2O and K2O containing aluminosilicate gels. Appl Catal 31:35–64

Pinto F, Paradela F, Gulyurtlu I, Ramos AM (2013) Prediction of liquid yields from the pyrolysis of waste mixtures using response surface methodology. Fuel Process Technol 116:271–283

Qin Z, Shen B, Gao X, Lin F, Wang B, Xu C (2011) Mesoporous Y zeolite with homogeneous aluminum distribution obtained by sequential desilication–dealumination and its performance in the catalytic cracking of cumene and 1,3,5-triisopropylbenzene. J Catal 278:266–275

Reule AA, Sawada JA, Semagina N (2017) Effect of selective 4-membered ring dealumination on mordenite-catalyzed dimethyl ether carbonylation. J Catal 349:98–109

Selvaganapathy T, Muthuvelayudham R, Jayakumar M (2020) Process parameter optimization study on thermolytic polystyrene liquid fuel using response surface methodology (RSM). Mater Today Proc 26:2729–2739

Shehata N, Mohamed HS, Emam HM, Ahmed S (2017) Fuel produced from catalytic pyrolysis of waste plastic. Emirat J Eng Res 22:1–6

Silvarrey LD, Phan AN (2016) Kinetic study of municipal plastic waste. Int J Hydrogen Energy 41:16352–16364

Sonawane YB, Shindikar MR, Khaladkar MY (2015) Use of catalyst in pyrolysis of polypropylene waste into liquid fuel. Int Res J Environ 4:24–28

Supatra B, Hunt AJ, Ngernyen Y (2019) Catalytic pyrolysis of plastic waste for the production of liquid fuels for engines. RSC Adv 9:5844–5857

van Laak ANC, Sagala SL, Zecevic J, Friedrich H, de Jongh PE, de Jong KP (2010) Mesoporous mordenites obtained by sequential acid and alkaline treatments—catalysts for cumene production with enhanced accessibility. J Catal 276:170–180

Verboekend D, Caicedo-Realpe R, Bonilla A, Santiago M, Perez-Ramírez J (2010) Properties and functions of hierarchical ferrierite zeolites obtained by sequential post-synthesis treatments. Chem Mater 22:4679–4689

Verboekend D, Chabaneix AM, Thomas K, Gilson JP, Perez-Ramírez J (2011) Mesoporous ZSM-22 zeolite obtained by desilication: peculiarities associated with crystal morphology and aluminium distribution. Cryst Eng Comm 13:3408–3416

Verboekend D, Vile G, Perez-Ramírez J (2012) Hierarchical Y and USY zeolites designed by post-synthetic strategies. Adv Funct Mater 22:916–928

Weitkamp J (2012) Catalytic hydrocracking—mechanisms and versatility of the process. Chem Cat Chem 4:292–306

Wong SL, Ngadi N, Amin NAS, Abdullah TAT, Inuwa IM (2016) Pyrolysis of low density polyethylene waste in subcritical water optimized by response surface methodology. Environ Technol 37:245–254

Xiong Q, Kong SC, Passalacqua A (2013) Development of a generalized numerical framework for simulating biomass fast pyrolysis in fluidized-bed reactors. Chem Eng Sci 99:305–313

Zenonos C, Sankar G, García-Martínez J, Aliev A, Beale AM (2003) Direct hydrothermal conversion of high-silica faujausite and zeolite β to Zsm-5 and its catalytic performance. Catal Lett 86:279–283

Zhang Z, Wang Q, Chen H, Zhang X (2017) Hydroconversion of waste cooking oil into green biofuel over hierarchical USY-supported NiMo catalyst: a comparative study of desilication and dealumination. Catalysts 7:281–294

Acknowledgements

The authors would like to acknowledge the support and facilities provided by the University of Bahrain, Kingdom of Bahrain and Sultan Qaboos University, Oman. The authors would like to thank the Department of Chemistry and Nanotechnology Center/Central Labs at College of Science, University of Bahrain, Kingdom of Bahrain for allowing to use the analytical equipment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: Fatih ŞEN.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mumtaz, F., Irfan, M.F., Butt, W.A. et al. Two-step optimization (catalyst and process) to maximize the liquid yield from the waste plastics mixture by hydrocracking process using hierarchical zeolite catalysts. Int. J. Environ. Sci. Technol. 20, 7149–7166 (2023). https://doi.org/10.1007/s13762-022-04446-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-022-04446-8