Abstract

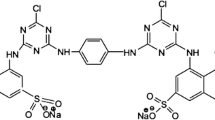

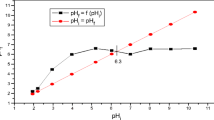

The textile industries release a substantial amount of effluents into water resources every year. The vast majority of these effluents are composed of heavy metals that bind the textile fibres with dyes. This work proposes to use an adsorption system composed of clay-minerals (kaolinite and montmorillonite) and molecular sieve (zeolite) for separating the Cu2+ and Cr6+ ions, considering the pH changes of aqueous solutions. The adsorbent materials were characterized using the following state of the art techniques such as X-ray fluorescence, X-ray diffraction, Raman spectroscopy and Cation exchange capacity. During the adsorption tests, the contact time of the adsorbates (Cu2+ and Cr6+ ions in concentrations of 100, 50, 10 and 5 mg/L) with the adsorbents vary from 1 to 4 h in acidic and alkaline conditions (pH 3.5 and 7.5). The results indicate maximum adsorption of Cu2+ (at pH 3.5) and Cr6+ (at pH 7.5) ions on application of the zeolitic material. The clay minerals conclusively proved to be less efficient when compared to zeolite. It can be concluded that the adsorption system has achieved the desired efficiency, with substantial removal of Cu2+ and Cr6+ ions for zeolites in synthetic wastewater solutions of the textile industry.

Similar content being viewed by others

References

L. Hossain, S.K. Sarker, M.S. Khan, Environ. Dev. 26, 23–33 (2018). https://doi.org/10.1016/j.envdev.2018.03.005

Z. Hussain, M. Arslan, M.H. Malik, S. Iqbal, M. Afzal, Sci. Total Environ. 645, 966–973 (2018). https://doi.org/10.1016/j.scitotenv.2018.07.163

E. Hassanzadeh, M. Farhadian, A. Razmjou, N. Askari, Environ. Nanotechnol. Monit. Manage 8, 92–96 (2017). https://doi.org/10.1016/j.enmm.2017.06.001

A. Taavoni-Gilan, E. Taheri-Nassaj, M. Shamsipur, J. Iran. Chem. Soc. 15, 2759–2769 (2018). https://doi.org/10.1007/s13738-018-1463-3

K. Nadeem, G.T. Guyer, B. Keskinler, N. Dizge, J. Clean Prod. 228, 1437–1445 (2019). https://doi.org/10.1016/j.jclepro.2019.04.205

M.A. Klunk, A. Oliveira, G. Furtado, G.H. Knornschild, L.F.P. Dick, ECS Trans. 43, 23–27 (2012). https://doi.org/10.1149/1.4704934

R. Ansari, Z. Mosayebzadeh, Chem. Pap. 65, 1–8 (2011). https://doi.org/10.2478/s11696-010-0083-x

M. Szynkowska, E. Rybicki, E. Leśniewska, A. Pawlaczyk, T. Paryjczak, E. Matyjas-Zgondek, Chem. Pap. 63, 537–542 (2009). https://doi.org/10.2478/s11696-009-0044-4

L.D.O. Pereira, R.V. Lelo, G.C.M. Coelho, F. Magalhães, J. Iran. Chem. Soc. 16, 2281–2289 (2019). https://doi.org/10.1007/s13738-019-01694-3

M.A. Klunk, L.H. Damiani, G. Feller, M.F. Rey, R.V. Conceiçao, M. Abel, L.F. De Ros, Braz. J. Geol. 45, 29–45 (2015). https://doi.org/10.1590/2317-4889201530145

M.A. Klunk, S. Dasgupta, R.V. Conceiçao, J. Palaeogeogr. 7, 12–26 (2018). https://doi.org/10.1186/s42501-018-0009-z

M.A. Klunk, S. Dasgupta, S.B. Schropfer, B.V.G. Nunes, P.R. Wander, Per. Tchê Quím. 16(31), 816–822 (2019)

P.R. Wander, F.M. Bianchi, N.R. Caetano, M.A. Klunk, M.L.S. Indrusiak, Energy 203, 117882 (2020). https://doi.org/10.1016/j.energy.2020.117882

R. Cataluña, Z. Shah, V. Venturi, N.R. Caetano, B.P. Da Silva, C.M.N. Azevedo, R. Da Silva, P.A.Z. Suarez, L.P. Oliveira, Fuel 228, 226–233 (2018). https://doi.org/10.1016/j.fuel.2018.04.167

R. Cataluña, Z. Shah, L. Pelisson, N.R. Caetano, R. Da Silva, C. Azevedo, J. Braz. Chem. Soc. (2017). https://doi.org/10.21577/0103-5053.20170100

A. Fraga, M.A. Klunk, A. Oliveira, G. Furtado, G.H. Knornschild, L.F.P. Dick, Mater. Res. 17, 1637–1643 (2014). https://doi.org/10.1590/1516-1439.305714

T. Madrakian, A. Afkhami, N. Rezvani-jalal, M. Ahmadi, J. Iran. Chem. Soc. 11, 489–498 (2014). https://doi.org/10.1007/s13738-013-0322-5

Y. Sürme, O. Demirci, Chem. Pap. 68(11), 1491–1497 (2014). https://doi.org/10.2478/s11696-014-0616-9

M. Šimek, P. Mikulášek, P. Kalenda, T. Weidlich, Chem. Pap. 70(4), 470–476 (2016). https://doi.org/10.1515/chempap-2015-0225

N. Bahadur, N. Bhargava, J. Water Process. Eng. 32, 100934 (2019). https://doi.org/10.1016/j.jwpe.2019.100934

L. Zhou, K. Xu, X. Cheng, Y. Xu, Q. Jia, J. Clean. Prod. 141, 721–727 (2017). https://doi.org/10.1016/j.jclepro.2016.09.047

A.C. Ruoso, L.C. Bittencourt, L.U. Sudati, M.A. Klunk, N.R. Caetano, Per. Tchê Quím 16(32), 560–571 (2019)

S.M. Stagnaro, M.C. Volzone, L. Huck, Proc. Mater. Sci. 8, 586–591 (2015). https://doi.org/10.1016/j.mspro.2015.04.112

S. Rangabhashiyam, N. Anu, N. Selvaraju, J. Environ. Chem. Eng. 1(4), 629–641 (2013). https://doi.org/10.1016/j.jece.2013.07.014

A.C. Ruoso, A. Lhamby, A.B. Missaggia, M.A. Klunk, N.R. Caetano, Per Tchê Quím. 17(34), 220–239 (2020)

M.A. Klunk, S. Dasgupta, M. Das, P.R. Wander, Per. Tchê Quím. 16(32), 108–118 (2019)

M.A. Klunk, S. Dasgupta, M. Das, P.R. Wander, A. Di Capua, Per. Tchê Quím. 16(33), 736–748 (2019)

A.M. Ferreira, J.A.P. Coutinho, A.M. Fernandes, M.G. Freire, Sep. Purif. Technol. 128, 58–66 (2014). https://doi.org/10.1016/j.seppur.2014.02.036

R.M. Jain, K.H. Mody, J. Keshri, B. Jha, Mar. Pollut. Bull. 84(1–2), 83–89 (2014). https://doi.org/10.1016/j.marpolbul.2014.05.033

U. Lucia, G. Grisolia, Energy Rep. 5, 62–69 (2019). https://doi.org/10.1016/j.egyr.2018.12.001

U. Lucia, M. Simonetti, G. Chiesa, G. Grisolia, Renew. Sustain. Energ. Rev. 70, 867–874 (2017). https://doi.org/10.1016/j.rser.2016.11.268

S. Islam, G. Bhat, J. Environ. Manage. 251, 109536 (2019). https://doi.org/10.1016/j.jenvman.2019.109536

M.A. Klunk, Z. Shah, N.R. Caetano, R.V. Conceição, P.R. Wander, S. Dasgupta, M. Das, Int. J. Environ. Stud. 77(3), 492–509 (2020). https://doi.org/10.1080/00207233.2019.1675295

S. Kumari, R. Naraian, J. Environ. Manage. 180, 172–179 (2016). https://doi.org/10.1016/j.jenvman.2016.04.060

U. Lucia, G. Grisolia, A.L. Kuzemsky, Entropy 22(8), 887–898 (2020). https://doi.org/10.3390/e22080887

G. Grisolia, D. Fino, U. Lucia, Energy Rep. 6, 1561–1571 (2020). https://doi.org/10.1016/j.egyr.2020.06.014

N.R. Caetano, R. Cataluña, H.A. Vielmo, Int. Review Mech. Eng. 9(2), 124–128 (2015). https://doi.org/10.15866/ireme.v9i2.4341

N.R. Caetano, D. Soares, R.P. Nunes, F.M. Pereira, P.S. Schneider, H.A. Vielmo, F.T. van der Laan, Open Eng. 5, 213–219 (2015). https://doi.org/10.1515/eng-2015-0016

N.R. Caetano, G. Lorenzini, A.R. Lhamby, V.M.M. Guillet, M.A. Klunk, L.A.O. Rocha, Int. J. Heat Technol. 38, 1–8 (2020). https://doi.org/10.18280/ijht.380101

N.R. Caetano, T.Z. Stapasolla, F.B. Peng, P.S. Schneider, F.M. Pereira, H.A. Vielmo, Defect Diffus. Forum 362, 29–37 (2015). https://doi.org/10.4028/www.scientific.net/DDF.362.29

N.R. Caetano, M.S. Venturini, F.R. Centeno, C.K. Lemmertz, K.G. Kyprianidis, Therm. Sci. Eng. Prog. 7, 241–247 (2018). https://doi.org/10.1016/j.tsep.2018.06.008

M. Khatamian, M. Irani, J. Iran. Chem. Soc. 6, 187–194 (2009). https://doi.org/10.1007/BF03246519

M.A. Klunk, S. Dasgupta, M. Das, M.G. Cunha, P.R. Wander, E.C.S.J. Solid, State Sci. Technol. 8(10), N144–N150 (2019). https://doi.org/10.1149/2.0131910jss

M.A. Klunk, S. Dasgupta, M. Das, P.R. Wander, Z. Shah, Per. Tchê Quím. 16(33), 70–81 (2019)

M.K. de Souza, M.A. Klunk, S.J.S. Xavier, M. Das, S. Dasgupta, Per. Tchê Quím. 17(35), 816–822 (2020)

F. Ma, Q. Jin, P. Li, Z. Chen, J. Lu, Z. Guo, W. Wu, Appl. Geochem. 84, 325–336 (2017). https://doi.org/10.1016/j.apgeochem.2017.07.002

M.A. Klunk, Z. Shah, P.R. Wander, Per. Tchê Quím. 16(32), 279–286 (2019)

M.A. Klunk, M. Das, S. Dasgupta, A.N. Impiombato, N.C. Caetano, P.R. Wander, C.A.M. Moraes, Mater. Res. Express 7, 015023 (2020). https://doi.org/10.1088/2053-1591/ab608d

M.A. Klunk, S.B. Schröpfer, S. Dasgupta, M. Das, N.R. Caetano, A.N. Impiombato, P.R. Wander, C.A.M. Moraes, Chem. Pap. 74, 2481–2489 (2020). https://doi.org/10.1007/s11696-020-01095-4

M. Das, S. Dasgupta, M.A. Klunk, S.J.S. Xavier, F. ChemaleJunior, P.R. Wander, Can. J. Chem. 98(10), 609–615 (2020). https://doi.org/10.1139/cjc-2020-0142

M.A. Klunk, S. Dasgupta, B.V.G. Nunes, P.R. Wander, Per. Tchê Quím. 16(31), 778–783 (2019)

M. Wdowin, M. Franus, R. Panek, L. Badura, W. Franus, Clean Technol. Environ. 16(6), 1217–1223 (2014). https://doi.org/10.1007/s10098-014-0719-6

V. Somerset, Talanta 64(1), 109–114 (2004). https://doi.org/10.1016/j.talanta.2003.10.059

K. Elaiopoulos, T. Perraki, E. Grigoropoulou, Microporous Mesoporous Mater. 134(1–3), 29–43 (2010). https://doi.org/10.1016/j.micromeso.2010.05.004

J.T. Kloprogge, Infrared and Raman Spectroscopies of Clay Minerals (Elsevier, Amsterdam, 2017), pp. 150–199. https://doi.org/10.1016/b978-0-08-100355-8.00006-0

T.G. Ryu, G.J.C. Ryu, C.H. Choi, C.G. Kim, S.J. Yoo, H.S. Yang, Y.H. Kim, J. Ind. Eng. Chem. 12, 401–407 (2006)

R. Nitzsche, A. Gröngröft, M. Kraume, Sep. Purif. Technol. 209, 491–502 (2019). https://doi.org/10.1016/j.seppur.2018.07.077

V.K. Singh, E.A. Kumara, Mater. Today Proc. 5(11), 23033–23042 (2018). https://doi.org/10.1016/j.matpr.2018.11.032

Q. Chen, R. Zhu, H. Fu, L. Ma, J. Zhu, H. He, Y. Deng, Microporous Mesoporous Mater. 260, 76–83 (2018). https://doi.org/10.1016/j.micromeso.2017.10.033

Acknowledgements

The authors acknowledge the Brazilian agencies of CNPq (National Council of Technological and Scientific Development – Brasília, DF, Brazil), CAPES (Coordination for the Improvement of Higher Education Personnel) and the Indian agencies such as IRCC (Industrial Research and Consultancy Centre), Indian Institute of Technology Bombay, MoE (Ministry of Education), India for the research funding and research grants of the Brazilian (PNPD/CAPES and DT2/CNPq) and Indian authors, respectively. The authors also acknowledge generous cooperation and assistance of all the people from the company who granted us access to their database and perception.

Funding

This research did not receive financial assistance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Dasgupta, S., Das, M., Klunk, M.A. et al. Copper and chromium removal from synthetic textile wastewater using clay minerals and zeolite through the effect of pH. J IRAN CHEM SOC 18, 3377–3386 (2021). https://doi.org/10.1007/s13738-021-02273-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13738-021-02273-1