Abstract

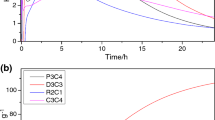

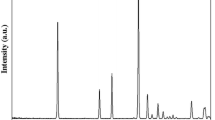

This paper provides a thorough investigation of the mechanical, thermal and morphological properties of polypropylene homopolymer (HPP) reinforced with unmodified minor mineral fuller’s earth (UMMFE) to comprehend and evaluate the properties over conventional polypropylene. UMMFE was characterised by FTIR, TGA, SEM and particle size analysis. HPP/UMMFE composites were prepared on a co-rotating twin-screw extruder with a varied content ranging from 0 to 5% (by weight). The dispersibility of HPP and UMMFE was analyzed using scanning electron microscopy (SEM). Mechanical tests showed an increment of 14% in the tensile modulus for HPP5, in which UMMFE demonstrated a strong reinforcing effect to sustain stress, also resulting in improved tensile strength-at-yield by 13%. Also the flexural modulus increased, showing a 28% rise from 1652 MPa (HPP) to 2122 MPa (HPP5). It was found that UMMFE particles in the HPP matrix affected the interfacial properties of the composites. The comparative investigation of thermogravimetric analysis (TGA) also revealed that the thermal stability of the composites reinforced with UMMFE at 5% (by weight) increased by approximately 56.37%. HPP/UMMFE composites exhibited optimum performance at 5% (by weight) clay loading. This study aims to use UMMFE clay as a potential filler in various sectors of application like automobile, manufacturing, construction, packaging and act as a cushion in the scenario of scarcity of material.

Graphical abstract

Similar content being viewed by others

References

Sharma GP, Agarwal R, Bansal A, Agrawal NK, Singh R (2020) Effect of climatic conditions on the thermal conductivity of earth fuller. J Mater Today Proc 30:183–189. https://doi.org/10.1016/j.matpr.2020.05.738

Lee MS, Tiwari D (2012) Organo and inorganic-organic-modified clays in the remediation of aqueous solution. J Appl Clay Sci 59:84–102. https://doi.org/10.1016/j.clay.2012.02.006

Encyclopaedia Britannica Editors (2020) Fuller’s earth. https://www.britannica.com/science/fullers-earth

Indian Minerals Yearbook (2020) (Part III: mineral reviews) 59th edition minor minerals 30.10 fuller’s earth, Government of India, Ministry of Mines, Indian Bureau of Mines, Indira Bhavan, Civil Lines, Nagpur-440 001

Maddah HA (2016) Polypropylene as a promising plastic: a review. Am J Polym Sci 6:1–11. https://doi.org/10.5923/j.ajps.20160601.01

Cathelin C, Dorini M, Mei G, Pater J, Rinaldi R (2018). In: Kirk RE, Othmer DF, Grayson M, Eckroth M (eds) Encyclopedia of chemical technology, vol 5. Wiley, New York. https://doi.org/10.1002/0471238961.1615122512090502.a01.pub3

Jamshidian M, Tehrany EA, Imran M, Akhtar MJ, Cleymand F, Desobry S (2012) Structural, mechanical and barrier properties of active PLA-antioxidant films. J Food Eng 110:380–389. https://doi.org/10.1016/j.jfoodeng.2011.12.034

Rhim JW, Hong SI, Ha CS (2009) Tensile, water vapour barrier and antimicrobial properties of PLA/nanoclay composite films. LWT Food Sci Technol 42:612–617. https://doi.org/10.1016/j.lwt.2008.02.015

Kausar A (2017) Physical properties of hybrid polymer/clay composites. Hybrid Polym Compos Mater Prop Charact 115–132. https://doi.org/10.1016/B978-0-08-100787-7.00005-6

Zeng QH, Yu AB, Max LuGQ, Paul DR (2005) Clay-based polymer nanocomposites: research and commercial development. J Nanosci Nanotechnol 5:1574–1592. https://doi.org/10.1166/jnn.2005.411

Jung BN, Kang D, Cheon S, Shim JK, Hwang SW (2019) The addition effect of hollow glass microsphere on the dispersion behaviour and physical properties of polypropylene/clay nanocomposite. J Appl Polym Sci 136:47476. https://doi.org/10.1002/app.47476

Okonkwo EG, Anabaraonye CN, Daniel MK, Pume CC, Egoigwe SV, Okeke PE, Whyte FG, Okoani AO (2020) Mechanical and thermomechanical properties of clay-Bambara nut shell polyester bio-composite. Int J Adv Manuf Technol 108:2483–2496. https://doi.org/10.1007/s00170-020-05570-w

Essabir H, Raji M, Laaziz SA, Rodrique D, Bouhfid R, Qaiss A (2018) Thermo-mechanical performances of polypropylene bio composites based on untreated, treated and compatibilized spent coffee grounds. Compos B 149:1–11. https://doi.org/10.1016/j.compositesb.2018.05.020

Lee C, Pang MM, Koay SC, Choo HL, Tshai KY (2020) Talc filled polylactic-acid biobased polymer composites: tensile, thermal and morphological properties. SN Appl Sci 2:354. https://doi.org/10.1007/s42452-020-2172-y

Li K, Yue S, Li X, Ahmad N, Cheng Q, Wang B, Zhang X, Li S, Li Y, Huang G, Kang H (2022) High efficiency perovskite solar cells employing quasi-2D Ruddlesden–Popper/Dion–Jacobson heterojunctions. Adv Funct Mater 32:2200024. https://doi.org/10.1002/adfm.202200024

Ahmad N, Zhao Y, Ye F, Zhao J, Chen S, Zheng Z, Fan P, Yan C, Li Y, Su Z, Zhang X (2023) Cadmium-free Kesterite thin-film solar cells with high efficiency approaching 12%. Adv Sci 10:2302869. https://doi.org/10.1002/advs.202302869

Mines and Minerals (Development and Regulation) Act, 1957 (No. 67 of 1957) (As amended up to 10th May, 2012) Issued by Controller: General, Indian Bureau of Mines, Nagpur August, 2012

Wang Y, Chen FB, L, YC, Wu KC, (2004) Melt processing of polypropylene/clay nanocomposites modified with maleated polypropylene compatibilizers. Compos Part B 35:111–124. https://doi.org/10.1016/s1359-8368(03)00049-0

Yaghmaeiyan N, Mirzaei M, Delghavi R (2022) Montmorillonite clay: introduction and evaluation of its applications in different organic syntheses as catalyst: a review. Results Chem 4:100549. https://doi.org/10.1016/j.rechem.2022.100549

Encyclopaedia Britannica Editors (2018) Kaolinite. Encyclopedia Britannica. https://www.britannica.com/science/kaolinite

Verma D, Goh KL (2019) Functionalized graphene-based nanocomposites for energy applications. Synth Process Appl Micro Nano Technol 219–243. https://doi.org/10.1016/b978-0-12-814548-7.00011-8

Billon N, Romain C, Jean Luc B, Guilhem R (2023) Viscoelastic properties of polypropylene during crystallization and melting: experimental and phenomenological modelling. Polymers 15:3846. https://doi.org/10.3390/polym15183846

Bajpai AK, Vishwakarma N (2003) Adsorption of polyvinylalcohol onto Fuller’s earth surfaces. Colloids Surf A 220:117–130. https://doi.org/10.1016/S0927-7757(03)00073-6

Latip W, Feizal V, Khim OK, Mohd Kasim NA (2021) Immobilization of mutant phosphotriesterase on fuller’s earth enhanced the stability of the enzyme. Catalysts 11:983. https://doi.org/10.3390/catal11080983

Purcell RJ, Jr. Arm G, Parker DC (2002) US Patent 6,444,601. https://patentimages.storage.googleapis.com/3a/4b/21/d346b15b88bee9/US6444601.pdf

Fang J, Zhang L, Sutton D, Wang X, Lin T (2012) Needleless melt-electrospinning of polypropylene nanofibres. J Nanomater 1–9. https://doi.org/10.1155/2012/382639

Othman N, Ismail H, Jaafar M (2004) Preliminary study on application of bentonite as filler in polypropylene composites. Polym Plast Technol Eng 43:713–730. https://doi.org/10.1081/ppt-120038061

Othman N, Ismail H, Mariatti M (2006) Effect of compatibilizers on mechanical and thermal properties of bentonite filled polypropylene composites. Polym Degrad Stab 91:1761–1774. https://doi.org/10.1016/j.polymdegradstab.2005

Gonzalez I, Eguiazabal JI, Nazabal J (2006) Nanocomposites based on a polyamide 6/maleated styrene-butylene-co-ethylene-styrene blend: effects of clay loading on morphology and mechanical properties. Eur Polym J 42:2905–2913. https://doi.org/10.1007/s00289-020-03265-6

Selezneva M, Swolfs Y, Katalagarianakis A, Ichikawa T, Hirano N, Taketa I, Karaki T, Verpoest I, Gorbatikh L (2018) The brittle-to-ductile transition in tensile and impact behavior of hybrid carbon fibre/self-reinforced polypropylene composites. Compos A 109:20–30. https://doi.org/10.1016/j.compositesa.2018.02.034

Chen L, Wong SC, Pisharath S (2003) Fracture properties of nanoclay-filled polypropylene. J Appl Polym Sci 88:3298–3305. https://doi.org/10.1002/app.12153

Unnikrishnan L, Mohanty S, Nayak S, Ali A (2011) Preparation and characterization of poly(methyl methacrylate)-clay nanocomposites via melt intercalation: effect of organoclay on thermal, mechanical and flammability properties. Mater Sci Eng 3943–3951. https://doi.org/10.1016/j.msea.2011.01.071

Mekhzoum ME, Raji M, Rodrigue D, Bouhfid R (2020) The effect of benzothiazolium surfactant modified montmorillonite content on the properties of polyamide 6 nanocomposites. Appl Clay Sci 185:105417–105430. https://doi.org/10.1016/j.clay.2019.105417

Gao X, Lx M, Jin RG, Zhang LQ, Tian M (2007) Structure and mechanical properties of PP/EPDM/Attapulgite ternary blends. Polym J 39:1011–1017. https://doi.org/10.1295/polymj.PJ2006166

Sharma SK, Nema AK, Nayak SK (2012) Effect of modified clay on mechanical and morphological properties of ethylene octane copolymer-polypropylene nanocomposites. J Compos Mater 46:1139–1150. https://doi.org/10.1177/0021998311413686

Rahman NA, Hassan A, Yahya R, Lafia-Araga RA, Hornsby PR (2012) Micro-structural, thermal, and mechanical properties of injection-molded glass fiber/nanoclay/polypropylene composites. J Reinf Plast Compos 31:269. https://doi.org/10.1177/0731684411435727

Mohamed MR, Amer AA, Soliman AM, El-Ghazawy RA, Shaker NO, Naguib HM, Kandil UF (2019) Surface activation of wood plastic composites (WPC) for enhanced adhesion with epoxy coating. Mater Perform Charact 8:22–40. https://doi.org/10.1520/MPC20180034

Essabir H, Raji M, Bouhfid R, Qaiss AK (2016) Nanoclay and natural fibers based hybrid composites: mechanical, morphological, thermal and rheological properties. Nanoclay reinforced polymer composites. Springer, Singapore. https://doi.org/10.1007/978-981-10-0950-1_2

Ahmad N, Mahmood T (2022) Preparation and properties of 4-aminobenzoic acid-modified polyvinyl chloride/titanium dioxide and PVC/TiO2 based nanocomposites membranes. Polym Polym Compos 30:09673911221099301. https://doi.org/10.1177/09673911221099301

Tarapow JA, Bernal CR, Alvare VA (2009) Mechanical properties of polypropylene/clay nanocomposites: effect of clay content, polymer/clay compatibility, and processing conditions. J App Polym Sci 111:768–778. https://doi.org/10.1002/app.29066

Doumeng M, Makhlouf L, Berthet F, Marsan O, Delbé K, Denape J, Chabert F (2020) A comparative study of the crystallinity of Polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. Polym Test 93:106878. https://doi.org/10.1016/j.polymertesting.2020

Huda MS, Drzal LT, Ray D, Mohanty AK, Mishra M (2008) Natural-fiber composites in the automotive sector. Prop Perform Nat Fibre Compos 221–268. https://doi.org/10.1533/9781845694593.2.221

Erbas KE, Kiziltas A, Bollin SC, Gardner DJ (2015) Preparation and characterization of transparent PMMA-cellulose based nanocomposites. Carbohydr Polym 127:381–389. https://doi.org/10.1016/j.carbpol.2015.03.029

Basara C, Yilmazer U, Bayram G (2005) Synthesis and characterization of epoxy based nanocomposites. J App Polym Sci 98:1081–1086. https://doi.org/10.1002/app.22242

Shelesh-Nezhad K, Orang H, Motallebi M (2013) Crystallization shrinkage and mechanical characteristics of polypropylene/CaCO3 nanocomposites. J Thermoplast Compos Mater 26:544–554. https://doi.org/10.1177/0892705712454866

Dikobe DG, Luyt AS (2010) Comparative study of the morphology and properties of PP/LLDPE/wood powder and MAPP/LLDPE/wood powder polymer blend composites. EXPRESS Polym Lett 4:729–741. https://doi.org/10.3144/expresspolymlett.2010.88

Leszczynska A, Pielichowski K (2008) Application of thermal analysis methods for characterization of polymer/montmorillonite nanocomposites. J Therm Anal Calorim 93:677–687. https://doi.org/10.1007/s10973-008-9128-6

Ashenai GF, Ghorbani A, Ghasemi I (2017) Mechanical, thermal and dynamic mechanical properties of PP/GF/XGNP nanocomposites. Mech Compos Mater 53:187–198. https://doi.org/10.1007/s11029-017-9647-y

Li L, Yumei J (2013) Effects of attapulgite on crystallization and thermal stability properties of poly (lactic acid). Acta Materiae Compositae Sinica 30:75–82

Zhang Y, Yu C, Hu P, Tong W, Lv F, Chu PK, Wang H (2016) Mechanical and thermal properties of palygorskite poly(butylene succinate) nanocomposite. Appl Clay Sci 119:96–102. https://doi.org/10.1016/j.clay.2015.07.022

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jaideva, R., Mondal, S. Polypropylene homopolymer/unmodified minor mineral fuller’s earth composites: a comprehensive experimental study on mechanical and thermal properties. Iran Polym J 33, 659–669 (2024). https://doi.org/10.1007/s13726-023-01272-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01272-8