Abstract

Polypropylene wastes were used to prepare carboxylated (CPP) and sulfonated (SPP) microparticles for the adsorption of Mn (II) from aqueous media. The microparticles derivatized with nitric or sulfuric acid were characterized in terms of their physico-chemical properties. The generated functional groups on CPP (–COOH and –NO2) and SPP (–COOH, –SO3H, and C = C) enhanced the adsorption of metal ions. The adsorption behavior of Mn (II) ions on the derivatized microparticles was studied under different conditions: Solution pH, polymer dose, contact time, initial concentration of Mn (II) ions, and temperature. Application of kinetics and equilibrium models to the data revealed that the adsorption processes followed pseudo-second order reactions and the Langmuir isotherm. SPP achieved a higher maximum adsorption capacity (9.15 mg g−1) than CPPs (5.51 mg g−1). Therefore, sulfonation was considered the most efficient approach to produce a suitable surface functionality for the removal of metal ions from aqueous solutions. However, thermodynamic studies showed that all adsorption processes are spontaneous and feasible (ΔG = − 1.32 and − 1.46 kJ mol−1 at 20 °C for CPP and SPP, respectively), which ensure the possibility of employing acid-derivatized PP microparticles for metal removal.

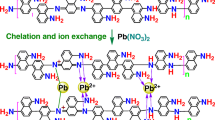

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The discharge of heavy metals from domestic, industrial, and commercial sources into water bodies has increased the pollution of water resources [1]. Among others, manganese wastes from steel production, electronics, and chemical industries have been discharged into water bodies on a large scale [2]. The presence of manganese in water affects its quality by causing reddish color, laundry stains, undesirable taste, and odor [3]. Manganese can also cause the formation of oxide layers in corroded pipes in drinking water systems, resulting in the deterioration of water quality [2]. In addition, exposure and ingestion of high doses of manganese can affect the nervous and digestive systems, as well as the kidneys and lungs of humans [4]. Therefore, the elimination of manganese contamination from water has become necessary. There are numerous approaches to circumvent this environmental problem, including chemical precipitation, membrane filtration, ion exchange, adsorption, and ultraviolet irradiation [5]. Most of these processes have some shortcomings, such as low treatment capacity, sludge disposal, space requirements, complexity, and operating costs [6].

Adsorption is a widely used water treatment technique that can successfully remove various types of heavy metals [7]. The adsorption process is a highly efficient, simple, and environmentally friendly approach [8]. Moreover, the adsorption process can remove pollutants at low adsorbent concentrations, and it consumes little energy without producing sludge [9]. In the adsorption process, the metal adsorbate interacts with the surface of the solid adsorbent either physically or chemically, according to the intermolecular forces [7]. Various adsorbents based on different materials have been used to remove manganese from water. These include carbon material [10], zeolite [11], magnetic nanoparticles/polymer composites [4], cationic and non-ionic polymer gel composites loaded with iron hydroxide [12], EDTA-grafted Merrifield resin [13], etc. Recently, adsorbents from waste materials have been extensively studied for the treatment of metal-contaminated water [14]. Agricultural wastes such as rice husk ash [15], tea wastes [16], peanut husk [17], and orange peel [18] have been investigated as adsorbents. Industrial waste materials such as red mud [19], coal ash [20], and lignin [21] have also been used for manganese removal. The metal adsorption from aqueous solution on the adsorbents include physical adsorption, π–π interactions, hydrogen bond formation, electrostatic attractions, complexation, and ion exchange [1]. Hence, materials that offer proper pore size distribution, high specific surface area, a hydrophobic structure and polar functional groups could serve as efficient adsorbents for the dye removal from water [22].

Plastics are low-cost materials and are produced in enormous quantities [23]. Therefore, plastic waste has also been considered as a technically feasible adsorbent for the removal of pollutants from water [24]. For example, polystyrene waste has been chemically nitrated or sulfonated to remove heavy metals from aqueous solutions [24, 25]. Among plastics, polypropylene (PP) is produced in large quantities and used for many industrial applications because of its ease of processing, low cost, and good physical properties [23, 26]. However, PP lacks hydrophilicity and biodegradability, which may limit its potential applications [27]. Moreover, the accumulation of large amounts of PP waste may cause environmental problems [26]. Therefore, the conversion of PP waste into a useful adsorbent to remove pollutants from water could reduce the accumulation of residues [8]. The introduction of specific functional groups into the polymer by various surface treatments such as plasma [23] and wet chemical treatments [8, 28] can improve the polarity and hydrophilicity of the surface. These surface treatments have shown that they can improve the accessibility of the surface of the polymer to cations and colored materials [29, 30].

Recycling of flexible PP film waste is ignored by recycling companies and often ends up in landfills. These films are so thin and have a low bulk density that they are treated as uneconomical material [31]. Therefore, this work aimed to produce useful derivatives from flexible PP film waste using appropriate chemical modifications to serve as valuable adsorbents for Mn (II) ions from aqueous solutions. The collected flexible PP film wastes from the industry were converted into microparticles by a dissolution/precipitation approach. The obtained PP microparticles were either carboxylated or sulfonated to generate polar functional groups on the PP surface, which serve as binding sites for Mn (II) ions. The adsorption studies on carboxylated PP (CPP) and sulfonated PP (SPP) microparticles were carried out under different conditions such as pH, polymer dose, temperature, and concentration of Mn (II) ions in aqueous solutions. Kinetic and isotherm models were applied to the adsorption data to analyze the adsorption processes. The effects of surface functionality and nature of the two adsorbents on adsorption kinetics were investigated. In addition, the thermodynamic parameters of adsorption were evaluated to investigate the feasibility of the adsorption processes. As far as we know from the literature, this is the first comprehensive study on the adsorption behavior of metal ions, e.g., Mn (II), on acid-derivatized PP microparticles derived from waste.

Experimental

Materials

Polypropylene film waste (density = 0.92 g cm−3) was collected from Technopack Modern Packaging Products Co. in Cairo, Egypt. Nitric acid (70%), sulfuric acid (98%), p-xylene, and manganese chloride tetrahydrate were purchased from Sigma-Aldrich Co. (St Louis, MO, USA). KCl, acetone, and NaOH were purchased from El-Gomhoria Co. in Egypt.

Preparation of CPP and SPP microparticles

Film waste from PP was converted into microparticles as previously reported [8, 31]. For this purpose, the films were cut into small pieces, cleaned from impurities by washing with tap water, soap, and distilled water, and dried at 60 °C. The films were dissolved in p-xylene at 135 °C in a vessel equipped with a reflux condenser to produce PP solutions (5% by weight). The resulting solution was filtered, and the PP microparticles were precipitated by treating the filtrate with acetone. The microparticles were collected by filtration, washed with acetone, and dried at 60 °C. The xylene/acetone mixture was separated for reuse in a distillation column.

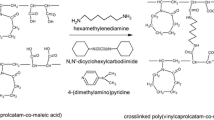

The recovered PP microparticles were then carboxylated or sulfonated as follows to produce CPP and SPP microparticles, respectively. SPP Microparticles were prepared by mixing recovered PP microparticles (3 g) with H2SO4 (98%, 75 mL) at 100 °C under reflux for 6 h [28]. The use of temperatures below 100 °C resulted in lower concentrations of acid groups. The prolonged treatment time at 100 °C did not significantly increase the concentration of acid groups on the polymer. After sulfonation, the mixture was cooled to room temperature and the SPP microparticles were obtained by filtration, washed with distilled water to neutral pH, and dried at 60 °C. CPP microparticles were prepared by mixing the recovered PP microparticles (3 g) with HNO3 (70%, 20 mL) for 6 h at 130 °C under reflux [8]. After cooling to room temperature, the CPP microparticles were collected by filtration, rinsed with distilled water to neutral pH, and finally dried at 60 °C.

Characterization of CPP and SPP

The properties of CPP and SPP microparticles were investigated using various characterization techniques. ATR-FTIR spectra were recorded with a Perkin-Elmer Spectrometer 400 (Perkin-Elmer Inc., Waltham, MA, USA) using a Golden Gate diamond single reflection device over the range 400–4000 cm−1 and with a resolution of 2 cm−1. The concentration of acid groups on CPP and SPP microparticles was estimated using a titrimetric method. Each sample (50 mg) was mixed with NaOH solution (0.1 mol L−1, 20 mL) and stirred for 24 h. The solution was then removed from the sample. The microparticles were separated by filtration, and excess NaOH was back-titrated with HCl (0.05 mol L−1). The concentration of acid groups (mmol g−1) was calculated as follows:

where M is the concentration of HCl solution (mmol L−1), V0 and Vs are the volumes of HCl solution (L) consumed by the blank solution and the sample solution, respectively, and m is the mass of microparticles (g).

The surface hydrophilicity of microparticles was studied following a previously described method for measuring the water contact angle (WCA) on the surface of polymer powders using the sessile drop technique [32]. Glass slides covered with a double-sided adhesive tape were used to hold the samples during the measurements. The microparticles were placed on the holder, and the excess microparticles were blown away with compressed air. The WCA measurements for the individual coated glass slides were performed using the FTA-200 goniometer (FOLIO instrument Inc., Kitchener, ON, USA). Since the measurements can be affected by the surface roughness of such specimens, five measurements were taken and averaged to obtain the final value. The standard deviation of these results was within 2°. The morphology of the microparticles was studied by SEM analysis using QUANTA FEG 250, USA. The average particle size and zeta potential of the microparticles were analyzed by DLS technique using a Malvern Zetasizer (Ver. 6.32, Malvern Instruments, Ltd.). The textural properties (specific surface area, pore volume, and pore size) were investigated by N2 sorption–desorption measurements using a Quantachrome TouchWin™ version 1.21 instrument. The specific surface area (SBET) was calculated using the Brunauer–Emmett–teller (BET) equation. The pore volume (VT) and pore size (D) were calculated using the Barrett–Joyner–Halenda (BJH) method. The zeta potentials (ζ) of the microparticles were measured using the Zetasizer (Ver. 6.32, Malvern Instruments, Ltd.). Samples were equilibrated in KCl electrolyte solution (0.001 M) for 2 h at 25 °C before measurements. The zero point of charge (pHPZC) of CPP and SPP microparticles, i.e., the pH at which the surface of the microparticles has no net electrical charge, was determined as follows. Each sample (100 mg) was mixed with KNO3 solutions (0.1 mol L−1, 25 mL) that had different initial pH values (pHinitial) ranging from 2 to 11. The pHinitial was adjusted by adding HNO3 (0.1 mol L−1) or NaOH (0.1 mol L−1) as needed. After stirring the microparticle-salt mixtures for 24 h, the pH was determined again (pHfinal). By plotting the values of pHinitial against ΔpH (pHinitial–pHfinal), pHPZC was determined to be the point at which ΔpH is zero. The thermal stability of the microparticles was investigated using a thermogravimetric analyzer (TGA-50H, Shimadzu, Columbia, USA) at a heating rate of 10 °C min−1 under an N2 atmosphere in the temperature range of 25–550 °C.

Adsorption experiments

Batch experiments were performed to study the adsorption of Mn (II) from aqueous solutions using CPP and SPP microparticles adsorbents. A solution of Mn (II) with a concentration of 100 mg L−1 was prepared (143 mg KMnO4 in 500 mL distilled water) and used to prepare other Mn (II) concentrations by appropriate dilution. In general, the adsorption experiments were performed with a polymer dose of 3 g L−1, a Mn (II) concentration of 20 mg L−1, pH at 6.5 and a temperature of 30 °C. Specific conditions were used to study the effects of pH (2–12), adsorbent dose (SPP: 0.25–4 g L−1; CPP: 0.25–9 g.L−1), contact time (10–150 min), and temperature (293–333 K). Different Mn (II) solutions with initial concentrations ranging from 10 to 40 mg.L−1 at a fixed dosage of microparticles of 3 g L−1, pH at 6.5, temperature of 30 °C, and contact time of 75 min were used to study the adsorption equilibrium. The adsorption experiment was performed each time by mixing the adsorbent with Mn (II) solution under specific conditions such as time, adsorbent dose, temperature and pH. The adsorption experiments were carried out in triplicate. After adsorption, the Mn (II) solution was separated, using a 0.45 µm filter membrane, and analyzed utilizing a Perkin-Elmer Model 214 flame atomic absorption spectrophotometer. The Mn (II) concentration before the adsorption process (Co, mg L−1) and the equilibrium concentration (Ce, mg L−1), the mass of the adsorbent (m, g), and the solution volume (V, L) were used to determine the adsorption efficiency (R%) and adsorption capacity (qe, mg g−1) values using Eqs. 2 and 3, respectively

Modeling the adsorption process

Kinetic analysis

Kinetic analysis of the experimental data was performed to investigate the mechanism of adsorption, equilibrium time, and rate-controlling steps. Kinetic models pseudo-first order (Eq. 4) [33], pseudo-second-order (Eq. 5) [34], intraparticle diffusion (Eq. 6) [35] and Elovich (Eq. 7) [36] were tested to fit the experimental data of the adsorption process.

where qt and qe (mg.g−1) are the adsorption capacity at time t and equilibrium, respectively; k1 and k2 (min−1) are the adsorption rate constants of pseudo-first-order, and pseudo-second-order models, respectively; Kid is the intraparticle diffusion rate constant (mg g−1 min0.5); Ci is the boundary layer thickness; α is the initial adsorption rate (mg g−1 min–1); β is the desorption constant (g mg−1).

Isotherm analysis

Adsorption isotherms describe the equilibrium conditions between the adsorbent and the adsorbate at a certain temperature. Different isotherms are employed to evaluate the capacity of adsorbents for adsorbates such as metal ions. In the current study, non-linear Freundlich (Eq. 8), Langmuir (Eq. 9) [37], and Dubinin-Radushkevich isotherm models (Eqs. 10–12) [38] were applied to the experimental results of the adsorption process.

where Ce is the equilibrium concentration of Mn (II) (mg L−1); qe is the adsorption capacity of the adsorbents at equilibrium time (mg g−1); qmax is the maximum Langmuir adsorption capacity of the adsorbent (mg g−1); KL is the Langmuir constant giving the adsorption energy and affinity of the binding sites (L mg−1); n is the adsorption intensity; KF is the Freundlich constant [mg g−1 (L mg−1)n]; qDR is a constant in the Dubinin-Radushkevich isotherm model which is related to adsorption capacity; ε is Polanyi potential; KDR (mol2 kJ−2) is Dubinin-Radushkevich constant related to the mean free energy of adsorption; R is gas constant (kJ mol−1 K−1), T is absolute temperature, and E is mean adsorption energy.

Desorption and reusability studies

Regeneration of the adsorbents was carried out using HCl (0.5 mol L−1) as the desorbing medium. Adsorbents microparticles (100 mg) were mixed with 50 mL Mn (VI) solution. After the adsorption processes, the adsorbents were separated from the solution of Mn (II) and mixed with HCl solution (50 mL) for a night at room temperature using a magnetic stirrer. The regenerated adsorbents were washed with distilled water and utilized for the subsequent adsorption-regeneration cycle. Each time, the residual concentration of Mn (II) that was not adsorbed was determined by a spectrophotometer to estimate the adsorption efficiency. The adsorption-regeneration processes were repeated for five cycles.

Results and discussion

Characteristics of acid-functionalized PP microparticles

FTIR analysis was used to determine the main functional groups acquired by PP microparticles obtained from film waste after sulfonation with sulfuric acid or carboxylation with nitric acid. In general, microparticles are known for their high specific surface area, which usually allows the detection of surface functional groups by FTIR analysis [39]. Figure 1 shows FTIR spectra for untreated PP, CPP, and SPP microparticles. All spectra show the characteristic absorption peaks corresponding to the structure of PP. The two peaks that appeared at 2867 and 2950 cm−1 are related to the symmetric and asymmetric stretching vibrations of the (–CH3) groups, respectively. The two peaks at 2838 and 2919 cm−1 are attributed to the symmetric and asymmetric stretching vibrations of the (–CH2) groups, respectively. The two peaks at 1372 and 1452 cm−1 correspond to the symmetric and asymmetric bending vibrations of the (–CH3) groups, respectively [23, 40]. The presence of all these peaks in the spectra confirms the chemical structure of PP microparticles obtained from waste films and the ability of PP microparticles to survive treatment with sulfuric and nitric acids. Compared to the spectrum of PP microparticles, the spectrum of SPP microparticles showed new peaks at 585, 1038 and 1218 cm−1 attributed to the stretching of S = O from –SO3H groups [41]. In addition, a broad-band peak appeared in the range 3000–3670 cm−1 with a maximum at 3363 cm−1 corresponding to the –OH groups in the -SO3H groups. Other peaks were observed in the spectra of the microparticles of SPP, indicating the presence of other functional groups besides the –SO3H groups. A band corresponding to C = O was observed at 1700 cm−1, which could be due to a slight oxidation of PP by sulfonation [41, 42]. Another broad band and a shoulder were detected at 1630 and 880 cm−1, respectively, assigned to C = C vibrations [42]. The presence of C = C resulted in the appearance of SPP microparticles with a deep brown color. The observation of C = O and C = C together with -SO3H groups, as well as the change in the color of PP after sulfonation, has also been reported previously [41, 42]. Sulfonation is thought to involve electrophilic S atoms attacking C atoms and forming—SO3H groups at PP chains that decompose at high temperatures to form reactive carbon intermediates that are either oxidized to form COOH groups or aromatized to form C = C groups [41, 43]. The resulting carbonaceous material could then interact with H2SO4 to form—SO3H on the surface of PP [42].

In the case of CPP microparticles, the spectrum contains new peaks that are not present in the original spectrum of PP. These peaks appear at 1707 and 1551 cm−1, corresponding to the carboxyl (–COOH) and nitro (-NO2) groups, respectively, formed after surface carboxylation [44]. There is also a broad band centered at 3270 cm.−1 that correspond to the hydroxyl group in − COOH groups [45]. In previous reports, it has been shown that treatment of PP with nitric acid causes oxidative degradation of the PP chains through –CR2–H (R is an alkyl group) at the expense of the amorphous domains, followed by nucleophilic substitution on the tertiary carbon atoms forming the carboxyl groups [44, 45]. The resulting polymer should have a general structure with two carboxylic acid groups and two nitro groups at the end of the polymer chain and other nitro groups along the polymer [41].

The concentrations of acid groups on CPP and SPP microparticles were quantified by a titrimetric method. CPP and SPP microparticles had 3.25 and 100.45 mmol of acid groups per gram of microparticles, respectively. Further extension of treatment time did not result in any significant change in acid group concentration. Sulfonation was a more efficient process for generating high concentrations of acid groups (both –COOH and –SO3H groups) on the surface of the microparticles than carboxylation (–COOH groups only). It has been previously reported that nitro groups contribute to the adsorption of cationic species from aqueous solutions [8]. Therefore, their amount on CPP microparticles was also estimated from FTIR analysis (Fig. 1), as previously reported [8, 44]. The NO2/COOH molar ratio for CPP was determined from the observed absorbances after correction with the extinction coefficient ratio (0.83) for NO2/COOH in 12-nitrododecanoic acid as a model compound [44]. CPP microparticles showed 2.71 mmol NO2 per gram of microparticles.

The presence of functional groups and surface hydrophilicity can be determined by WCA measurements [29]. Solids with high hydrophilicity can achieve good dispersibility in an aqueous medium and high adsorption capacity [8]. PP has a highly hydrophobic surface because there are no functional groups on its surface. It is expected that the incorporation of polar groups such as –COOH and –SO3H groups will increase the hydrophilicity of the surface. Surfaces that have a WCA value of less than 90° are considered hydrophilic [46]. The results of WCA measurements on untreated PP, CPP, and SPP microparticles were 99.5°, 80°, and 61°, respectively. The significant decrease in WCA after carboxylation and sulfonation treatments was attributed to the formation of polar –COOH and –SO3H groups on the surface. Films based on SPP microparticles, which have a higher concentration of polar groups, showed higher hydrophilicity than films based on CPP microparticles.

Figures 2a–c show the SEM observations for untreated PP, CPP and SPP microparticles. All microparticles exhibited a spherical shape. When the microparticles were viewed at higher magnification (Figs. 2a'–c', 12 kX), it was observed that the surfaces of both PP and CPP microparticles appeared to be rougher and more porous than the surface of SPP microparticles, which appeared to be smoother and more compact. The average size and size distribution of the microparticles were investigated using the DLS technique (Figs. 3a–c). The observed average hydrodynamic sizes for PP, CPP, and SPP microparticles are 0.453, 0.761, and 1.1 µm, respectively. The increase in hydrodynamic volume after surface treatment could be due to the mutual interactions between the acid functional groups and the water molecules. SPP microparticles with the highest concentrations of acid groups exhibited the largest hydrodynamic size.

The surface area and pore structure of microparticles were determined because they can affect the adsorption capacity of the adsorbent [47]. A large surface area, a porous structure, and a high percentage of active sites are desirable to perform the adsorption process efficiently [48]. The results of the BET analysis for microparticles are summarized in Table 1. As expected, PP and CPP particles with rough surfaces have a larger surface area and thus a larger surface area to volume ratio than SPP microparticles. All samples had pore diameters less than 50 nm, indicating that CPP and SPP microparticles have mesoporous structures (pore size 2–50 nm) suitable for adsorption applications.

The zero-point charge (pHPZC) of CPP and SPP microparticles was evaluated to determine the optimal pH that can provide the appropriate medium to maximize the electrostatic interactions between the adsorbent and the adsorbate. CPP and SPP microparticles showed pHPZC values of 4.9 and 3.8, respectively. This indicates that CPP and SPP microparticles exist in their protonated form in acidic media at pH values below pHPZC and do not exhibit a strong tendency to bind cationic species. Therefore, pH values above pHPZC are expected to stimulate the deprotonation of microparticles that provide negatively charged surfaces for more efficient binding of cations. The zeta potentials of the microparticles were also measured at neutral pH (Fig. 4). Untreated PP, CPP and SPP microparticles exhibited negative zeta potential values of − 0.048, − 13.6 and − 55.3 mV, respectively. These results indicate that a large number of dissociated surface acidic groups are present on CPP and SPP microparticles even at neutral pH, without being completely neutralized by positive ions present in the medium used during the analysis [49]. It was concluded that the negatively charged CPP and SPP microparticles might have a strong tendency to interact with positive ions in the aqueous solutions such as Mn (II). It was also expected that SPP microparticles (ζ = − 55.3 mV) would show a higher tendency to positive ions than CPP microparticles (ζ = − 13.6 mV). The significant difference between the observed values of ζ could be attributed to the fact that SPP microparticles contain more acid groups than CPP microparticles.

The thermal stability of microparticles was studied by thermogravimetric analysis. The resultant TGA curves and their derivatives (DTGA) are shown in Fig. 5. The temperature of initial decomposition Td (1%) (temperature at which 1% of mass loss occurs), and the temperature of maximum decomposition rate Tmax (temperature at which the rate of decomposition is at highest) were estimated and reported in Table 2. All TGA curves showed a one-step mass loss. It was found that the CPP sample had the lowest Td (1%). This can be attributed to the presence of short polymer chains formed by the oxidative degradation of PP by nitric acid [44]. It seems that these chains had low thermal stability and started to degrade at a relatively low temperature. This could also explain why the CPP microparticles had the lowest residue (by weight percent). However, the SPP microparticles exhibited a Td (1%) that was slightly higher than that of untreated PP microparticles. Moreover, SPP microparticles exhibited the highest Tmax. The higher thermal stability of SPP microparticles compared to other samples might be due to the crosslinking of polymer chain segments that occurs during the sulfonation process [50].

Adsorption studies of Mn (II)

Influence of operational parameters

The effects of different operating parameters on the adsorption behavior of Mn (II) ions on CPP and SPP microparticles were investigated in a batch process to determine the optimal adsorption conditions. These parameters include the dose of adsorbent, the contact time, and the solution pH. The effects of these parameters on the removal efficiency of CPP and SPP microparticles are shown in Fig. 6.

Effects of operating parameters on adsorption capacity (q) and efficiency (R, %) of CPP and SPP microparticles at 30 °C: a adsorbent dose (SPP: 0.25–4 g L−1, CPP: 0.25–9 g L−1); b contact time; c pH. Conditions: Mn (II) = 20 mg L−1; b and c adsorbent dose = 3 g L−1; a and (b): pH = 6.5; a contact time = 2 h and c contact time = 0.5 h

Influence of CPP and SPP doses

Increasing the dose of adsorbents, CPP and SPP microparticles, had a positive effect on the removal efficiency (R%) of Mn (II) from aqueous solutions (Fig. 6a). A dose of 3 g L−1of SPP microparticles was required to adsorb 98% of Mn (II) from its aqueous solution (20 mg L−1) after 2 h at 30ºC. Under the same conditions, a dose of 3 g L−1 from CPP could adsorb only about 63.5% of Mn (II) from the solution. However, complete adsorption of Mn (II) was achieved by using 9 g L−1 CPP microparticles. The increase in adsorption with increasing the adsorbent dose is explained by an increase in the number of available binding sites for adsorbate uptake. The higher efficiency of SPP microparticles over CPP microparticles could be due to the differences in the amount and type of binding sites on both. SPP microparticles contain a higher amount of acid groups than CPP microparticles. In addition, sulfonic acid groups on SPP microparticles are more active than carboxyl groups in accepting positively charged ions from solutions. In addition, the C = C bonds on SPP microparticles could contribute to the adsorption process as will be shown later. It has also been previously reported that the double bonds are involved in the adsorption processes of cations [8]. Based on these findings and in order to compare the adsorption behavior of SPP and CPP microparticles, further adsorption experiments were performed with microparticles at a dose of 3 g L−1.SPP microparticles showed a higher adsorption capacity than CPP microparticles. Increasing the dose of adsorbents showed negative effects on the adsorption capacity (qe) of the adsorbents (Fig. 6a). These findings reveal the unsaturation of adsorption sites affects adsorption during the adsorption process. Higher adsorbent/adsorbate concentration ratios accelerate the adsorption process and decrease the concentration of the adsorbate in the solution more than in the case of lower adsorbent/adsorbate concentration ratios. Therefore, the decrease in the values of qe when the adsorbent dose is increased could be due to the splitting of the flux or the concentration gradient between the adsorbate concentration in the solution and the concentration on the adsorbent [37]. High dosage of adsorbent could also lead to aggregation of microparticles, which decreases the available surface area of the adsorbent. Hence, the adsorption capacity of Mn (II) on both SPP and CPP microparticles decreases with increasing the dose of microparticles.

Influence of contact time

The influence of contact time on the adsorption behavior of CPP and SPP microparticles was investigated to understand the adsorption–desorption equilibrium that occurs during adsorption. The study was conducted with an adsorbent dose of 3 g L−1 and an initial concentration of Mn (II) of 20 g L−1 at 30 ºC. The increase in the values of R (%) and qt of Mn (II) with contact time was rapid for SPP microparticles compared to CPP microparticles. After the first hour of adsorption, the R (%) values were 50% for CPP and 70% for SPP microparticles. The values of R (%) increased rapidly and continuously and reached 98% after 1.5 h of adsorption in the case of SPP microparticles. This means that under these adsorption conditions, there were many active and available binding sites on SPP microparticles during the adsorption process. However, the values of R (%) increased only slightly until they reached 63.5% in the case of CPP microparticles after 2 h of the adsorption process. Further increase in the contact time to 3 h resulted in a slight increase in adsorption (R = 65%). It appears that the adsorbing sites on the CPP microparticles were saturated during the first 2 h of adsorption. The changes in the qt values of the adsorbents with contact time showed a similar trend to the changes in R (%). Initially, a rapid increase in qt values was observed, which then slowed with time.

Influence of pH

The effect of changing the pH of aqueous Mn (II) solutions from 2 to 12 on R (%) and qt of SPP and CPP microparticles is shown in Fig. 6c. Adsorption of Mn (II) from acidic solutions (pH ≤ 4) was not efficient. This can be explained by the fact that both CPP and SPP microparticles are in their protonated form at these pH values. Both R(%) and qt of SPP and CPP microparticles increased significantly with increasing pH of the medium. Apparently, the increase in pH from acidic to basic values stimulated the deprotonation of the acid groups on the surface of the derivatized microparticles. Accordingly, these microparticles tended to acquire more negative charges on their surface by increasing the pH of the medium. This in turn enhanced the electrostatic interactions between such negatively charged microparticles and the positively charged Mn (II) ions in the solution, thus increasing the adsorption efficiency. The adsorption processes were carried out at different pH values for 30 min. Longer contact times resulted in a slight increase in the removal rate of Mn (II) from the aqueous solutions, especially at pH values above 7. This is probably due to the adsorption of sodium counter-ions from the sodium hydroxide used to adjust the pH of the medium together with Mn (II). Accordingly, further adsorption processes were carried out at neutral pH.

Kinetic studies

The fit of the adsorption data of Mn (II) to CPP and SPP microparticles with the kinetic models (Eqs. 4–7) is shown in Fig. 7. The parameters derived from these kinetic models are listed in Table 3. The pseudo-second-order model showed higher correlation coefficients (R2 > 0.99) than the pseudo-first order-model. Moreover, the calculated adsorption capacities (qe,cal) of the pseudo-second-order model are close to the experimental capacities (qe,exp). Therefore, the pseudo-second-order model could fit the adsorption data of Mn (II) on CPP and SPP microparticles better than the pseudo-first-order model. The possibility of the occurrence of intraparticle diffusion during adsorption was investigated by applying the Weber and Morris kinetic model (Eq. 6) to the adsorption data. This model can define the mechanism and the rate-limiting step of the adsorption process. In this model, the correlation between the extent of adsorption and the square root of the contact time (t0.5) rather than (t) is examined. When a plot of qt versus t0.5 gives a straight line through the origin, intraparticle diffusion is considered to be the only rate-controlling step [51]. In this study, two intersecting lines instead of one were observed in the plot of qt versus t0.5 (Fig. 7b). This indicates that the adsorption process involved two limiting steps, namely surface adsorption and intraparticle diffusion, which controlled the adsorption rate [52]. Surface adsorption occurred at t0.5 below 8.43 and 10.54 min0.5 for CPP and SPP microparticles, respectively, followed by intraparticle diffusion at larger values of t0.5. The values of the rate constants for surface adsorption (ki1) and intraparticle diffusion (ki2) for both adsorbents are listed in Table 3. Obviously, the intraparticle diffusion was not the only rate-limiting step, although it occurred at a lower rate than surface adsorption (ki2 < ki1). SPP microparticles showed the highest ki1value, which reveals that the surface adsorption is fastest for SPP microparticles. CPP microparticles showed higher ki2 than SPP microparticles, indicating that intraparticle diffusion is a larger contributor in the case of CPP microparticles. The different behavior of the two adsorbents could be due to their different surface chemistry and texture properties. SPP microparticles offer the highest surface functionalities for surface interactions with cations, while CPP microparticles provide the largest surface area and pore volume for cation diffusion.

Adsorption isotherm

The adsorption equilibrium of Mn (II) on CPP and SPP microparticles was investigated by starting the adsorption experiments with different initial concentrations of aqueous Mn (II) solutions. The observed adsorption data were analyzed using Freundlich, Langmuir, and Dubinin-Radushkevich adsorption isotherms as shown in Fig. 8. The derived parameters of these isotherms are listed in Table 4. The Langmuir adsorption isotherm had higher values for the regression coefficient (R2) than the Freundlich isotherm. This means that the Langmuir adsorption isotherm can describe the adsorption process better than the Freundlich isotherm. The maximum adsorption capacities (qmax) estimated from the Langmuir isotherm for CPP and SPP microparticles at 30 °C were 5.51 and 9.15 mg g−1, respectively. The numerical value of adsorption energy (E) estimated from the Dubinin-Radushkevich isotherm model (Eq. 12), can be used to determine the type of adsorption. Lower values of E than 8 kJ mol−1 indicate a physisorption process, whereas higher values than 8 kJ mol−1 indicate chemisorption [38]. The observed values for E are well below 8 kJ mol−1 (Table 4), indicating that the adsorption processes are physisorption. Table 5 provides a comparison between the values of qmax obtained in this study and those reported in the literature.

The feasibility of adsorption processes can be studied by estimating the equilibrium parameter (RL) based on Langmuir constant KL and the initial concentration of Mn (II) (Co, mg L−1) using Eq. 13.

Adsorption is favorable for 0 < RL < 1, irreversible for RL = 0, unfavorable for RL > 1, and linear for RL = 1 [57]. The obtained values of RL for Mn (II) adsorption onto SPP and CPP microparticles were in the range of 0.28 to 0.10 and 0.35 to 0.14, respectively. These values mean that the adsorption process is favorable.

Thermodynamic studies

The temperature change could affect the diffusion of adsorbate ions at the adsorption sites on the adsorbent. The effect of increasing the temperature from 20 °C (298 K) to 50 °C (323 K) on the adsorption behavior of Mn (II) on derivatized microparticles is shown in Fig. 9. The removal efficiency was increased with increasing temperature (Fig. 9a). It seems that the mobility and diffusion of manganese ions increases with increasing temperature, resulting in more interactions between manganese ions and the active sites on CPP and SPP microparticles. Accordingly, the adsorption processes of Mn (II) on CPP and SPP microparticles were endothermic. The thermodynamic parameters, namely the entropy change (ΔS), enthalpy changes (ΔH) and Gibbs free energy change (ΔG) for the adsorption processes were derived using the partition coefficient (Kp) using Eqs. 14–17.

Kp can be defined as:

where as and ae are the activities of Mn (II) adsorbed on the adsorbent and in solution at equilibrium, respectively, γs and γe are the activity coefficients of adsorbed Mn (II) adsorbed on the adsorbent and in solution at equilibrium, respectively, and Cs and Ce are the concentrations of adsorbed Mn (II) adsorbed on the adsorbent and in solution at equilibrium (mg L−1), respectively.

If the concentration of the adsorbate in the solution approaches zero (Cs → 0 and Ce → 0), the activity of coefficient γ approaches unity, and Eq. 15 can be written as:

The Kp values can be obtained by plotting ln (Cs/Ce) against Cs and extrapolating Ce against zero. The intercept of the straight line with the vertical axis gives Kp. The value of ΔG can be calculated directly using Eq. 14. The van’t Hoff plot (ln Kp versus (1/T) (Eq. 15, Fig. 9b) can be used to determine the values of ΔS and ΔH from the intercept (\(\frac{\Delta S}{R}\)) and the slopes (\(\frac{-\Delta H}{R}\)) of the resultant straight lines. The results of ΔS, ΔH and ΔG corresponding to the adsorption processes are summarized in Table 6. The positive values observed for ΔH reveal the endothermic nature of Mn (II) adsorption on CPP and SPP microparticles. The adsorption processes also exhibited positive values for ΔS, indicating an increase in the randomness at the adsorbent/adsorbate interfaces during the adsorption processes. ΔG of adsorption exhibited negative values at all temperatures. The spontaneity (increase in the negativity of ΔG values) increased with increasing temperature. This confirms the high tendency of adsorbents to Mn (II), and the adsorption processes were spontaneous, feasible and could be improved by increasing temperature.

Mechanism of adsorption

To investigate the types of interactions that may take place during the adsorption of Mn (II) on surface functionalized PP microparticles, microparticles loaded with Mn (II) were studied by FTIR analysis. The spectra are reported in Fig. 10 in comparison with unloaded microparticles. To investigate the functional groups involved in the adsorption process, the areas of the peaks of interest were normalized to the area of the peak at 1453 cm−1 as an internal reference peak. It was found that the normalized peak area of − COOH and − NO2 groups decreased from 0.54 to 0.42 and from 0.95 to 0.77, respectively, after adsorption of Mn (II) ions on CPP microparticles (Fig. 10a). On the other hand, the normalized area of the peak at 590 cm−1 corresponding to − SO3H group decreased from 0.796 to 0.624 after adsorbing Mn (II) ions on SPP microparticles (Fig. 10b). In addition, the normalized area of the peaks corresponding to both C = C and − COOH in the range between 1500 and 1845 cm−1 decreased from 1.123 to 0.684 after adsorption. It can be concluded that the − COOH and − NO2 groups on CPP microparticles as well as acid and C = C groups on SPP microparticles were involved in the adsorption processes. The adsorption processes were carried out at pH of 6.5, which is greater than the pHPZC of the microparticles. Therefore, it is expected that the acid groups acquire negative charges due to surface deprotonation. Therefore, the negatively charged carboxylate and sulfonate groups appear to interact with the manganese ions through electrostatic interactions [8]. In addition, electron exchange, sharing, or transfer may also occur to form a chemical bond between deprotonated acid groups and cations [58]. The C = O (of carboxylates), S = O (of sulfonates), and C = C groups could serve as active binding sites for the adsorption of Mn (II) through electron acceptor/donor interactions. Electrostatic interactions may also occur between the electron-rich groups such as NO2 and C = C and positive ions such as Mn (II)[59]. Accordingly, electrostatic interactions could occur first, allowing the adsorbate to approach the surface of the adsorbent. This in turn enables some chemical interactions to occur between the adsorbate and the adsorbent.

Regeneration studies

Desorption studies provide an understanding of the nature of adsorption and the reusability of the adsorbent. Both CPP and SPP microparticles showed low adsorption efficiency of Mn (II) in acidic media (Fig. 6c). Therefore, an aqueous HCl solution was used to regenerate CPP and SPP microparticles. The observations showed that HCl could desorb Mn (II) from the surface of the adsorbents. It seems that the H3O+ ions generated in the acidic medium were probably adsorbed on the surface of the adsorbents, resulting in electrostatic repulsions between positively charged adsorbents and Mn (II). This in turn stimulated the desorption of Mn (II) from the surface of the adsorbents. The desorption and reusability of the adsorbents toward Mn (II) were studied in five cycles. The successive removal efficiencies of the adsorbents are shown in Fig. 11. A decrease in the removal efficiency of the regenerated microparticles was observed, indicating that the adsorption processes were not fully reversible. This means that there may have been strong interactions between the adsorbents and the Mn (II) ions. The strongly adsorbed Mn (II) ions on the surface of the microparticles appeared to resist the desorption process. However, the ability to achieve removal efficiencies of 79% and 53% following 5 cycles of adsorption–desorption in the case of SPP and CPP microparticles, respectively, indicates the reusability of the microparticles.

Application to real wastewater samples

The performance of CPP and SPP microparticles in the uptake of Mn (II) ions from real wastewater obtained from Abu Zaabal for Fertilizers and Chemicals Company ([Mn (II)] = 17.2 mg L−1) was investigated. The removal efficiency of Mn (II) from these samples on CPP or SPP microparticles (adsorbent dose 10 g L−1, at 25 °C for 4 h) was found to be 83.5% and 68.7%, respectively. To achieve proper uptake of Mn (II) from such real wastewater samples, higher doses of microparticles were required than in the case of synthetic samples. This may be attributed to the acidic nature (pH 3.5) of real wastewater samples and the presence of other extraneous ions (cations and anions) that may interfere and compete in the adsorption processes. The achieved removal efficiencies of SPP and CPP microparticles indicate the suitability of the acid-derivatized PP microparticles for the removal of Mn (II) ions from wastewater.

Conclusion

In the present study, the feasibility of using carboxylated and sulfonated polypropylene microparticles obtained from wastes to treat water contaminated with Mn (II) was investigated. Sulfonation and carboxylation of PP microparticles under controlled time and temperature conditions improved surface hydrophilicity and zeta potential through the formation of functional groups, e.g., acid, nitro, and C = C groups on the surface. Derivatized microparticles exhibited a large surface area and a mesoporous structure. These properties of derivatized microparticles enable the uptake of Mn (II) from aqueous solutions. Increasing the adsorbent dose, pH, contact time and temperature favored the adsorption processes. Application of kinetic models to the adsorption data revealed that the adsorption processes followed the pseudo-second-order model and were controlled by both surface adsorption and intra-particle diffusion. SPP microparticles have the highest surface functionalities for surface adsorption of cations, while CPP microparticles provide the most suitable texture for cationic diffusion. SPP microparticles showed higher maximum adsorption capacity (9.15 mg g−1) compared to CPP microparticles (5.51 mg g−1) due to the synergy between the –COOH, –SO3H and C = C groups which exist in high concentrations on SPP microparticles. Fitting the adsorption data with the isotherm models showed that the adsorption processes followed the Langmuir isotherm. The observed values for the thermodynamic parameters of the adsorption process proved the endothermic nature of the process (ΔH = + 54.94 and + 79.84 kJ.mol−1 for CPP and SPP, respectively), the increase in randomness (ΔS = + 11.40 and + 24.45 J mol−1 K−1 for CPP and SPP, respectively), and spontaneity and feasibility of the adsorption (ΔG = − 1.32 and − 1.46 kJ mol−1 at 20 °C for CPP and SPP, respectively). Preliminary treatment of real wastewater showed that adsorbents have the potential to effectively remove Mn (II) from real wastewater. Therefore, sulfonation or carboxylation of polypropylene waste can lead to valuable materials that contribute to the removal of heavy metals from water and reduce the volume of waste.

References

Janani R, Gurunathan B, Sivakumar K, Varjani S, Ngo HH, Gnansounou E (2022) Advancements in heavy metals removal from effluents employing nano-adsorbents: way towards cleaner production. Environ Res 203:111815. https://doi.org/10.1016/j.envres.2021.111815

Rudi NN, Muhamad MS, Te Chuan L, Alipal J, Omar S, Hamidon N, Hamid NH, Sunar NM, Ali R, Harun H (2020) Evolution of adsorption process for manganese removal in water via agricultural waste adsorbents. Heliyon 6:e05049. https://doi.org/10.1016/j.heliyon.2020.e05049

Deniz F (2022) Green purification of heavy metal pollution from aquatic environment by biorefinery waste biomass of Nigella sativa L.: A novel and effective treatment agent. Environ Technol Innov 25:102118. https://doi.org/10.1016/j.eti.2021.102118

Zheng M, Wei Y, Ren J, Dai B, Ma M, Li T, Ma Y (2021) 2-Aminopyridine functionalized magnetic core-shell Fe3O4@polypyrrole composite for removal of Mn (VII) from aqueous solution by double-layer adsorption. Sep Purif Technol 277:119455. https://doi.org/10.1016/j.seppur.2021.119455

Rajendran S, Priya TA, Khoo KS, Hoang TK, Ng HS, Munawaroh HS, Karaman C, Orooji Y, Show PL (2022) A critical review on various remediation approaches for heavy metal contaminants removal from contaminated soils. Chemosphere 287:132369. https://doi.org/10.1016/j.chemosphere.2021.132369

Feng X, Long R, Wang L, Liu C, Bai Z, Liu X (2022) A review on heavy metal ions adsorption from water by layered double hydroxide and its composites. Sep Purif Technol 284:120099. https://doi.org/10.1016/j.seppur.2021.120099

Fei Y, Hu YH (2022) Design, synthesis, and performance of adsorbents for heavy metal removal from wastewater: a review. J Mater Chem A 10:1047–1085. https://doi.org/10.1039/d1ta06612a

Bakry A, Darwish MSA, Hassanein TF (2022) Adsorption of methylene blue from aqueous solutions using carboxyl/nitro-functionalized microparticles derived from polypropylene waste. Iran Polym J 31:185–197. https://doi.org/10.1007/s13726-021-00979-w

Bakry A, Adel M, El Naggar A, Helal MH (2022) Nickel hydroxide/polystyrene composites for adsorptive removal of Fe (III) and methylene blue from aqueous solutions. Egypt J Chem 65:605–615. https://doi.org/10.21608/EJCHEM.2021.105565.4937

Embaby MA, Abdel Moniem SM, Fathy NA, El-kady AA (2021) Nanocarbon hybrid for simultaneous removal of arsenic, iron and manganese ions from aqueous solutions. Heliyon 7:e08218. https://doi.org/10.1016/j.heliyon.2021.e08218

Meiramkulova K, Kydyrbekova A, Devrishov D, Nurbala U, Tuyakbayeva A, Zhangazin S, Ualiyeva R, Kolpakova V, Yeremeyeva Y, Mkilima T (2023) Comparative analysis of natural and synthetic zeolite filter performance in the purification of groundwater. Water 15:588. https://doi.org/10.3390/w15030588

Safi SR, Gotoh T (2021) Simultaneous removal of arsenic and manganese from synthetic aqueous solutions using polymer gel composites. Nanomaterials 11:1032. https://doi.org/10.3390/nano11041032

López OR, Ortega HS, Navarro RE, Valenzuela-García JL, Machi L, Quiroz-Castillo JM (2023) Effect of spacer on the mechanism of metal adsorption in EDTA supported on a polymeric resin. Results Mater. https://doi.org/10.1016/j.rinma.2023.100369

Paranjape P, Sadgir P (2023) Heavy metal removal using plant origin biomass and agricultural waste-derived biomass from aqueous media: a review. Water Conserv Sci Eng 8:9

Adekola FA, Hodonou DSS, Adegoke HI (2016) Thermodynamic and kinetic studies of biosorption of iron and manganese from aqueous medium using rice husk ash. Appl Water Sci 6:319–330. https://doi.org/10.1007/s13201-014-0227-1

Badrealam S, Darrell VC, Dollah Z, Latiff MMHR (2019) Adsorption of manganese and zinc in synthetic wastewater by tea waste (TW) as a low cost adsorbent. J Phys Conf Ser 1349:012061. https://doi.org/10.1088/1742-6596/1349/1/012061

Zaini H, Sami M, Arifin R (2019) Activated variation of adsorbent and variation of contact time effects on manganese (II) in groundwater by column system using peanut shell as bioadsorbent. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/536/1/012092

Surovka D, Pertile E (2017) Sorption of iron, manganese, and copper from aqueous solution using orange peel: optimization, isothermic, kinetic, and thermodynamic studies. Polish J Environ Stud 26:795–800. https://doi.org/10.15244/pjoes/60499

Liu J, Huang Z, Chen J, Sun Y, Gao EW (2020) Resource utilization of swine sludge to prepare modified biochar adsorbent for the efficient removal of Pb (II) from water. J Clean Prod 257:120322. https://doi.org/10.1016/j.jclepro.2020.120322

Ma J, Qin G, Zhang Y, Sun J, Wang LJ (2018) Heavy metal removal from aqueous solutions by calcium silicate powder from waste coal fly-ash. J Clean Prod 182:776–782. https://doi.org/10.1016/j.jclepro.2018.02.115

Ge ZL (2018) Application of lignin and its derivatives in adsorption of heavy metal ions in water: a review. ACS Sustain Chem Eng 6:7181–7192. https://doi.org/10.1021/acssuschemeng.8b01345

Vishnu D, Dhandapani B, Authilingam S, Sivakumar SV (2022) A comprehensive review of effective adsorbents used for the removal of dyes from wastewater. Curr Anal Chem 18:255–268. https://doi.org/10.2174/1573411016999200831111155

Morsy FA, Elsayad SY, Bakry A, Eid MA (2006) Surface properties and printability of polypropylene film treated by an air dielectric barrier discharge plasma. Surf Coatings Int Part B Coatings Trans 89:49–55. https://doi.org/10.1007/BF02699614

Tran AT, Pham TT, Nguyen QH, Hoang NT, Bui DT, Nguyen MT, Nguyen MK, Van der Bruggen B (2020) From waste disposal to valuable material: Sulfonating polystyrene waste for heavy metal removal. J Environ Chem Eng 8:104302. https://doi.org/10.1016/j.jece.2020.104302

Mahmoud ME, Abdou AEH, Ahmed SB (2016) Conversion of waste styrofoam into engineered adsorbents for efficient removal of cadmium, lead and mercury from water. ACS Sustain Chem Eng 4:819–827. https://doi.org/10.1021/acssuschemeng.5b01149

Thiounn T, Smith RC (2020) Advances and approaches for chemical recycling of plastic waste. J Polym Sci 58:1347–1364. https://doi.org/10.1002/pol.20190261

Zhang C, Bai Y, Liu W (2014) The approaches for promoting PP adhesion based on the surface modification. J Adhes Sci Technol ISSN 28:454–465. https://doi.org/10.1080/01694243.2013.838826

Bakry A, Elmesallamy SM (2022) Sulfonated polypropylene microparticles from waste as adsorbents for methylene blue: kinetic, equilibrium, and thermodynamic studies. Sep Sci Technol 57:2374–2392. https://doi.org/10.1080/01496395.2022.2064874

Bakry A (2021) Synergistic effects of surface aminolysis and hydrolysis on improving fibroblast cell colonization within poly (L-lactide) scaffolds. J Appl Polym Sci 138:49643. https://doi.org/10.1002/app.49643

Bakry A (2019) Synergistic effects of surface grafting with heparin and addition of poly(d, l-lactide) microparticles on properties of poly(l-lactide) single crystals scaffolds. J Appl Polym Sci 136:47797. https://doi.org/10.1002/app.47797

Poulakis JG, Papaspyrides CD (1997) Recycling of polypropylene by the dissolution/reprecipitation technique: I. A model study Resour Conserv Recycl 20:31–41. https://doi.org/10.1016/S0921-3449(97)01196-8

Dove JW, Buckton G, Doherty C (1996) A comparison of two contact angle measurement methods and inverse gas chromatography to assess the surface energies of theophylline and caffeine. Int J Pharm 138:199–206. https://doi.org/10.1016/0378-5173(96)04535-8

Lagergren SK (1898) About the theory of so-called adsorption of soluble substances. Sven Vetenskapsakademiens Handl 24:1–39

Ho YS, McKay G (1999) Pseudo-second order model for sorption processes. Process Biochem 34:451–465. https://doi.org/10.1016/S0032-9592(98)00112-5

Weber WJ, Morris JC (1963) Kinetics of adsorption on carbon from solution. J Sanit Eng Div 89:31–60. https://doi.org/10.1061/JSEDAI.0000430

Low MJD (1960) Kinetics of chemisorption of gases on solids. Chem Rev 60:267–312. https://doi.org/10.1021/cr60205a003

Vadivelan V, Vasanth Kumar K (2005) Equilibrium, kinetics, mechanism, and process design for the sorption of methylene blue onto rice husk. J Colloid Interface Sci 286:90–100. https://doi.org/10.1016/j.jcis.2005.01.007

Dubinin MM, Radushkevich LV (1947) The equation of the characteristic curve of the activated charcoal USSR Phys. Chem Sect 55:331

Bakry A, Martinelli A, Bizzarri M, Cucina A, D’Ilario L, Francolini I, Piozzi A, Proietti S (2012) A new approach for the preparation of hydrophilic poly(L-lactide) porous scaffold for tissue engineering by using lamellar single crystals. Polym Int 61:1177–1185. https://doi.org/10.1002/pi.4197

Haji A, Shoushtari AM, Abdouss M (2015) Desalination and water treatment plasma activation and acrylic acid grafting on polypropylene nonwoven surface for the removal of cationic dye from aqueous media. Desalin Water Treat 53:3632–3640. https://doi.org/10.1080/19443994.2013.873350

Tada H, Ito S (1997) Conformational change restricted selectivity in the surface sulfonation of polypropylene with sulfuric acid. Langmuir 13:3982–3989. https://doi.org/10.1021/la960885l

Matos JP, Terezinha M, Sansiviero C, Lago RM (2010) Surface chemical modification of polypropylene fiber waste by H2SO4: mechanistic investigation and application as cation-exchange adsorbent. J Appl Polym Sci 115:3586–3591. https://doi.org/10.1002/app

Ecevit ST, Aras L, Tinçer T (2008) Synthesis and characterization of surface sulfonated polypropylene films. J Adhes Sci Technol 22:1285–1299. https://doi.org/10.1163/156856108X319818

Fu P, Tomalia MK (2004) Carboxyl-terminated isotactic polypropylene:preparation, characterization, kinetics, and reactivities. Macromolecules 37:267–275. https://doi.org/10.1021/ma0303061

Urbaniak-domagala W (2011) Pretreatment of polypropylene films for the creation of thin polymer layers: Part 1-the use of chemical, electrochemical, and UV methods. J Appl Polym Sci 122:2071–2080. https://doi.org/10.1002/app

Bakry A, Darwish MSA, El Naggar AMA (2018) Assembling of hydrophilic and cytocompatible three-dimensional scaffolds based on aminolyzed poly(l-lactide) single crystals. New J Chem 42:16930–16939. https://doi.org/10.1039/c8nj03205j

Elzoghby AA, Bakry A, Masoud AM, Mohamed WS, Taha MH, Hassanein TF (2021) Synthesis of polyamide-based nanocomposites using green-synthesized chromium and copper oxides nanoparticles for the sorption of uranium from aqueous solution. J Environ Chem Eng 9:106755. https://doi.org/10.1016/j.jece.2021.106755

Morshedy AS, Taha MH, Abd El-Aty DM, Bakry A, El Naggar AM (2021) Solid waste sub-driven acidic mesoporous activated carbon structures for efficient uranium capture through the treatment of industrial phosphoric acid. Environ Technol Innov 21:101363. https://doi.org/10.1016/j.eti.2021.101363

Aranberri-Askargorta I, Lampke T, Bismarck A (2003) Wetting behavior of flax fibers as reinforcement for polypropylene. J Colloid Interface Sci 263:580–589. https://doi.org/10.1016/S0021-9797(03)00294-7

Karacan I, Benli H (2012) Use of sulfonation procedure for the development of thermally stabilized isotactic polypropylene fibers prior to carbonization. J Appl Polym Sci 123:234–245. https://doi.org/10.1002/app.34454

Lv Q, Qiu Y, Wu M, Wang L (2020) Poly (acrylic acid)/poly (acrylamide) hydrogel adsorbent for removing methylene blue. J Appl Polym Sci 137:49322. https://doi.org/10.1002/app.49322

Pandey PK, Sharma SK, Sambi SS (2010) Kinetics and equilibrium study of chromium adsorption on zeolitenax. Int J Environ Sci Technol 7:395–404. https://doi.org/10.1007/BF03326149

Nassar MY, El-Shahat MF, Osman A, Sobeih MM, Zaid MA (2021) Adsorptive removal of manganese ions from polluted aqueous media by glauconite clay-functionalized chitosan nanocomposites. J Inorg Organomet Polym Mater 31:4050–4064. https://doi.org/10.1007/s10904-021-02028-8

Akl MA, Yousef AM, AbdElnasser S (2013) Removal of iron and manganese in water samples using activated carbon derived from local agro-residues. J Chem Eng Process Technol 4:1–10. https://doi.org/10.4172/2157-7048.1000154

Dutta D, Borah JP, Puzari A (2021) Adsorption of Mn2+ from aqueous solution using manganese oxide-coated hollow polymethylmethacrylate microspheres (MHPM). Adsorpt Sci Technol 2021:5597299. https://doi.org/10.1155/2021/5597299

Hallajiqomi M, Eisazadeh H (2017) Adsorption of manganese ion using polyaniline and its nanocomposite: kinetics and isotherm studies. J Ind Eng Chem 55:191–197. https://doi.org/10.1016/j.jiec.2017.06.045

Crini G (2008) Kinetic and equilibrium studies on the removal of cationic dyes from aqueous solution by adsorption onto a cyclodextrin polymer. Dye Pigment 77:415–426. https://doi.org/10.1016/j.dyepig.2007.07.001

Jiaqi Z, Yimin D, Danyang L, Shengyun W, Liling Z, Yi Z (2019) Synthesis of carboxyl-functionalized magnetic nanoparticle for the removal of methylene blue. Colloids Surf A Physicochem Eng Asp 572:58–66. https://doi.org/10.1016/j.colsurfa.2019.03.095

Zhang B, Yan J, Li G, Wang Z (2019) Carboxyl-, hydroxyl-, and nitro-functionalized porous polyaminals for highly selective CO2capture. ACS Appl Polym Mater 1:1524–1531. https://doi.org/10.1021/acsapm.9b00297

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bakry, A., Elmesallamy, S.M. & Fekry, M. Acid functionalized polypropylene derivatives to adsorb Mn (II) from aqueous solutions: equilibrium, kinetics, and thermodynamic modeling. Iran Polym J 32, 1047–1063 (2023). https://doi.org/10.1007/s13726-023-01181-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01181-w