Abstract

Poly(lactic acid) (PLA) can be functionalized with maleic anhydride (MA) to obtain MA-grafted PLA (PLA-g-MA), which in turn, can be functionalized with ammonium polyphosphate (APP) to obtain PLA-g-APP. This functionalization should facilitate the obtaining of compounds with flame-retardant properties through intumescence and also could function as a compatibilizer for the addition of bio-fillers. To achieve this, the PLA was first functionalized with MA using dicumyl peroxide (DCP) as free radical former, at varying peroxide and maleic anhydride concentrations. FTIR and NMR confirmed the functionalization. In addition, it was found that at certain DCP and MA concentrations, the attained grafting values were close to 1% MA into PLA. Thereafter, APP was grafted onto PLA-g-MA, in order to obtain PLA-g-MA/APP. XPS analyzes showed the effective functionalization of PLA with MA and subsequently, the grafting of APP. The SEM images showed that the “new” material (PLA-g-APP) does not show a brittle fracture as that of pure PLA, although a tough fracture and an interfacial adhesion between PLA and APP is improved revealing its compatibilization effect. This compatibilization allowed an improvement in tensile strength, impact resistance and a slight increase in HDT of the PLA. Finally, it was observed that the use of PLA-g-APP in a pure PLA matrix has a positive effect on its mechanical properties. The flame retardancy was tested by cone calorimeter which showed that pHRR and THR are reduced at 30% and 35%, respectively. In addition, the better flame retardancy was obtained when using PLA-g-APP with 15% (by weight) of grafted APP. This functionalized PLA (PLA-g-APP) is a new and good option to prepare bio-fire retardant composites with enhanced flame-retardant properties, in sustainable and environmentally friendly applications.

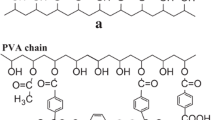

Graphical abstract

Similar content being viewed by others

Availability of data and material

Supplementary data and material related with this manuscript will be available under request

References

Ilyas RA, Sapuan SM, Harussani MM, Hakimi MYAY, Haziq MZM, Atikah MSN, Asyraf MRM, Ishak MR, Razman MR, Nurazzi NM, Norrrahim MNF, Abral H, Asrofi M (2021) Polylactic acid (PLA) biocomposite: processing, additive manufacturing and advanced applications. Polymers 13:1326

McKeown P, Jones MD (2020) The chemical recycling of PLA: A review. Sustain Chem 1:1–22

Dong X, Wu Z, Wang Y, Li T, Yuan H, Zhang X, Ma P, Chen M, Huang J, Dong W (2022) Improving the toughness and flame retardancy of poly(lactic acid) with phosphorus-containing core-shell particles. J Appl Polym Sci 139:e52390

Li G, Zhao M, Xu F, Yang B, Li X, Meng X, Teng L, Sun F, Li Y (2020) Synthesis and biological application of polylactic acid. Molecules 25:5023

Yankov D (2022) Fermentative lactic acid production from lignocellulosic feedstocks: from source to purified product. Front Chem 10:823005

Hughes J, Thomas R, Byun Y, Whiteside S (2012) Improved flexibility of thermally stable poly-lactic acid (PLA). Carbohydr Polym 88:165–172

Schmidmaier G, Wildemann B, Stemberger A, Haas NP, Raschke M (2001) Biodegradable poly(D, L-lactide) coating of implants for continuous release of growth factors. J Biomed Mater Res 58:449–455

Jeevitha D, Amarnath K (2013) Chitosan/PLA nanoparticles as a novel carrier for the delivery of anthraquinone: synthesis, characterization and in vitro cytotoxicity evaluation. Colloid Surf B Biointerf 1:126–134

Jamshidian M, Tehrany EA, Imran M, Jacquot M, Desobry S (2010) Poly-lactic acid: production, applications, nanocomposites, and release studies. Compr Rev Food Sci Food Saf 9:552–571

Tawiah B, Yu B, Fei B (2018) Advances in flame retardant poly(lactic acid). Polymers 10:876

Song YP, Wang DY, Wang XL, Lin L, Wang YZ (2011) A method for simultaneously improving the flame retardancy and toughness of PLA. Polym Adv Technol 22:2295–2301

Chen H, Wang J, Ni A, Ding A, Sun Z, Han X (2018) Effect of novel intumescent flame retardant on mechanical and flame retardant properties of continuous glass fibre reinforced polypropylene composites. Compos Struct 203:894–902

Lim KS, Bee ST, Sin LT, Tee TT, Ratnam CT, Hui D, Rahmat AR (2016) A review of application of ammonium polyphosphate as intumescent flame retardant in thermoplastic composites. Compos Part B Eng 84:155–174

Fang Q, Zhan Y, Chen X, Wu R, Zhang W, Wang Y, Wu X, He Y, Zhou J, Yuan B (2022) A bio-based intumescent flame retardant with biomolecules functionalized ammonium polyphosphate enables polylactic acid with excellent flame retardancy. Eur Polym J 177:111479

Xiaolong W, Weiguang G, Xin M, Chenyang L, Jin G (2022) Preparation of a biobased core-shell flame retardant and its application in polylactic acid. J Appl Polym Sci 139:e52720

Qing Z, Huiyuan L, Junxia G, Xiaochun Y, Baojing L (2022) Synergistic flame retardancy of phosphatized sesbania gum/ammonium polyphosphate on polylactic acid. Mol Open Access 27:4748

Chuan D, Fan R, Wang Y, Ren Y, Wang C, Du Y, Zhou L, Yu J, Gu Y, Chen H, Guo G (2020) Stereocomplex poly(lactic acid)-based composite nanofiber membranes with highly dispersed hydroxyapatite for potential bone tissue engineering. Compos Sci Technol 192:108107

Clasen SH, Müller CMO, Pires ATN (2015) Maleic anhydride as a compatibilizer and plasticizer in TPS/PLA blends. J Brazil Chem Soc 26:1583–1590

Przybysz M, Hejna A, Haponiuk J, Formela K (2019) Structural and thermo-mechanical properties of poly(ε-caprolactone) modified by various peroxide initiators. Polymers 11:1101

Ghasemi S, Behrooz R, Ghasemi I, Shahbazian R, Long F (2018) Development of nanocellulose-reinforced PLA nanocomposite by using maleated PLA (PLA-g-MA). J Thermoplast Compos Mater 31:1090–1101

Hwang SW, Lee SB, Lee CK, Lee JY, Shim JK, Selke SEM, Soto-Valdez H, Matuana L, Rubino M, Auras R (2012) Grafting of maleic anhydride on poly(L-lactic acid). Effects on physicaland mechanical properties. Polym Test 31:333–344

Chow WS, Tham WL, Seow PC (2013) Effects of maleated-PLA compatibilizer on the properties of poly(lactic acid)/halloysite clay composites. J Thermoplast Compos Mater 26:1349–1363

Tariq A, Ahmad NM, Abbas MA, Shakir F, Khaliq Z, Rafiq S, Ali Z, Elaissari A (2021) Reactive extrusion of maleic-anhydride-grafted polypropylene by torque rheometer and its application as compatibilizer. Polymers 13:495

Ospina-Orejarena A, Graziano RV, Mastillo-Ortega M, Hinestroza JP, Rodriguez-Gonzalez M, Palomares-Aguilera L, Morales-Moctezuma M, Maciel-Cerda A (2016) Grafting collagen on poly (lactic acid) by a simple route to produce electrospun scaffolds, and their cell adhesion evaluation. Tissue Eng Regen Med 13:375–387

Sookprasert P, Hinchiranan N (2017) Morphology, mechanical and thermal properties of poly(lactic acid) (PLA)/natural rubber (NR) blends compatibilized by NR-graft-PLA. J Mater Res 32:788–800

Gross IP, Schneider FSS, Caro MSB, da Conceição TF, Caramori GF, Pires ATN (2018) Polylactic acid, maleic anhydride and dicumyl peroxide: NMR study of the free-radical melt reaction product. Polym Degrad Stab 155:1–8

Li W, Zhang L, Chai W, Yin N, Semple K, Li L, Zhang W, Dai C (2021) Enhancement of flame retardancy and mechanical properties of polylactic acid with a biodegradable fire-retardant filler system based on bamboo charcoal. Polymers 13:2167

Nazir R, Gaan S (2020) Recent developments in P(O/S)–N containing flame retardants. J Appl Polym Sci 137:47910

Wu X, Gong K, Zhao G, Lou W, Wang X, Liu W (2018) Mechanical synthesis of chemically bonded phosphorus-graphene hybrid as high-temperature lubricating oil additive. RSC Adv 8:4595–4603

Singh K, Ohlan A, Saini P, Dhawan SK (2008) Poly(3,4-ethylenedioxythiophene)-g-Fe2O3 polymer composite–super paramagnetic behavior and variable range hopping 1D conduction mechanism–synthesis and characterization. Polym Adv Technol 19:229–236

Arjmandi R, Ismail A, Hassan A, Abu Bakar A (2017) Effects of ammonium polyphosphate content on mechanical, thermal and flammability properties of kenaf/polypropylene and rice husk/polypropylene composites. Constr Build Mater 152:484–493

Xue Y, Zuo X, Wang L, Zhou Y, Pan Y, Li J, Yin Y, Li D, Yang R, Rafailovich MH, Guo Y (2020) Enhanced flame retardancy of poly (lactic acid) with ultra-low loading of ammonium polyphosphate. Compos Part B: Eng 196:108124

Bee ST, Lim KS, Sin LT, Ratnam CT, Bee SL, Rahmat AR (2018) Interactive effect of ammonium polyphosphate and montmorillonite on enhancing flame retardancy of polycarbonate/acrylonitrile butadiene styrene composites. Iran Polym J 27:899–911

Zhang S, Lu C, Gao X, Huang X, Cao C, Yao D (2019) Synergistic flame-retarded effect between carbon nanotubes and ammonium polyphosphate in Nylon6 and Nylon6/polystyrene blends. Fire Mater 43:401–412

Tang W, Qian L, Chen Y, Qiu Y, Xu B, Li J (2020) Joint-aggregation intumescent flame-retardant effect of ammonium polyphosphate and charring agent in polypropylene. Polym Adv Technol 31:1699–1708

Akbari A, Jawaid M, Hassan A, Balakrishnan H (2014) Epoxidized natural rubber toughened polylactic acid/talc composites: mechanical, thermal, and morphological properties. J Compos Mater 48:769–781

Lim KS, Bee ST, Sin LT, Tee TT, Ratnam CT, Hui D, Rahmat AR (2016) A review of application of ammonium polyphosphate as intumescent flame retardant in thermoplastic composites. Compos Part B: Eng 84:155–174

Tábi T, Ageyeva T, Kovács JG (2021) Improving the ductility and heat deflection temperature of injection molded poly(lactic acid) products: a comprehensive review. Polym Test 101:107282

Wang J, Shi H, Zhu P, Wei Y, Hao J (2020) Ammonium polyphosphate with high specific surface area by assembling zeolite imidazole framework in EVA resin: significant mechanical properties, migration resistance, and flame retardancy. Polymers 112:534

Hanna AA, Nour MA, Souaya ER, Sherief MA, Abdelmoaty AS (2018) Studies on the flammability of polypropylene/ammonium polyphosphate and montmorillonite by using the cone calorimeter test. Open Chem 16:108–115

Zhao X, Guerrero FR, Llorca J, Wang DY (2016) New superefficiently flame-retardant bioplastic poly(lactic acid): flammability, thermal decomposition behavior, and tensile properties. ACS Sustain Chem Eng 4:202–209

Ouyang Z, Yang Y, Zhang C, Shumin Z, Qin L, Wang W, He D, Zhou Y, Luo H, Qina F (2021) Recent advances in photocatalytic degradation of plastics and plastic-derived chemicals. J Mater Chem A 9:13402–13441

Zhao P, Liu Z, Wang X, Pan YT, Kuehnert I, Gehde M, Wang DY, Leuteritz A (2018) Renewable vanillin based flame retardant for poly(lactic acid): a way to enhance flame retardancy and toughness simultaneously. RSC Adv 8:42189–42199

Acknowledgements

One author, JD Zuluaga thanks Conacyt for granting his scholarship to carry out his PhD studies at CIQA. In addition, the authors gratefully acknowledge the financial support of Conacyt through Project Conacyt-317097 and Fordecyt-292399. The authors wish to thank National Laboratory of Graphene (Conacyt-232753), LANIAUTO (Conacyt-294030) and Conacyt-31735 for the facilities support. The authors would like to thank: A Ochoa-Cordoba, JL Saucedo-Morales, JA Mercado-Silva, Alejandro-Espinoza, M Lozano, J Rodriguez, G Mendez, ML Guillen, Silvia-Torres, G Mendez, ML Guillen, J Rodriguez, J Lopez-Rivera, M Palacios-Mesta, R Cedillo, S Zertuche, R Rangel-Ramirez, MI Solis-dePeña, JA Cepeda, SA de Leon, MI Ulloa, E Alvidrez, JJ Campos, LE Reyes, Hugo-Jiménez and D Alvarado for their technical assistance.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zuluaga-Parra, J.D., Ramos-deValle, L.F., Sánchez-Valdes, S. et al. Grafting of ammonium polyphosphate onto poly(lactic acid) and its effect on flame retardancy and mechanical properties. Iran Polym J 32, 225–238 (2023). https://doi.org/10.1007/s13726-022-01120-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01120-1