Abstract

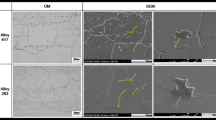

Nickel-based superalloy, Haynes 282, is a promising material for aero and land-based gas turbine applications and advanced ultra-supercritical (AUSC) steam power plants due to its outstanding combination of high thermal stability, high-temperature strength; excellent fatigue, creep and oxidation resistance; remarkable fabricability and weldability. Despite its several budding attributes, the alloy needs further developmental activities to realize material challenges for AUSC applications. In the present study, an attempt was made to investigate the influence of long-term exposure of this alloy at AUSC power plant operating temperature on microstructure and hardness. The alloy was subjected to two-step aging and followed by long-term exposure at 760 °C up to 2000 h. The alloy was also put through single-step aging for comparison purpose. The microstructural characterization of the alloy reveals major phases γ, γ', M23C6 and M6C in single-step and two-step aging and in long-term exposure conditions without any deleterious phases, viz. μ, η, σ phases. The morphology of γ' precipitate and its volume fraction was evaluated by using electron microscope images. Vickers hardness of the alloy increased from 334 ± 3 HV10 in two-step aged condition to 372 ± 2 HV10 upon exposure to 250 h and dropped to 360 ± 2 HV10 at 500 h and thereafter saturated.

Similar content being viewed by others

Data Availability

The data supporting the findings of this study can be available from the corresponding author upon request.

References

D.H. Bechetti, J.N. DuPont, J.A. Siefert, J.P. Shingledecker, Microstructural evolution and creep-rupture behavior of A-USC alloy fusion welds. Metall. Mater. Trans. A. 47, 4502–4518 (2016). https://doi.org/10.1007/s11661-016-3603-7

Y. Yang, Microstructural evolution of large cast Haynes 282 at elevated temperature. Crystals. 11(8), 867 (2021). https://doi.org/10.3390/cryst11080867

R. Fu, S. Zhao, Y. Wang, Q. Li, Y. Ma, F. Lin, C. Chi, The microstructural evolution of Haynes 282 alloy during long-term exposure tests, in Energy Materials 2014, Conference Proceedings, pp. 193–202 (2014). https://doi.org/10.1002/9781119027973.ch21

K. Vattappara, V.A. Hosseini, C. Joseph, F. Hanning, J. Andersson, Physical and thermodynamic simulations of gamma-prime precipitation in Haynes® 282® using arc heat treatment. J. Alloys Compd. 870, 159484 (2021). https://doi.org/10.1016/j.jallcom.2021.159484. (ISSN 0925-8388)

A. Deshpande, S. Deb Nath, S. Atre, K. Hsu, Effect of post processing heat treatment routes on microstructure and mechanical property evolution of Haynes 282 Ni-based superalloy fabricated with selective laser melting (SLM). Metals. 10(5), 629 (2020). https://doi.org/10.3390/met10050629

L.M. Pike, HAYNES® 282™ alloy: a new wrought superalloy designed for improved creep strength and fabricability. Proc. ASME Turbo Expo. (2006). https://doi.org/10.1115/GT2006-91204

C. Joseph, C. Persson, M. HörnqvistColliander, Influence of heat treatment on the microstructure and tensile properties of Ni-base superalloy Haynes 282. Mater. Sci. Eng. A. 679, 520–530 (2017). https://doi.org/10.1016/j.msea.2016.10.048. (ISSN 0921-5093)

S. Haas, J. Andersson, M. Fisk, J.-S. Park, U. Lienert, Correlation of precipitate evolution with Vickers hardness in Haynes® 282® superalloy: in-situ high-energy SAXS/WAXS investigation. Mater. Sci. Eng. A. 711, 250–258 (2018). https://doi.org/10.1016/j.msea.2017.11.035. (ISSN 0921-5093)

A. Polkowska, W. Polkowski, M. Warmuzek et al., Microstructure and hardness evolution in Haynes 282 nickel-based superalloy during multi-variant aging heat treatment. J. Mater. Eng. Perform. 28, 3844–3851 (2019). https://doi.org/10.1007/s11665-019-3886-0

K.A. Unocic, D. Shin, X. Sang, E. Cakmak, P.F. Tortorelli, Single-step aging treatment for a precipitation-strengthened Ni-based alloy and its influence on high temperature mechanical behavior. Scr. Mater. 162, 416–420 (2019). https://doi.org/10.1016/j.scriptamat.2018.11.045. (ISSN 1359-6462)

L.M. Pike, Development of a fabricable gamma prime (γ') strengthened superalloy, in Proceedings of the International Symposium on Superalloys, pp. 191–200 (2008). https://doi.org/10.7449/2008/Superalloys_2008_191_200

L.M. Pike, Long Term Thermal Exposure of HAYNES 282 Alloy, pp. 645–660 (2010). https://doi.org/10.7449/2010/Superalloys_2010_645_660

X. Zhao, Y. Dang, H. Yin, Y. Yuan, J. Lu, Z. Yang, Y. Gu, Evolution of the microstructure and microhardness of a new wrought Ni–Fe based superalloy during high temperature aging. J. Alloys Compd. 644, 66–70 (2015). https://doi.org/10.1016/j.jallcom.2015.04.184. (ISSN 0925-8388)

K.-Y. Shin, J.-H. Kim, M. Terner, B.-O. Kong, H.-U. Hong, Effects of heat treatment on the microstructure evolution and the high-temperature tensile properties of Haynes 282 superalloy. Mater. Sci. Eng. A. 751, 311–322 (2019). https://doi.org/10.1016/j.msea.2019.02.054. (ISSN 0921-5093)

A. Karasev, H. Suito, Analysis of size distributions of primary oxide inclusions in Fe-10 mass Pct Ni-M (M= Si, Ti, Al, Zr, and Ce) alloy. Metall. Mater. Trans. B. 30, 259–270 (1999). https://doi.org/10.1007/s11663-999-0055-0

S. Yin, Y. Liu, F. Zhao, Effect of thermomechanical treatment on MX phase precipitation behavior in CLAM steel. Fusion Eng. Des. 173, 112785 (2021). https://doi.org/10.1016/j.fusengdes.2021.112785. (ISSN 0920-3796)

K.L. Kruger, 15-HAYNES 282 alloy, in Materials for Ultra-supercritical and Advanced Ultra-supercritical Power Plants. ed. by A. Di Gianfrancesco (Woodhead Publishing, Cham, 2017), pp.511–545. https://doi.org/10.1016/B978-0-08-100552-1.00015-4 (ISBN 9780081005521)

M.G. Fahrmann, L.M. Pike, Experimental TTT diagram of HAYNES 282 alloy, in The Minerals, Metals & Materials Series. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-89480-5_37

C. Tian, G. Han, C. Cui, X. Sun, Effects of stacking fault energy on the creep behaviors of Ni-base superalloy. Mater. Des. 64, 316–323 (2014). https://doi.org/10.1016/j.matdes.2014.08.007. (ISSN 0261-3069)

G.U.O. Yan, L.I. Tai-jiang, W.A.N.G. Cai-xia, H.O.U. Shu-fang, W.A.N.G. Bo-han, Microstructure and phase precipitate behavior of Inconel 740H during aging. Trans. Nonferrous Metals Soc. China. 26(6), 1598–1606 (2016). https://doi.org/10.1016/S1003-6326(16)64266-8

P.J. Ennis, A. Strang, S.P. Gill, G.M. McColvin, Microstructural stability of nickel based alloys for advanced power plant applications. Energy Mater. 4(4), 184–188 (2009). https://doi.org/10.1179/174892312X13269692038978

C.M. Fernandes, A.M.R. Senos, Cemented carbide phase diagrams: a review. Int. J. Refract. Metals Hard Mater. 29(4), 405–418 (2011). https://doi.org/10.1016/j.ijrmhm.2011.02.004. (ISSN 0263-4368)

J. Andersson, G. Sjöberg, M. Chaturvedi, Hot ductility study of HAYNES® 282® superalloy, in 7th International Symposium on Superalloy 718 and Derivatives, TMS. ed. by E.A. Ott, J.R. Groh, A. Banik, I. Dempster, T.P. Gabb, R. Helmink, X. Liu, A. Mitchell, G.P. Sjörberg, A. Wusatowska-Sarnek (2010), pp.539–554 https://doi.org/10.1002/9781118495223.ch41

L.O. Osoba, R.G. Ding, O.A. Ojo, Microstructural analysis of laser weld fusion zone in Haynes 282 superalloy. Mater Charact. 65, 93–99 (2012). https://doi.org/10.1016/j.matchar.2011.12.009. (ISSN 1044-5803)

H. Matysiak, M. Zagorska, J. Andersson, A. Balkowiec, R. Cygan, M. Rasinski, M. Pisarek, M. Andrzejczuk, K. Kubiak, K.J. Kurzydlowski, Microstructure of Haynes® 282® superalloy after vacuum induction melting and investment casting of thin-walled components. Materials. 6(11), 5016–5037 (2013). https://doi.org/10.3390/ma6115016

F. Hanning, A.K. Khan, J. Steffenburg-Nordenström, O. Ojo, J. Andersson, Investigation of the effect of short exposure in the temperature range of 750–950 °C on the ductility of Haynes® 282® by advanced microstructural characterization. Metals. 9(12), 1357 (2019). https://doi.org/10.3390/met9121357

C. Joseph, C. Persson, M. HörnqvistColliander, Precipitation kinetics and morphology of grain boundary carbides in Ni-base superalloy Haynes 282. Metall. Mater. Trans. A. 51, 6136–6141 (2020). https://doi.org/10.1007/s11661-020-06019-1

A.S. Shaikh, F. Schulz, K. Minet-Lallemand, E. Hryha, Microstructure and mechanical properties of Haynes 282 superalloy produced by laser powder bed fusion. Mater. Today Commun. 26, 102038 (2021). https://doi.org/10.1016/j.mtcomm.2021.102038. (ISSN 2352-4928)

J.R. Robertson, Continued developments in the characteristics of HAYNES® 282® alloy for use in A-USC applications, in Proceedings of the ASME 2018 Symposium on Elevated Temperature Application of Materials for Fossil, Nuclear, and Petrochemical Industries. ASME 2018 Symposium on Elevated Temperature Application of Materials for Fossil, Nuclear, and Petrochemical Industries. Seattle, Washington, USA. April 3–5, 2018. V001T01A007. ASME. https://doi.org/10.1115/ETAM2018-6745

P.D. Jablonski, C.J. Cowen, J.A. Hawk, Effects of Al and Ti on Haynes 282 with fixed gamma prime content, in Proceedings of the 7th International Symposium on Superalloy, vol. 718 (2010). https://doi.org/10.1002/9781118495223.ch48

S. Zhao, X. Xie, G.D. Smith, S.J. Patel, Microstructural stability and mechanical properties of a new nickel-based superalloy. Mater. Sci. Eng. A. 355(1–2), 96–105 (2003). https://doi.org/10.1016/S0921-5093(03)00051-0. (ISSN 0921-5093)

M. Warmuzek, A. Polkowska, T. Dudziak, P, Characteristics of the evolution of carbide morphology in the Haynes® 230® alloy as a result of high temperature annealing. J. Appl. Mater. Eng. 60, 109–119 (2020)

J. Caron, L. Pike, Weldability of HAYNES 282 superalloy after long-term thermal exposure. MATEC Web Conf. 14, 13003 (2014). https://doi.org/10.1051/matecconf/20141413003

C. Joseph, M. Thuvander, C. Persson, M.H. Colliander, Precipitation of γ’ during cooling of nickel-base superalloy Haynes 282. Philos. Mag. Lett. 101(1), 30–39 (2021). https://doi.org/10.1080/09500839.2020.1841314

S. Mukherjee, B.P. Sahu, S.K. Sarkar, S. Ahlawat, A. Biswas, G.K. Mandal, S. Tarafder, S.K. Kar, Temporal evolution of γ′ precipitate in HAYNES 282 during ageing: growth and coarsening kinetics, solute partitioning and lattice misfit. Materialia. 26, 101633 (2022). https://doi.org/10.1016/j.mtla.2022.101633. (ISSN 2589-1529)

J.A. Hawk, T.-L. Cheng, J.S. Sears, P.D. Jablonski, Y.-H. Wen, Gamma prime stability in Haynes 282: theoretical and experimental considerations. J. Mater. Eng. Perform. 24, 4171–4181 (2015). https://doi.org/10.1007/s11665-015-1711-y

D.M. Collins, L. Yan, E.A. Marquis, L.D. Connor, J.J. Ciardiello, A.D. Evans, H.J. Stone, Lattice misfit during ageing of a polycrystalline nickel-base superalloy. Acta Mater. 61(20), 7791–7804 (2013). https://doi.org/10.1016/j.actamat.2013.09.018. (ISSN 1359-6454)

S. Jiang, Z. Tian, W. Liu, H. Chen, Z. Yang, Z. Liu, C. Zhang, Y. Weng, Microstructural evolution and hardness of a heat resistant alloy during long term aging at 700 °C. J. Alloys Compd. 765, 1267–1274 (2018). https://doi.org/10.1016/j.jallcom.2018.05.263. (ISSN 0925-8388)

Ł Rakoczy, M. Grudzień-Rakoczy, F. Hanning, G. Cempura, R. Cygan, J. Andersson, A. Zielińska-Lipiec, Investigation of the γ′ precipitates dissolution in a Ni-based superalloy during stress-free short term annealing at high homologous temperatures. Metall. Mater. Trans. A. 52, 4767–4784 (2021). https://doi.org/10.1007/s11661-021-06420-4

J. Zhang, L. Liu, T. Huang, J. Chen, K. Cao, X. Liu, J. Zhang, Fu. Hengzhi, Coarsening kinetics of γ′ precipitates in a Re-containing Ni-based single crystal superalloy during long-term aging. J. Mater. Sci. Technol. 62, 1–10 (2021). https://doi.org/10.1016/j.jmst.2020.05.034. (ISSN 1005-0302)

Y. Jinxia, Z. Qi, S. Xiaofeng, G. Hengrong, H. Zhuangq, Morphological evolution of MC carbide in K465 superalloy. J. Mater. Sci. 41, 6476–6478 (2006). https://doi.org/10.1007/s10853-006-0684-5

J.M. Larson, Carbide morphology in p/m IN-792. Metall. Mater. Trans. A. 7, 1497–1502 (1976). https://doi.org/10.1007/BF02656391

P. Zhang, Y. Yuan, H. Yin, Y. Gu, J. Wang, M. Yang, G. Yang, X. Song, Tensile properties and deformation mechanisms of Haynes 282 at various temperatures. Metall. Mater. Trans. A. 49, 1571–1578 (2018). https://doi.org/10.1007/s11661-018-4515-5

Acknowledgements

The authors acknowledge Bharat Heavy Electricals Limited (BHEL) (R&D), Hyderabad for providing Haynes 282 alloy for carrying out this work. Authors also thank Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad for their help in FESEM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Damodhar Naidu, G., Nageswara Rao, G.V.S. & Chaube, R.K. Effect of Long-Term Exposure on Microstructure and Hardness of Aged Haynes 282 Alloy. Metallogr. Microstruct. Anal. 12, 965–985 (2023). https://doi.org/10.1007/s13632-023-01009-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-023-01009-2