Abstract

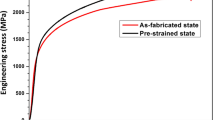

The present study aims at investigating the low cycle fatigue behavior of two fully AISI 1080 pearlitic steels which differed in their interlamellar spacing (72 ± 15 and 143 ± 32 nm). Low cycle fatigue tests were performed under positive strain control at different total strain variations (0.6% ≤ ∆εt ≤ 1.6%). It is shown that both alloys presented an asymmetric stress response and a cyclic softening during the first fatigue life fractions. The tension stress peaks were higher for the fine pearlitic steel than for the coarse one but the compression stress peaks were less different. The extrusion–intrusion pairs formed at the external surface were more developed for the coarse pearlitic steel. The results suggest that the critical short crack size to propagate in the bulk is much smaller in the fine pearlitic steel which explains the shorter fatigue lives. For both steels, the entire fracture surface comprised a fatigue propagation zone, a final fully brittle zone separated by a narrow ductile transition zone.

Similar content being viewed by others

Abbreviations

- ILS:

-

Interlamellar spacing

- CP:

-

Coarse pearlite

- FP:

-

Fine pearlite

- LCF:

-

Low cycle fatigue

- ∆ε t (%):

-

Total strain range

- ∆ε p (%):

-

Plastic strain range

References

Millau viaduct https://structurae.net/en/structures/millau-viaduct

O.P. Modi, N. Desmukh, D.P. Mondal, A.K. Jha, A.H. Yegneswaran, H.K. Khaira, Effect of interlamellar spacing on the mechanical properties of 0.65% C steel. Mater. Charact. (2001). https://doi.org/10.1016/S1044-5803(00)00113-3

C.M. Bae, C.S. Lee, W.J. Nam, Effect of carbon content on mechanical properties of fully pearlitic steels. Mater. Sci. Technol. (2002). https://doi.org/10.1179/026708302225007556

J. Toribio, B. González, J.-C. Matos, F.J. Ayaso, Influence of microstructure on strength and ductility in fully pearlitic steels. Metals. (2016). https://doi.org/10.3390/met6120318

C.-L. Zhang, X. Liu, L.-Y. Zhou, Y.-Z. Liu, Influence of pearlite interlamellar spacing on strain hardening behaviour in spring steel 60Si2MnA. Proc. Eng. (2014). https://doi.org/10.1016/j.proeng.2014.10.111

V.N. Khiratkar, K. Mishra, P. Srinivasulu, A. Singh, Effect of inter-lamellar spacing and test temperature on the Charpy impact energy of extremely fine pearlite. Mater. Sci. Eng. A. (2019). https://doi.org/10.1016/j.msea.2019.03.121

F. Zhang, Y. Zhao, Y. Tan, X. Ji, S. Xiang, Study on the nucleation and growth of pearlite colony and impact toughness of eutectoid steel. Metals. (2019). https://doi.org/10.3390/met9111133

F.P.L. Kavishe, T.J. Baker, Effect of prior austenite grain size and pearlite interlamellar spacing on strength and fracture toughness of a eutectoid rail steel. Mater. Sci. Technol. (1986). https://doi.org/10.1179/mst.1986.2.8.816

J. Toribio, B. González, J.-C. Matos, Analysis of fatigue crack paths in cold drawn pearlitic steel. Materials. (2015). https://doi.org/10.3390/ma8115388

L.B. Godefroid, L.P. Moreira, T.C.G. Vilela, G.L. Faria, L.C. Candido, E.S. Pinto, Effect of chemical composition and microstructure on the fatigue crack growth resistance of pearlitic steels for railroad application. Int. J. Fatigue. (2019). https://doi.org/10.1016/j.ijfatigue.2018.10.016

S. Maya-Johnson, A.J. Ramirez, A. Toro, Fatigue crack growth rate of two pearlitic rail steels. Eng. Fract. Mech. (2015). https://doi.org/10.1016/j.engfracmech.2015.03.023

G.F. Vander Voort, A. Roósz, Measurement of the interlamellar spacing of pearlite. Metallography. 17(1), 1–17 (1984)

S.S. Manson, Fatigue: a complex subject—some simple approximations. Exp. Mech. (1965). https://doi.org/10.1007/bf02321056

R.E. Stoltz, R.M. Pelloux, The Bauschinger effect in precipitation strengthened aluminium alloys. Metall. Mater. Trans. (1976). https://doi.org/10.1007/BF02658814

L.E. Levine, M.R. Stoudt, A. Creuziger, T.Q. Phan, R. Xu, M.E. Kassner, Basis for the Bauschinger effect in copper single crystals: changes in the long-range internal stress with reverse deformation. J. Mater. Sci. (2019). https://doi.org/10.1007/s10853-018-03295-6

J. Toribio, V. Kharin, F.-J. Ayaso, M. Lorenzo, B. González, J.-C. Matos, L. Aguado, Analysis of the Bauschinger effect in cold drawn Pearlitic steels. Metals. (2020). https://doi.org/10.3390/met10010114

M. Bönisch, M. Seefeldt, A. Van Bael, N. Sanchez, S. Cooreman, Towards a dislocation-based model for strain path effects in bainitic pipeline steels, in Paper presented at ESAFORM 2021. 24th International Conference on Material Forming, Liège, Belgique (2021) https://doi.org/10.25518/esaform21.2403

J.-B. Vogt, I.M.O.A. Costa, A. Addad, J. Bouquerel, Fatigue intrusion-extrusion in a fully pearlitic steel. Mater. Lett. (2020). https://doi.org/10.1016/j.matlet.2020.127539

C. Schayes, J.-B. Vogt, J. Bouquerel, F. Palleschi, S. Zaefferer, Cyclic plasticity mechanism of the M330-35A steel. Int. J. Fatigue. (2016). https://doi.org/10.1016/j.ijfatigue.2015.09.008

Acknowledgements

The SEM and TEM national facility in Lille (France) is supported by the Conseil Regional des Hauts-de-France and the European Regional Development Fund (ERDF). The authors thank Mr. Damien Creton and Mr. Jocelyn Golek for their help in the fatigue and metallography experiments. One the authors (D.B.) acknowledges the European Union and Centrale Lille Institut for supporting her intern at UMET inside the Erasmus agreement between Centrale Lille Institut (France) and Lviv Polytechnical National University (Ukraine).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ávila de Oliveira Silva, L., Adinolfi Colpaert Sartori, G., Bondarchuk, D. et al. Effect of Interlamellar Spacing on the Low Cycle Fatigue Behavior of a Fully Pearlitic Steel. Metallogr. Microstruct. Anal. 10, 692–699 (2021). https://doi.org/10.1007/s13632-021-00775-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00775-1