Abstract

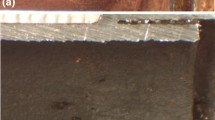

Polyvinyl chloride (PVC) is produced in petrochemical plants by polymerization of vinyl chloride monomer prepared by cracking of ethylene dichloride, which takes place at 500 °C in furnace tubes made of 347 stainless steel. Hydrochloric acid resulting from the cracking process is recycled in the gaseous state and used in an oxychlorination process. However, after less than half the life expectancy, gas leakage has been detected due to a crack in a furnace tube. Another problem has been encountered in the dewatering and drying unit of PVC where the outlet gas at a temperature of 40–60 °C contains 110 ppm of hydrogen. In this case, a dryer support made of 304 stainless steel has fractured. Various electron-optical techniques and x-ray diffraction have been used to characterize the microstructure of damaged materials. The mechanical strength has been evaluated by microhardness measurements. It is concluded that the furnace tube has been damaged by chloride stress corrosion cracking, which is correlated with precipitation of Cr-rich phases including M23C6 carbide and sigma phase due to long-term exposure at elevated temperatures as well as the presence of chloride ions in the environment due to un-cycled HCl. However, the dryer support is found to be damaged by hydrogen-assisted quasi-cleavage.

Similar content being viewed by others

References

L. Garverick, Corrosion in the Petrochemical Industry (ASM International, Materials Park, OH, 1994)

P.A. Schweitzer, Stainless steels, in Corrosion and Corrosion Protection Handbook, ed. by P.A. Schweitzer (Marcel Dekker, New York, 1983), p. 37

G. Matthews, PVC: Production, Properties and Uses (The Institute of Materials, London, 1997)

S.M.R. Ziaei, J. Mostowfi, M. Golestani, S.A.R. Ziaei, Failure analysis: chloride stress corrosion cracking of AISI 316 stainless steel downhole pressure memory gauge cover. Eng. Fail. Anal. 33, 465–472 (2013)

S.H. Khodamorad, D.H. Fatmehsari, H. Rezaie, A. Sadeghipour, Analysis of ethylene cracking furnace tubes. Eng. Fail. Anal. 21, 1–8 (2012)

H.M. Tawancy, Failure of hydrocracker heat exchanger tubes in an oil refinery by polythionic acid-stress corrosion cracking. Eng. Fail. Anal. 16, 2091–2097 (2009)

R.C. Yin, A.H. Al-Shawaf, W. Al-Harbi, Chloride-induced stress corrosion cracking of furnace burner tubes. Eng. Fail. Anal. 14, 36–40 (2007)

R.C. Yin, Y. Al-Bakheet, A.H. Al-Shawaf, Failure analysis of EDC incinerator quench nozzle. Eng. Fail. Anal. 14, 41–46 (2007)

V. Kain, Stress corrosion cracking (SCC) in stainless steels, in Stress Corrosion Cracking: Theory and Practice, ed. by V.S. Raja, T. Shoji (Woodhead Publishing, Cambridge, 2011), p. 199

S. Wang, Conditions for stress corrosion cracking to occur from crevice corrosion sites and related electrochemical effects. Mater. Corros. 55, 901–908 (2004)

W. Lan, X. Deng, M.A. Sutton, C.S. Cheng, Study of slant fracture in ductile materials. Int. J. Fract. 141, 469–496 (2006)

A. Pytel, F.L. Singer, Strength of Materials (HarperCollins, New York, 1987)

H. Uno, A. Kimura, T. Misawa, Effect of Nb on intergranular precipitation behavior of Cr carbides in N-bearing austenitic stainless steels. Corrosion 48, 467–474 (1992)

B. Sasmal, Mechanism of formation of M23C6 plates around undissolved NbC particles in a stabilized austenitic stainless steel. J. Mater. Sci. 32, 5439–5444 (1997)

R. Ayer, C.F. Klein, C.M. Marzinsky, Instabilities in stabilized austenitic stainless steel. Met. Trans. 32A, 2455–2467 (1992)

J.W. Edington, Typical Electron Microscope Investigations (N.V. Philips, Eindhoven, 1976)

J.B. Mitchell, Imperfection and microstructure. Metallography 8, 5–70 (1975)

F.R. Beckitt, B.R. Clark, The shape and mechanism of formation of M23C6 carbide in austenite. Acta Met. 15, 113–129 (1967)

M.H. Lewis, B. Hattersley, Precipitation of M23C6 in austenitic steels. Acta Met. 13, 1159–1168 (1965)

G. Wallwork, J. Croll, A review of the strengthening mechanisms in iron and nickel based Fe-Ni-Cr alloys used at high temperatures, in Reviews of High Temperature Materials, ed. by J. Newkirk (Freund Publishing House, London, 1976), p. 69

K. Chandra, V. Kain, R. Tewari, Microstructural and electrochemical characterization of heat-treated 347 stainless steel with different phases. Corros. Sci. 67, 118–129 (2013)

R.C. Newman, W.R. Whitney, Understanding the corrosion of stainless steel. Corrosion 57, 1030–1040 (2001)

S.P. Lynch, Mechanistic and fractographic aspects of stress-corrosion cracking (SCC), in Stress Corrosion Cracking: Theory and Practice, ed. by V.S. Raja, T. Shoji (Woodhead Publishing, Cambridge, 2011), p. 1

H.S. da Costa Mattos, I.N. Bastos, J.A.C.P. Gomes, A thermodynamically consistent modeling of stress corrosion tests in elasto-viscoplastic materials. Corros. Sci. 80, 143–153 (2014)

K.C. Thomas, R.J. Allio, An integrated theory of stress corrosion. Nature 206, 82–83 (1965)

D.L. Douglass, G. Thomas, R. Roser, Ordering, stacking faults and stress corrosion cracking in austenitic alloys. Corrosion 20, 15t–28t (1964)

A. Bagdasarian, J. Feather, B. Hull, R. Stephenson, R. Strong, Crude unit corrosion and corrosion control, General Electric technical paper no. 1105 (2010)

M. Koyama, E. Akiyama, T. Sawagucchi, K. Ogawa, I.V. Kireeva, Y.L. Chumlyakov, K. Tsuzaki, Hydrogen-assisted quasi-cleavage fracture in a single crystalline type 316 austenitic stainless steel. Corros. Sci. 75, 345–353 (2013)

I.M. Bernstein, A.W. Thompson, Resisting hydrogen embrittlement, in Alloy and Microstructural Design, ed. by J.K. Tien, G.S. Ansell (Academic Press, New York, 1976), p. 303

M. Koyama, E. Akiyama, K. Tsuzaki, D. Raabe, Hydrogen-assisted failure in a twinning-induced plasticity steel studied under in situ hydrogen charging by electron channeling contrast imaging. Acta Mater. 61, 4607–4618 (2013)

J.H. Ryu, S.K. Kim, C.S. Lee, D.-W. Suh, H.K.D.H. Bhadeshia, Effect of aluminium on hydrogen-induced fracture behaviour in austenitic Fe-Mn-C steel, Proc. R. Soc. A 469, article no. 20120458 (2013)

M. Koyama, E. Akiyama, T. Sawaguchi, D. Raabe, K. Tsuzaki, Hydrogen-induced cracking at grain and twin boundaries in an Fe-Mn-C austenitic steel. Scr. Mater. 66, 459–462 (2012)

T. Michler, C.S. Marchi, J. Naumann, S. Weber, M. Martin, Hydrogen environment embrittlement of stable austenitic steels. Int. J. Hydrogen Energy 37, 1624–16231 (2012)

M.L. Martin, I.M. Robertson, P. Sofronis, Interpreting hydrogen fracture surfaces in terms of deformation processes. Acta Mater. 59, 3680–3687 (2011)

M.L. Martin, J.A. Fenske, G.S. Liu, P. Sofronis, I.M. Robertson, On the formation and nature of quasi-cleavage fracture surfaces in hydrogen embrittled steels. Acta Mater. 59, 1601–1606 (2011)

Acknowledgments

It is a pleasure to acknowledge the continued support of the King Fahd University of Petroleum and Minerals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tawancy, H.M. Failure Analysis of Process Equipment Used in the Production of Polyvinyl Chloride. Metallogr. Microstruct. Anal. 3, 310–322 (2014). https://doi.org/10.1007/s13632-014-0144-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-014-0144-6