Abstract

Key message

The sawtooth parameters of the side edges likely affect surface roughness to a large extent in wood sawing. Our results point out the need to optimize the parameters of the side edges in order to maximize wood surface quality.

Context

Improving surface roughness of wood in rip sawing by optimizing the sawtooth parameters is a significant topic of focus in the research of wood processing. However, existing research focuses mainly on the optimization of the sawtooth parameters of the major cutting edges without taking into account the influences of length and angle of the side edges on surface roughness. Thus, adaptive parameters for the side edges should be proposed.

Aims

This study analyzes how the different parameters of side edges influence surface roughness when circular saws are used, and aims to resolve disparities between high feed speeds and better surface roughness.

Methods

In particular, this article presents the use of a sawtooth with a mic-zero-degree radial clearance angle. Northeast China ash (Fraxinus spp.) serves as the material for conducting this rip-sawing experiment. Nine types of sawtooth geometries at different feed speeds are used to study the influences of both the different radial clearance angles and the straight length of the zero-degree radial clearance angle on surface roughness (Ra).

Results

Surface roughness increases with the increase in feed speed, and the smaller the radial clearance angle of the sawteeth, the smaller the surface roughness. When the sawteeth have a mic-zero-degree radial clearance angle, the sawing surface roughness is lower than that of the value of sawteeth with radial clearance angles, especially when the straight length of the zero-degree radial clearance increases from 0 to 0.5 mm, in which case the decrease is most obvious.

Conclusion

Surface roughness depends, to a certain extent, on the depth of the saw notch. A small part of the side edge that forms the sawing surface participates in the actual cutting, and the length of this section is approximately equal to the feed per tooth. Sawteeth with mic-zero-degree radial clearance angles can improve the surface quality of sawing. Also, if the other cutting factors remain unchanged, surface roughness can be improved and friction can be reduced between the side edges and the wood by increasing the feed speed.

Similar content being viewed by others

1 Introduction

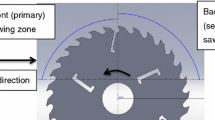

Circular rip sawing is applied mainly in the conversion of logs into solid wood products and in the production of furniture. The woodcutting process, when rip-sawing wood with circular saw blades, occurs with each of several cutting teeth. The cutting process of wood is considered a technological scheme that consists of several connected and relatively inseparable parts such as that presented in Fig. 1 (Marko and Holík 2000; Kováč and Mikleš 2009). The surface quality of solid wood and wood-based panels is one of the most important properties influencing manufacturing processes such as finishing as well as affecting adhesive strength characteristics. The surface quality from sawing is a function of factors related to the process (i.e., feed rate), factors related to the tooling system (i.e., cutting angle), and factors related to the material (i.e., moisture, density, or heterogeneity) (Thibaut et al. 2016).

Technological system, “the cutting process” (Kováč and Mikleš 2009), consists of a four-part subsystem: workpiece (wood species, humidity, density, and toughness), cutting conditions (sum of conditions relating to workpiece, cutting tool, and cutting mechanism), cutting mechanism (mechanism of the main movement; feed; number of working movements; and procedure of performance, thickness, and width of a layer, which is cut; cutting angle; speed of cutting movement and feed; cutting forces; and friction forces), and a cutting tool (cutting wedge angle, number of teeth, material properties, surface roughness, cutting edge length)

Many researchers have been interested in surface roughness (Koch 1964), which can be affected by different factors. Thibaut et al. (2016) summed up the influence factors on surface roughness in two sets of parameters:

(i) Those linked to the material: anatomical, physical, chemical, and mechanical properties required to take into account for the scale effects (Triboulot 1984; Triboulot et al. 1991; Brémaud et al. 2011). Thus, softwood, mainly consisting of tracheids, and hardwood, consisting of fibers and vessels, present a range of surface roughness (Leban and Triboulot 1994; Akbulut and Ayrilmis 2006; Bekhta et al. 2009).

(ii) Those linked to the manufacturing process: vibrations of machines (Martin 1992); stability, wear of the cutting edges of the tools (Aguilera Leon 2000); and cutting conditions (Khazaeian 2006; Kilic et al. 2006). Thus, some authors have found that a higher cutting speed can, in some cases, improve the quality of the surface obtained from routing (Costes 2001; Korkut and Donertas 2007). Another way to improve the sawing process is to identify the best match between the cutting material and the blade geometry (Simonin et al. 2009).

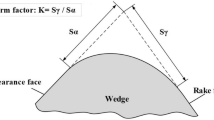

In recent years, much research has focused on efficient, energy-saving, and cost-reducing sawing. Optimizing the sawtooth parameters to improve surface roughness has been one of the most significant research topics. Figure 2 shows the sawtooth shape and angle of a traditional circular saw.

The cutting mechanics of woodworking regarding surface quality in general have been studied and described by several authors; for instance, Kirbach and Ngusya (1988) and Krilov (1988) have reported that saws with beveled teeth perform better in plant trials than those with swage teeth. In North America, the “triple-chip” tooth design, which has chamfered teeth alternating with swage teeth, is widely preferred for the circular sawing of smooth surfaces. Krilov (1988) reported improved performance in sawmill trials of a symmetrical full-width bevel design. Another design with symmetrically beveled top edges and slightly curved side edges was found by Heisel et al. (1998) to produce “extraordinary” improvement in surface quality. McKenzie (2000), in the USA, theoretically analyzes the influences of five-teeth shapes on surface roughness.

The study of sawtooth with a zero-degree radial clearance angle was first presented by Meng and Qi (1999) in China. The results show that the band saw blade of a zero-degree radial clearance could improve the quality of surface cutting (Meng et al. 2001a, b). However, most of the previous work has focused on the cutting quality of the main edge, whereas the influence of length and angle of the sawtooth side edge on the surface quality of sawing was not taken into account. In the process of sawing wood, the side edge also plays a role in cutting. In fact, with the extensive application of the ultrathin-cemented carbide circular saw for woodworking, the width of the main edge of the sawtooth continues to narrow, and the width of some blades reaches 1.0 to 1.2 mm. Wood is an elastic–plastic material with anisotropy, and a large quantity of chips could be produced in the process of wood sawing through wood fiber extrusion, tearing, severing, and other forms of damage. Friction occurs between the sawtooth and the surface of the sawed wall during the process of chip generation in the gullet area, and the formation of the sawing surface is caused mainly by the side edges. Thus, the geometric parameters of the side edges can play a significant role in the process of wood sawing.

The main objectives of this paper include analyzing the influences of the parameters of the side edges on surface roughness by using a circular saw with varying parameters of side edges, resolving contradictions between high feed speeds and improving surface roughness, and providing references for redesigning woodworking circular saws.

2 Theoretical background

In wood machining, three main cutting directions can be defined (Fig. 3). Also, factors to take into account include the angle between the tool edge and the direction of the fiber and the angle between the cutting direction and the direction of the fiber (Fig. 3). The three main cutting directions are as follows: (1) When the cutting direction is 90°–90°, both the cutting edge and the cutting direction are perpendicular to the grain (as for rip sawing). (2) When the cutting direction is 0°–90°, the cutting edge is parallel to the grain, but the cutting direction is perpendicular to the grain (as for veneer cutting). (3) When the cutting direction is 90°–0°, the cutting edge is perpendicular to the grain, but the cutting direction is parallel to the grain (as for planing).

Wood sawing is closed cutting, that is, the sawteeth cut the wood with three cutting blades (one main edge and two side edges). The three cutting planes (two sawing surfaces and one kerf surface) can be achieved after the motion of the sawtooth. Circular rip sawing is widely used as a head saw for the primary breakdown of wood at the 90°–90° cutting direction for the main edge and at the approximately 0°–90° cutting direction for the two side edges by using the McKenzie notation (McKenzie 1961; Laternser et al. 2003). The angle between the cutting direction of two side edges and the direction of the fiber changes as the circular saw blade rotates. The sawing surface is formed by the two side edges. Because of the radial clearance angle and blade vibration, the saw notch appeared on the sawing surface (Fig. 4). Given that the circular saw cuts wood under the premise of having no deflection and transverse vibration, the surface roughness of sawing is predetermined and consists of numerous saw notches. Sawing kinematics on the circular sawing machine is shown in Fig. 5a; Fig. 5b shows a case in which the radial clearance angle is λ from the M-M cut section. The profile of the sawtooth is b-e-e′-b′, a small part of two side edges (b-e and b′-e′) produced the sawing surfaces, and the main edge (b-b′) generated the kerf surface. The depth of the saw notch refers to the distance between the wave peak and the wave bottom caused by the main edge and the side edges, represented by S n , whereas the width of the saw notch refers to the distance between the wave troughs caused by the contiguous tooth top, represented by S b.

a Sawing kinematics on a circular sawing machine: U z = feed per tooth; D = circular saw blade diameter; h = uncut chip thickness; Hp = workpiece height (depth of cut); a = position of the workpiece; ϕ = angular tooth position. b Schematic of the formation of sawing surfaces with a radial clearance angle from the M-M cut section. c Schematic of the formation of sawing surfaces with a straight length of zero-degree radial clearance and a zero-degree radial clearance angle from the M-M cut section

The feed per tooth U z is associated with the surface roughness of the saw cutting. The smaller the U z , the smaller the surface roughness.

Because chip thickness refers to the normal direction between the two adjacent tracks of the tooth top at a certain position, it is equal to the width of the saw notch S b.

As shown in Fig. 5a, b, the equation of the width of the saw notch of the circular saw is as follows:

In sawing, when the sawtooth cuts the wood at the beginning, the width is the smallest. Concurrent to the sawing, the sawtooth gradually goes deep into the wood, and the width continues to increase. When the sawtooth leaves the saw line and the angle is zero degrees, a = 0 and sinφ = 1. At this time, h = S b = U z , as shown in Fig. 5b.

The depth of the saw notch is

As shown in Eq. 4, the methods for reducing the depth of the saw notch and the surface roughness—under the condition that the number of sawteeth Z and the angular tooth position are fixed—would be to increase the rotation speed n and to reduce either the feed speed U or the radial clearance angle λ.

During the actual cutting, the reduction of feed speed U affects the cutting efficiency. Also, the increase of the rotation speed n of the saw blade is also within a certain range, which affects the user safety of the saw blade.

Schematic of sawing surfaces formed by sawtooth with a straight length of zero-degree radial clearance and a zero-degree radial clearance angle from the M-M cut section are shown in Fig. 5c. The profile of a sawtooth with a zero-degree radial clearance angle is b-d-d′-b′. When λ = 0°, and the depth of the saw notch is theoretically zero, the cutting surface will be a theoretical surface. If the sawtooth with zero-degree radial clearance angle is used in sawing, the surface roughness will not be reduced with an increase in the feed per tooth in order to increase processing efficiency.

A small part of the side edges participates in wood sawing, in which the length of the participation is approximately equal to the feed per tooth; thus, the straight length of the zero-degree radial clearance could be designed on the edges of the sawteeth to reduce the friction between the side edges and the wood. The sawtooth profile is b-c-e-e′-c′-b′ (Fig. 5c), and the straight segment is b-c and b′-c. The ideal length is close to that of the feed per tooth; thus, the sawing surface quality can be ensured, and the friction area can be reduced.

On the basis of the research scenario provided, we put forward the concept of micro sawteeth with zero-degree radial clearance angles. The side edge consists of a zero-degree radial clearance angle section l (b-c or b′-c′; Fig. 6b) and a nonzero-degree radial clearance angle section l′ (c-e or c′-e′, Fig. 6b). The zero-degree radial clearance angle section l participates in cutting. Because the feed per tooth in cutting is relatively small, and the zero-degree radial clearance angle section l is quite small compared with the total length of the edges, the sawteeth are called a sawteeth with mic-zero-degree radial clearance angles. Compared with a sawtooth with a zero-degree radial clearance angle (Fig. 6a), a sawtooth with a mic-zero-degree radial clearance angle touches the sawing wall only in the zero-degree radial clearance angle section of the side edge. Thus, a smaller friction force occurs. Relative to a sawtooth with the zero-degree radial clearance angle, a sawtooth with the mic-zero-degree radial clearance angle causes a smaller temperature rise and has better stability.

a Sawtooth with a zero-degree radial clearance angle (Meng and Qi 1999). b Sawtooth with a mic-zero-degree radial clearance angle: λ = radial clearance angle; B = width of sawtooth; S′ = tooth side clearance; l = zero-degree radial clearance angle section; l′ = nonzero-degree radial clearance angle section; h′ = height of sawtooth

3 Materials and methods

3.1 Materials and equipment

The raw material was ash (Fraxinus spp.) with a depth of cut equal to that of Hp (Table 1) derived from the northeast region in China, which has an air-dry density of 0.67 g/cm3 and 18% moisture content. Test samples were 750 mm long, 35 mm wide, and 120 mm high. The samples were machined in NC-1325 IP with variable rotation and feed speeds (Fig. 7a). The basic sawing machine data and cutting parameters for which the computations were performed are given in Table 1.

The circular saw involved in the test was a Z 36 tungsten carbide (HW) tooth with a 20° rake angle, a 15° back-clearance angle, a 250-mm cutting diameter, and a 2.6-mm kerf. The cutting head of the saw blade consisted of YG6X, and the base material was 65 Mn. The grinding process of the traditional cemented carbide sawtooth was as follows: the bevel grinding of the side tooth surface (radial clearance angle)–back-clearance angle (back face)–rake angle (rake face). To grind different zero-degree radial clearance angle sections with the side edges to guarantee the same width of the cutting head, the sequence of the grinding process is adjusted as follows: grinding the side tooth surface (linear)–back-clearance angle (back face)–rake angle (rake face)–bevel grinding of the side tooth surface (radial clearance angle). In this way, not only the width of the cutting edge but also the length of the zero-degree radial clearance angle sections is ensured. Also, the microscope was adopted for observing the shapes of the sawteeth. Because of the limitation in grinding-machining precision, the minimum length of the mic-zero-degree radial clearance angle section is 0.5 mm based on the existing technology.

Surface roughness measurements were performed with a contact diamond stylus (Fig. 7b), and the cutoff length was 2.5 mm sampling lengths. The roughness parameter characterized by ISO 4287 standard (ISO 1997), considered for assessing the surface characteristics of the samples, was the arithmetical mean deviation Ra.

3.2 Design of the test

Nine different tooth geometries were tested: 0°, 1°, 1°–0.5 mm, 1°–1 mm, 1°–2 mm, 2°, 2°–0.5 mm, 2°–1 mm, and 2°–2 mm. The first number is the angle of the radial clearance angle (λ), and the second is the straight length of the zero-degree radial clearance (l). The cutting speeds were 5, 10, and 15 m/min, and three cuts were made in each test. The test consisted of perpendicular cutting (90°–90°) on the tangential section.

To minimize inaccuracies when comparing blade displacement obtained from cutting different samples of wood, after each cut, the remaining specimen of 75 × 35 mm was evaluated by measuring its roughness at 10 points. The measurement avoids the wood ray. The maximum and minimum values of each group are removed, and the average value is selected as the experimental determination value.

4 Results

4.1 Surface roughness under the feed speed change

Figure 8 shows the varying values of surface roughness under feed speed changes with different radial clearance angles and zero-degree radial clearance angle sections. As shown in Fig. 8, under the condition that the sawteeth of the circular saw blade have radial clearance angles, the surface roughness increases with increases in feed speed, respectively, from 25.7 to 30.1 μm and from 27.1 to 33.3 μm. Also, the larger the radial clearance angle is, the larger the increase in degree. When the radial clearance angle is zero degrees, the surface roughness Ra changes significantly with increases in feed speed, from 19.5 to 21.0 μm. However, when the sawtooth has a zero-degree radial clearance angle section, whether the radial clearance angle is 1° or 2°, the surface roughness is significantly reduced compared with the sawtooth with a nonzero-degree clearance. Also, the larger the feed speed is, the more obvious the influence.

Effect of feed speed on surface roughness: the first number is the angle of the radial clearance angle; the second is the straight length of the zero-degree radial clearance, such as 1°–0.5 mm, on behalf of the circular saw blade with a sawtooth structure radial clearance angle of 1° and a straight length of zero-degree radial clearance of 0.5 mm

4.2 Surface roughness under the radial clearance angle change

Figure 9 shows the surface roughness of sawing with different sawteeth of radial clearance angles. Also shown, under the same cutting conditions, surface roughness increases with increases in the radial clearance angle. When the feed speed remains at 5 m/min, the surface roughness value increases from 19.5 to 27.1 μm. When the feed speed remains at 10 m/min, the surface roughness increases from 20.1 to 29.7 μm. When the feed speed remains at 15 m/min, the surface roughness increases from 21.0 to 33.3 μm. Also, when the sawtooth has a radial clearance angle, its surface roughness also increases when the feed speed increases.

4.3 Surface roughness under the straight length of a zero-degree radial clearance change

Figure 10 shows the influences of different zero-degree radial clearance angle sections on surface roughness Ra when the radial clearance angles are 1° and 2°, respectively. As shown in Fig. 10, when the zero-degree radial clearance angle section increases from 0 to 0.5 mm, the decrease in surface roughness is most significant. Also, Fig. 10 shows the difference in value increases with increases in feed speed. When the feed speed is 15 m/min, the surface roughness values decrease from 30.1 to 23.8 μm and from 33.3 to 26.2 μm, respectively. However, when the zero-degree radial clearance angle section is larger than 0.55 mm, the increase of the surface roughness with the increase of the zero-degree radial clearance angle section is not obvious.

Effect of the straight length of zero-degree radial clearance on surface roughness at different feed speeds. a Radial clearance angle is 1°; b radial clearance angle is 2°. The horizontal lines are the length of the zero-degree radial clearance l (mm); the vertical whisker represents the surface roughness Ra (μm)

5 Discussion

Surface roughness increases with increases in feed speed. Also, the larger the radial clearance angle is, the larger the degree of increase. This occurrence is mainly attributable to the surface roughness of the sawing being affected by the depth of the saw notch to a certain extent. According to Eq. 4, if the other factors remain unchanged, the depth of the saw notch increases with increases in feed speed, thus increasing the roughness of the cutting surface. However, when the sawtooth has a zero-degree radial clearance angle section, whether the radial clearance angle is 1° or 2°, the surface roughness is significantly reduced compared with that from a sawtooth with a nonzero-degree clearance. The larger the feed speed, the more obvious the influence.

As given in Eq. 4, the surface roughness increases with increases to the radial clearance angle, and the radial clearance angle directly affects the depth of the saw notch. If factors such as saw vibration, wear, and anisotropy of wood structure are ignored, and when the radial clearance angle is zero degrees, the theoretical value of the surface roughness is 0. However, the actual result is that the surface roughness also increases with increases in feed speed, although by a smaller increase, which is mainly attributable to the sawtooth with zero-degree radial clearance angle. However, with the increase in feed speed, saw vibration problems occur more frequently. This finding suggests that a sawtooth with a zero-degree radial clearance angle can effectively alleviate the problem of increased surface roughness caused by increased feed speed.

When the sawteeth have mic-zero-degree radial clearance angles, the sawing surface roughness is lower than that from sawteeth with radial clearance angles. Especially when the straight length of a zero-degree radial clearance increases from 0 to 0.5 mm, the decrease is most obvious. With increased feed rate, the difference in surface roughness is greater. According to the previous analysis, a small part of the side edge, which formed the sawing surface, participates in the actual cutting, and the length of a small part of the side edge is approximately equal to the feed per tooth. Also, the straight length of the zero-degree radial clearance 0.5 mm is greater than that of the feed per tooth of 0.04 mm (the maximum feed per tooth in this experiment). The zero-degree radial clearance angle section of the side edge plays a role in the planing of wood. Thus, compared with a sawtooth with a zero-degree radial clearance, a zero-degree radial clearance angle section on the side edge can also improve sawing surface quality. The advantage of this type of sawtooth is that the surface roughness can be improved on the premise that increasing feed speed and friction can be reduced between the side edges and the wood.

6 Conclusion

Surface roughness depends on the depth of the saw notch to a certain extent. If other factors remain unchanged, the depth of the saw notch increases with increases in feed speed, thus improving surface roughness.

The smaller the radial clearance angle is, the smaller the surface roughness is in wood rip sawing. A circular saw with a zero-degree radial clearance angle can effectively alleviate the disparity of increased surface roughness caused by the increase in feed speed.

A small part of the side edge, which formed the sawing surface, participates in the actual cutting, and the length of this part of the side edge is approximately equal to the feed per tooth. Thus, the zero-degree radial clearance angle section of its side edge plays a role in planing wood. Compared with a sawtooth with a zero-degree radial clearance angle, it can also improve the surface quality of sawing. Also, if the other cutting factors remain unchanged, surface roughness can be improved on the premise of increased feed speed and reduction in friction between the side edges and the wood. Thus, the contradiction between high feed speed and better surface roughness can be resolved effectively.

References

Aguilera Leon AA (2000) Optimisation des conditions de coupe pour l’usinage du bois. Application de la méthode du couple outil matière au défonçage des panneaux de fibres de densité moyenne. Dissertation, Université de Nancy 1 Henri Poincaré

Akbulut T, Ayrilmis N (2006) Effect of compression wood on surface roughness and surface absorption of medium density fiberboard. Silva Fennica 40:161–167 http://www.metla.fi/silvafennica/full/sf40/sf401161.pdf

Bekhta P, Hiziroglu S, Shepelyuk O (2009) Properties of plywood manufactured from compressed veneer as building material. Mater Des 30:947–953

Brémaud I, Gril J, Thibaut B (2011) Anisotropy of wood vibrational properties: dependence on grain angle and review of literature data. Wood Sci Technol 45:735–754. doi:10.1007/s00226-010-0393-8

Costes J-P (2001) Approche de l’usinage à grande vitesse du bois: application au défonçage. Dissertation, Université Paul Sabatier, Toulouse III

Heisel U, TroÈger J, Fritz H (1998) Circular saw tools with curved lateral cutting edges extraordinary cutting results. Space Cut Fritz KG, Gewerbestrasse

ISO (1997) Geometrical product specifications (GPS)—surface texture: profile method—terms, definitions and surface texture parameters. International Organization for Standardization, Geneva, Switzerland

Khazaeian A (2006) Caractérisation 3D de l’état de surface du bois: Stratégie de mesure—Influence des parametres liés al’essence et al’usinage. Dissertation, Université Paul Sabatier, Toulouse III

Kilic M, Hiziroglu S, Burdurlu E (2006) Effect of machining on surface roughness of wood. Build Environ 41:1074–1078. doi:10.1016/j.buildenv.2005.05.008

Kirbach E, Ngusya M (1988) The effect of bevelling ripsaws on sawing accuracy and surface roughness of lumber. In: Lemaster RL (ed) Proceedings of the Ninth International Wood Machining Seminar, pp 229–236

Koch P (1964) Wood machining processes. Ronald Press, New York

Korkut I, Donertas M (2007) The influence of feed rate and cutting speed on the cutting forces, surface roughness and tool–chip contact length during face milling. Mater Des 28:308–312. doi:10.1016/j.matdes.2005.06.002

Kováč J, Mikleš M (2009) Analysis a cutting edge geometry influence on circular saw teeth at the process of crosscutting wood. Acta Univ Agric Silvic Mendelianae Brun 57:177–182. doi:10.11118/actaun200957050177

Krilov A (1988) New sawblade design: practical aspects and advantages. In: Lemaster RL (ed) Proceedings of the 9th International Wood Machining Seminar, pp 237–249

Laternser R, Gänser H-P, Taenzer L, Hartmaier A (2003) Chip formation in cellular materials. J Eng Mater Technol 125:44–49. doi:10.1115/1.1526126

Leban J, Triboulot P (1994) Défauts de forme et états de surface. In: Jodin P (ed) Le bois matériau d’ingénierie. ARBOLOR, Nancy, pp 333–363

Marko J, Holík J (2000) Teória delenia dreva. Technická Univerzita, Zvolen

Martin P (1992) Bois et productique. Cépaduès éditions, Toulouse

McKenzie WM (1961) Fundamental analysis of the wood-cutting process. Dissertation, University of Michigan

McKenzie WM (2000) Effects of bevelling the teeth of rip saws. Wood Sci Technol 34:125–133. doi:10.1007/s002260000037

Meng Q-W, Qi Y-J (1999) The study on mechanism of bandsaw of zero degree side clearance angle. For Mach Woodworking Equip:18–20 (in Chinese) http://www.cnki.com.cn/Article/CJFDTotal-LJMG199911005.htm

Meng Q-W, Li C-X, Gan X-J (2001a) Effect of saw side clearance angle on cutting roughness. China Wood Ind 15:22–24 (in Chinese) http://en.cnki.com.cn/Article_en/CJFDTotal-MCGY200106007.htm

Meng Q-W, Li C-X, Gan X-J (2001b) Performance analysed again on the sawblades of zero degree side clearance angle. Wood Process Mach 14–16. (in Chinese) http://en.cnki.com.cn/Article_en/CJFDTOTAL-MCJG200102004.htm

Simonin G, Meausoone P-J, Rougie A, Triboulot P (2009) Carbide characteriza for spruce rip-sawing. Pro Ligno 5:49–57

Thibaut B, Denaud L, Collet R, Marchal R, Beauchêne J, Mothe F, Méausoone P-J, Martin P, Larricq P, Eyma F (2016) Wood machining with a focus on French research in the last 50 years. Ann For Sci 73:163–184. doi:10.1007/s13595-015-0460-2

Triboulot P (1984) Réflexions sur les surfaces et mesures des états de surface du bois. Ann Sci For 41:335–354

Triboulot P, Kremer P, Martin P, Leban JM (1991) Planing of Norway spruce with very varied ring width. Holz als Roh-und Werkstoff 49:181–184. doi:10.1007/BF02613266

Acknowledgements

The authors are very grateful for financial support from the Natural Science Foundation of China (NSFC) Study on the Property and Mechanism of Wood Sawing with micro radial clearance angle tools (No. 31270605).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Jean-Michel Leban

Contribution of the co-authors

Weiguang Li: laboratory experiments, data collection, running the data analysis, analysis and discussion of the data, and writing the paper.

Zhankuan Zhang: laboratory experiments, data collection, analysis, and discussion of the data.

Xiaorui Peng: experimental design and laboratory experiments.

Bo Li: experimental design and supervising the work.

Rights and permissions

About this article

Cite this article

Li, W., Zhang, Z., Peng, X. et al. The influences of circular saws with sawteeth of mic-zero-degree radial clearance angles on surface roughness in wood rip sawing. Annals of Forest Science 74, 37 (2017). https://doi.org/10.1007/s13595-017-0632-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13595-017-0632-3