Abstract

We studied the distribution of coumaphos in beeswax after a single application of CheckMite® to 15 bee colonies in the fall according to the manufacturer’s instruction. Immediately after the treatment, residue levels were especially elevated in the wax that came into contact with the CheckMite® strips. During the following spring season, coumaphos levels ranged from 36 to 159 mg/kg in the wax of the brood frames next to the CheckMite® strips, and residue levels were about 10 times lower in the wax of frames that did not come into contact with the strips. Beeswax that was newly constructed 5 months after removing the treatment strips contained up to 7.3 mg/kg of coumaphos, and up to 0.5 and 2.3 mg/kg was detected in the honeycomb and capping wax, respectively. These results suggest that beeswax exposed to CheckMite® should not be recycled in order to prevent elevated concentrations of coumaphos in new foundations and hence to prevent honeybee larvae from being exposed to detrimental residue levels.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

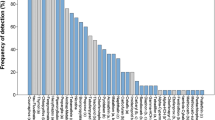

Veterinary medicinal products that contain coumaphos as an active ingredient, such as Perizin®, Asuntol®50 and CheckMite®, are authorised in several European and North American countries to protect honeybees from the parasitical mite Varroa destructor. CheckMite® is also approved to treat hives that are infested with Aethina tumida. As a lipophilic substance, coumaphos accumulates in various bee products, particularly in beeswax. As a result, residues from coumaphos-containing drugs have been found in the beeswax of European origin, as reported for Belgium (Ravoet et al. 2015), France (Chauzat et al. 2011), Germany (Wallner 1999), Switzerland (Bogdanov 2006), Italy (Boi et al. 2016; Porrini et al. 2016; Perugini et al. 2018) and Spain (Orantes-Bermejo et al. 2010; Calatayud-Vernich et al. 2017; Lozano et al. 2019), and also reviewed recently in Wilmart et al. (2016). Substantial coumaphos levels have also been found in the beeswax of apiaries outside of Europe, such as for example in North America (Mullin et al. 2010; Wu et al. 2011; Ostiguy et al. 2019; Fulton et al. 2019) or Uruguay (Harriet et al. 2017). A common beekeeping practice is to recycle old wax combs to produce new wax foundation sheets on which bees build their combs. Coumaphos residues are still present in the newly produced wax foundation sheets because coumaphos does not degrade during the recycling process (Bogdanov et al. 1998; Martel et al. 2007). While many studies have examined residue levels in beeswax with unknown history, fewer studies have examined coumaphos residue levels after applying a known product formulation for a known number of treatments. Bogdanov et al. (1998) found that the average residue level in beeswax was 4.3 mg/kg after a single application of Perizin containing 32 mg of coumaphos. Residue levels in beeswax reached up to 12.5 mg/kg after treatment with Asuntol®50 (300 mg coumaphos per application; Martel et al. 2007) and up to 35.1 mg/kg after two treatments with CheckMite® (2.72 g coumaphos per application; Premrov Bajuk et al. 2017).

However, the distribution of coumaphos residue within the beeswax of hive combs has not been studied in detail. This information is important to prevent the unintended accumulation of coumaphos in beeswax through wax recycling (Bogdanov et al. 1998; Martel et al. 2007). Such an accumulation could expose the queen, worker and drone larvae to elevated residue levels. Coumaphos could also migrate from wax into honey (Kochansky et al. 2001), thus affecting honey quality.

In the recent years, we observed an increase of coumaphos residues in Swiss commercial beeswax. We hypothesised that the use of CheckMite®, a product that has been authorised for use in Switzerland since 2006 was causing high residue levels in beeswax. Therefore, we performed a field study that applied CheckMite® to hives that had never been exposed to coumaphos before. First, we investigated the spatial and temporal differences of coumaphos residues in beeswax after a single treatment with CheckMite® containing 2.72 g of coumaphos (in two strips). Positions closer to the strips could contain higher residue levels than more distant positions and residue levels are most likely higher in the autumn, immediately after treatment, than in the following spring season. Second, we were interested in knowing the residue levels in melted comb wax in order to be able to provide recommendations to beekeepers regarding beeswax recycling. Finally, we also aimed to determine if residues can be found in wax that was not present during the treatment. Additionally, knowing the residue levels in beeswax serves to estimate the level of larval exposure to coumaphos, thus allowing to estimate the potential negative effect of coumaphos on bee health.

2 Material and methods

2.1 Honeybee colonies

The honeybee (Apis mellifera) colonies used in this study were located in Bellechasse, Switzerland (GPS coordinates: 46° 58′ 58.065″ N, 7° 08′ 42.817″ E). The colonies were on eight frames in 12-frame Dadant-Blatt hives and were treated against Varroa destructor infestation using organic acids before and after CheckMite® treatment (August and December). Two out of 15 colonies were eliminated during the winter due to small colony size or a drone-laying queen. In the spring, the colonies were expanded to 10 frames. Honey supers were added at the beginning of April.

2.2 CheckMite® treatment and beeswax sampling

Fifteen honeybee colonies were treated with CheckMite® (Bayer Healthcare AG) using two strips per colony for six weeks (7 September to 19 October 2016), according to the manufacturer’s instructions. The strips were suspended in the central part of the hive between two adjacent frames (Figure 1). Before the treatment on 7 September 2016, beeswax samples were collected from each frame of all the colonies and a mixed sample per colony was analysed for coumaphos residues (controls). After the CheckMite® treatment (28 October 2016), wax samples (25 cm2) were cut out of the combs adjacent to the CheckMite® strips, as well as from combs that did not come into contact with the strips (Figure 1, samples 1 and 2). The sampling was performed on the left side of the hive. The sample collection process was repeated in the same way during the following spring season on 29 May 2017 (Figure 1, samples 3 and 4). At the same time, two of the combs on the right side of the hive, which had previous contact with the strips were combined and melted (Figure 1, sample 5), as were the two combs from the frames that had no previous contact with the strips (Figure 1, sample 6).

Sampling from brood frames. Front view of a Dadant hive system with eight combs (indicated in grey) and two CheckMite® strips (indicated in black) suspended in the central part of the hive between two adjacent brood frames. The wax from the brood frames was sampled one week after the CheckMite® treatment on the left side of the hive (sample 1 came into contact with the strips and sample 2 did not). Seven months later, sampling was repeated (sample 3 came into contact with the strips and sample 4 did not). Two combs from brood frames that came into contact with the product on the right side of the hive were melted together (sample 5), and two combs from brood frames that did not come into contact with the strips were also melted together (sample 6)

We also analysed beeswax that was not present in the hive during the CheckMite® application, such as newly constructed wax and wax from the honey super. To produce newly constructed wax, an empty brood frame with only a small foundation strip was placed in each hive on 24 March 2017, 5 months after the CheckMite® strips were removed. Wax samples (25 cm2) were cut from these new combs on 29 May 2017. The honey supers were placed on ten hives at the beginning of April until the end of May 2017. On 26 May 2017, the supers were removed for honey collection. The wax sheets for the honey combs built in the previous year was from the same wax as the sheets of the brood frames. They originated from our own wax, which has never been exposed to coumaphos before. We chose three to five frames filled with honey per super. A piece of wax (25 cm2) that included the foundation was cut from these frames (Figure 2, sample 8) after the honey centrifugation process was complete. The capping wax was collected separately. A sufficient amount of capping wax for analysis was collected from five colonies (Figure 2, sample 9).

2.3 Sample preparations

Wax from entire combs was pre-treated by wrapping the combs in large cloths (miobrill swansoft spezial, Migros, Switzerland) and heating them in a beaker that contained distilled water at a temperature of 85 °C for 2–3 h. The wax was squeezed from the cloth and the water was allowed to cool. The wax samples were then collected from the surface of the water.

All beeswax samples, including the pre-treated samples, were wrapped in cloths (silk organza) that were previously washed with water to remove any possible residue and dried at room temperature. The wrapped samples were then heated in a beaker containing distilled water at a temperature of 85 °C for 2–3 h. As before, the wax was squeezed from the cloth, and the water was allowed to cool. Next, the hardened wax was collected from the surface of the water. Finally, all of the samples were melted once again at 85 °C and shaken before sampling to ensure homogeneity.

For analysis, 1.0 g of beeswax (samples 2–9) or 0.1 g of beeswax (sample 1) was weighed in a 50-mL polypropylene conical tube. The samples were prepared according to a modified QuEChERS method, which is based on a procedure previously described by Niell et al. (2014). After adding 10 mL of acetonitrile, the tube was placed in a water bath at a temperature of ca. 80 °C until the beeswax was melted. The tube was vigorously shaken by hand for 15 s and then placed back in the water bath. This procedure was repeated three more times. Next, the tube was left to cool down at room temperature before placing the tube in a deep freezer at a temperature of − 18 °C overnight to ensure precipitation of the wax. The next day, the sample was centrifuged at 1620g (Eppendorf Centrifuge 5804) at room temperature for 5 min. Next, 2 mL of the supernatant was added to an Eppendorf tube containing 50 mg of primary-secondary amine (PSA) (Bondesil-PSA 40 μm, Agilent Technologies, USA, Part No 12213024) and 50 mg of Bondesil-C18 40 μm sorbent (Agilent Technologies, USA, Part No 12213012). The tube was mixed two times for 30 s on a vortex and placed back in the deep freezer overnight. The next day, the sample was centrifuged at 1620g (Eppendorf Centrifuge 5804) at room temperature for 5 min. Finally, the supernatant was filtered (0.45 μm) to obtain the final extract for analysis.

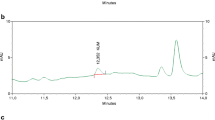

2.4 GC-MS/MS analysis

Gas chromatography analysis was performed based on a method described by Bogdanov et al. (1998). In brief, analysis was performed using a Thermo Trace Ultra 2000 gas chromatograph that was equipped with a deans heartcut switching system coupled with a MS/MS triple quadrupole (Thermo Quantum) and an FID detector with a 15-m transfer column. An autosampler (CTC Combi PAL Systems) was used for automatic injection. The carrier gas was helium. A retention capillary column deactivated with OV-1701-OH (0.53 mm ID) of 50 cm and a DB-1 analytical capillary column (J+W, 0.25 mm ID, 0.25-μm film thickness) of 30 m as well as a transfer column Rxi®-5 Sil MS (0.25 mm ID, 0.25-μm film thickness) were used. One microliter of the final beeswax extract was injected on column. The gas chromatograph was operated using the constant pressure mode (225 kPa). The gas chromatograph temperature program was 2.0 min at 75 °C, 75 to 250 °C at 5 °C/min, 250 to 300 °C at 3 °C/min, where it was held for 50 min. The source temperature (TSQ Quantum) and the temperature of the transfer column were at 250 °C. The ionisation energy was 70eV. The deans heartcut switching system allowed for the detection of the coumaphos peak (RT window 43.0 to 48.5 min) on the MS/MS triple quadrupole, while the rest of the chromatogram was directed to an FID detector in order to prevent pollution of the MS system. Coumaphos was identified using the retention time and mass fragmentation. The transitions of mz 362 to 334 (CE10), mz 362 to 109 (CE25) and mz 226 to 163 (CE18) were used for identification and the transition mz 226 to 163 was used for quantification.

Quantification was achieved through external calibration using coumaphos (PESTANAL™, No 45403, Sigma-Aldrich; Switzerland). The standard solutions were prepared in blank matrix extract to compensate for matrix effects. The linear responses were obtained from 0.008 to 40 mg/L, and the limit of detection (LOD) was experimentally determined using spiked blank wax extracts. The LOD was 0.008 mg/L, which corresponds to 0.08 mg/kg wax for samples 2–9, or 0.8 mg/kg wax for sample 1. The LOD was defined as the lowest coumaphos concentration that was considerably above the matrix signal (signal to noise [s/n] 100). The limit of quantitation (LOQ) was set at 0.01 mg/L, which corresponds to an LOQ of 0.1 mg/kg wax for samples 2–9 or 1.0 mg/kg wax for sample 1. The LOQ was defined as the lowest validated spiked level where the recovery was equal to or above 80%. The recovery for the extraction procedure starting with 1.0 g beeswax in 10 mL acetonitrile (extraction procedure for samples 2–9) was tested at nine spiking levels (0.1, 0.5, 1, 10, 20, 50, 100, 200 and 400 mg/kg) with three to five repetitions per spiking level. The recoveries for these spiking levels were between 80 and 96%. The recovery for the extraction procedure starting with 0.1 g beeswax in 10 mL acetonitrile (extraction procedure for sample 1) was tested at four spiking levels (1000 mg/kg, 2000 mg/kg, 3000 mg/kg and 4000 mg/kg) with five repetitions for each spiking level. The recoveries for these spiking levels were between 77 and 100%.

3 Results

The beeswax samples that were collected before the CheckMite® treatment contained no coumaphos residues above the LOD (0.08 mg/kg). However, after the treatment, high residue levels were detected in beeswax that came into contact with the CheckMite® strips. The mean coumaphos concentration was 800 mg/kg in samples that were collected immediately after treatment and 254 mg/kg in samples that were collected seven months later (Figure 3, samples 1 and 3). Substantial residue levels were also detected in the samples that were collected from combs that did not come into contact to the treatment strips. The residue levels were on average 28 mg/kg in the samples that were collected immediately after the CheckMite® application and 5.3 mg/kg in the samples that were collected during the following spring season (Figure 3, samples 2 and 4). Therefore, the residue levels were substantially higher near the treatment strips than further away. Furthermore, residue levels decreased during the winter months and were 3 to 5 times lower in the subsequent spring season.

Coumaphos concentrations (mg/kg) in beeswax samples collected from brood combs (mean +/- SD, median, minimum and maximum, and number (n) of samples). Sample 1, which came into contact with the treatment strips (vertical lines), and sample 2, which did not come into contact with the strips (white), were collected immediately after the CheckMite® treatment. Sample 3, which came into contact (horizontal lines) with the strips, and sample 4, which did not come into contact with the strip (black), were collected 7 months later

To estimate the implications for wax recycling, we combined in the spring two entire combs that came into contact with the treatment strips (sample 5) and separately two entire combs that did not come into contact with the strips (sample 6). On average, coumaphos concentrations of 65 mg/kg were measured in combs that came into contact with the strips and concentrations of 6.7 mg/kg were measured in combs that did not come into contact with the strips (Figure 4). The residue levels were approximately 10 times higher in combs that came into contact with the strips compared to those that did not, which means that especially the central combs should not be recycled.

Coumaphos concentrations (mg/kg) in beeswax several months after CheckMite® treatment (mean ± SD, median, minimum and maximum, and number (n) of samples). Two combs that came into contact with the treatment strips were combined and melted (dark grey, sample 5), and two combs that did not come into contact with the strips (light grey, sample 6) were also combined and melted. Newly constructed combs (white, sample 7)

We also aimed to determine whether coumaphos residues were detectable in beeswax that was not present during the CheckMite® treatment. Therefore, an empty frame was placed in the hive to produce new wax, which showed 2.8 mg/kg of coumaphos residue on average (Figure 4, sample 7). Moreover, beeswax was collected from the supers that were placed on the beehives 6 months after treatment. The wax collected from super contained 0.3 mg/kg of coumaphos on average (Figure 5, sample 8). Finally, 1.2 mg/kg of coumaphos was measured in the capping wax on average (Figure 5, sample 9). Taken together, these results show that coumaphos residues can become dispersed within the beehive, resulting in detectable residue levels in beeswax that was not present during the CheckMite® treatment.

Coumaphos concentrations (mg/kg) in beeswax samples collected from supers that were placed on the hives six months after CheckMite® treatment (mean ± SD median, minimum and maximum, and number (n) of samples). The samples include comb (horizontal lines, sample 8) and capping wax (vertical lines, sample 9)

4 Discussion

Our results show that treating bees against Varroa destructor using a one-time application of CheckMite® in the autumn, according the manufacturer’s instructions, leads to substantial coumaphos residue in the beeswax, and especially in wax near the strips. The use of CheckMite® could be problematic for honeybee larvae because residue levels are still high during the following spring season. Our results also demonstrate that residues are found in beeswax that is usually considered residue free, such as capping wax and newly constructed wax.

Residue levels were unevenly distributed within the beeswax in the hive. The wax adjacent to the strips, in particular, contained very high coumaphos levels. Meanwhile, wax from the combs that did not come into contact with the strips showed 29- to 48-fold lower residue levels. Spatial differences have also been previously reported for brood chamber honey, showing that residues accumulated mainly in brood chamber honey next to the CheckMite® strips reaching up to 0.2 mg/kg, while residue levels were constantly below 0.1 mg/kg in honey stored in combs without contact to the strips (Karazafiris et al. 2008). Hence, the expected residue levels in both wax and brood chamber honey largely depends on the proximity to the strips.

Residue levels in wax within the hive decreased over time. A study by Tremolada et al. (2004) using Perizin® (50 mL solution corresponding to a dose of 32 mg coumaphos/hive) calculated based on a first order kinetics model that coumaphos residues in beeswax decrease in the hive to half of the initial concentration within 100 days. In our study, coumaphos levels in wax decreased at a similar rate (3- to 5-fold within 7 months from the end of treatment to following spring season), thus supporting the model established by Tremolada et al. (2004).

In our study, coumaphos levels were higher than the levels reported by Premrov Bajuk et al. (2017), which were 1.5–10.8 mg/kg for wax without contact to the strips, immediately after a single CheckMite® application, but lower than levels measured in another study reporting coumaphos levels up to 271 mg/kg for wax without contact to the strips (Berry et al. 2013). Since we observed large spatial and temporal differences, we conclude that the obtained residue levels largely depend on position and time point of sample collection. Furthermore, we observed large variations in our wax samples from different colonies. Bees use wax combs for storage of honey and pollen and the queen lays eggs in the combs, which together with the activity of the bees influences residues levels in wax at a given position. Hence, studies should include a sufficient number of colonies to obtain robust residue data. In our study on 15 colonies, we obtained detailed information about coumaphos distribution and decrease over time.

A previous study reported high levels of coumaphos after CheckMite® application for 3 years, which were on average 45 mg/kg (eight colonies with queen failure) and 24 mg/kg (eight good active colonies) (Nasr and Wallner 2003). These levels are in similar order of magnitude as levels in our study, where we obtained average coumaphos concentrations of 65 mg/kg in melted combs with contact and 6.7 mg/kg in combs without contact to the strips. This is also in line with residue levels in wax up to 32 mg/kg as stated in the package insert for CheckMite® ad us. vet. (Tierarzneimittel Kompendium der Schweiz 2019). Finally, based on the data on CheckMite® submitted by Bayer Corporation, the environmental protection agency (USA) reported that residue levels in beeswax are not expected to exceed 100 mg/kg (United States Environmental Protection Agency 2002). Substantial levels of coumaphos were also found in brood comb wax that was newly constructed by bees five months after the treatment strips were removed. Similarly, newly produced capping wax contained coumaphos, suggesting that bees still produce new wax containing residues more than half a year after the end of CheckMite® treatment. This observation supports a previous study on Perizin, which proposes that bees that come into contact with contaminated wax may accumulate coumaphos in their cuticles and subsequently transfer the product into the newly constructed wax (Van Buren et al. 1992). On the other hand, honey combs were already built when supers were placed on the colonies. They also contained traces of coumaphos, which suggests that bees distribute the product within various hive compartments (Tremolada et al. 2004). Alternatively, bees may directly transfer coumaphos-containing wax from contaminated combs into the newly constructed wax or honey supers.

Multiple negative effects of coumaphos on bees, including drones and queens, have been previously described and recently reviewed (Tihelka 2018). Previous studies have shown that bees exposed to CheckMite® as larvae have increased mortality rates as adults (Berry et al. 2013), and the viability of stored sperm was lower for drones that were previously exposed to CheckMite® (Burley et al. 2008). Furthermore, reduced queen acceptance and mating success was associated with CheckMite® treatment (Fell and Tignor 2001). Since coumaphos is a lipophilic substance that accumulates in beeswax, honey bee larvae are exposed if they come into direct contact with contaminated beeswax or if coumaphos migrates from the beeswax into the larval jelly. Previous studies have shown that coumaphos residues in beeswax have negative effects on the queen larvae: queen rearing in beeswax that contained 100 mg/kg of coumaphos resulted in rejection of more than 50% of the queen cells (Pettis et al. 2004), and the surviving queens weighed less and showed reduced performance (Collins et al. 2004). Furthermore, queens reared in beeswax containing a combination of fluvalinate and coumaphos at sublethal levels showed lower sperm counts in their spermathecae (Rangel and Tarpy 2015), but negative effects could not be observed on a colony level (Rangel and Tarpy 2016).

In our study, coumaphos residues ranged from 36 to 159 mg/kg in central brood combs seven months after a single CheckMite® application. These residue levels were close to 100 mg/kg, which is the level that is shown to have severely negative effects on the queen larvae (Pettis et al. 2004). We suspect that high residue levels in wax could also be problematic for the larval development of worker bees, if coumaphos migrates into larval jelly, since previous studies have revealed the oral toxicity of coumaphos to honey bee larvae reared in vitro at dietary coumaphos levels of 8 mg/L (Zhu et al. 2014) or 25 mg/L (Dai et al. 2018). Coumaphos levels up to 0.6 mg/kg have been previously measured in brood after CheckMite® treatment (Premrov Bajuk et al. 2017). Moreover, residue levels in wax combs likely increase with repeated CheckMite® applications (Berry et al. 2013; Premrov Bajuk et al. 2017). Therefore, further experiments should determine the level of coumaphos in beeswax that can be tolerated by larvae, as well as the critical concentration of coumaphos that affects larval development. Taken together, the central frames are likely to be inadequate for brood rearing; therefore, beekeepers should replace the central frames. This measure is recommended in the manufacturer’s instructions (CheckMite® ad us. vet. authorised in Switzerland).

Beeswax from colonies treated with CheckMite® can be recycled to produce new foundations. However, high residue levels in old wax combs leads to substantial residues in newly produced wax foundations (Bogdanov et al. 1998; Martel et al. 2007). Therefore, beeswax should not be recycled after the use of CheckMite®. Especially, the central frames are inadequate for wax recycling due to their particularly elevated levels of residue. On the other hand, discarding the central combs after a single CheckMite® treatment means that half of the wax is no longer available for recycling after a single CheckMite® treatment. With respect to the current shortage of beeswax, we consider it as highly problematic to discard half of all wax combs.

At our institute, we perform a monitoring program for Swiss beeswax (Bogdanov 2004) in collaboration with eight to eleven manufacturers of foundation sheets. Every second year, we obtain wax samples of each production lot. We combine the wax lots to yield a representative annual sample from each manufacturer, which we analyse for acaricide residues. In all the years 1996 to 2013, average yearly coumaphos levels were 1 mg/kg or below for all manufacturers, while in 2015 and 2017 maximal coumaphos levels in annual samples of some manufacturers increased to 5 and 6 mg/kg, respectively (data not shown). Yearly surveys on winter mortality in which we also ask for the type of Varroa treatment suggest that few beekeepers in Switzerland use CheckMite® (currently the only coumaphos containing product authorized), while the big majority of beekeepers uses organic acids. In a common recycling process, coumaphos residues are diluted with clean wax from beekeepers that use alternative treatments, such as organic acids that do not accumulate in beeswax. On the other hand, residue levels increase for all beekeepers that participate in common wax recycling if some beekeepers use products with high doses of lipophilic coumaphos, such as CheckMite®. Therefore, a few beekeepers could spoil the efforts of those who aim to keep residue levels as low as possible.

Furthermore, the treatment with CheckMite® has led to the appearance of parasitical Varroa destructor mites that are resistant to coumaphos after only three years of being exposed to the product (Pettis 2004). Previous studies have shown that the presence of coumaphos residue in beeswax is enough to increase the risk of coumaphos resistance in Varroa mites, because the parasite is in constant contact with the active ingredient (Medici et al. 2015; Mitton et al. 2018).

In conclusion, we recommend alternative bee health management approaches, and we advise against using lipophilic miticides, such as CheckMite®. Our study shows that a single application of CheckMite® leads to very high concentrations of coumaphos residues that are near the level that is critical for queen rearing and probably for the development of worker larvae. Therefore, beeswax from colonies treated with CheckMite® should not be recycled to produce new foundations.

References

Berry, J.A., Hood, W.M., Pietravalle, S., Delaplane, K.S. (2013) Field-level sublethal effects of approved bee hive chemicals on honey bees (Apis mellifera L). PloS One 8 (10), e76536. https://doi.org/10.1371/journal.pone.0076536

Bogdanov, S. (2004) Beeswax: quality issues today. Bee World 85 (3), 46–50. https://doi.org/10.1080/0005772X.2004.11099623

Bogdanov, S. (2006) Contaminants of bee products. Apidologie 37, 1–18. https://doi.org/10.1051/apido:2005043

Bogdanov, S., Kilchenmann, V., Imdorf, A. (1998) Acaricide residues in some bee products. J. Apic. Res. 37 (2), 57–67. https://doi.org/10.1080/00218839.1998.11100956

Boi, M., Serra, G., Colombo, R., Lodesani, M., Massi, S., Costa, C. (2016) A 10-year survey of acaricide residues in beeswax analysed in Italy. Pest Manag. Sci. 72, 1366–1372. https://doi.org/10.1002/ps.4161

Burley, L.M., Fell, R.D., Saacke, R.G. (2008) Survival of honey bee (Hymenoptera: Apidae) spermatozoa incubated at room temperature from drones exposed to miticides. J. Econ. Entomol. 101 (4), 1081–1087. https://doi.org/10.1093/jee/101.4.1081

Calatayud-Vernich, P., Calatayud, F., Simó, E., Picó, Y. (2017) Occurrence of pesticide residues in Spanish beeswax. Sci. Total Environ. 605–606, 745–754. https://doi.org/10.1016/j.scitotenv.2017.06.174

Chauzat, M.P., Martel, A.C., Cougoule, N., Porta, P., Lachaize, J., Zeggane, S., Aubert, M., Carpentier, P., Faucon, J.P. (2011) An assessment of honeybee colony matrices, Apis mellifera (Hymenoptera Apidae) to monitor pesticide presence in continental France. Environ Toxicol. Chem. 30 (1), 103–111. https://doi.org/10.1002/etc.361

Collins, A.M., Pettis, J.S., Wilbanks, R., Feldlaufer, M.F. (2004) Performance of honey bee (Apis mellifera) queens reared in beeswax cells impregnated with coumaphos. J. Apic. Res. 43 (3), 128–134. https://doi.org/10.1080/00218839.2004.11101123

Dai, P., Jack, C.J., Mortensen, A.N., Bustamante, T.A., Ellis, J.D. (2018) Chronic toxicity of amitraz, coumaphos and fluvalinate to Apis mellifera L. larvae reared in vitro. Sci. Rep. 8, 5635. https://doi.org/10.1038/s41598-018-24045-3

Fell, R.D., Tignor, K. (2001) Miticide effects on the reproductive physiology of queens and drones. Am. Bee J. 141, 888–889.

Fulton, C.A., Huff Hartz, K.E., Fell, R.D., Brewster, C.C., Reeve, J.D., Lydy, M.J. (2019) An assessment of pesticide exposures and land use of honey bees in Virginia. Chemosphere 222, 489-493. https://doi.org/10.1016/j.chemosphere.2019.01.156

Harriet, J., Campá, J.P., Grajales, M., Lhéritier, C., Gómez Pajuelo, A., Mendoza-Spina, Y., Carrasco-Letelier, L. (2017) Agricultural pesticides and veterinary substances in Uruguayan beeswax. Chemosphere 177, 77–83. https://doi.org/10.1016/j.chemosphere.2017.02.131

Karazafiris, E. , Tananaki, C. , Menkissoglu-Spiroudi, U., Thrasyvoulou, A. (2008) Residue distribution of the acaricide coumaphos in honey following application of a new slow-release formulation. Pest. Manag. Sci., 64, 165-171. https://doi.org/10.1002/ps.1493

Kochansky, J., Wilzer, K., Feldlaufer, M. (2001) Comparison of the transfer of coumaphos from beeswax into syrup and honey. Apidologie 32 (2), 119–125. https://doi.org/10.1051/apido:2001117

Lozano, A., Hernando, M.D., Uclés, S., Hakme, E., Fernández-Alba, A.R. (2019) Identification and measurement of veterinary drug residues in beehive products. Food Chem. 274, 61–70. https://doi.org/10.1016/j.foodchem.2018.08.055.

Martel, A.C., Zeggane, S., Aurières, C., Drajnudel, P., Faucon, J.P., Aubert, M. (2007) Acaricide residues in honey and wax after treatment of honey bee colonies with Apivar® or Asuntol®50. Apidologie 38 (6), 534–544. https://doi.org/10.1051/apido:2007038

Medici, S.K., Maggi, M.D., Sarlo, E.G., Ruffinengo, S., Marioli, J.M., Eguaras, M.J. (2015) The presence of synthetic acaricides in beeswax and its influence on the development of resistance in Varroa destructor. J. Apic. Res. 54 (3), 276–274. https://doi.org/10.1080/00218839.2016.1145407

Mitton, G.A., Szawarski, N., Ramos, F., Fuselli, S., Meroi Arcerito, F.R., Eguaras, M.J., Ruffinengo, S.R., Maggi, M.D. (2018) Varroa destructor: when reversion to coumaphos resistance does not happen. J. Apic. Res. 57 (4), 536–540. https://doi.org/10.1080/00218839.2018.1475038

Mullin, C.A., Frazier, M., Frazier, J.L., Ashcraft, S., Simonds, R., van Engelsdorp, D., Pettis, J.S. (2010) High levels of miticides and agrochemicals in North American apiaries: Implications for honey bee health. PLoS One 5,(3), e9754. https://doi.org/10.1371/journal.pone.0009754

Nasr, M.E., Wallner, K. (2003) Miticides residues in honey and wax in North America. Am.Bee J. 143, 322.

Niell, S., Cesio, V., Hepperle, J., Doerk, D., Kirsch, L., Kolberg, D., Scherbaum, E., Anastassiades, M., Heinzen, H. (2014) QuEChERS-based method for the multiresidue analysis of pesticides in beeswax by LC-MS/MS and GC×GC-TOF. J. Agric. Food Chem.62 (17), 3675-3683. https://doi.org/10.1021/jf405771t

Orantes-Bermejo, F.J., Gomez Pajuelo, A., Megias Megias, M., Torres Fernandez-Pinar, C. (2010) Pesticide residues in beeswax and beebread samples collected from honey bee colonies (Apis mellifera L.) in Spain. Possible implications for bee losses. J. Apic. Res. 49 (3), 243–250. https://doi.org/10.3896/IBRA.1.49.3.03

Ostiguy, N., Drummond, F.A., Aronstein, K., Eitzer, B., Ellis, J.D., Spivak, M., Sheppard, W.S. (2019) Honey bee exposure to pesticides: A four-year nationwide study. Insects10 (13), 1–35. https://doi.org/10.3390/insects10010013

Perugini, M., Tulini, S.M.R., Zezza, D., Fenucci, S., Conte, A., Amorena, M. (2018) Occurrence of agrochemical residues in beeswax samples collected in Italy during 2013–2015. Sci. Total Environ. 625, 470–476. https://doi.org/10.1016/j.scitotenv.2017.12.321

Pettis, J.S. (2004) A scientific note on Varroa destructor resistance to coumaphos in the United States. Apidologie 35, 91–92. https://doi.org/10.1051/apido:2003060

Pettis, J.S., Collins, A.M., Wilbanks, R., Feldlaufer, M.F. (2004) Effects of coumaphos on queen rearing in the honey bee, Apis mellifera. Apidologie 35, 605–610. https://doi.org/10.1051/apido:2004056

Porrini, C., Mutinelli, F., Bortolotti, L., Granato, A., Laurenson, L., Roberts, K., Gallina, A., Silvester, N., Medrzycki, P., Renzi, T., Sgolastra, F., Lodesani, M. (2016) The status of honey bee health in Italy: Results from the Nationwide Bee Monitoring Network. PLoS One 11 (5), e0155411. https://doi.org/10.1371/journal.pone.0155411

Premrov Bajuk, B., Babnik, K., Snoj, T., Milčinski, L., Pislak Ocepek, M., Škof, M., Jenčič, V., Filazi, A., Štajnbaher, D., Kobal, S. (2017) Coumaphos residues in honey, bee brood, and beeswax after Varroa treatment. Apidologie 48 (5), 588–598. https://doi.org/10.1007/s13592-017-0501-y

Rangel, J., Tarpy, D.R. (2015) The combined effects of miticides on the mating health of honey bee (Apis mellifera L.) queens. J. Apic. Res. 54 (3), 275–283. https://doi.org/10.1080/00218839.2016.1147218

Rangel, J., Tarpy, D.R. (2016) In-hive miticides and their effect on queen supersedure and colony growth in the honey bee (Apis mellifera). J. Environ. Anal. Toxicol. 6 (3), 1000377. https://doi.org/10.4172/2161-0525.1000377

Ravoet, J., Reybroeck, W., de Graaf, D.C. (2015) Pesticides for apicultural and/or agricultural application found in Belgian honey bee wax combs. Bull. Environ. Contam. Toxicol. 94, 543–548. https://doi.org/10.1007/s00128-015-1511-y

Tierarzneimittel Kompendium der Schweiz (2019). https://www.vetpharm.uzh.ch/TAK/05000000/00057473.01

Tihelka, E. (2018) Effects of synthetic and organic acaricides on honey bee health: a review. Slov. Vet. Res. 55(2), 119–140. https://doi.org/10.26873/SVR-422-2017

Tremolada, P., Bernardinelli, I., Colombo, M., Spreafico, M., Vighi, M. (2004) Coumaphos distribution in the hive ecosystem: case study for modeling applications. Ecotoxicology 13, 589–601. https://doi.org/10.1023/B:ECTX.0000037193.28684.05

United States Environmental Protection Agency Washington, D.C. 20460 (2002) Office of Prevention, Pesticides and Toxic Substances. http://pmep.cce.cornell.edu/regulation/sec18/2003/coumaphos_sec18_2003.html

Van Buren, N.W.M., Marien, J., Velthuis, H.H.W., Oudejans, R.C.H.M. (1992) Residues in beeswax and honey of perizin, an acaricide to combat the mite Varroa jacobsoni Oudemans (Acari: Mesostigmata). Environ. Entomol. 21 (4), 860–865. https://doi.org/10.1093/ee/21.4.860

Wallner, K. (1999) Varroacides and their residues in bee products. Apidologie 30, 235–238. https://doi.org/10.1051/apido:19990212

Wilmart, O., Legrève, A., Scippo, M.L., Reybroeck, W., Urbain, B., de Graaf, D.C., Steurbaut, W., Delahaut, P., Gustin, P., Nguyen, B.K., Saegerman, C. (2016) Residues in beeswax: A health risk for the consumer of honey and beeswax? J. Agric. Food Chem. 64 (44), 8425–8434. https://doi.org/10.1021/acs.jafc.6b02813

Wu, J.Y., Anelli, C.M., Sheppard, W.S. (2011) Sub-lethal effects of pesticide residues in brood comb on worker honey bee (Apis mellifera) development and longevity. PLoS One 6 (2), e14720. https://doi.org/10.1371/journal.pone.0014720.

Zhu, W., Schmehl, D.R., Mullin, C.A., Frazier, J.L. (2014) Four common pesticides, their mixtures and a formulation solvent in the hive environment have high oral toxicity to honey bee larvae. PLoS One 9 (1), e77547. https://doi.org/10.1371/journal.pone.0077547

Author information

Authors and Affiliations

Contributions

CK, VK and BD designed the experiments. BD treated the beehives with CheckMite® and performed the sample collection. VK performed the chemical analysis. CK, VK and BD interpreted the data. CK wrote the paper, and VK, BD and CK revised it. All of the authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Manuscript editor: Peter Rosenkranz

Distribution du coumaphos dans la cire d'abeille après traitement des colonies d'abeilles avec CheckMite® contre l'acarien parasite Varroa destructor.

cire d'abeille / coumaphos / CheckMite® / abeilles domestiques / Apis mellifera / Varroa destructor.

Verteilung von Coumaphos in Bienenwachs nach Behandlung von Bienenvölkern mit CheckMite® gegen die parasitische Milbe Varroa destructor.

Bienenwachs / Coumaphos / CheckMite® / Honigbienen / Apis mellifera / Varroa destructor .

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kast, C., Kilchenmann, V. & Droz, B. Distribution of coumaphos in beeswax after treatment of honeybee colonies with CheckMite® against the parasitical mite Varroa destructor. Apidologie 51, 112–122 (2020). https://doi.org/10.1007/s13592-019-00724-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13592-019-00724-6