Abstract

Microwave heating is one of the leading methods that save energy, time, and cost for the conversion of bio-waste into biochar in the agricultural sector. In this study, in the first stage, economical biochar production from pistachio green hulls by microwave heating method is in question. In the second step, sodium hydroxide(NaOH) activation was followed to improve the surface properties of biochar. This adsorbent obtained was applied to remove copper ions(Cu(II)) from wastewater. Fourier-transform infrared spectroscopy (FTIR), scanning electron microscopy (SEM), energy dispersive X-ray analysis (EDX), thermogravimetry differential thermal analysis (TG/DTG), and nitrogen adsorption/desorption methods were used to characterize the biochar samples. In adsorption studies, kinetic, isotherm, and thermodynamic parameters were investigated. Cu(II) adsorption capacity on modified biochar obtained by Langmuir isotherm was found to be 227.27 mg/g. In addition, the mechanism of Cu(II) adsorption on modified biochar has been proposed. Biochar, which is obtained from the green shells of pistachios, which is widely available and grown in Turkey, by microwave method and then NaOH activation, is a potential solution for both the improvement of water pollution caused by heavy metals and the disposal of related wastes with an appropriate method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As a porous material with unique physicochemical properties, carbon-based biochars are commonly produced through differential thermochemical decomposition of agricultural waste biomass [1]. With its advantages, such as environmental friendliness, utilization of waste raw material resources, and carbon sequestration potential, biochar is considered an alternative to conventional adsorbents [2]. Biochar, which can be produced with cheap, abundant, and sustainable raw materials, is effectively preferred in various application areas such as the removal of pollutants [3], catalytic application [4], electrochemical energy conversion, and storage [5] with its physical and chemical properties. Convective or conductive heating, which takes a longer time, is used to heat materials such as biochar or activated carbon [6]. However, these heating methods have high energy consumption during pyrolysis, and carbonization temperature and rate are limiting factors. In contrast, microwave-assisted heating interacts with the dipoles of the biomass for the heat required for pyrolysis. Thus, surface heating is more efficient compared to conventional heating methods, and energy consumption can be reduced by shortening the heating time [7]. In other words, in the production of biomass compared to conventional pyrolysis methods, there is lower energy consumption and faster heating with a shorter processing time, with the direct transfer of energy to the materials in an electromagnetic field with microwave heating [8]. At the same time, the physical and chemical properties of the obtained biochar can be improved with various modifications [9,10,11]. With chemical modification methods, the specific surface area and pore structure of biochar, which is important in applications, can be changed [10, 12,13,14]. Various acids such as phosphoric acid and nitric acid, bases such as potassium hydroxide (KOH) and NaOH, salts such as zinc chloride, and oxidizers such as hydrogen peroxide are preferred as chemicals for these modifications [15,16,17]. The activation of alkali with chemicals such as NaOH and KOH has the advantages of both developing synergistic effects to fully reveal active adsorption sites and increasing active functional groups through the reaction between carbon-oxygen bond and alkaline [18, 19]. The USA, Turkey, and Iran are the leading producers of pistachio production in the world. World pistachio commercial production, which was 345,408 tons in 1994, increased by more than three times to 1.1 million tons in 2020 [20]. Approximately 35–40% of the pistachio’s weight consists of the discarded green husk [21]. The accumulation of such large amounts of waste can lead to environmental problems [22]. Considered waste in the food processing industries, pistachio shells contain functional ingredients that have enormous industrial and nutraceutical applications. In recent years, the evaluation of such agricultural wastes and the recovery of bioactive compounds from by-products has been recognized as one of the important emerging research trends [23].

One of the problems facing humanity in the twenty-first century is the pollution of drinking water, which is at a limited level. More and more heavy metals are discharged into the environment from different applications [24]. One of these heavy metals is copper, which is widely used in industrial processes. Excessive Cu(II) intake may cause serious health problems such as severe headaches, kidney damage, nausea, hypoglycemia, Wilson’s disease, and Menkes syndrome [25]. Therefore, it is important to remove the high Cu(II) concentration, which causes environmental pollution and negative effects on living things, with effective methods. As one of the effective methods, the adsorption method has an important place due to its environmental friendliness, low cost, and convenient resource recovery. In recent years, materials-based carbon samples have been used as effective adsorbents to eliminate heavy metal ions in wastewater [26,27,28,29,30].

In this study, in the first stage, economical biochar production from pistachio green hulls by microwave heating method is in question. In the second step, NaOH activation was followed to improve the surface properties of biochar. This adsorbent obtained was applied to remove Cu(II) from wastewater. FTIR, SEM, EDX, TG/DTG, and nitrogen adsorption/desorption methods were used to characterize the biochar samples. In adsorption studies, kinetic, isotherm, and thermodynamic parameters were investigated. In addition, the mechanism of Cu(II) adsorption on modified biochar has been proposed.

2 Materials and experimental procedure

2.1 Materials

This pistachio’s outer green shell was obtained from the Siirt (Turkey) Pistachio Factory. NaOH and hydrochloric acid (HCl) chemicals were obtained from a company by Merck (Germany). Analytical-grade copper nitrate salts were purchased from Tekkim (Turkey).

2.2 Production of biochar by microwave heating method and NaOH activation

Siirt pistachio green hulls, which is a bio waste, were chosen as the starting material for the production of biochar by microwave heating method (Roto Synth Rotative solid-Phase Microwave Reactor). The pistachio green hulls were obtained from Siirt Pistachio Factory. The samples were dried, ground, and passed through a 60-mesh sieve. For the synthesis of biochar by microwave heating method, approximately 5 g of pistachio green hulls (PH) were weighed and placed in a glass balloon under a nitrogen gas atmosphere and placed in the microwave device. For microwave heating at 100°C, the microwave power was 500 watts, and the microwave application time was 30 min. Biochar (PHMAC) samples obtained as a result of these processes were filtered through filter paper. It was left to dry in an oven at 80°C. The obtained PHMAC samples were kept for later use.

NaOH was used to modify the surface properties of the obtained PHMAC sample. NaOH concentrations of 0.5 M, 1 M, 2 M, and 3 M were preferred. For the activation of biochar with NaOH, approximately 4 g of sample was taken into a flask and mixed with 100 mL of NaOH at different concentrations for 120 min at room temperature in a magnetic stirrer. The biochar activated with NaOH was washed repeatedly with hot distilled water and filtered through filter paper. This sample (PHMAC-NaOH). It was left to dry in an oven at 80°C for 24 h.

2.3 Characterization

An FT-IR spectrometer in ATR mode was used in the range of 500–4000 cm-1 for the determination of functional groups on carbonaceous samples (Thermo/Nicolet). Nitrogen adsorption/desorption (Micromerıtıcs Gemini VII Surface Area and Porosity) analysis at 77 K was used to determine the pore structural properties of the carbonaceous samples. The BET (Brunauer, Emmett, and Teller) method was used to determine the surface area, and the Barrett-Joyner-Halenda ((BJH) model was used to calculate the volume and width of the pores. Weight changes of carbonaceous samples with temperature were carried out under a nitrogen atmosphere with thermogravimetric analysis (Shimadzu DTG-60H) at a heating rate of 10 °C min-1. A scanning electron microscope (SEM) (Quanta FEG 250) was used to determine the surface morphology of these samples. In addition, the current atomic contents of the samples were determined by EDX with this device. The percentage ratios of carbon (C), hydrogen (H), nitrogen (N), and sulfur (S) atoms in the PH and PHMAC-NaOH samples were determined with an elemental CHNS analyser (Elementar Vario Micro, Germany).

2.4 Adsorption studies

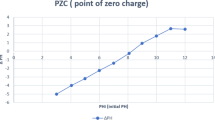

A 1000 ppm Cu(II) stock solution was prepared. Solutions of 50 mg/L, 100 mg/L, 150 mg/L, 200 mg/L, and 300 mg/L were prepared separately by dilution from the stock solution. 0.1 g adsorbent was used for adsorption experiments. This adsorption was carried out at pH 6 on a mechanical shaker for 150 min in a 100 mL beaker at 35 °C. For kinetic studies, 15, 30, 45, 60, 90, 120, and 150 min were preferred. Isotherm studies were carried out at concentrations of 50, 100, 150, 200, and 300 mg/L. Thermodynamic experiments were performed at 25, 35, and 45°C. The concentrations of ions remaining in the solution after centrifugation for about 5 min after adsorption were analyzed with an AAS (Perkin Elmer, USA). Each experiment was repeated at least three times. pH 6 and 0.1 g were chosen based on the literature and our previous experiments. Because at higher pH values, metals precipitate with the hydroxyl groups in the solution [15, 31,32,33].

Equation 1 was used to calculate the adsorption capacity (mg/g).

m and V were the adsorbent mass (g) and the solution volume (L), Ci (mg/L) was the initial concentration of Cu(II), and Ce (mg/L) was the final Cu(II) concentration.

3 Results and discussion

3.1 Characterization results

Figure 1 presents the FTIR spectra for PH, PHMAC, and PHMAC-NaOH. There are some differences between all three samples. Compared to the PH sample, there are decreases in peak intensities and changes in peak positions in the FTIR spectrum of the biochar obtained by microwave heating. The reason for this result can be attributed to the removal of surface functional groups by microwave heating. However, after the activation of the obtained biochar with NaOH, there are significant increases in peak intensities. In addition, after the treatment with NaOH, there are new peaks due to the oxygenated groups attached to the surface, especially in the range of 1000–1750 cm-1 [34, 35]. For all three samples, the bands appearing at 1570–1606 cm-1 can be interpreted as C=C groups, and the bands at 3200–3400 cm-1 can be interpreted as O–H vibrations [36]. The peak C=O groups at 1750 cm-1 and the absorption bands observed around 673 cm-1 for PHMAC-NaOH may be related to the vibration of Na–O bonds. Symmetrical and asymmetrical vibratory stresses in the region of 2800–2900 cm-1 for all three samples can be attributed to the methylene groups [37]. Peaks near 1400 cm-1 can be interpreted as C–C asymmetric and symmetric stretching [38]. The C–O bond of carboxyl groups can be associated with peaks between 1100 and 1000 cm-1.

The surface morphology of the PH (a, b, c) and PHMAC-NaOH (d, e, f) samples was examined by SEM, and the images obtained are given in Fig. 2. The SEM image for pH showed a smooth, partially layered, and homogeneous structure. However, the SEM images obtained from the conversion of the PH sample to biochar by microwave heating and the activation of this biochar with NaOH showed a more heterogeneous and partially porous structure. The reason for these changes can be attributed to both the microwave heating process and the activation of NaOH. This heterogeneous and partially porous structure may offer the necessary active sites for the adsorption of Cu(II) ions.

The results of the EDX analysis of PH (a) and PHMAC-NaOH (b) samples are shown in Fig. 3. The dominant atoms for both samples are C and O atoms. The contents of C and O atoms for PH were found to be 54.6% and 34.85%, respectively. However, the contents of C and O atoms for PHMAC-NaOH were found to be 52.6% and 37.52%, respectively. As can be understood, there is a significant increase in the content of oxygen atoms as a result of activation with NaOH. At the same time, the content of Na atoms for PHMAC-NaOH was found to be 2.31%.

As a result of the NaOH modification, there is a decrease in the C atom content due to the reaction of some C atoms with itself and the dissolution of other substances [39].

Additionally, EDX analyses and C, H, N, and S elemental analyses were performed for PH and PHMAC-NaOH samples. The O atom content in the samples was calculated from the sum of the percentages of these elements. With elemental analysis, the element contents for C, H, N, S and O atoms for the PH sample were found to be 50.75%, 6.47%, 1.98%, 0.22%, and 40.48%, respectively. In contrast, the same element percentages for PHMAC-NaOH were found to be 48.22%, 6.74%, 1.60%, 0.10%, and 43.34%, respectively. These results showed that O atoms increased for PHMAC-NaOH with NaOH activation, which is consistent with the EDX results. Similar results were obtained by NaOH activation on biochar with classical heating methods for different adsorption applications [40,41,42,43].

H/C, O/C and (O+N)/C ratios are commonly used for aromaticity, surface hydrophobicity and polarity, respectively [44]. The H/C ratios expressing aromaticity for pH and PHMAC-NaOH were 0.127 and 0.139, respectively. The (O+N)/C ratios for the same samples were 0.830 and 0.931, respectively, indicating that the polarity of PHMAC-NaOH increased due to NaOH activation. Additionally, O/C ratios as a measure of hydrophobicity for the same samples were 0.79 and 0.89, respectively. These results indicate that the NaOH activation of the PH sample was successful. In addition, active sites formed by the increase of oxygenated groups on the surface may contribute positively to Cu(II) adsorption.

The BET isotherms of PH (a) and PHMAC (b) samples are given in Fig. 4. Also, the pore parameter results of these samples are given in Table 1. The BET surface areas of the PH(a) and PHMAC(b) samples were found to be 0.331 and 0.492 m2/g, respectively. As can be understood, these surface area values are quite low. However, there is a partial increase in the surface area of the biochar obtained by the microwave heating method. The surface areas of some biochars obtained without using any chemicals in the literature are low, as in this study [45, 46].

However, new oxygenated groups are present on the surface of the sample obtained by NaOH activation, as shown by the FTIR, EDX, and CHNS elemental analysis results. As it is known, in adsorption processes, not only the width of the surface area but also the surface active functional groups are very important for adsorption. Also, the BJH pore width values for PH and PHMAC were calculated as 38.7 and 29.7 nm, respectively. According to IUPAC, pore width values in the range of 2 nm < w < 50 nm are considered mesoporous [47].

TG/DTG analyses of PH (a) and PHMAC (b) samples are given in Fig. 5. There is a four-stage weight loss for both samples. These weight losses occurred below 100 °C, between 200 and 300°C, between 400 and 500 °C, and around 600°C. The initial weight loss can be attributed to the water loss in the structure. The latter weight loss can be interpreted as the loss of volatile components such as oxygenated functional groups. The other two weight losses can be attributed to structural decompositions such as cellulose, hemicellulose, and lignin. It showed a weight loss of about 85% for both samples.

3.2 Adsorption studies

The qe values obtained for Cu(II) adsorption onto biochar treated by 0.5 M, 1M, 2M, and 3M NaOH were 78.16, 107.31, 73.05, and 72.71 mg/g, respectively. The FTIR spectrum was used for the effect of NaOH concentration on the PHMAC sample and the obtained spectrum is given in Fig. 6. NaOH concentrations 0.5 M, 1M, 2M, and 3M were chosen.

As can be seen from Fig. 6, there was a similar spectrum for the samples treated with 1M, 2M, and 3M NaOH, while the sample treated with 0.5 M NaOH gave a slightly different spectrum. It is possible that as a result of activation with 0.5 M NaOH, sufficient active groups cannot be formed on the surface. NaOH of 1 M as the optimum concentration was chosen by the qe values obtained for Cu(II) adsorption onto biochar treated by 0.5 M, 1M, 2M, and 3M NaOH. In addition, 1 M NaOH was chosen as the optimum concentration since the FTIR spectrum obtained for 1M NaOH gave more prominent peaks, especially in the range of 1000-2000 cm-1.

Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich (DR) isotherms were used to determine the qm values of Cu(II) adsorption on PHMAC-NaOH. Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich isotherm models were given in Equations 2, 3, 4, and 5, respectively:

In Equation 2, the equilibrium concentration of the adsorbate remaining in the solution is shown as Ce (mg/L) for the Langmuir isotherm, which expresses a homogeneous adsorbent surface with a monolayer adsorbate. The amount of adsorbate per unit mass of the adsorbent at equilibrium was shown as qe (mg/g). Maximum adsorption capacity is given by qm (mg/ g), and Langmuir constant related to adsorption heat is given by b (L m/g).

Freundlich adsorption isotherm, which expresses heterogeneous surfaces with multilayer adsorption, is also widely used. The Freundlich adsorption isotherm is commonly used to investigate the adsorption behavior for the heterogeneous surface and assume multilayer adsorption. In this isotherm, Kf refers to the Freundlich isotherm constant. In the Temkin isotherm, T is the absolute temperature in Kelvin; R (8.314 J/mol K) is the universal gas constant; b is the constant for the heat of adsorption; A is the Temkin isotherm constant (l/g), and Ce is the equilibrium concentration of the adsorbate.

In the Dubinin-Radushkevich (D-R) isotherm model, which expresses a heterogeneous adsorbent surface in Equation 5, qe is the number of metal ions adsorbed on the adsorbent surface at equilibrium; qm is the maximum adsorption capacity (mg/g); β represents the Adsorption energy constant and € represents the Polanyi potential. Table 2 presents the values obtained by Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich (DR) isotherms for Cu(II) adsorption on PHMAC-NaOH. Considering the R2 values, it can be said that the best isotherm for Cu(II) adsorption on PHMAC-NaOH is the Langmuir isotherm. Figure 7 shows the Langmuir isotherms of Cu(II) adsorption) on PHMAC-NaOH at different temperatures (30, 40, and 50 °C). The maximum adsorption capacity of Cu(II) adsorption with PHMAC-NaOH at 30°C was found to be 227 mg/g. Table 3 shows a simple comparison of the maximum adsorption capacity (qm) of PHMAC-NaOH with Cu(II) adsorption with different adsorbents in the literature [48,49,50,51,52,53,54,55,56,57,58,59]. As can be understood, it can be considered that the maximum adsorption capacity obtained for Cu(II) adsorption with PHMAC-NaOH is a very good result.

Pseudo-first order, pseudo-second order, intraparticle diffusion, and Elovich kinetic models were used to determine the kinetic values of Cu(II) adsorption on PHMAC-NaOH. Pseudo-first order, pseudo-second order, intraparticle diffusion, and Elovich kinetic models were given in Equations 6, 7, 8, and 9, respectively.

qe for the pseudo-first-order kinetic model equation (Equation 6) represents the adsorbate uptake at equilibrium, and qt represents the adsorbate uptake per mass of adsorbent at any equilibrium time t (min), and the rate constant K1 (1/min).

Table 4 shows the pseudo-first and pseudo-second order, intraparticle diffusion, and Elovich kinetic model constants of Cu(II) adsorption. The amount of adsorbate adsorbed at equilibrium for the pseudo-second-order kinetic model equation (Equation 7) is expressed with qe, and the amount of adsorbate adsorbed at any time t (minute) is expressed as qt. k2 (g/mg × min) is the pseudo-second-order rate constant. In the intraparticle diffusion model (Equation 8) qt (mg/g) is the amount of Cu(II) adsorbed on the adsorbent at time t; kp (mg/g min0.5) is the intraparticle diffusion rate constant and C is the boundary layer thickness effect. In the Elovich kinetic model (Equation 9), α and β are equation constants. Intra-particle diffusion is known as having limiting steps in the adsorption process due to the liquid phase mass transport, and since the intra-particle mass transport rate controls the sorption on the adsorbent, internal diffusion or intra-particle diffusion, adsorption or desorption on the surface of the interior sites [60,61,62]. As can be seen in Table 4, the highest correlation coefficient values were obtained with the pseudo-second-order kinetic model.

Thermodynamic parameters ΔG°, ΔH°, and ΔS° represent Gibbs free energy (kJ/mol), enthalpy (kJ/mol), and entropy (kJ/mol.K), respectively. Thermodynamic parameters of Cu (II) on PHMAC-NaOH were determined using Equations 10 and 11.

where T(K), R (8.314 J /mol /K), and Ka (L/ g) present the temperature, gas constant, and equilibrium constant, respectively.

Table 5 shows the values obtained with thermodynamic parameters for Cu(II) adsorption on PHMAC-NaOH at temperatures of 298-308–318 K. The negative values of ΔG° from Table 5 show that Cu(II) removal from aqueous solution is possible and spontaneous. In addition, the decrease in ΔG° with an increase in temperature indicates that the spontaneity of the process decreases with an increase in temperature. A positive ΔH° indicates that the adsorption process is endothermic. The positivity of ΔS° indicates that the randomness at the solid and solution interface decreases during the adsorption process.

3.3 Cu (II) adsorption mechanism

Interactions between PHMAC-NaOH adsorbent and Cu(II) ions can occur in the form of ion exchange, physical absorption, coordination interaction with π-electrons, electrostatic interaction, and complex formation with oxygen functional groups. FTIR(a), EDX(b), and SEM(c) analyses were performed after adsorption to explain the mechanism of Cu(II) adsorption by PHMAC-NaOH (Fig. 8). As can be seen from the FTIR spectrum in Fig. 8, there is a decrease in peak intensities after adsorption, especially for PHMAC-NaOH at 1000–2000 cm-1. The interaction of Cu(II) ions with the oxygenated groups in these regions on the adsorbent surface can be shown as the possible reason for this decrease. These changes may favor the interaction of Cu(II) with aromatic π-electrons. Therefore, it can be said that groups such as hydroxyl, carboxylic, and phenolic are involved in the adsorption of Cu(II). These results are also consistent with other studies in the literature [63, 64]. Also, these results could be electrostatic attraction or interaction between Cu(II) and functional groups on the adsorbent to form metal complexes, including surface complex [65]. Also, EDX and SEM analyses obtained after Cu(II) adsorption on PHMAC-NaOH are given in Figs. 8b and c. SEM analyses show that after adsorption, the adsorbent surface is covered with Cu(II) ions. In addition, EDX analyses confirm 10% Cu atom content on the adsorbent surface after adsorption. Again, EDX analyses confirmed that the oxygen atoms content of the PHMAC-NaOH adsorbent was reduced by 10%. Thus, it was confirmed that oxygenated groups play an important role in adsorption. In the adsorption mechanism for Cu(II), it can be represented as an ion exchange process as follows: PHMAC-NaOH−COOH+Cu(II)→PHMAC-NaOH−COO−Cu-1+H+.

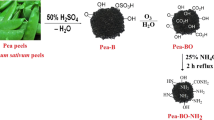

The preparation of the PHMAC-NaOH adsorbent and the possible Cu(II) adsorption mechanism scheme is presented in Fig. 9.

4 Conclusion

In this study, in the first stage, economical biochar production from pistachio green shells by microwave heating method is in question. In the second step, NaOH activation was followed to improve the surface properties of biochar. This adsorbent obtained was applied to remove Cu(II) from wastewater. FTIR, SEM, EDX, CHNS elemental analysis, TG/DTG, and nitrogen adsorption/desorption methods were used to characterize the biochar samples. FTIR spectrum shows that after the treatment with NaOH, there are new peaks due to the oxygenated groups attached to the surface, especially in the range of 1000–1750 cm-1. SEM images obtained from the conversion of the PH sample to biochar by microwave heating and the activation of this biochar with NaOH showed a more heterogeneous and partially porous structure. There is a significant increase in the content of oxygen atoms as a result of activation with NaOH by CHNS elemental analysis and EDS results. In adsorption studies, kinetic, isotherm, and thermodynamic parameters were investigated. Cu(II) adsorption capacity on modified biochar obtained by Langmuir isotherm was found to be 227.27 mg/g. The highest correlation coefficient values for the kinetic models were obtained with the pseudo-second-order kinetic model (0.999–0.997). The negative values of ΔG° from Cu(II) removal from aqueous solution are possible and spontaneous. A positive ΔH° indicates that the adsorption process is endothermic. The positivity of ΔS° indicates that the randomness at the solid and solution interface decreases during the adsorption process. In addition, the mechanism of Cu(II) adsorption on modified biochar has been proposed. EDX analyses confirm 10% Cu atom content on the adsorbent surface after adsorption. Again, EDX analyses confirmed that the oxygen atoms content of the PHMAC-NaOH adsorbent was reduced by 10%. Thus, it was confirmed that oxygenated groups play an important role in adsorption. Biochar, which is obtained from the pistachio green hulls, which is widely available and grown in Turkey, by microwave method and then NaOH activation, is a potential solution for both the improvement of water pollution caused by heavy metals and the disposal of related wastes with an appropriate method.

Data availability

Data cannot be shared as it forms part of a work in progress.

References

Xiang W, Zhang X, Cao C et al (2022) Microwave-assisted pyrolysis derived biochar for volatile organic compounds treatment: characteristics and adsorption performance. Bioresour Technol 355:127274. https://doi.org/10.1016/J.BIORTECH.2022.127274

Zhu L, Shen D, Luo KH (2020) A critical review on VOCs adsorption by different porous materials: Species, mechanisms and modification methods. J Hazard Mater 389:122102. https://doi.org/10.1016/J.JHAZMAT.2020.122102

Govindaraju K, Vinu R, Gautam R et al (2022) Microwave-assisted torrefaction of biomass Kappaphycus alvarezii–based biochar and magnetic biochar for removal of hexavalent chromium [Cr(VI)] from aqueous solution. Biomass Convers Biorefinery 1:1–11. https://doi.org/10.1007/S13399-022-02512-2/TABLES/4

Das SK, Ghosh GK, Avasthe R (2020) Valorizing biomass to engineered biochar and its impact on soil, plant, water, and microbial dynamics: a review. Biomass Convers Biorefinery 12(9):4183–4199. https://doi.org/10.1007/S13399-020-00836-5

Rahman MZ, Edvinsson T, Kwong P (2020) Biochar for electrochemical applications. Curr Opin Green Sustain Chem 23:25–30. https://doi.org/10.1016/J.COGSC.2020.04.007

Nzediegwu C, Arshad M, Ulah A et al (2021) Fuel, thermal and surface properties of microwave-pyrolyzed biochars depend on feedstock type and pyrolysis temperature. Bioresour Technol 320:124282. https://doi.org/10.1016/J.BIORTECH.2020.124282

Foong SY, Liew RK, Yang Y et al (2020) Valorization of biomass waste to engineered activated biochar by microwave pyrolysis: progress, challenges, and future directions. Chem Eng J 389:124401. https://doi.org/10.1016/J.CEJ.2020.124401

Zaker A, Chen Z, Wang X, Zhang Q (2019) Microwave-assisted pyrolysis of sewage sludge: A review. Fuel Process Technol 187:84–104. https://doi.org/10.1016/J.FUPROC.2018.12.011

Sajjadi B, Chen WY, Egiebor NO (2019) A comprehensive review on physical activation of biochar for energy and environmental applications. Rev Chem Eng 35:735–776. https://doi.org/10.1515/REVCE-2017-0113/XML

Das SK, Ghosh GK, Avasthe R (2023) Biochar application for environmental management and toxic pollutant remediation. Biomass Convers Biorefinery 13:555–566. https://doi.org/10.1007/S13399-020-01078-1/TABLES/4

Islam MA, Parvin MI, Dada TK et al (2022) Silver adsorption on biochar produced from spent coffee grounds: validation by kinetic and isothermal modelling. Biomass Convers Biorefinery 1:1–15. https://doi.org/10.1007/S13399-022-03491-0/FIGURES/5

Duan S, Ma W, Pan Y et al (2017) Synthesis of magnetic biochar from iron sludge for the enhancement of Cr (VI) removal from solution. J Taiwan Inst Chem Eng 80:835–841. https://doi.org/10.1016/J.JTICE.2017.07.002

Amer NM, Lahijani P, Mohammadi M (2022) Mohamed AR (2022) Modification of biomass-derived biochar: a practical approach towards development of sustainable CO2 adsorbent. Biomass Convers Biorefinery 1:1–48. https://doi.org/10.1007/S13399-022-02905-3

Guo J, Xiao H, Zhang JB et al (2022) Characterization of highly stable biochar and its application for removal of phenol. Biomass Convers Biorefinery 1:1–11. https://doi.org/10.1007/S13399-022-03375-3/FIGURES/7

Murtazaoğlu Ç, Teğin İ, Saka C (2023) Facile hydrogen peroxide modification of activated carbon particles produced by potassium hydroxide activation for removal of heavy metals from aqueous solutions. Diam Relat Mater 136:110049. https://doi.org/10.1016/J.DIAMOND.2023.110049

Kahvecioğlu K, Teğin İ, Yavuz Ö, Saka C (2022) Phosphorus and oxygen co-doped carbon particles based on almond shells with hydrothermal and microwave irradiation process for adsorption of lead (II) and cadmium (II). Environ Sci Pollut Res 30:37946–37960. https://doi.org/10.1007/S11356-022-24968-5/TABLES/9

Saka C, Teğin İ, Kahvecioğlu K, Yavuz Ö (2023) Nitrogen- and oxygen-doped carbon particles produced from almond shells by hydrothermal method for efficient Pb(II) and Cd(II) adsorption. Biomass Convers Biorefinery 1:1–14. https://doi.org/10.1007/S13399-023-03920-8/FIGURES/8

Liu J, Yang X, Liu H et al (2020) Modification of calcium-rich biochar by loading Si/Mn binary oxide after NaOH activation and its adsorption mechanisms for removal of Cu(II) from aqueous solution. Colloids Surf A Physicochem Eng Asp 601:124960. https://doi.org/10.1016/J.COLSURFA.2020.124960

Liu WJ, Jiang H, Yu HQ (2015) Development of biochar-based functional materials: toward a sustainable platform carbon material. Chem Rev 115:12251–12285. https://doi.org/10.1021/ACS.CHEMREV.5B00195/ASSET/IMAGES/ACS.CHEMREV.5B00195.SOCIAL.JPEG_V03

(2019) http://www.fao.org/faostat/en/#data/QCL. http://www.fao.org/faostat/en/#data/QCL

Bartzas G, Komnitsas K (2017) Life cycle analysis of pistachio production in Greece. Sci Total Environ 595:13–24. https://doi.org/10.1016/J.SCITOTENV.2017.03.251

Akbari-Alavijeh S, Soleimanian-Zad S, Sheikh-Zeinoddin M, Hashmi S (2018) Pistachio hull water-soluble polysaccharides as a novel prebiotic agent. Int J Biol Macromol 107:808–816. https://doi.org/10.1016/J.IJBIOMAC.2017.09.049

Hassoun A, Bekhit AED, Jambrak AR et al (2022) The fourth industrial revolution in the food industry—part II. Emerging Food Trends 101080/1040839820222106472. https://doi.org/10.1080/10408398.2022.2106472

Fiyadh SS, AlSaadi MA, Jaafar WZ et al (2019) Review on heavy metal adsorption processes by carbon nanotubes. J Clean Prod 230:783–793. https://doi.org/10.1016/J.JCLEPRO.2019.05.154

Batool S, Idrees M, Hussain Q, Kong J (2017) Adsorption of copper (II) by using derived-farmyard and poultry manure biochars: efficiency and mechanism. Chem Phys Lett 689:190–198. https://doi.org/10.1016/J.CPLETT.2017.10.016

Saka C, Şahin Ö, Küçük MM (2012) Applications on agricultural and forest waste adsorbents for the removal of lead (II) from contaminated waters. Int J Environ Sci Technol 9:379–394. https://doi.org/10.1007/s13762-012-0041-y

Saka C (2012) BET, TG-DTG, FT-IR, SEM, iodine number analysis and preparation of activated carbon from acorn shell by chemical activation with ZnCl 2. J Anal Appl Pyrolysis. https://doi.org/10.1016/j.jaap.2011.12.020

Jiang Y, Xing Y, Liu S et al (2023) A longer biodegradation process enhances the cadmium adsorption of the biochar derived from a manure mix. Biomass Bioenergy 173:106787. https://doi.org/10.1016/J.BIOMBIOE.2023.106787

Quan C, Wang W, Su J et al (2023) Characteristics of activated carbon derived from Camellia oleifera cake for nickel ions adsorption. Biomass Bioenergy 171:106748. https://doi.org/10.1016/J.BIOMBIOE.2023.106748

Zhou Y, Shen C, Xiang L et al (2023) Facile synthesis of magnetic biochar from an invasive aquatic plant and basic oxygen furnace slag for removal of phosphate from aqueous solution. Biomass Bioenergy 173:106800. https://doi.org/10.1016/J.BIOMBIOE.2023.106800

Saka C, Teğin İ, Kahvecioğlu K (2023) Sulphur-doped carbon particles from almond shells as cheap adsorbent for efficient Cd(II) adsorption. Diam Relat Mater 131:109542. https://doi.org/10.1016/J.DIAMOND.2022.109542

Ahmad M, Zhang B, Wang J et al (2019) New method for hydrogel synthesis from diphenylcarbazide chitosan for selective copper removal. Int J Biol Macromol 136:189–198. https://doi.org/10.1016/J.IJBIOMAC.2019.06.084

Rahmani Z, Ghaemy M, Olad A (2022) Removal of heavy metals from polluted water using magnetic adsorbent based on κ-carrageenan and N-doped carbon dots. Hydrometallurgy 213:105915. https://doi.org/10.1016/J.HYDROMET.2022.105915

Rajani MR, Ravishankar R, Naik M et al (2023) Carbonaceous MnFe2O4 nano-adsorbent: Synthesis, characterisation and investigations on chromium (VI) ions removal efficiency from aqueous solution. Appl Surf Sci Adv 16:100434. https://doi.org/10.1016/J.APSADV.2023.100434

Ghorbannezhad P, Shen G, Ali I (2023) Microwave-assisted hot water treatment of sugarcane bagasse for fast pyrolysis. Biomass Convers Biorefinery 13:14425–14432. https://doi.org/10.1007/S13399-022-02492-3/FIGURES/4

Thomas R, Balachandran M (2023) Fuel coke derived nitrogen and phosphorus co-doped porous graphene structures for high-performance supercapacitors: the trail towards a brown-to-green transition. J Energy Storage 72:108799. https://doi.org/10.1016/J.EST.2023.108799

Khoshraftar Z, Ghaemi A (2022) Evaluation of pistachio shells as solid wastes to produce activated carbon for CO2 capture: isotherm, response surface methodology (RSM) and artificial neural network (ANN) modeling. Curr Res Green Sustain Chem 5:100342. https://doi.org/10.1016/J.CRGSC.2022.100342

Wu Q, Li Z, Hong H (2013) Adsorption of the quinolone antibiotic nalidixic acid onto montmorillonite and kaolinite. Appl Clay Sci 74:66–73. https://doi.org/10.1016/J.CLAY.2012.09.026

Lü F, Lu X, Li S et al (2022) Dozens-fold improvement of biochar redox properties by KOH activation. Chem Eng J 429:132203. https://doi.org/10.1016/J.CEJ.2021.132203

Lu Y, Liu Y, Li C et al (2022) Adsorption characteristics and mechanism of methylene blue in water by NaOH-modified areca residue biochar. Processes 10:2729. https://doi.org/10.3390/PR10122729

Wang H, Wang X, Teng H et al (2022) Purification mechanism of city tail water by constructed wetland substrate with NaOH-modified corn straw biochar. Ecotoxicol Environ Saf 238:113597. https://doi.org/10.1016/J.ECOENV.2022.113597

Alchouron J, Navarathna C, Chludil HD et al (2020) Assessing South American Guadua chacoensis bamboo biochar and Fe3O4 nanoparticle dispersed analogues for aqueous arsenic(V) remediation. Sci Total Environ 706:135943. https://doi.org/10.1016/J.SCITOTENV.2019.135943

Ye H, Yu K, Li B, Guo J (2023) Study on adsorption properties and mechanism of sodium hydroxide–modified ball-milled biochar to dislodge lead(II) and MB from water. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-03740-w

Li M, Zhao Z, Wu X et al (2017) Impact of mineral components in cow manure biochars on the adsorption and competitive adsorption of oxytetracycline and carbaryl. RSC Adv 7:2127–2136. https://doi.org/10.1039/C6RA26534K

Mahmoud Fodah AE, Ghosal MK, Behera D (2021) Bio-oil and biochar from microwave-assisted catalytic pyrolysis of corn stover using sodium carbonate catalyst. J Energy Inst 94:242–251. https://doi.org/10.1016/J.JOEI.2020.09.008

Liu C, Liu X, He Y et al (2021) Microwave-assisted catalytic pyrolysis of apple wood to produce biochar: Co-pyrolysis behavior, pyrolysis kinetics analysis and evaluation of microbial carriers. Bioresour Technol 320:124345. https://doi.org/10.1016/J.BIORTECH.2020.124345

Kiani Ghaleh sardi F, Behpour M, Ramezani Z, Masoum S (2021) Simultaneous removal of Basic Blue41 and Basic Red46 dyes in binary aqueous systems via activated carbon from palm bio-waste: optimization by central composite design, equilibrium, kinetic, and thermodynamic studies. Environ Technol Innov 24:102039. https://doi.org/10.1016/J.ETI.2021.102039

Iqbal M, Saeed A, Kalim I (2009) Characterization of adsorptive capacity and investigation of mechanism of Cu2+, Ni2+ and Zn2+ adsorption on mango peel waste from constituted metal solution and genuine electroplating effluent. Sep Sci Technol 44:3770–3791. https://doi.org/10.1080/01496390903182305

Pavan Kumar GVSR, Malla KA, Yerra B, Srinivasa Rao K (2019) Removal of Cu(II) using three low-cost adsorbents and prediction of adsorption using artificial neural networks. Appl Water Sci 9:1–9. https://doi.org/10.1007/S13201-019-0924-X/FIGURES/8

Moreno-Piraján JC, Giraldo L (2010) Adsorption of copper from aqueous solution by activated carbons obtained by pyrolysis of cassava peel. J Anal Appl Pyrolysis 87:188–193. https://doi.org/10.1016/J.JAAP.2009.12.004

Li M, Messele SA, Boluk Y, Gamal El-Din M (2019) Isolated cellulose nanofibers for Cu (II) and Zn (II) removal: performance and mechanisms. Carbohydr Polym 221:231–241. https://doi.org/10.1016/J.CARBPOL.2019.05.078

Ahmad Z, Gao B, Mosa A et al (2018) Removal of Cu(II), Cd(II) and Pb(II) ions from aqueous solutions by biochars derived from potassium-rich biomass. J Clean Prod 180:437–449. https://doi.org/10.1016/J.JCLEPRO.2018.01.133

Demiral H, Güngör C (2016) Adsorption of copper(II) from aqueous solutions on activated carbon prepared from grape bagasse. J Clean Prod 124:103–113. https://doi.org/10.1016/J.JCLEPRO.2016.02.084

Bouhamed F, Elouear Z, Bouzid J (2012) Adsorptive removal of copper(II) from aqueous solutions on activated carbon prepared from Tunisian date stones: Equilibrium, kinetics and thermodynamics. J Taiwan Inst Chem Eng 43:741–749. https://doi.org/10.1016/J.JTICE.2012.02.011

Anirudhan TS, Sreekumari SS (2011) Adsorptive removal of heavy metal ions from industrial effluents using activated carbon derived from waste coconut buttons. J Environ Sci 23:1989–1998. https://doi.org/10.1016/S1001-0742(10)60515-3

Zhu CS, Wang LP, Chen WB (2009) Removal of Cu(II) from aqueous solution by agricultural by-product: peanut hull. J Hazard Mater 168:739–746. https://doi.org/10.1016/J.JHAZMAT.2009.02.085

Guiza S (2017) Biosorption of heavy metal from aqueous solution using cellulosic waste orange peel. Ecol Eng 99:134–140. https://doi.org/10.1016/J.ECOLENG.2016.11.043

Saravanan A, Sundararaman TR, Jeevanantham S et al (2020) Effective adsorption of Cu(II) ions on sustainable adsorbent derived from mixed biomass (Aspergillus campestris and agro waste): Optimization, isotherm and kinetics study. Groundw Sustain Dev 11:100460. https://doi.org/10.1016/J.GSD.2020.100460

Li Z, Shao L, Ruan Z et al (2018) Converting untreated waste office paper and chitosan into aerogel adsorbent for the removal of heavy metal ions. Carbohydr Polym 193:221–227. https://doi.org/10.1016/J.CARBPOL.2018.04.003

Kayranli B (2021) Mechanism of interaction and removal of zinc with lignocellulosic adsorbents, closing the cycle with a soil conditioner. J King Saud Univ Sci 33:101607. https://doi.org/10.1016/J.JKSUS.2021.101607

Kayranli B (2022) Cadmium removal mechanisms from aqueous solution by using recycled lignocelluloses. Alex Eng J 61:443–457. https://doi.org/10.1016/J.AEJ.2021.06.036

Kayranli B (2011) Adsorption of textile dyes onto iron based waterworks sludge from aqueous solution; isotherm, kinetic and thermodynamic study. Chem Eng J 173:782–791. https://doi.org/10.1016/J.CEJ.2011.08.051

Kołodyńska D, Krukowska J, Thomas P (2017) Comparison of sorption and desorption studies of heavy metal ions from biochar and commercial active carbon. Chem Eng J 307:353–363. https://doi.org/10.1016/J.CEJ.2016.08.088

Liu N, Zhang Y, Xu C et al (2020) Removal mechanisms of aqueous Cr(VI) using apple wood biochar: a spectroscopic study. J Hazard Mater 384:121371. https://doi.org/10.1016/J.JHAZMAT.2019.121371

Lu H, Zhang W, Yang Y et al (2012) Relative distribution of Pb2+ sorption mechanisms by sludge-derived biochar. Water Res 46:854–862. https://doi.org/10.1016/J.WATRES.2011.11.058

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

İbrahim TEĞİN: writing—review and editing, investigation,

Sema ÖC: investigation

Cafer SAKA: writing—original draft, conceptualization, methodology

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Teğin, İ., Öc, S. & Saka, C. Adsorption of copper (II) from aqueous solutions using adsorbent obtained with sodium hydroxide activation of biochar prepared by microwave pyrolysis. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05477-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05477-6