Abstract

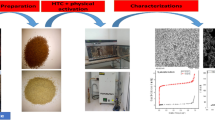

In the present study, high-quality activated carbons (ACs) were prepared from a mixture of olive stones and olive mill wastewater (OMWW) through successive hydrothermal carbonization (HTC) and potassium hydroxide (KOH) activation. Textural, morphological, and chemical characteristics of hydrochar (HC) and derived ACs, produced using two KOH/HC ratios (2 and 4), were investigated. KOH activation improved the porous structure of HC and its surface functionality. The best properties were obtained for HC activated by KOH at a ratio of 2 exhibiting a promising surface area (≈1000 m2/g) and high adsorptive properties towards methylene blue and iodine (617 and 1203 mg/g, respectively). Batch tests were performed to explore the ability of the produced ACs in removing phenolic compounds (PCs) from OMWW, while investigating the effect of contact time, pH, and PCs initial concentration on the adsorption process. The higher removal efficiency was obtained at a pH of 10 after ~ 4 h of contact time. The adsorption kinetic data are well described by the pseudo-second-order kinetic model, while the isotherm adsorption data were found to fit both Langmuir and Freundlich isotherm models. HTC of olive mill wastes followed by KOH activation could be a promising method to produce AC with high porosity and promising potential to remove PCs from OMWW.

Similar content being viewed by others

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon request.

References

Pari G, Darmawan S, Prihandoko B (2014) Porous carbon spheres from hydrothermal carbonization and KOH activation on cassava and tapioca flour raw material, Procedia. Environ Sci 20:342–351

Enaime G, Ennaciri K, Ounas A, Baçaoui A, Seffen M, Selmi T, Yaacoubi A (2017) Preparation and characterization of activated carbons from olive wastes by physical and chemical activation: application to indigo carmine adsorption, Journal of Materials and Environmental. Science 8:4125–4137

Benavente V, Calabuig E, Fullana A (2015) Upgrading of moist agro-industrial wastes by hydrothermal carbonization. J Anal Appl Pyrolysis 113:89–98

Gao Y, Chen H, Wang J, Shi T, Yang H, Wang X (2011) Characterization of products from hydrothermal liquefaction and carbonation of biomass model compounds and real biomass. J Fuel Chem Technol 39:893–900

Zhu X, Liu Y, Zhou C, Luo G, Zhang S, Chen J (2014) A novel porous carbon derived from hydrothermal carbon for efficient adsorption of tetracycline. Carbon 77:627–636

Aljvanieh MG, Geçgel C, Yabala E (2023) Hydrochar synthesis from waste corncob using subcritical water and microwave-assisted carbonization methods and ammonium enrichment of synthesized hydrochars. Environ Res 226:115715

Yu Y, Lou X, Wu H (2008) Some recent advances in hydrolysis of biomass in hot-compressed water and its comparisons with other hydrolysis methods. Energy Fuels 22:46–60

Teğin IAEYI, Demirel MF (2022) Investigation of the effectiveness of waste nut shell–based hydrochars in water treatment: a model study for the adsorption of methylene blue. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02996-y

Funke A, Ziegler F (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering, Biofuels. Bioprod Biorefining 4:160–177

Yabalak E, Eliuz EAE (2022) Green synthesis of walnut shell hydrochar, its antimicrobial activity and mechanism on some pathogens as a natural sanitizer. Food Chem 366:130608

Yan W, Acharjee T, Coronella C, Vsquez V (2009) Thermal pretreatment of lignocellulosic biomass, Environ. Prog. Sustain. Energy 28:435–440

Enaime G, Baçaoui A, Yaacoubi A, Wichern M, Lübken M (2022) Hydrothermal carbonization of the filter bed remained after filtration of olive mill wastewater on olive stones for biofuel application. Biomass Conv Bioref 12:1237–1247

Cao D, Sun Y, Wang G (2007) Direct carbon fuel cell: fundamentals and recent developments. Power Sources 167:250–257

Libra J, Ro K, Kammann C, Funke A, Berge N, Neubauer Y, Titirici M, Fühner C, Bens O, Emmerich K (2011) Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2:71–81

Ighalo JO, Rangabhashiyam S, Dulta K, Umeh CT, Iwuozor KO, Aniagor CO, Eshiemogie SO, Iwuchukwu FU, Igwegbe CA (2022) Recent advances in hydrochar application for the adsorptive removal of wastewater pollutants. Chem Eng Res Des 184:419–456

Liu Z, Zhang F (2009) Removal of lead from water using biochars prepared from hydrothermal liquefaction of biomass. J Hazard Mater 167:933–939

Falco C, Marco-Lozar J, Salinas-Torres D, Morallon E, Cazorla-Amoros D, Titirici M, Lozano- Castelló D (2013) Tailoring the porosity of chemically activated hydrothermal carbons: influence of the precursor and hydrothermal carbonization temperature. Carbon 62:346–355

Shen F, Wang Y, Li L, Zhang K, Smith RL, Qi X (2018) Porous carbonaceous materials from hydrothermal carbonization and KOH activation of corn stover for highly efficient CO2 capture. Chem Eng Commun. 205:423–431

Wu Y, Cao J, Zhao X, Hao Z, Zhuang Q, Zhu J, Wang X, Wei X (2017) Preparation of porous carbons by hydrothermal carbonization and KOH activation of lignite and their performance for electric double layer capacitor. Electrochim Acta 252:397–407

Mopoung S, Moonsri P, Palas W, Khumpai S (2015) Characterization and properties of activated carbon prepared from tamarind seeds by KOH activation for Fe(III) adsorption from aqueous solution. Scientific World Journal 2015:9

Saad MJ, Chia CH, Zakaria S, Sajab MS, Misran S, Rahman MHA, Chin SX (2019) Physical and chemical properties of the rice straw activated carbon produced from carbonization and KOH activation processes. Sains Malaysiana 48:385–391

Gao F, Shao G, Qu J, Lv S, Li Y, Wu M (2015) Tailoring of porous and nitrogen-rich carbons derived from hydrochar for high-performance supercapacitor electrodes. Electrochim Acta 155:201–208

Li S, Han K, Li J, Li M, Lu C (2017) Preparation and characterization of super activated carbon produced from gulfweed by KOH activation. Microporous Mesoporous Mater 243:291–300

Enaime G, Baçaoui A, Yaacoubi A, Lübken M (2020) Biochar for wastewater treatment—conversion technologies and applications. Appl Sci 10:3492

Abid N, Masmoudi MA, Megdiche M, Barakat A, Ellouze M, Chamkha M, Ksibi M, Sayadi S (2022) Biochar from olive mill solid waste as an eco-friendly adsorbent for the removal of polyphenols from olive mill wastewater. Chem Eng Res Des 181:384–398

Galiatsatou P, Metaxas M, Arapoglou D, Kasselouri-Rigopoulou V (2002) Treatment of olive mill wastewater with activated carbons from agri-cultural by-products. Waste Manage 22:803–812

Ubago-Perez R, Carrasco-Marin F, Fairen-Jimenez D, Moreno-Castilla C (2006) Granular and monolithic activated carbons from KOH-activation of olive stones. Microporous Mesoporous Mater 92:64–70

ASTM D4607-94 (2006) Standard Test Method for Determination of Iodine Number of Activated Carbon. ASTM International 100 Barr Harbor Drive: United States

Baçaoui A, Yaacoubi A, Dahbi A, Bennouna C, Phan Tan Luu R, Maldonado-Hodar F, Rivera-Utrilla J, Moreno-Castilla C (2001) Optimization of conditions for the preparation of activated carbons from olive- waste cakes. Carbon 39:425–432

Singleton V, Rossi J (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Amer J Enol Viticult 16:144–158

Cheng S, Zhang L, Xia H, Peng J, Shu J, Li C, Jiang X, Zhang Q (2017) Adsorption behavior of methylene blue onto waste-derived adsorbent and exhaust gases recycling. RSC Adv 7:27331–27341

Ho Y, McKay G (1998) Sorption of dye from aqueous solution by peat. Chem Eng J 70:115–124

Langmuir I (1918) The adsorption of gases on plane surfaces of glass, mica and platinum. J Am Chem Soc 40:1361–1403

Wang Y, Zhang Y, Li S, Zhong W, Wei W (2018) Enhanced methylene blue adsorption onto activated reed-derived biochar by tannic acid. J Mol Liq 268:658–666

Pala M, Kantarli I, Buyukisik H, Yanik J (2014) Hydrothermal carbonization and torrefaction of grape pomace: A comparative evaluation. Bioresour Technol 161:255–262

Spagnoli A, Giannakoudakis D, Bashkova S (2017) Adsorption of methylene blue on cashew nutshell-based carbons activated with zinc chloride: the role of surface and structural parameters. J Mol Liq 229:465–471

Wang S, Wang K, Liu Q, Gu Y, Luo Z, Cen K, Fransson T (2009) Comparison of the pyrolysis behavior of lignins from different tree species. Biotechnol Adv 27:562–567

Chen Z, Chen B, Chiou C (2012) Fast and slow rates of naphthalene sorption to biochars produced at different temperatures. Environ Sci Technol 46:11104–11111

Islam M, Tan I, Benhouria A, Asif M, Hameed B (2015) Mesoporous and adsorptive properties of palm date seed activated carbon prepared via sequential hydrothermal carbonization and sodium hydroxide activation. Chem Eng J 270:187–195

Javed H, Luong D, Lee C-G, Zhang D, Tour JM, Alvarez P (2018) Efficient removal of bisphenol-A by ultra-high surface area porous activated carbon derived from asphalt. Carbon 140:441–448

Titirici M, Thomas A, Yu S, Müller J, Antonietti M (2007) A direct synthesis of mesoporous carbons with bicontinuous pore morphology from crude plant material by hydrothermal carbonization. Chem Mater 19:4205–4212

Li W-H, Yue Q-Y, Gao B-Y, Ma Z-H, Li Y-J, Zhao H-X (2011) Preparation and utilization of sludge-based activated carbon for the adsorption of dyes from aqueous solutions. Chem Eng J 171:320–327

Chen X, Zhang H, Guo Y, Cao Y, Cheng F (2020) Activation mechanisms on potassium hydroxide enhanced microstructures development of coke powder. Chin J Chem Eng 28:299–306

Tan I, Ahmad A, Hameed B (2008) Preparation of activated carbon from coconut husk: optimization study on removal of 2,4,6-trichlorophenol using response surface methodology [j]. J Hazard Mater 153:709–717

Guo S, Dong X, Wu T, Shi F, Zhu C (2015) Characteristic evolution of hydrochar from hydrothermal carbonization of corn stalk. J Anal Appl Pyrolysis 116:1–9

Erdogan E, Atila B, Mumme J, Reza MT, Toptas A, Elibol M, Yanik J (2015) Characterization of products from hydrothermal carbonization of orange pomace including anaerobic digestibility of process liquor. Bioresour Technol 196:35–42

Figueiredo J, Pereira M, Freitas M, Órfão J (1999) Modification of the surface chemistry of activated carbons. Carbon 37:1379–1389

de Araújoa TP, Quesadaa HB, Bergamasco R, Vareschinia DT, de Barros MASD (2020) Activated hydrochar produced from brewer’s spent grain and its application in the removal of acetaminophen. Biores Technol 310:123399

Yu X, Liu S, Lin G, Yang Y, Zhang S, Zhao H, Zheng C, Gao X (2020) KOH-activated hydrochar with engineered porosity as sustainable adsorbent for volatile organic compounds. Colloids Surf A 588:124372

Hoekman S, Broch A, Robbins C (2011) Hydrothermal carbonization (HTC) of lignocellulosic biomass. Energy Fuels 25:1802–1810

Thommes M, Kaneko K, Neimark A, Olivier J, Rodriguez-Reinoso F, Rouquerol J, Sing K (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC technical report). Pure Appl Chem 87:1051–1069

Stavropoulos G, Zabaniotou A (2005) Production and characterization of activated carbons from olive-seed waste residue. Microporous Mesoporous Mater 82:79–85

Shen F, Wang Y, Li L, Zhang K, Jr RS, Qi X (2017) Porous carbonaceous materials from hydrothermal carbonization and KOH activation of corn stover for highly efficient CO2 capture. Chem Eng Commun 205:423–431

Abdel-Ghani N, El-Chaghaby G, ElGammal M, Rawash E (2016) Optimizing the preparation conditions of activated carbons from olive cake using KOH activation. New Carbon Mater 31:492–500

Tseng R, Tseng S, Wu F, Hu C, Wang C (2008) Effects of micropore development on the physicochemical properties of KOH-activated carbons. J Chinese Inst Chem Eng 39:37–47

Patil B, Kulkarni K (2012) Development of high surface area activated carbon from waste material [j]. Int J Adv Eng Res Stud I:2249–8974

El-Hendawy A (2009) An insight into the KOH activation mechanism through the production of microporous activated carbon for the removal of pb2+ cations. Appl Surf Sci 255:3723–3730

Lu X, Pellechia P, Flora J, Berge N (2013) Influence of reaction time and temperature on product formation and characteristics associated with the hydrothermal carbonization of cellulose. Bioresour Technol 138:180–190

Liu MY, Tsang DC, Hu J, Ng KT, Liu T, Lo IM (2008) Adsorption of methylene blue and phenol by wood waste derived activated carbon. J Environ Eng 134:338–345

Rodriguez-Reinoso F (2001) Activated carbon and adsorption. Encyclopedia of materials: Science and technology, pp 22–34

Roostaei N, Tezel H (2004) Removal of phenol from aqueous solutions by adsorption. J Environ Manage 70:157–164

Senol A, Hasdemir M, Hasdemir B, Kurdas I (2017) Adsorptive removal of biophenols from olive mill wastewaters (OMW) by activated carbon: mass transfer, equilibrium and kinetic studies, Asia-Pacific. J Chem Eng 12:128–146

Aliakbarian B, Casazza A, Perego P (2015) Kinetic and isotherm modelling of the adsorption of phenolic compounds from olive mill wastewater onto activated carbon. Food Technol Biotechnol 53:207–214

Ahmaruzzaman M, Sharma D (2005) Adsorption of phenols from wastewater. J Colloid Interface Sci 287:14–24

Stasinakis A, Elia I, Petalas A, Halvadakis C (2008) Removal of total phenols from olive-mill wastewater using an agricultural by-product, olive pomace. J Hazard Mater 160:408–413

Laszlo K, Podkoscielny P, Dabrowski A (2003) Heterogeneity of polymer-based active carbons in adsorption of aqueous solutions of phenol and 2,3,4-trichlorophenol. Langmuir 19:5287–5294

Michailof C, Stavropoulos GG, Panayiotou C (2008) Enhanced adsorption of phenolic compounds, commonly encountered in olive mill wastewaters, on olive husk derived activated carbons. Biores Technol 99:6400–6408

Radovic L, Silva I, Ume J, Menendez J, Leon CL, Scaroni A (1997) An experimental and theoretical study of the adsorption of aromatics possessing electron-withdrawing and electron-donating functional groups by chemically modified activated carbons. Carbon 35:1339–1348

Romero-Cano L, Gonzalez-Gutierrez L, Baldenegro-Perez L (2016) Biosorbents prepared from orange peels using instant controlled pressure drop for Cu (II) and phenol removal. Ind Crops Prod 84:344–349

Dabrowski A, Podkoscielny P, Hubicki Z, Barczak M (2005) Adsorption of phenolic compounds by activated carbon — a critical review. Chemosphere 58:1049–1070

Lawal A, Hassan M, Ahmad Farid M, Yasim-Anuar T, Mohd Yu-soff M, Zakaria M, Roslan A, Mokhtar M, Shirai Y (2020) One-step steam pyrolysis for the production of mesoporous biochar from oil palm frond to effectively remove phenol in facultatively treated palm oil mill effluent. Environ. Technol. Innov 18:100730

Achak M, Hafidi A, Mandi L, Ouazzani N (2014) Removal of phenolic compounds from olive mill wastewater by adsorption onto wheat bran. Desalin Water Treat 52:2875–2885

Malkoc E, Nuhoglu Y, Dundar M (2006) Adsorption of chromium (VI) on pomace—an olive oil industry waste: batch and column studies. J Hazard Mater B 138:142–151

El-Sayed Y, Bandosz T (2002) Acetaldehyde adsorption on nitrogen- containing activated carbons. Langmuir 18:3213–3218

Acknowledgements

Enaime G. acknowledges the Alexander von Humboldt Foundation for financial support via the Georg Forster Research Fellowship for postdoctoral researchers.

Funding

Enaime G. acknowledges the Alexander von Humboldt Foundation for financial support via the Georg Forster Research Fellowship for postdoctoral researchers (MAR 1220883 GF-P).

Author information

Authors and Affiliations

Contributions

Conceptualization and methodology, G.E., W.E., M.Lo., and A.B.; analysis and interpretation of data, G.E., A.B., and A.Y.; investigation, writing (original draft preparation), G.E.; review and editing, G.E. and M.Lü.; supervision, A.B, A.Y., M.Loud., M.Lü., and M.W. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Enaime, G., El Bouaidi, W., Louarrat, M. et al. Activated-hydrochar derived from olive mill wastes for the removal of phenolic compounds from olive mill wastewater. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-023-05261-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05261-y