Abstract

A significant factor affecting the mechanical, chemical, and visual characteristics of historical parchment is biodeterioration. In order to treat and shield parchment samples from microbial and UV light degradation, gelatin, a biodegradable polymer, loaded with titanium dioxide/silver (TiO2/Ag-NPs) nanocomposites was utilized as a protective coating. TEM and XRD were used to characterize the synthesized nanocomposite, and it was subjected to antimicrobial activity tests, via disc agar plate diffusion and colony-forming units (CFU) technique, against a variety of microbes, including Aspergillus fumigatus N1, Byssochlamys spectabilis N2, Cladosporium xanthochromaticum SPN, and Streptomyces albidoflavus SP11, which had been previously isolated from historical parchment manuscripts. Samples that were not treated served as the negative control, while samples that were separately treated with titanium dioxide and silver served as the positive control. The findings revealed that the TiO2/Ag-NPs/gelatin nanocomposite (NCG) demonstrated remarkable antimicrobial properties in contrast to TiO2NPs, which demonstrated only a minor antimicrobial activity. Investigations were also conducted into the treated parchment’s morphological, chemical, mechanical, and optical qualities. Without compromising any of its characteristics, the prepared film can shield the treated parchment from microbial attack and slow down its accelerated aging process.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Historic documents made of parchment—a collagen-based biomaterial made from animal rawhide after careful processing—can serve as the source of philosophical and cultural proof of human labor. From the second century BC until the end of the Middle Ages, these parchments were typically used as writing surfaces [1, 2]. One powerful agent that damages parchment's functional, esthetic, and other characteristic is biodeterioration. It mostly happens when there is a high relative humidity level [3]. Ancient parchment provides a suitable environment for the development of proteolytic microorganisms, which can hydrolyze the proteinaceous molecules of the parchment, alter its inorganic components, or produce pigments and organic acids that cause the parchment to discolor and eventually degrade [2, 4]. The parchment becomes stiff, inelastic, and blemished as a result, losing its distinctive physiognomies. Parchment denaturation is frequently the result of damage progressions [5]. Certain requirements, like high efficacy against microorganisms, durability, ease of handling, maintaining of health during and after treatment, and lastly cost-effectiveness, should be met by appropriate disinfection techniques [6].

Nanomaterials have come to light as innovative antimicrobial agents, owing to their exceptional chemical and physical characteristics. Due to their excellent surface area and apparent antimicrobial efficacy, different nanomaterials are considered the most proficient due to their antimicrobial efficacy against various microorganisms [7, 8]. Metal nanoparticles have excellent antimicrobial properties and can overcome the growth of rare species, which poses a real threat to researchers due to the increased resistance to metal ions and antibiotics [9].

Titanium dioxide (TiO2) nanoparticles are among the most nanomaterial brought to use in heritage preservation, as it is cheap, chemically stable, and environmentally friendly. The well-reported antimicrobial properties of TiO2 were based on its photoactivity [10, 11]. The efficiency of these nanomaterials has been enhanced through the development of nanocomposites [12]. Several nanomaterials may father synergic effects with TiO2 to enhance its biocidal action particularly or in general its photocatalytic activity. The addition of metallic nanoparticles owing proven sanitizing trait integrated with the recognized photocatalytic activity of TiO2 may additionally increase its efficacy against biodegradation of many materials [13,14,15].

Silver nanoparticles are one of the most effective metal nanoparticles used as disinfectants and are widely used in various fields. The interaction between silver and TiO2 nanoparticles allows enhancing the properties of each nanomaterial separately [12, 16, and 17].

Eco-friendly polymers were considered as barriers in front of external degradation factors such as humidity, condensation, fumes, and soluble substances. These polymers are suitable containers for the addition of various additives, likewise antimicrobials and antioxidants. A major advantage of biopolymers over synthetic polymeric materials is their biodegradability [18]. Technical gelatin is the purified active ingredient in collagen adhesives derived from skin or bones. This biopolymer is a hydrocolloid composed of a heterogeneous mixture of water-soluble high molecular weight proteins. When the aqueous dispersion dries, a three-dimensional network with intermolecular microcrystalline junctions is formed. Macroscopically, this microstructure leads to the fabrication of a thermo-reversible film [19]. In our study, gelatin was chosen over cellulosic adhesives because it is collagen-based, compatible with parchment, and provided a strong bond with parchment [20]. By adding titanium dioxide nanoparticles to the polymer matrix, it is possible to protect the treated material from microbes and photodamage in the presence of short-wavelength light close to ultraviolet light. TiO2 is usually used to block the passage of light and formation of colors in concentrations of about 1–2%. TiO2 nanoparticle showed antimicrobial action due to their photocatalytic characteristics [18]. The combination of TiO2 and silver nanoparticles enhances the photocatalytic properties of TiO2 for microbial inactivation. High antimicrobial efficacy and low silver release are the two main characteristics of silver-containing polymers. In addition, when silver nanoparticles with high antimicrobial activity are embedded in a porous matrix, the release time of silver is delayed for a long time, making it a good candidate for antibacterial use [12, 16,17,18].

By incorporating a silver-titanium dioxide nanocomposite into the gelatin biopolymer matrix, this study aimed to create a protective multifunctional coating that would help shield historical parchments from oxidative processes, light aging, and microbes using environmentally friendly methods. Using microanalytical techniques, the protective coating’s effects on the treated parchment’s chemical, mechanical, morphological, and optical properties were examined both before and after accelerated aging.

2 Materials and methods

2.1 Materials

-

2.1.1: Parchment samples were purchased from “William Cowley Parchment Makers, United Kingdom, London”. These parchment sheets were prepared according to historical reference manner with high quality.

-

2.1.2: Bovine hide Gelatin gel strength -225g Bloom, type B SIGMA-ALDRICH G9382-100G Lot # SLBN8199V B0Fe.

-

2.1.3: All chemicals and other ingredients used in the nanocomposite preparation and the antimicrobial assay were purchased from Sigma-Aldrich.

2.2 Methods

2.2.1 TiO2 nanoparticles (TiO2-NPs) fabrication

Youssef et al. [21] employed the sol-gel process to create titanium dioxide nanoparticles (TiO2-NPs). Hydrolysis and condensation of titanium tetraisopropoxide (TTIP) were performed. Diluting 5 mL of TTIP with 20 mL of isopropanol yielded a solution. This solution was dropped into distilled water that was kept at a pH of 2–3. Stir HNO3 for 2 h, then heat in a water bath for 20 h at 60–70°C. At 100°C, the produced TiO2 nanoparticles were collected and dried.

TiO2 nanoparticles doped silver nanoparticles (TiO2/Ag-NPs) preparation

In order to obtain TiO2 nanoparticles doped with Ag-NPs, silver nitrate salt (AgNO3) was dissolved in deionized water to liberate Ag+ ions, which were then added to the suspension solution of TiO2-NPs (Ag+ concentration was 1% relative to TiO2-NPs). At the time, the mixture of Ag+ and TiO2 nanoparticles was irradiated with UV light for 8 h using 4 mercury lamps (8 Watts) and continuous air supply. The Ag+ and TiO2-NPs suspensions were filtered and washed with deionized water and ethyl alcohol numerous times before drying to generate TiO2-NPs-doped Ag-NPs (TiO2/Ag-NPs). A simple casting method was used to create the gelatin/TiO2 nanoparticles doped Ag-NPs films. First, 1 g of gelatin powder was dissolved in 100 ml of distilled water while stirring at 50°C. The gelatin solution was supplemented with titanium dioxide doped silver nanoparticles (TiO2/Ag-NPs). Glycerin was then added to the mixture as a plasticizer, and the mixture was stirred for another 30 min. Then, an Elmasonic S10 H ultrasonic cleaning agent was used to ensure a consistent distribution of nanoparticles in the ultrasonic mixture [22].

2.2.2 Characterization of prepared nanocomposite

Transmission electron microscope (TEM)

The morphology of a gelatin/TiO2/Ag-NPs film was monitored using transmission electron microscopy (TEM) (JEM-2010; JEOL Ltd., Tokyo, Japan) at a 200 kV accelerating voltage. A drop of the test suspension was placed on a copper-coated copper grating for testing.

X-ray diffraction (XRD)

TiO2/Ag-NPs prepared for crystallite size measurements were evaluated with a Philips X-ray diffractometer (PW 1820 protractor, PW 1930 generator) immobilized with CuKα radiation (45 kV, 40 mA, λ = 1.5418 Å)). The test was scanned at a 2θ range of 5 to 80° with a step size of 0.02 and a step time of 1s.

2.2.3 Antimicrobial activity of prepared nanocomposite

Disc agar diffusion method

The antimicrobial activities of prepared nanocomposite were assessed via disc agar plate method, against three fungal test microbes; Aspergillus fumigatus (N1), Byssochlamys spectabilis (N2), Cladosporium xanthochromaticum (SPN), and one Streptomyces; Streptomyces albidoflavus (SP11), previously isolated from contaminated parchment manuscript and assessed for their biodegradative abilities [23]. The 10-mm diameter discs of treated parchment were placed on the surface of solidified agar plate having 25 ml of potato–dextrose agar (PDA) medium for fungi, the PH was adjusted at 6.0; and starch nitrate for bacteria where the pH was attuned to 7.0. The culture of each test microbe was diluted by distilled water to about 107–108 cells/ml, then 100 μl from each was used to inoculate the plates with the treated parchment discs. The plates were then incubated at 30◦C for 48h for bacteria and 72h for fungi. Clear zone’s diameters (including the film itself) that appeared around the discs were recorded [24, 25].

Colony forming units (CFU)

The numbers of viable cells were calculated by quantifying colony forming units (CFUs) for both types of microbial strains upon treatment with 0.005 Ag-NPs, 0.5 TiO2-NPs, Ag/TiO2 nanocomposite, and TiO2/Ag-NPs/gelatin nanocomposite. For CFU measurement, a serial dilution up to 10−6 has been assembled and 10μl from different reaction mixtures have been spread on the nutrient agar plates. The plates were incubated 48 h at 37 °C. The number of viable cells after treatment with each NPs material were quantified and compared with positive control (culture without NP) to assess the antimicrobial proficiency of NPs [26].

The reduction growth rate (R) for treated versus untreated inoculum was calculated using the equation

where A represents CFU/ml for the treated inoculum after incubation and B represents CFU/ml for the untreated one after the same period of incubation [27].

2.2.4 Statistical analyses

The mean standard error of the mean (SEM) was used to represent the data gathered from the antimicrobial analyses of nanoparticles and their nanocomposites. One-way analysis of variance (ANOVA) was used to evaluate the suggested intergroup variance, which was then followed by the Tukey’s test. P < 0.05 values were regarded as statistically significant. The PAST statistical programme was used for all statistical analyses.

2.2.5 Accelerated light aging

In order to test if applied composite nanoparticles could stop or accelerate the aging process caused by UV light exposure—a minor yet significant factor in parchment degradation—artificial aging was carried out. In the weather–ometer weathering chamber (Ci4000 Weather-OmeterTM, Atlas, Chicago, USA), all samples were light aged for 144 h at a light exposure of 700 W/m2 to simulate light exposure; the temperature was set to 30°C and the relative humidity was adjusted to 50% [28, 29]. The samples’ mechanical, chemical, morphological, and optical properties were observed both before and after aging.

2.2.6 Characterization of treated parchment

Mechanical properties

A universal test machine (Zwick/Roell, Germany) was used to measure the elongation and tensile parameters at a crosshead speed of 5 mm/min. Samples were made in accordance with ASTM D 638 guidelines. Three distinct samples for each were measured and then averaged. The processed and control samples’ tensile strength and elongation at break were measured and contrasted.

Fourier transform infrared spectroscopy in attenuated total refection mode (FTIR‑ATR)

A Platinum ATR module-equipped Bruker Vector 33 FTIR spectrometer (Germany) was used to perform FTIR-ATR measurements. The 4000–400 cm−1 range was used to record the infrared spectra. The triple-helix structure changes of collagen can be observed with FTIR-ATR analysis.

Scanning electron microscope (SEM) examination

Before and after artificial aging, SEM micrographs of the treated samples were captured at three different magnifications: 100 μm, 50 μm, and 10 μm. Notable surface variations were monitored. Samples were fractured and coated with AuPd film after immersion in liquid nitrogen for 45s. The fractured surfaces were examined using a Hitachi S– 3000N SEM instrument.

Color change

The CIE *Lab system was utilized to evaluate the color change of treated parchment before and after the aging process, employing Ultra Scan PRO Hunter Lab D65, 10 A. The colorimetric parameters were measured as the L value determines the transparency after 0 (black). One hundred (excellent white). As (+ a) denotes more red and (−a) denotes more green, its value determines red-green. And as (+ b) denotes more yellow and (−b) denotes dark blue, the value of b is yellow-blue [30]. The following equation was used to calculate the total color difference (ΔE):

3 Results and discussion

3.1 Evaluation of the prepared nanomaterials

The produced Ag-NPs’ TEM image (Fig. 1A) showed that they were spherical in shape and ranged in size from 6 to 8 nm, while TiO2-NPs measuring between 20 and 25 nm are shown in Fig. 1B. When compared to Ag-NPs, TiO2-NPs were remarkably distinct, exhibiting distinct shapes and agglomerations, which could be attributed to their nanoscale nature. TiO2/Ag-NPs were formed in large particles with two phases, as shown in Fig. 1C. The presence of Ag-NPs and TiO2-NPs in the polymer matrix with obvious aggregation is attributed to the two phases that were fashioned. Nonetheless, the produced TiO2/Ag-NPs particles are still visible at small sizes, ranging from 20 to 35 nm.

Using the X-ray diffraction method (XRD), the prepared Ag-NPs’ crystalline structure was assessed. The main characteristic peaks found in the XRD pattern (Fig. 1D) revealed and established the fabricated TiO2-Ag-NPs. According to JCPDS files 84–0713 and 04–0783, Ag-NPs showed four distinct peaks at various 2θ values: 38.3 for the plane of (111), 44.4 for the plane of (2 0 0), 65.8 for the plane of (2 2 0), and 78.3 for the plane of (3 1 1), indicating that they are (fcc) and crystalline in nature. The formation of silver nanoparticles is described by the broadening of Bragg’s peaks. Furthermore, using the ICDD no. 00–001-1292 that conforms to the rutile structure, the major characteristic peaks of different 2θ at 27, 29, 41, 44, 48, 54, 63, and 69 owing for various planes (110), (101), (111), (210), (211), (220), (002), and (301), respectively, are displayed in the XRD diffraction patterns of the prepared TiO2-NPs. However, the presence of Ag-NPs in the lattice structure of TiO2-NPs has been accountable for the success of the prepared TiO2@Ag-NPs, which displayed all of the Ag-NPs planes' diffraction patterns as well as the TiO2- planes' diffraction pattern.

3.2 Antimicrobial activities of the prepared nanomaterials

The antimicrobial activity of prepared TiO2/Ag-NPs nanocomposite loaded on gelatin against the previously isolated microbial strains as mentioned in section (“2.2.3”) was represented via disc agar diffusion method. The diameters of inhibition zone of Ag-NPs, TiO2-NPs, TiO2/Ag-NPs, and TiO2/Ag-NPs/Gelatin nanocomposite were presented in Table 1 and Fig. 2. Results indicated that Ag-NPs alone exhibited considerable antimicrobial activities against the used test microbes with inhibition zones of 16, 15, 22, and 27mm against A. fumigatus, B. spectabilis, C. xanthochromaticum, and S. albidoflavus, respectively. The prepared TiO2-NPs didn’t exhibit antimicrobial activity against any test microbe. TiO2/Ag-NPs revealed antimicrobial activity against all test microbes better than Ag-NPs when used solely with inhibition zones of 19, 19, 21, and 29mm against A. fumigatus, B. spectabilis, C. xanthochromaticum, and S. albidoflavus, respectively. Additionally, TiO2/Ag-NPs/gelatin composite exhibited higher antimicrobial activity over the other tested samples with inhibition values of 22, 20, 23, and 31 mm against A. fumigatus, B. spectabilis, C. xanthochromaticum, and S. albidoflavus, respectively. The concentration of Ag in the nanocomposite was determined according to Saada et al. [31], and titanium dioxide concentration was one hundred time of Ag concentration according to Becerra et al. [12].

Colony-forming units (CFU) were utilized to assess quantitatively the viable microbial cells after treatments, and the colony forming unit numbers were presented in Table 2 and Fig. 3. Results revealed that TiO2-NPs showed that the lowest reduction in microbial growth with R (%) of 67.26, 51.19, 85.60, and 86.60% against Aspergillus fumigatus, Byssochlamys spectabilis, Cladosporium xanthochromaticum, and Streptomyces albidoflavus, respectively. The rest of the tested materials (Ag-NPs, TiO2/Ag-NPs and TiO2/Ag-NPs/gelatin) exhibited approximately 100% reduction in growth against all test microbes. The most susceptible strain was Streptomyces albidoflavus (SP11), while Byssochlamys spectabilis (N2) showed the highest resistance, in comparison with other tested strains.

Numbers of Colony Forming Units of Aspergillus fumigatus (N1), Byssochlamys spectabilis (N2), Cladosporium xanthochromaticum (SPN) and Streptomyces albidoflavus (SP11) after treating with (0.005 Ag-NPs (Ag), 0.5 TiO2-NPs (Ti), TiO2/Ag-NPs nanocomposite (NC), and TiO2/Ag-NPs/Gelatin nanocomposite (NCG)) compared to control untreated ones

The statistical representation of the data introduced in these Tables in Fig. 4A, B, respectively indicated that TiO2-NPs in the concentration used has no activity against tested microbes. A significant improvement in antimicrobial activity was observed after the addition of Ag nanoparticles. Ag-doped TiO2 nanocomposite exhibited much stronger antimicrobial abilities.

Statistical representation of antimicrobial activity by means of zone of inhibition (A), and percent reduction of colony-forming units (B) of (0.005 Ag-NPs (Ag), 0.5 TiO2-NPs (Ti), TiO2/Ag-NPs nanocomposite (NC), and TiO2/Ag-NPs/gelatin nanocomposite (NCG)) against Aspergillus fumigatus (N1), Byssochlamys spectabilis (N2), Cladosporium xanthochromaticum (SPN) and Streptomyces albidoflavus (SP11)

Loading TiO2/Ag-NPs on gelatin helped in the ideal distribution of the nanoparticles in the entire composite and prevented their aggregation; and consequently, improved its performance. Improved performance could be also attributed to small size, large surface area, high bandwidth energy of the mesoporous TiO2 membrane, added active sites for photocatalysis, as well as the antimicrobial capability of Ag itself [39]. The doping of tiny amount of Ag played an important role in promoting the antimicrobial activity of TiO2. It has been reported that tetravalent Ti ions in TiO2 would be substituted by monovalent Ag ions, a high density of defects, for example, oxygen vacancies are generated, which supposed to be also important for the enhancement of antibacterial performance of the Ag-TiO2 nanocomposite coating [40]. By adding the silver nanoparticles in the TiO2 layer, recombination of the photoexcited electron–hole pairs in the (a) TiO2 thin film was delayed, while the pore structure was unchanged. Decrease in the recombination rate and accumulation of the silver nanoparticles on the film surface let the mesoporous Ag–TiO2/(a)TiO2 nanocomposite thin films have excellent antimicrobial activity [41].

3.3 Mechanical properties of treated parchment samples

As shown in Fig. 5, the mechanical characteristics of the treated parchment samples (tensile strength and elongation values) increased as a result of the treatment, suggesting that the treatment had no negative impact on the treated parchment. Tensile strength values increased to a maximum of 25 to 30 MPa in the samples treated with 0.2% gelatin and with TiO2/Ag-NPs gelatin nanocomposite. An increase of three to ten MPa was observed in the other treated samples. The elongation values showed a relatively small percent increase, ranging from 0.8 to 3.8%, which was irrelevant to the tensile strength value.

Both treated and untreated parchment samples showed a decline in mechanical properties after 144 h of UV aging. However, treated samples’ tested parameter values were still higher than those of the untreated samples. Compared to the tensile strength values, there was a less noticeable decrease in the elongation values. According to the findings, the treatment did not hasten the parchment’s aging process.

The impact of Ag-NPs disinfection on historical organic items was previously studied by Gutarowska et al. [38]. Following the disinfection, the tensile strength of historical leather items increased by 17–20%. The tensile strength of leather samples was not significantly affected by UV light aging, which is equivalent to about 24 years of museum exposure, according to the same authors. However, the elongation changes showed values that were 20% higher than before aging. Ag-NPs treated leathers did not exhibit any appreciable changes in their mechanical properties when compared to non-treated leathers, as confirmed by Maestre-López et al. [42].

A hybrid composite film was created by Boughriba et al. [22] by adding Ag-NP from TiO2 alloy in varying amounts to a gelatinous Rhinobatos cemiculus matrix. They found that elongation and tensile strength during rupture gradually decreased as the amount of TiO2-Ag nanoparticles increased. When compared to the nanoparticle film, the control film displayed the highest EAB and TS. The same authors speculate that the uneven distribution of TiO2-Ag nanoparticles, which leads to a slight aggregation when the concentration of nanoparticles in the protein matrix increases, may be responsible for the decrease in the mechanical properties of the nanocomposite membrane. Aggregates have the ability to limit the location of protein domains and lessen the prepared films’ mechanical properties.

3.4 Fourier transforms infrared spectroscopy (FTIR) analysis

Collagen fiber amide bands, which include the C = O stretching vibrations, N–H bend, and C-N stretch, are highly susceptible to the chemical surroundings around them. The best method for investigating possible alterations in protein molecules due to changes in their surroundings or other factors is infrared spectroscopy. A hypothesis regarding the secondary structure (β-sheet, random coil, α-helix) of the proteins can be made by examining the band position and intensity ratio of the amide I/amide II bands.

The main spectrum lines that were taken into account for estimating the changes brought about by treatment—both prior to and following aging—in the parchment are shown in Fig. 6A, B. The characteristic vibrational features of collagen that could change its three-dimensional structure were not clearly altered in the IR-ATR spectra. It is also important to remember that after UV irradiation, the distinctive bands did not exhibit any discernible changes.

The evaluation of degradation was based on the primary characteristics of the spectra: the amide I doublet and the amide II band at 1630 cm–1 and 1530 cm–1, respectively, are typically caused by the N–H bending and C = O stretching of both the OH and NH groups, which results in a strong and broadband band centered at 3400 cm–1. Inter-chain hydrogen bonding-related stretching of peptide N–H groups was correlated with the amides A at 3300 cm–1and B at 3080 cm–1. In addition to the absorptions of the asνCH2 and sνCH2, there are well-defined peaks at 2920 cm–1 and 2850 cm–1, respectively [32,33,34]. In the presence of TiO2-NPs, the spectra showed the presence of a band at 1742 cm–1 that could be attributed to ν(C = O) [35]. Additionally, motion near 1740 cm–1 and a peak at 1555 cm–1 confirmed that amide and amine groups were present in pure gelatin [36].

Ag-NPs collagen was essentially conjugated by electrostatic interactions. The effects of Ag-NPs stability and the conformational changes in collagen upon Ag-NP interaction are discussed based on these data. Strong intermolecular interactions are formed between interactants through electrostatic attractions and hydrogen bonding, with bands seen at 2920, 2850, 1640, and 1500 cm−1 [43]. The S–H stretching band was observed at 2870 cm−1 because Ag-NPs functionalized with mercaptosilane were present [44].

3.5 Scanning electron microscope (SEM) analysis

SEM micrographs were demonstrating the morphological alterations in the collagen fibers of the treated and untreated (control) samples. The ordered fibril network of a parchment with a well-preserved fibrillar structure was depicted in (Fig. 7). The bundles of fibrils revealed an integral collagen fiber network with distinct edges and contours. Without any signs of fiber degradation, the treated samples displayed a fibril network that was identical to the untreated sample. As expected, the SEM results revealed no discernible alterations in the parchment’s appearance following irradiation, indicating that this treatment is safe to use and would not cause the treated parchment’s collagen to deteriorate [37].

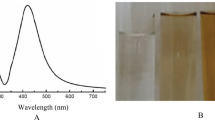

3.6 Change of color

Total color difference (ΔE) and color variations (L, a, and b) of treated parchment samples before and after aging as shown in (Fig. 8A, B), indicated that, except for the sample treated with Ag-NPs after aging, which showed a clear color change near ten degrees on the CIE Lab* system, all the materials used caused acceptable total color differences ≤ 3) before and after exposing to UV light aging for 144 h, which was equivalent to 24 years of museum exposure, according to Gutarowska et al. [38].

More specifically, for the samples treated with TiO2/Ag-NPs and TiO2/Ag-NPs/gelatin nanocomposite, L value dropped by slightly less than two degrees. Samples treated with gelatin and TiO2-NPs showed variations of less than 0.5°. The only sample with Ag-NPs treatment showed about 4° less than the untreated control sample. When compared to the control, unaged sample, the control and gelatin-treated samples show a decrease in lightening of less than three degrees after aging. Samples treated with TiO2-NPs showed almost no changes. Less than 4° of decrease were observed in samples treated with TiO2/Ag-NPs nanocomposite prior or after loading on gelatin in the same comparison. Once more, the Ag-NPs treated sample showed the biggest change among all samples, ten degrees lower. According to the a* value results, all samples had a slight increase in this value both before and after aging, indicating greater reddening of the samples. This was especially evident in the sample that had been treated with Ag-NPs after aging. The untreated sample after aging and the samples treated with gelatin both before and after aging displayed a slight increase in the b* value, indicating more yellowing. This value decreased in all other samples both before and after aging, indicating that the samples were more bluish.

In the colorimetric analysis of the carboxyl methyl cellulose/gelatin modified composition with TiO2/Ag-NPs, the transparency of the membrane slightly increased with the addition of gelatin, whereas an increase in the TiO2-Ag content decreased the transparency Pirsa et al. [18]. Because TiO2/Ag-NPs accumulate in the matrix of carboxyl methyl cellulose and gelatin films, the turbidity of the L* index is directly correlated with the amount of nanoparticles. The same authors demonstrated that while an increase in gelatin or TiO2-Ag concentration alone did not significantly affect parameter a*, a simultaneous increase in both concentrations was found to significantly increase parameter a*. The b* index was considerably raised by the increase in TiO2-Ag, but it was not significantly affected by the increase in gelatin. However, when TiO2-Ag-NPs were added to the Rhinobatos cemiculus hybrid gelatin composite film by Boughriba et al. [22] at varying concentrations, the parameters a* and b* increased while the L* value decreased. The (a* and b*) values have decreased, indicating a tendency towards reddening and yellowing. The authors associated these color shifts with the original brownish-gray hue of TiO2-Ag-NPs.

Furthermore, Ag-NPs misting of historical items, such as parchment, caused a negligible level of whiteness contamination, according to Gutarowska et al. [45]. According to Gutarowska et al. [38], both the undisinfected and Ag-NPs disinfected substrates’ color parameters changed as a result of UV irradiation. But generally speaking, the samples that had been misted with Ag-NPs showed the biggest color changes.

4 Conclusion

This study evaluated for the first time the antimicrobial activity of the TiO2/Ag-NPs/Gelatin nanocomposite against three fungi, A. fumigatus, B. spectabilis, and C. xanthochromaticum, as well as one bacterial, S. albidoflavus, microbial strain that was previously isolated from historical parchment dating back to the third century AD. Byssochlamys spectabilis was the most resistant strain, and Streptomyces albidoflavus was the most susceptible, according to a quantitative analysis of the data obtained. By incorporating titanium dioxide nanoparticles into silver nanoparticles, the antimicrobial activity of the former was enhanced and the coloring effect on the treated samples was mitigated. The prepared nanocomposite was loaded onto gelatin, which aided in the particles’ effective dispersion and binding to the samples that were treated. None of the evaluated properties of the treated parchment were negatively impacted by the created composite. Compared to the untreated control samples, the treated samples remained mechanically, chemically, and physically stable even after 144 h of light aging under UV light. Our findings confirmed that TiO2/Ag-NPs/Gelatin nanocomposite is an efficient disinfectant for written heritage, particularly parchment-based writing. It is still necessary to conduct additional analysis to determine how it affects the manuscript’s structural elements, such as leather, inks, pigments, waxes, and glues.

Data availability

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author/s.

References

Velivasaki G (2014) Investigation of the deterioration degree of parchment marked with iron gall inks. In CeROArt. Conservation, exposition, Restauration d’Objets d’Art (No. HS). Assoc CeROArt asbl. https://doi.org/10.4000/ceroart.4447

Troiano F, Polo A, Villa F, Cappitelli F (2014) Assessing the microbiological risk to stored sixteenth century parchment manuscripts: a holistic approach based on molecular and environmental studies. Biofouling 30(3):299–311. https://doi.org/10.1080/08927014.2013.871539

Orlita A (2004) Microbial biodeterioration of leather and its control: a review. Int Biodeterior Biodegradation 53(3):157–163. https://doi.org/10.1016/S0964-8305(03)00089-1

Pinzari F, Colaizzi P, Maggi O, Persiani AM, Schütz R, Rabin I (2012) Fungal bioleaching of mineral components in a twentieth-century illuminated parchment. Anal Bioanal Chem 402:1541–1550. https://doi.org/10.1007/s00216-011-5263-1

Voronina LI, Nazarova ON, Petushkova YP (1980) Disinfection and straightening of parchment damaged by microorganisms. https://doi.org/10.1515/rest.1980.4.2.91

Gutarowska B, Rembisz D, Zduniak K, Skóra J, Szynkowska M, Gliścińska E, Koziróg A (2012) Optimization and application of the misting method with silver nanoparticles for disinfection of the historical objects. Int Biodeterior Biodegradation 75:167–175. https://doi.org/10.1016/j.ibiod.2012.10.002

Helmi FM, Ali NM, Ismael SM (2015) Nanomaterials for the inhibition of microbial growth on ancient Egyptian funeral masks. Mediterr Archaeol Archaeom 15:87–95. https://doi.org/10.5281/zenodo.18360

El Sayed MT, El-Sayed AS (2020) Biocidal activity of metal nanoparticles synthesized by Fusarium solani against multidrug-resistant bacteria and mycotoxigenic fungi. J Microbiol Biotechnol 30(2):226. https://doi.org/10.4014/jmb.1906.06070

Rai M, Yadav A, Gade A (2009) Silver nanoparticles as a new generation of antimicrobials. Biotechnol Adv 27(1):76–83. https://doi.org/10.1016/j.biotechadv.2008.09.002

Goffredo GB, Accoroni S, Totti C, Romagnoli T, Valentini L, Munafò P (2017) Titanium dioxide based nanotreatments to inhibit microalgal fouling on building stone surfaces. Build Environ 112:209–222. https://doi.org/10.1016/j.buildenv.2016.11.034

Franco-Castillo I, Hierro L, Jesús M, Seral-Ascaso A, Mitchell SG (2021) Perspectives for antimicrobial nanomaterials in cultural heritage conservation. Chem 7(3):629–669. https://doi.org/10.1016/j.chempr.2021.01.006

Becerra J, Mateo M, Ortiz P, Nicolás G, Zaderenko AP (2019) Evaluation of the applicability of nano-biocide treatments on limestones used in cultural heritage. J Cult Herit 38:126–135. https://doi.org/10.1016/j.culher.2019.02.010

Amin SA, Pazouki M, Hosseinnia A (2009) Synthesis of TiO2–Ag nanocomposite with sol–gel method and investigation of its antibacterial E coli. Powder Technol 196(3):241–245. https://doi.org/10.1016/j.powtec.2009.07.021

Garcidueñas-Piña C, Medina-Ramírez IE, Guzmán P, Rico-Martínez R, Morales-Domínguez JF, Rubio-Franchini I (2016) Evaluation of the antimicrobial activity of nanostructured materials of titanium dioxide doped with silver and/or copper and their effects on Arabidopsis thaliana. Int J Photoenergy 2016. https://doi.org/10.1155/2016/8060847

Goffredo GB, Accoroni S, Totti C (2019) Nanotreatments to inhibit microalgal fouling on building stone surfaces. In: Nanotechnology in Eco-efficient Construction (pp. 619–647). Woodhead Publishing. https://doi.org/10.1016/B978-0-08-102641-0.00025-6

Yaşa İ, Lkhagvajav N, Koizhaiganova M, Çelik E, Sarı Ö (2012) Assessment of antimicrobial activity of nanosized Ag doped TiO 2 colloids. World J Microbiol Biotechnol 28:2531–2539. https://doi.org/10.1007/s11274-012-1061-y

Ghosh M, Mondal M, Mandal S, Roy A, Chakrabarty S, Chakrabarti G, Pradhan SK (2020) Enhanced photocatalytic and antibacterial activities of mechanosynthesized TiO2–Ag nanocomposite in wastewater treatment. J Mol Struct 1211:128076. https://doi.org/10.1016/j.molstruc.2020.128076

Pirsa S, Farshchi E, Roufegarinejad L (2020) Antioxidant/antimicrobial film based on carboxymethyl cellulose/gelatin/TiO2–Ag nano-composite. J Polym Environ 28:3154–3163. https://doi.org/10.1007/s10924-020-01846-0

Lee Y, Martín-Rey S, Osete-Cortina L, Martín-Sánchez I, Bolívar-Galiano F, Doménech-Carbó MT (2018) Evaluation of a gelatin-based adhesive for historic paintings that incorporates citronella oil as an eco-friendly biocide. J Adhes Sci Technol 32(21):2320–2349. https://doi.org/10.1080/01694243.2018.1477411

Banou P, Stassinou A (2012) Approaches to the conservation of patriarchal sigillia on parchment from the General State Archives of Greece. J Inst Conserv 35(2):201–218. https://doi.org/10.1080/19455224.2012.744952

Ahmed MA, El-Shennawy M, Althomali YM, Omar AA (2016) Effect of titanium dioxide nano particles incorporation on mechanical and physical properties on two different types of acrylic resin denture base. World J Nano Sci Eng 6(3):111–119. https://doi.org/10.4236/wjnse.2016.63011

Boughriba S, Souissi N, Jridi M, Li S, Nasri M (2020) Thermal, mechanical and microstructural characterization and antioxidant potential of Rhinobatos cemiculus gelatin films supplemented by titanium dioxide doped silver nanoparticles. Food Hydrocoll 103:105695. https://doi.org/10.1016/j.foodhyd.2020.105695

Saada NS, GOMAA AMG, Youssef AM, AZIZ MSA (2018) The hydrolytic activities of two fungal species isolated from historical quranic parchment manuscript. J Soc Leather Technol Chem 102(3):141–148

Collins CH, Lyne PM (1985) Microbiological methods, fifth ed. Butterworth and Co. Pub.Ltd., London, UK and Toronto, Canada, pp.167–181

Youssef AM, Abdel-Aziz MS, El-Sayed SM (2014) Chitosan nanocomposite films based on Ag-NP and Au-NP biosynthesis by Bacillus subtilis as packaging materials. Int J Biol Macromol 69:185–191. https://doi.org/10.1016/j.ijbiomac.2014.05.047

Arakha M, Pal S, Samantarrai D, Panigrahi TK, Mallick BC, Pramanik K, ..., Jha S (2015) Antimicrobial activity of iron oxide nanoparticle upon modulation of nanoparticle-bacteria interface. Sci Rep 5(1):14813. https://doi.org/10.1038/srep14813

Gupta D, Khare SK, Laha A (2004) Antimicrobial properties of natural dyes against Gram-negative bacteria. Color Technol 120(4):167–171. https://doi.org/10.1111/j.1478-4408.2004.tb00224.x

Manfredi M, Bearman G, France F, Shor P, Marengo E (2015) Quantitative multispectral imaging for the detection of parchment ageing caused by light: a comparison with atr-ftir, gc-ms and tga analyses. Int J Conserv Sci 6(1):3–14. http://www.scopus.com/inward/record.url?scp=84924699763&partnerID=8YFLogxK

Kern MS, Pataki-Hundt A, Wouters J, Kirby DP (2018) Accelerated ageing of parchment: investigation of a photo catalysed, low-heat approach. Restaurator Int J Preserv Libr Arch Mater 39(1):33–70. https://doi.org/10.1515/res-2017-0013

Abdel-Maksoud G, Ibrahim M, Issa YM, Magdy M (2020) Investigation of painting technique of Coptic icon by integrated analytical methods: imaging, spectroscopic and chemometric methods. J Archaeol Sci Rep 29:102085. https://doi.org/10.1016/j.jasrep.2019.102085

Saada NS, Abdel-Maksoud G, Abd El-Aziz MS, Youssef AM (2021) Green synthesis of silver nanoparticles, characterization, and use for sustainable preservation of historical parchment against microbial biodegradation. Biocatal Agric Biotechnol 32:101948. https://doi.org/10.1016/j.bcab.2021.101948

Badea E, Miu L, Budrugeac P, Giurginca M, Mašić A, Badea N, Della Gatta G (2008) Study of deterioration of historical parchments by various thermal analysis techniques complemented by SEM, FTIR, UV-Vis-NIR and unilateral NMR investigations. J Therm Anal Calorim 91(1):17–27. https://doi.org/10.1007/s10973-007-8513-x

Velmurugan P, Lee SM, Cho M, Park JH, Seo SK, Myung H, ..., Oh BT (2014) Antibacterial activity of silver nanoparticle-coated fabric and leather against odor and skin infection causing bacteria. Appl Microbiol Biotechnol 98:8179–8189. https://doi.org/10.1007/s00253-014-5945-7

Latour G, Robinet L, Dazzi A, Portier F, Deniset-Besseau A, Schanne-Klein MC (2016) Correlative nonlinear optical microscopy and infrared nanoscopy reveals collagen degradation in altered parchments. Sci Rep 6(1):26344. https://doi.org/10.1038/srep26344

Degabriel T (2015) Study of the interaction between proteins and TiO2 NPs: nature of the interfacial processes (Doctoral dissertation, Paris 6), p 70

Samimi Gharaie S, Habibi S, Nazockdast H (2018) Fabrication and characterization of chitosan/gelatin/thermoplastic polyurethane blend nanofibers. J Text Fibrous Mater 1:2515221118769324. https://doi.org/10.1177/2515221118769324

Vyskočilová G, Kopecká R, Pavliňák D, Laichmanová M, Sedláček I, Orlita A, ..., Miu L (2022) The influence of soil environment on the degradation of archaeological leather. Archaeometry 64(2):483–499. https://doi.org/10.1111/arcm.12717

Gutarowska B, Pietrzak K, Machnowski W, Danielewicz D, Szynkowska M, Konca P, Surma-Slusarska B (2014) Application of silver nanoparticles for disinfection of materials to protect historical objects. Curr Nanosci 10(2):277–286. https://doi.org/10.2174/15734137113096660121

Liu Y, Wang X, Yang F, Yang X (2008) Excellent antimicrobial properties of mesoporous anatase TiO2 and Ag/TiO2 composite films. Microporous Mesoporous Mater 114(1–3):431–439. https://doi.org/10.1016/j.micromeso.2008.01.032

Zhang Q, Sun C, Zhao Y, Zhou S, Hu X, Chen P (2010) Low Ag-doped titanium dioxide nanosheet films with outstanding antimicrobial property. Environ Sci Technol 44(21):8270–8275. https://doi.org/10.1021/es1019383

Akhavan O, Ghaderi E (2010) Self-accumulated Ag nanoparticles on mesoporous TiO2 thin film with high bactericidal activities. Surf Coat Technol 204(21–22):3676–3683. https://doi.org/10.1016/j.surfcoat.2010.04.048

Maestre-López IM, Payà-Nohales FJ, Cuesta-Garrote N, Arán-Ais F, Martínez-Sánchez MÁ, Orgilés-Barceló C, Bertazzo M (2015) Antimicrobial effect of coated leather based on silver nanoparticles and nanocomposites: synthesis, characterisation and microbiological evaluation. J Biotechnol Biomaterials 5(1):1. https://doi.org/10.4172/2155-952X.1000171

Diniz FR, Maia RCA, de Andrade LRM, Andrade LN, Vinicius Chaud M, da Silva CF, ..., Severino P (2020) Silver nanoparticles-composing alginate/gelatine hydrogel improves wound healing in vivo. Nanomaterials 10(2):390. https://doi.org/10.3390/nano10020390

Mandal A, Sekar S, Chandrasekaran N, Mukherjee A, Sastry TP (2015) Synthesis, characterization and evaluation of collagen scaffolds crosslinked with aminosilane functionalized silver nanoparticles: in vitro and in vivo studies. J Mater Chem B 3(15):3032–3043. https://doi.org/10.1039/c4tb02124j

Gutarowska B, Skora J, Zduniak K, Rembisz D (2012) Analysis of the sensitivity of microorganisms contaminating museums and archives to silver nanoparticles. Int Biodeterior Biodegradation 68:7–17. https://doi.org/10.1016/j.ibiod.2011.12.002

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors contributed equally to that manuscript regarding design of experiments, experimental work, preparing, and reviewing the manuscript before submission.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Saada, N.S., Youssef, A.M., Helmi, F.M. et al. Sustainable gelatin bionanocomposite based on multifunctional TiO2/Ag-NPs for parchment preservation. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05241-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05241-2