Abstract

Reduction and widespread consumption of fossil fuels have been diverted researcher attention towards alternative energy resources and a variety of biomass resources (energy crops, agricultural waste, animal waste and municipal waste) conversion into bioethanol production. Here, we have evaluated the effectiveness of green synthesized zinc oxide in term of harvesting efficiency, reducing sugar and fermentation products. Biomass was harvested by ZnO nanoparticles and got 92.9% harvesting efficiency within 5 min at 200 mg/L of ZnO nanoparticles. ZnO-harvested algae treated with nitric acid, sodium hydroxide, and potassium hydroxide give highest reducing sugars ranging from 150 to 200 μg/μL. The average value of bioethanol percentage varies between 1.60 and 6.02% among all samples which were fermented using Saccromyces cerivicae (yeast) as fermenting agent. Highest ethanol was shown by ZnO-harvested algae treated with nitric acid, sodium hydroxide, and potassium hydroxide which was in range of 3.78–6.02% v/v. Green synthesized nanoparticles method with reducing agent coating is an interesting and fascinating multiple application as compared to conventional physical and chemical methods. The outcome of this work is very useful for local biomass conversation into first and second-generation bioethanol production on large scale commercial process.

Similar content being viewed by others

Data availability

The authors confirm that the data and materials for supporting the findings of this study are available within the article and its supporting information.

References

UN (2019) World population projected to reach 98 billion in 2050, and 112 billion in 2100. UN Department of Economic and Social Affairs

Ajjur SB, Al-Ghamdi SG (2022) Towards sustainable energy, water and food security in Qatar under climate change and anthropogenic stresses. Energy Rep 8. https://doi.org/10.1016/j.egyr.2022.02.099

Ekici B, Turkcan OFSF, Turrin M, Sariyildiz IS, Tasgetiren MF (2022) Optimising high-rise buildings for self-sufficiency in energy consumption and food production using artificial intelligence: case of Europoint Complex in Rotterdam. Energies (Basel) 15. https://doi.org/10.3390/en15020660

Goswami RK, Agrawal K, Verma P (2022) Microalgae Dunaliella as biofuel feedstock and β-carotene production: an influential step towards environmental sustainability. Energy Convers Manag: X 13. https://doi.org/10.1016/j.ecmx.2021.100154

Bala R, Mondal MK (2022) Opportunities and challenges in industrial production of biofuels. Biofuels Bioenergy. https://doi.org/10.1016/B978-0-323-85269-2.00003-4

Mikulski D, Kłosowski G (2020) Microwave-assisted dilute acid pretreatment in bioethanol production from wheat and rye stillages. Biomass Bioenergy 136. https://doi.org/10.1016/j.biombioe.2020.105528

Mohd Azhar SH, Abdulla R, Jambo SA, Marbawi H, Gansau JA, Mohd Faik AA, Rodrigues KF (2017) Yeasts in sustainable bioethanol production: a review. Biochem Biophys Rep 10. https://doi.org/10.1016/j.bbrep.2017.03.003

Vasić K, Knez Ž, Leitgeb M (2021) Bioethanol production by enzymatic hydrolysis from different lignocellulosic sources. Molecules 26. https://doi.org/10.3390/molecules26030753

Sharma P, Prasad M (2021) Gold nanoparticles: synthesis and applications in biofuel production. In: Nanomaterials: Application in Biofuels and Bioenergy Production Systems. https://doi.org/10.1016/B978-0-12-822401-4.00030-1

Rodríguez-Couto S (2019) Green nanotechnology for biofuel production. https://doi.org/10.1007/978-3-319-75052-1

Qidwai A, Shukla SK, Kumar R, Pandey A, Dikshit A (2018) Introduction of nanotechnology in the field of biofuel production. https://doi.org/10.1007/978-3-319-75052-1_3

Manik A (2020) Studi Penerimaan Konsumen Terhadap Dim Sum Ikan Patin (Pangasius Hypophthalmus) Yang Difortifikasi Dengan Alga Hijau Biru (Spirulina). Bussiness Law Binus 7 3492/E2/DT.01.00/2023

Dabirian E, Hajipour A, Mehrizi AA, Karaman C, Karimi F, Loke-Show P, Karaman O (2023) Nanoparticles application on fuel production from biological resources: a review. Fuel 331. https://doi.org/10.1016/j.fuel.2022.125682

Gupta K, Chundawat TS (2020) Zinc oxide nanoparticles synthesized using Fusarium oxysporum to enhance bioethanol production from rice-straw. Biomass Bioenergy 143. https://doi.org/10.1016/j.biombioe.2020.105840

Aarti C, Khusro A, Agastian P, Kuppusamy P, Al Farraj DA (2022) Synthesis of gold nanoparticles using bacterial cellulase and its role in saccharification and bioethanol production from aquatic weeds. J King Saud Univ Sci 34. https://doi.org/10.1016/j.jksus.2022.101974

Nduka FO, Onwurah INE, Obeta CJ, Nweze EJ, Nkwocha CC, Ujowundu FN, Eje OE, Nwigwe JO (2023) Effect of nickel oxide nanoparticles on bioethanol production by Pichia kudriavzveii IFM 53048 using banana peel waste substrate. Environ Technol (United Kingdom). https://doi.org/10.1080/09593330.2023.2215450

Vidhya CV (2022) Microalgae—the ideal source of biofuel. Biofuels Bioenergy. https://doi.org/10.1016/B978-0-323-85269-2.00007-1

Yaashikaa PR, Keerthana Devi M, Senthil Kumar P (2022) Algal biofuels: technological perspective on cultivation, fuel extraction and engineering genetic pathway for enhancing productivity. Fuel 320. https://doi.org/10.1016/j.fuel.2022.123814

Varaprasad D, Raghavendra P, Sudha NR, Sarma LS, Parveen SN, Chandana PS, Chandra MS, Chandrasekhar T (2022) Bioethanol production from green alga Chlorococcum minutum through reduced graphene oxide-supported platinum-ruthenium (Pt-Ru/RGO) nanoparticles. Bioenergy Res 15. https://doi.org/10.1007/s12155-021-10282-4

Ortiz RJ (2020) Oil-fueled accumulation in late capitalism: energy, uneven development, and climate crisis. Crit Hist Stud 7. https://doi.org/10.1086/710799

Rüdiger M (2014) The 1973 oil crisis and the designing of a Danish energy policy. Hist Soc Res 39:10.12759/hsr.39.2014.4.94-112

Park JH, Yoon JJ, Park HD, Lim DJ, Kim SH (2012) Anaerobic digestibility of algal bioethanol residue. Bioresour Technol 113. https://doi.org/10.1016/j.biortech.2011.12.123

Chiu SY, Kao CY, Huang TT, Lin CJ, Ong SC, da Chen C, Chang JS, Lin CS (2011) Microalgal biomass production and on-site bioremediation of carbon dioxide, nitrogen oxide and sulfur dioxide from flue gas using Chlorella sp cultures. Bioresour Technol 102. https://doi.org/10.1016/j.biortech.2011.06.091

Nichodemus CO (2017) Bioethanol: production, advantages, disadvantages and environmental impacts. Biotech Articles

Papong S, Rewlay-ngoen C, Itsubo N, Malakul P (2017) Environmental life cycle assessment and social impacts of bioethanol production in Thailand. J Clean Prod 157. https://doi.org/10.1016/j.jclepro.2017.04.122

Duque A, Álvarez C, Doménech P, Manzanares P, Moreno AD (2021) Advanced bioethanol production: from novel raw materials to integrated biorefineries. Processes 9. https://doi.org/10.3390/pr9020206

Zighmi S, Goudjil MB, Bencheikh SE, Ladjel S (2018) The valorization of the green alga Spirogyra’s biomass in the region of Ouargla-Algeria into renewable biofuel. Green Energy Technol. https://doi.org/10.1007/978-3-319-62575-1_11

Eshaq FS, Ali MN, Mohd MK (2010) Spirogyra biomass a renewable source for biofuel (bioethanol) production. Int J Eng Sci Technol 2

Mercy Anitha DP, Selvam SP, Sadiku ER (2021) Biobutanol: a promising alternative commercial biofuel, in: handbook of nanomaterials and nanocomposites for energy and environmental applications, vol 1-4. https://doi.org/10.1007/978-3-030-11155-7_163-1

Shackira AM, Jazeel K, Puthur JT (2021) Phycoremediation and phytoremediation: promising tools of green remediation. Sustainable Environmental Clean-up: Green Remediation. https://doi.org/10.1016/B978-0-12-823828-8.00013-X

Hidalgo D, Martín-Marroquín JM, Corona F (2023) Metal-based nanoadditives for increasing biomass and biohydrogen production in microalgal cultures: a review. Sustain Chem Pharm 33. https://doi.org/10.1016/j.scp.2023.101065

Sharma P, Bano A, Pratap Singh S, Atkinson JD, Shiung Lam S, Iqbal HMN, Wah Tong Y (2022) Nanomaterials as highly efficient photocatalysts used for bioenergy and biohydrogen production from waste toward a sustainable environment. Fuel 329. https://doi.org/10.1016/j.fuel.2022.125408

Gur T, Meydan I, Seckin H, Bekmezci M, Sen F (2022) Green synthesis, characterization and bioactivity of biogenic zinc oxide nanoparticles. Environ Res 204. https://doi.org/10.1016/j.envres.2021.111897

Bala N, Saha S, Chakraborty M, Maiti M, Das S, Basu R, Nandy P (2015) Green synthesis of zinc oxide nanoparticles using Hibiscus subdariffa leaf extract: effect of temperature on synthesis, anti-bacterial activity and anti-diabetic activity. RSC Adv 5. https://doi.org/10.1039/C4RA12784F

Saleem S, Jameel MH, Akhtar N, Nazir N, Ali A, Zaman A, Rehman A, Butt S, Sultana F, Mushtaq M, Zeng JH, Amami M, Althubeiti K (2022) Modification in structural, optical, morphological, and electrical properties of zinc oxide (ZnO) nanoparticles (NPs) by metal (Ni, Co) dopants for electronic device applications. Arab J Chem 15. https://doi.org/10.1016/j.arabjc.2021.103518

Yirgu Z, Leta S, Hussen A, Khan MM, Aragaw T (2023) Pretreatment of lipid-extracted biomass of Scenedesmus sp grown in wastewater for bioethanol production. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-03917-3

Reaño RL, Halog A (2020) Analysis of carbon footprint and energy performance of biohydrogen production through gasification of different waste agricultural biomass from the Philippines. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-020-01151-9

Javed HU, Wang D, Abdullah M, Hasan LY, Zeng Y, Lan Y, Shi CQD (2023) Interrogating raisin associated unsaturated fatty acid derived volatile compounds using HS–SPME with GC–MS. Foods 12. https://doi.org/10.3390/foods12030428

Anitha R, Singaravel V, Vinoth J (2022) Zinc oxide nanoparticle inhibits the biofilm formation of Candida glabrata: a sustainable approach to use an agro-waste of cashew apple juice. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03663-y

Saka A, Jule LT, Gudata L, Shuma S, Nagaprasad N, Subramanian K, Afessa G, Ramaswamy K (2022) Preparation of biobutanol via coffee bean harsh extracts by zinc oxide nanoparticle as catalyst. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-02749-x

Saka A, Enkosa E, Jule LT, Nagaprasad N, Subramanian K, Ramaswamy K (2022) Biofuel production from mango (Mangifera indica) seed extracts through zinc oxide nanoparticle. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03005-y

Huang L, Chen R, Luo J, Hasan M, Shu X (2022) Synthesis of phytonic silver nanoparticles as bacterial and ATP energy silencer. J Inorg Biochem 231. https://doi.org/10.1016/j.jinorgbio.2022.111802

Mustafa G, Hasan M, Yamaguchi H, Hitachi K, Tsuchida K, Komatsu S (2020) A comparative proteomic analysis of engineered and bio synthesized silver nanoparticles on soybean seedlings. J Proteomics. https://doi.org/10.1016/j.jprot.2020.103833

Zafar A, Tariq T, Hasan M, Nazar M, Rasheed MN, Mahmood N, Shu X (2021) Green-maturation of cobalt-oxide nano-sponges for reinforced bacterial apoptosis. Colloids Interface Sci Commun 45. https://doi.org/10.1016/j.colcom.2021.100531

Gao H, Huang Q, Li Q, Wu L, Liao H, Hasan M, Gong S, Zhou X (2023) An efficient designing of nitrogen decorated carbon quantum dots as Fe fluorescent probe: on account of binary carbon source system. Mater Today Commun 35. https://doi.org/10.1016/j.mtcomm.2023.105707

Hasan M, Teng Z, Iqbal J, Awan U, Meng S, Dai R, Qing H, Deng Y (2013) Assessment of bioreducing and stabilizing potential of dragon’s blood (dracaena cochinchinensis, Lour S C Chen) resin extract in synthesis of silver nanoparticles. Nanosci Nanotechnol Lett. https://doi.org/10.1166/nnl.2013.1600

Luo F, Wang W, Chen M, Zheng Z, Zeng D, Hasan M, Fu Z, Shu X (2020) Synthesis and efficacy of the n-carbamoyl-methionine copper on the growth performance, tissue mineralization, immunity, and enzymatic antioxidant capacity of nile tilapia (oreochromis niloticus). ACS Omega. https://doi.org/10.1021/acsomega.0c03220

Hasan M, Yang W, Ju Y, Chu X, Wang Y, Deng Y, Mahmood N, Hou Y (2017) Biocompatibility of iron carbide and detection of metals ions signaling proteomic analysis via HPLC/ESI-Orbitrap. Nano Res. https://doi.org/10.1007/s12274-016-1375-4

Hasan M, Sajjad M, Zafar A, Hussain R, Anjum SI, Zia M, Ihsan Z, Shu X (2022) Blueprinting morpho-anatomical episodes via green silver nanoparticles foliation. Green Process Synth 11:697–708. https://doi.org/10.1515/gps-2022-0050

Lee YC, Lee K, Oh YK (2015) Recent nanoparticle engineering advances in microalgal cultivation and harvesting processes of biodiesel production: a review. Bioresour Technol 184. https://doi.org/10.1016/j.biortech.2014.10.145

Akbar S, Haleem KS, Tauseef I, Rehman W, Ali N, Hasan M (2018) Raphanus sativus mediated synthesis, characterization and biological evaluation of zinc oxide nanoparticles , nanoscience and nanotechnology letters. https://doi.org/10.1016/j.biortech.2014.10.145

Luo F, Wang M, Huang L, Wu Z, Wang W, Zafar A, Tian Y, Hasan M, Shu X (2020) Synthesis of zinc oxide Eudragit FS30D nanohybrids: structure, characterization, and their application as an intestinal drug delivery system. ACS Omega. https://doi.org/10.1021/acsomega.0c01216

Luo F, Zeng D, Wang W, Yang Y, Zafar A, Wu Z, Tian Y, Huang Y, Hasan M, Shu X (2021) Bio-conditioning poly-dihydromyricetin zinc nanoparticles synthesis for advanced catalytic degradation and microbial inhibition. J Nanostructure Chem. https://doi.org/10.1016/j.rechem.2022.100537

Jaya D, Setiyaningtyas R, Prasetyo S (2018) Pembuatan Bioetanol Dari Alga Hijau Spirogyra sp bioethanol production from green algae Spirogyra sp. Eksergi 15:10.31315/e.v15i1.2290

Sulfahri M, Amin SB, Sumitro M (2016) Saptasari, Bioethanol production from algae Spirogyra hyalina using Zymomonas mobilis. Biofuels 7. https://doi.org/10.1080/17597269.2016.1231954

Saif MS, Zafar A, Waqas M, Hassan SG, Haq AU, Tariq T, Batool S, Dilshad M, Hasan M, Shu X (2021) Phyto-reflexive zinc oxide nano-flowers synthesis: an advanced photocatalytic degradation and infectious therapy. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2021.05.107

Hasan M, Altaf M, Zafar A, Ali Z, Munawar T, Saif MS, Iqbal F, Khan MW, Mustafa G, Mahmood A, Mahmood N, Shu X (2020) Bioinspired synthesis of zinc oxide nano-flowers: a surface enhanced antibacterial and harvesting efficiency. Mater Sci Eng: C. https://doi.org/10.1016/j.msec.2020.111280

Sun AL, Qi QA, Zhi LJ (2020) Cross-linkage urease nanoparticles: a high-efficiency signal-generation tag for portable pH meter-based electrochemical immunoassay of lipocalin-2 protein diagnostics. Microchim Acta 187. https://doi.org/10.1007/s00604-020-04466-6

Zhu J, Jiao N, Zhang H, Xu G, Xu Y (2022) Detoxification of lignocellulosic prehydrolyzate by lignin nanoparticles prepared from biorefinery biowaste to improve the ethanol production. Bioprocess Biosyst Eng 45. https://doi.org/10.1126/sciadv.1701735

Javid A, Amiri H, Kafrani AT, Rismani-Yazdi H (2022) Post-hydrolysis of cellulose oligomers by cellulase immobilized on chitosan-grafted magnetic nanoparticles: a key stage of butanol production from waste textile. Int J Biol Macromol 207. https://doi.org/10.1016/j.ijbiomac.2022.03.013

Mikulski D, Kłosowski G (2022) Integration of first- and second-generation bioethanol production from beet molasses and distillery stillage after dilute sulfuric acid pretreatment. Bioenergy Res 15. https://doi.org/10.1007/s12155-021-10260-w

de Medeiros Dantas JM, Neto AÁM, Ghislain T, Lavoie JM (2022) Bioethanol production as an alternative end for maple syrups with flavor defects. Fermentation 8. https://doi.org/10.3390/fermentation8020058

El-Zawawy WK, Ibrahim MM, Abdel-Fattah YR, Soliman NA, Mahmoud MM (2011) Acid and enzyme hydrolysis to convert pretreated lignocellulosic materials into glucose for ethanol production. Carbohydr Polym 84. https://doi.org/10.1016/j.carbpol.2010.12.022

Torabi S, Satari B, Hassan-Beygi SR (2021) Process optimization for dilute acid and enzymatic hydrolysis of waste wheat bread and its effect on aflatoxin fate and ethanol production. Biomass Convers Biorefin 11. https://doi.org/10.1007/s13399-020-00676-3

Varaprasad D, Narasimham D, Paramesh K, Sudha NR, Himabindu Y, Keerthi Kumari M, Nazaneen Parveen S, Chandrasekhar T (2021) Improvement of ethanol production using green alga Chlorococcum minutum. Environ Technol (United Kingdom) 42. https://doi.org/10.1080/09593330.2019.1669719

Condor BE, de Luna MDG, Chang YH, Chen JH, Leong YK, Chen PT, Chen CY, Lee DJ, Chang JS (2022) Bioethanol production from microalgae biomass at high-solids loadings. Bioresour Technol 363. https://doi.org/10.1016/j.biortech.2022.128002

Acebu PIG, de Luna MDG, Chen C-Y, Abarca RRM, Chen J-H, Chang J-S (2022) Bioethanol production from Chlorella Vulgaris Esp-31 grown in unsterilized swine wastewater. SSRN Electron J. https://doi.org/10.1016/j.biortech.2022.127086

Sulfahri DRH, Kasbawati ACMT, Nurfadilah DP, Wulandari WLT (2019) Bioethanol production from algae Spirogyra peipingensis using Saccharomyces cerevisiae, Pichia kudriavzevii and Kluyveromyces thermotolerans. J Phys Conf Ser. https://doi.org/10.1088/1742-6596/1341/2/022004

Bader AN, Sanchez Rizza L, Consolo VF, Curatti L (2020) Efficient saccharification of microalgal biomass by Trichoderma harzianum enzymes for the production of ethanol. Algal Res 48. https://doi.org/10.1016/j.algal.2020.101926

Gengiah K, Moses GLP, Baskar G (2020) Bioethanol production from Codium tomentosum residue, energy sources, Part A: Recovery. Util Environ Eff. https://doi.org/10.1080/15567036.2020.1771481

Zahra J, Iqbal S, Latif M, Ali M, Shad MA, Tabish TA, Ashiq MN, Iqbal F (2017) A note on the biocompatibility of zinc oxide nanoparticles in male albino mice. Nanosci Nanotechnol Lett 9. https://doi.org/10.1166/nnl.2017.2342

Abdelmigid HM, Hussien NA, Alyamani AA, Morsi MM, Alsufyani NM, Kadi HA (2022) Green synthesis of zinc oxide nanoparticles using pomegranate fruit peel and solid coffee grounds vs chemical method of synthesis, with their biocompatibility and antibacterial properties investigation. Molecules 27. https://doi.org/10.3390/molecules27041236

Samiei M, Ghasemi N, Asl-Aminabadi N, Divband B, Golparvar-Dashti Y, Shirazi S (2017) Zeolite-silver-zinc nanoparticles: biocompatibility and their effect on the compressive strength of mineral trioxide aggregate. J Clin Exp Dent 9. https://doi.org/10.4317/jced.53392

Funding

There is no specific funding, but the authors would like to acknowledge The Islamia University Bahawalpur, Pakistan, National Research Program for University (NRPU), for Higher Education Commission, Pakistan (Grant ID: 9458), for providing the funds. And also acknowledge the Zhongkai University of Agriculture and Engineering, Guangzhou China (510225), Guangdong Provincial Department of Agriculture and Rural affairs Project, Grant/Award Number 2020KJ115, 2021KJ115.

Author information

Authors and Affiliations

Contributions

Xue Huang: supervision, idea, writing first drafting. Iqra Kainat: investigation, experimentation. Murtaza Hasan: writing — original draft, design, idea. Ayesha Zafar: conceptualization, writing, review. Tuba Tariq: data interpretation, formal analysis, experimentation. Muhammad Khalil: formal analysis, interpretation of data. Shahbaz Gul Hassan: review, software, statistical analysis. Hafiz Umer Javed: data collection, formal analysis. Jianjin Guo: experimentation, drafting, analysis. Xugang Shu: supervision, conceptualization. Mansour Ghorbanpour: writing, review.

Corresponding authors

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1.

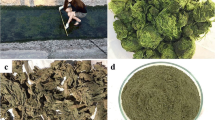

Fig. S1. Microscopic view of spirogyra. Fig. S2 (a). Wet algae (b) Dry algae (c) Fine powdered algae. Fig. S3. Effect of ZnO nanoparticle dosage on (a) harvesting efficiency and (b) recovery capacity of algal sample. (DOCX 358 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, X., Kainat, I., Hasan, M. et al. Investigation of pretreatment parameters for bioethanol production from Spirogyra using ZnO nanoparticles. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-05024-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-05024-9