Abstract

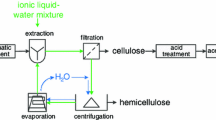

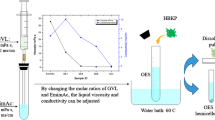

Dissolving pulp as a purified chemical pulp with high cellulose content, is an important raw material for many applications such as cellulose derivatives and regenerated cellulose, hence paper-grade bagasse pulp as a cheap alternative non-wood raw material can be used to produce dissolving-grade pulp. In this work, the potential of ECF and TCF bleached paper-grade soda bagasse pulp in the production of dissolving pulp was studied. To find an effective method, bleaching sequences followed by the different hemicellulose extraction processes including CCE, xylanase treatment, IONCELL-P, combination of xylanase treatment and IONCELL-P were investigated. The unbleached bagasse pulp was subjected to the IONCELL-P process using mixtures of 1-ethyl-3-methylimidazolium acetate/water for the extraction of xylan from an initial of 30.5 to 7.0%. The ECF (ODEpQP1.5%) sequence resulted in the optimum bleached pulp in terms of physical and chemical properties and the consumption of bleaching chemicals, which was selected for subsequent treatments to remove xylan to produce dissolving pulp. In the IONCELL-P treatment of bleached pulp, the xylan content could even be reduced to 5.9% (80% removal) and in X-IONCELL-P to 3.3% (90% removal). All the extraction methods investigated in this study removed xylan with differences in the selectivity and efficiency successfully.

Similar content being viewed by others

Data availability

Data and materials will be available on request.

Abbreviations

- CCE:

-

Cold caustic extraction

- CED:

-

Cupriethylenediamine

- DBNH:

-

1,5-Diazabicyclo[4.3.0]non-5-enium

- DMAc:

-

N,N-dimethylacetamide

- DTR:

-

Dissolution-base torque reactivity

- ECF:

-

Elemental chlorine-free

- emim:

-

1-Ethyl-3-methylimidazolium

- GPC:

-

Gel permeation chromatography

- HCE:

-

Hot caustic extraction

- IDR:

-

Initial dissolution rate

- IL:

-

Ionic liquid

- IONCELL-P:

-

IONCELL-Pulp, an ionic liquid treatment for hemicellulose extraction from pulp.

- MMD:

-

Molar mass distribution

- PDI:

-

Poly dispersity index

- TCF:

-

Totally chlorine-free

- X:

-

Xylanase enzymatic treatment

References

Köpcke V, Ibarra D, Ek M (2008) Increasing accessibility and reactivity of paper grade pulp by enzymatic treatment for use as dissolving pulp. Nord Pulp Pap Res J 23:363–368

Liu Y, Shi L, Cheng D, He Z (2016) Dissolving pulp market and technologies: Chinese prospective- a mimi-review. Bioresources 11:7902–7916. https://doi.org/10.15376/biores.11.3.Liu

The Fiber Year (2022) World survey on textiles and nonwovens, The Fiber Year GmbH 22:402. https://www.thefiberyear.com/. Accessed May 2022

Statista (2022) Production of chemical pulp worldwide 2020–2025. https://www.stataista.com/

Wu C, Zhou S, Li R, Wang D, Zhao C (2015) Reactivity improvement of bamboo dissolving pulp by xylanase modification. BioResources 10:4970–4977. https://doi.org/10.15376/biores.10.3.4970-4977

Das S, Lachenal D, Marlin N (2013) Production of pure cellulose from Kraft pulp by a totally chlorine-free process using catalyzed hydrogen peroxide. Ind Crop Prod 49:844–850

Stepan AM, Monshizadeh A, Hummel M, Roselli A, Sixta H (2016) Cellulose fractionation with IONCELL-P. Carbohydr Polym 150:99–106. https://doi.org/10.1016/j.carbpol.2016.04.099

Helmy SA, Abou-State MA (1991) Viscose pulps from Egyptian bagasse with high chemical reactivity. Holzforschung 45:433–436

Horio M, Takahama M (1958) Studies on manufacturing dissolving pulp from bagasse. Bull Inst Chem Res Kyoto Univ 36:172–180

Ibrahim AA, Nada AMA, Hagemann U, El seoud OA (1996) Preparation of dissolving pulp from sugarcane bagasse, and its acetylation under homogeneous solution condition. Holzforschung 50:221–225

Vena PF, García-Aparicio MP, Brienzo M, Görgens JF, Rypstra T (2013) Impact of hemicelluloses pre-extraction on pulp properties of sugarcane bagasse. Cellul Chem Technol 47:469–477

Andrade MF, Colodette JL (2014) Dissolving pulp production from sugar cane bagasse. Ind Crop Prod 52:58–64. https://doi.org/10.1016/j.indcrop.2013.09.041

Köpcke V, Ibarra D, Larsson PT, Ek M (2010) Optimization of treatment sequences for the production of dissolving pulp from birch kraft pulp. Nord Pulp Pap Res J 1:191–198

Ceccherini S, Maloney TC (2017) 16th fundamental research symposium, September, 2017: novel CED-based rheological test to evaluate pulp reactivity. The Pulp and Paper Fundamental Research Society, Manchester. https://doi.org/10.15376/frc.2017.2.909

Ibarra D, Köpcke V, Larsson PT, Jääskeläinen AS, Ek M (2010) Combination of alkaline and enzymatic treatments as a process for upgrading sisal paper-grade pulp to dissolving-grade pulp. Bioresour Technol 101:7416–7423. https://doi.org/10.1016/j.biortech.2010.04.050

Ribas Batalha LA, Colodette JL, Gomide JL, Barbosa LCA, Maltha CRA, Borges Gomes FJ (2012) Dissolving pulp from bamboo. BioResources 7:640–651

Monshizadeh A (2015) Influence of the molecular weight of cellulose on the solubility in ionic liquid-water mixtures. Master’s thesis pp 58. Aalto University. https://aaltodoc.aalto.fi. Accessed June 2015

Zhao L (2016) Xylan removal by xylanase for the production of dissolving pulp from bamboo. The degree of master of applied science, the faculty of graduate and postdoctoral studies (Chemical and Biological Engineering). The University of British Columbia

Abushammala H, Mao J (2020) A review on the partial and complete dissolution and fractionation of wood and lignocelluloses using imidazolium ionic liquids. Polymers 12:195. https://doi.org/10.3390/polym12010195

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose (sic) with ionic liquids. J Am Chem Soc 124:4974–4975. https://doi.org/10.1021/ja025790m

Froschauer C, Hummel M, Iakovlev M, Roselli A, Schottenberger H, Sixta H (2013) Separation of hemicellulose and cellulose from wood pulp by means of ionic liquid/cosolvent systems. Biomacromolecules 14:1741–1750. https://doi.org/10.1021/bm400106h

Roselli A, Asikainen S, Stepan A, Monshizadeh A, Weymarn N, Kovasin K, Wang Y, Xiong H, Turunen O, Hummel M et al (2016) Comparison of pulp species in IONCELL-P: selective hemicellulose extraction method with ionic liquids. Holzforschung 70:291–296. https://doi.org/10.1515/hf-2014-0313

Janson J (1970) Calculation of the polysaccharide composition of wood and pulp. Paperi Ja Puu 52:323–329

Jääskeläinen A, Saariaho A, Vuorinen T (2005) Quantification of lignin and hexenuronic acid in bleached hardwood kraft pulps: a new calibration method for UVRR spectroscopy and evaluation of the conventional methods. J Wood Chem Technol 25:51–65

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Milanez A, Colodette JL (2005) Optimal conditions for bleaching eucalyptus kraft pulp with three stage sequence. In: Proceeding of 5th International Pulp Bleaching Conference (IPBC). June 14-16, Stockholm, Sweden

Liu YL, Chen KF, Li J, Mo LH, Xu J, Wu HM (2009) Hydrogen peroxide reinforced oxygen delignification of wheat straw soda-AQ pulp. Chung-kuo Tsao Chih/China Pulp and Pap 28:13–16

Khristova P, Kordsachia O, Patt R, Karar I, Khider T (2006) Environmentally friendly pulping and bleaching of bagasse. Ind Crop Prod 23:131–139. https://doi.org/10.1016/j.indcrop.2005.05.002

Karar IGE (2004) Environmentally friendly pulping and bleaching of bamboos and bagasse from Sudan. Ph.D. thesis, p 166. University of Khartoum. https://core.ac.uk

Beltramino F, Roncero MB, Vidal T, Valls C (2018) Facilitating the selection of raw materials: evaluation of the effects of TCF and ECF bleaching sequences on different wood and non-wood pulps. Afinidad 75:91–96

Vaysi R, Behrooze R, Khaj-e-Ali E (2016) The effect of ECF bleaching on optical and mechanical of bagasse soda pulp. IJWPR 31: 349-361. https://doi.org/10.22092/IJWPR.2016.105981

Loureiro PEG, Domingues EF, Evtuguin DV, Carvalho GVS (2010) ECF bleaching with a final hydrogen peroxide stage: impact on chemical composition of Eucalyptus globulus kraft pulps. BioResources 5:2567–2580

Ceccherini S, Maloney TC (2019) Assessing wood pulp reactivity through its rheological behavior under dissolution. Cellulose 26:9877–9888. https://doi.org/10.1007/s10570-019-02750-0

Yuan Z, Wen Y, Sella Kapu N, Beatson R, Martinez M (2017) A biorefinery scheme to fractionate bamboo into high-grade dissolving pulp and ethanol. Biotechnol Biofuels 10(38). https://doi.org/10.1186/s13068-017-0723-2

Friebel C, Bischof RH, Schild G, Fackler K, Gebauer I (2019) Effects of caustic extraction on properties of viscose grade dissolving pulp. Processes 7(3):122. https://doi.org/10.3390/pr7030122

Sixta H (2006) Handbook of Pulp, Volume 2, Chapter 11: pulp properties and application. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Cao Y, Tan H (2006) Improvement of alkali solubility with enzymatic treatment. Appl Microbiol Biotechnol 70:176–182

Le Moigne N (2008) Swelling and dissolution mechanisms of cellulose fibers. Ph.D. thesis, p 133. Ecole Nationale superrieure des mines de paris. https://pastel.hal.science/tel-0053429

Acknowledgements

The authors would like to thank Dr. Leena Pitkänen for her advice in evaluating the results of pulp molar mass distribution obtained from GPC analyses.

Funding

The authors received no financial support.

Author information

Authors and Affiliations

Contributions

Kajal Moradian Gilan: conceptualization, methodology, formal analysis, investigation, writing—original draft.

Sahab Hedjazi: conceptualization, methodology, validation, writing—review and editing, supervision.

Huy Quang Lê: methodology, formal analysis, writing—review and editing.

Ali Abdulkhani: conceptualization, methodology, formal analysis.

Herbert Sixta: conceptualization, validation, resources, writing—review and editing, supervision.

Corresponding author

Ethics declarations

Ethical approval

This declaration is not applicable as this study does not involve human and/or animal studies.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gilan, K.M., Hedjazi, S., Lê, H.Q. et al. The potential of different hemicelluloses extraction methods in conversion of environmentally friendly ECF and TCF bleached paper-grade bagasse soda pulp to dissolving-grade pulp. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04979-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04979-z