Abstract

Bone biochar is used as an adsorbent in water pollution control because of its high surface area and pore volumes. This study is attempting to prepare a low-cost adsorbent from waste fish bones by chemical activation and use it for the removal of Cd2+ and Pb2+ from polluted water. The preparation of fish bone adsorbents involved two methods. The first method includes the chemical activation of waste fish bone using different chemical activators (0.001 M HNO3, 0.1 M NaOH, 0.5% H2O2, and ethanol) (FB), while the second one includes the calcination of waste fish bone after the chemical activation at 873 K (FB-Hy). The synthesized fish bone adsorbent (FB) was characterized by electron microscopy (SEM), X-ray diffractometer (XRD), X-ray fluorescence (XRF), Brunauer–Emmett–Teller (BET) surface area, and Fourier transform infrared (FT-IR). The effectiveness of the prepared adsorbent (FB) in removing Pb and Cd was evaluated based on contact time, solution pH, solution temperature, initial metal concentration, and adsorbent dose. Metal concentrations were measured by atomic absorption spectroscopy. The results show that 0.1 M NaOH activation of bone waste (FB) is suitable for higher adsorption of Cd2+ and Pb2+ compared with other activators. The maximum adsorption of Pb and Cd with the FB adsorbent was 99.74 and 99.35%, respectively, at optimum conditions (pH 6.0, contact time 30 min, initial metal concentration 10 ppm, adsorbent dosage 0.1 g, and temperature at 328 K). The results of kinetic adsorption obeyed a pseudo-second-order model. Freundlich and Langmuir isotherms were applied, and the adsorption was found to fit well with the Langmuir model. This study ended with the success of preparing an eco-friendly and low-cost fish bone adsorbent from the waste fish bone and using it for the removal of Cd2+ and Pb2+ from polluted water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Industrial, domestic, and agricultural wastewaters are the major pollutants contaminating the aquatic environment. Most wastewater contains toxic materials that when dispose into water streams without specific treatment cause pollution of water bodies. So, it is essential to treat wastewater to remove heavy metals before its disposal to water body. Now, the world trends in the reliable low-cost and practical methods for wastewater treatment. This treatment has great necessary to prevent the contamination of receiving water.

Even in low quantities, heavy metals like Pb, Cd, Mn, Ni, Fe, and Zn can be harmful to humans. It accumulates in food and causes human health problems. They can also contaminate soil and groundwater, which could harm plants and animals over the long run [1]. Because of their toxicity, lengthy atmospheric half-lives, and capacity to bioaccumulate in the human body, heavy metals are well-known environmental contaminants. Heavy metal pollution of terrestrial and aquatic ecosystems is a significant environmental issue with negative effects on human health. The majority of heavy metals are produced naturally, although some come from man-made sources [2].

Heavy metals like Pb and Cd are poisonous. Human health was impacted by Pb ions through kidney failure, nerve damage, genital issues, and brain injuries. Additionally, Cd ions cause cancer, infertility, hypertension, lung damage, muscular cramping, and abnormalities of protein metabolism [3].

Different approaches to removing heavy metal ions from wastewater, which include chemical precipitation, ion exchange, reverse osmosis, electro-kinetic remediation, phytoremediation, and adsorption have been used. Research have shown that adsorption is the simplest and best cost-effective method. Adsorbents that are applied in the adsorption technique can be recycled and recycled again [4, 5]. Adsorption technology is an attractive process in water treatment because of its high efficiency and economic trends. The most common adsorbents include activated carbons, zeolites, clays, biomass, and polymeric materials [6]. As a result, current research looks for cheaper biomass alternatives to commercial adsorbents, including agricultural, industrial, forest, and other residual sources [7, 8].

Bones have consisted of 30% organic and 70% inorganic compounds. The major component of bone minerals is hydroxyapatite Ca10(PO4)6(OH)2 (HAP). HAP is considered an effective adsorbent as it has a high heavy metal removal capacity ion exchange with calcium ions on the surface of bone. Animal bones are used as adsorbents for the removal of heavy metals due to their biogenic apatite. They have been used as an adsorbent due to their low-cost, efficient, and natural abundance [9].

Bone char is a porous, black, and granular material produced by heating animal bones. Its composition varies depending on how it is made; however, it consists mainly of tricalciumphosphate (or hydroxylapatite) 57–80%, calcium carbonate 6–10%, and carbon 7–10% [10]. A substantial amount of bone will be produced as solid waste and contaminate the environment as a result of the rise in meat consumption. Waste bones can be converted into bone char, which can be used as an adsorbent to remove contaminants from wastewater and effluent gas, via pyrolysis or gasification [11].

Bone biochar is widely used as adsorbent in water pollution control because of its high surface area and pore volumes and its outstanding physicochemical properties [12]. It is characterized by a mesoporous structure with a specific surface area from 80 to 120 m2/g [13]. During the last few decades, several studies have reported the removal of a variety of organic and inorganic compounds from aqueous solutions with bone biochar [14,15,16,17,18].

Due to the negatively charged surfaces of the biochar, it can positively charge metals through electrostatic attraction. Various functional groups and ligands specificities on the surface of biochars can interact with heavy metals forming complexes [19]. Compared with activated carbon, biochar appears to be low-cost and effective adsorbent. High temperatures are needed for the production of carbon. Ultimately, biochar production is cheaper with lower energy requirements [20].

To obtain better adsorption performance, several modification technologies have been developed to produce bone biochar such as ball milling activation, pyrolysis, sulfonation, compositing, and amination [21]. In addition, chemical activation of bone to produce bone biochar was applied with acid/alkali treatment as a common approach to vary the composition and pore structure of bone biochar [22]. Aparecido et al. [8] prepared tilapia fish bone-based biochar in two steps: carbonization of the precursor material followed by chemical treatment with a 0.1 mol L−1 HCl solution. Rauf et al. [23] generated adsorbent from hydroxyapatite chicken beaks/zeolitic imidazolate framework-8 (HApB/ZIF-8) using Zn(NO3)2; 6H2O in methanol as an activator. Maria et al. [24] prepared activated carbon adsorbent from cow bone by carbonization and activation with HNO3. Fish scale biochar with a high specific surface area was prepared by H3PO4 acid activation method [25]. Zn-doped cuttlefish bone adsorbent was prepared by chemical activation of cuttlefish bone waste [26]. K2CO3 was used as an activating agent for preparing fish bone biochar [27].

Doostmohammadi et al. [28] found that when charring bovine and pig bones under air atmosphere the values of BET specific surface areas were 2.2 and 44 m2 /g, respectively. Murillo et al. [29] reported surface area values of chicken pyrolysis in nitrogen atmosphere about 130 m2/g.

More recently, fish bones have been used as adsorbent materials for wastewater remediation [9, 14, 29,30,31]. Fish bones, as a low-cost and natural abundant material have proven to be one of the most effective heavy metal adsorbent for wastewater treatment. The adsorption efficiency of fish bone is due to the presence of hydroxyapatite Ca10(PO4)6(OH)2, and this because of the exchange reaction with calcium ions with heavy metals [31]. Also, organic phosphates have high affinities for adsorption to mineral surfaces; so, fish bone waste could be used as a phosphate source for treating heavy metals in wastewater.

Mostofa et al. [32] investigated the adsorption of Pb onto apatite extracted from mixed fish bones. Terzioğlu et al. [33] found that the fish bones are a rich resource of calcium phosphates, low-cost, and an abundant material. Nahum et al. [34] used synthesized bone char (BC) from pleco fish (Pterygoplichthys spp.) to remove Cd in water and found that the capacity of BC for adsorbing Cd(II) was enhanced by increasing the solution pH. Wange et al. [27] prepared activated fishbone charcoal after treatment with K2CO3 as an activating agent and used it for the removal of emulsified oil from oily wastewater.

Kizilkaya et al. [35] investigated the removal of Pb from aqueous solutions using pretreated fish bones. They reported that the maximum adsorption capacity for Pb (II) was found to be 323 mg/g at optimum conditions. The experiments showed that the kinetic and adsorption isotherm results of adsorption obeyed a pseudo second-order model and fitted well to the Langmuir isotherm. Desorption/leaching experiments showed that desorption of the Pb on the bone surface exhibited very low ratios. Hassan et al. [36] studied the removal of Zn ions from aqueous solutions using powdered fish bones, and found high Zn adsorption (98%) at adsorption conditions pH 5.0, adsorbent dose 1.80 g/100 mL, and 12-h contact time at room temperature 30 ± 1 °C.

In the present study, fish bone waste has been used for the preparation of new biochar adsorbents using chemical activation with 0.001 M HNO3, 0.1 M NaOH, 0.5% H2O2, and ethanol, followed by calcination. The synthesized adsorbent was used to remove Pb and Cd ions from polluted water. The characterization of adsorbent was performed by FTIR, SEM, XRD, and BET analyses. The efficiency of Cd2+ and Pb2+ ion adsorption on the prepared adsorbent will be studied. Impacts of pH, contact time, solution temperature, adsorbent dose, and metal concentration on adsorption efficiency were explored. To better understand mechanisms of the metal removal process, adsorption isotherms, kinetic, and thermodynamic models were used. A real wastewater sample was also treated by the designed adsorbent. The novelty of this study is that it use different concentrations of the activators that have not published before.

2 Materials and methods

2.1 Reagents and chemicals

High analytical grade chemicals and reagents (Merk, Sigma, Aldrich) were used: Cd and Pb standard solutions (1000 ppm) were from BDH, UK.

2.2 Sample collection

For the synthesis of fish bone biochar, the waste fish bone was used as a suitable primary source. The fish bone waste sample was obtained from the fresh discard of the local butcher’s shops in Aswan City. The fish bone was boiled in hot deionized water for 2 h until it became very clean from attaching meat and fat, dried, and kept in a clean container.

2.3 Preparation and pretreatment of fish bone adsorbent by chemical activation

The clean fish bone sample was transferred to the oven for drying over night at 378 K, crushed into small pieces, milled in an agate mortar, and sieved to a particle size < 63 µm. One gm of clean fish bone powder was agitated in 50 mL of 0.01 M HNO3 for 2 h at a stirring rate of 250 rpm. The mixture was filtered, and the treated bone adsorbent was cleaned with deionized water to pH near 7. Then, the adsorbent was dried overnight at 373 K, milled, and sieved to particle size 63 µm. The previous step was repeated using three other different chemical activators, including 0.1 NaOH, 0.5% H2O2 and absolute ethanol. These chemically treated fish bone samples were stored in dry and clean containers and denoted as FB. Calcined chemically activated adsorbent (denoted as FB-Hy) were prepared by the calcination of FB samples at 873 K for 1 h. The prepared adsorbents were milled and sieved to obtain particle size < 63 µm and then maintained in clean containers for later studies.

2.4 Adsorption experiment

Adsorption studies were performed in 100-mL Erlenmeyer flasks containing 0.05 g of the two prepared adsorbent portions (the chemically calcinated FB-Hy, chemically raw bone FB) with 10 mL 20 ppm metal ion (Pb2+, Cd2+) solution at a fixed room temperature, stirring rate 250 rpm for 1 h, and initial solution pH 6 ± 0.3. The concentration of the metal ions in the final solution after filtration was determined by an atomic absorption spectrometer (Thermo scientific ICE 3000 atomic absorption spectrometer, USA).

All adsorption experiments were repeated three times and standard mean was calculated.

The percentage removal of metal ions was calculated by the following equation:

The amount of metal adsorbed per unit mass of the adsorbent was evaluated by using the following equation, qe (mg/g)

where.

- Co:

-

initial concentration of metal ion (ppm).

- Ce:

-

the equilibrium concentration of metal ion (ppm).

- V:

-

the volume of metal ion solution (L).

- m:

-

the mass of adsorbent (g).

2.5 Morphological characterization of adsorbents

A number of techniques were used to look at the surface chemistry, crystalline properties, and textural aspects of fish bone biochar (FB).

Chemically activated bone biochar before and after activation was characterized by XRD, FTIR, SEM and BET analysis techniques, X-rays diffraction patterns (XRD, Brukeraxs D8, Germany), scanning electron microscopy (SEM, Quanta FEG electron microscopy), Fourier transform infrared spectroscopy (Cary 630 FTIR spectrometer, Agilent technologies Company), and specific surface area by Quatachrome Instruments (NOVA 2000 series, UK).

2.6 Batch adsorption

The effects of initial metal concentration, adsorbent dosage, solution pH, pHzpc, contact time, and solution temperature on the adsorption of Pb2+ and Cd2+ onto the bone adsorbents were investigated to obtain the optimum conditions for the high adsorption efficiency of Pb2+and Cd2+ on FB adsorbent.

2.6.1 Effect of pH on adsorption

Solution pH can affect the interactions on the adsorbent surface and lead to the ionization of functional groups on the adsorbent [37].

Adsorption of Pb2+ and Cd2+ metal ions by FB adsorbent was studied using an initial pH range of 4–7. No further increase in pH was done in order to avoid hydroxide precipitation of metal ions. The adsorbent dosage was 0.05 mg/10 mL metal solution (initial concentration = 10 ppm) for 1 h (250 rpm) at room temperature. After the agitation period, the residual metal ion concentrations were measured by an atomic absorption spectrometer (AAS).

2.6.2 Effect of adsorbent dosage on adsorption

To study the adsorbent dose effect on Pb2+ and Cd2+ removal, FB adsorbent ranging from 0.01 to 0.1 g was used. A 10 mL 10 ppm of metal ion (Cd2+ and Pb2+) solution at pH 6 ± 0.3 was used for 1 h (250 rpm) at room temperature. The liquid phase was separated from the solid phase by filtration, and the concentrations of the metal ions in the aliquot were detected by AAS.

2.6.3 Effect of solution temperature on adsorption

The effect of temperature on the uptake capacity of Cd2+ and Pb2+ using the FB adsorbent was studied at a temperature range (298–328 K) with constant conditions at 0.05 g/10 mL of the metal ion solution, agitation time 30 min (250 rpm), pH = 6 ± 0.3 and initial concentration 10 ppm.

2.6.4 Effect of contact time on adsorption

This factor plays an important role in determining the rate of the adsorption process. This experiment was carried out at the variation of the contact time range 30–120 min (250 rpm).

2.6.5 Effect of initial metal concentration on adsorption

The adsorption of metal ions onto the FB adsorbent was performed using initial metal concentrations (Pb, Cd) ranging from 10 up to 70 ppm. A 0.02-g adsorbent per 10 mL of metal ions solution was stirred for 1 h (250 rpm) at pH 6 ± 0.3, and solution temperature 328 K. The filtrated liquid through a Whatman filter paper was analyzed with AAS to calculate the removal percentage before and after adsorption.

2.6.6 Effect of pHpzc on the adsorption

The surface chemistry of the FB adsorbent has been determined by its point of zero charge pH (pHpzc). A solution of 0.1 M NaCl was used as the zero pH solution buffer.After adding 0.01 g of FB adsorbent to 5 ml of 0.1 M NaCl solutions pH ranges (1, 3, 5, 7, 9), the pH was adjusted by adding a few drops of HNO3 and NaOH solutions with different concentrations. The pH of the solutions were recorded before and after the adsorption process using 0.1 M NaCl on the treated bone adsorbent. A curve was drawn between the initial and final pH values.

2.7 Adsorption Isotherms

The obtained adsorption data was fitted into the following adsorption isotherms: Linear, Langmuir, Freundlich, Temkin, and Dubinin-Raduskevich (D-R) isotherm models.

The Linear model can be expressed as:

where qe is the amount of metal adsorbed (mg/g) and Ce is the concentration of metal ion after adsorption (ppm). The constant of proportionality or distribution coefficient KD refers as the partition coefficient.

The Langmuir equation can be expressed as follows:

where Ce is the concentration of metal ion (ppm) in solution at equilibrium, Qe is the amount of metal ion adsorbed on adsorbent mg/g, b is Langmuir constant related to the energy of adsorption L/mg, and Qo is the maximum adsorption capacity of adsorbent mg/g.

The Freundlich equation was given as follows:

where Kf is the adsorption capacity (mg−1/n L1/n g−1) and n is the adsorption intensity (L/mg). The value of 1/n indicates the affinity and favorability of the metal adsorption. Ce is the equilibrium concentration of metal ions in the solution (ppm).

Linear form of Temkin equation is expressed as follows:

where b is the Temkin constant associated with the heat of sorption, qe (mg/g) is the amount of adsorbed metal ion per unit weight of adsorbent, Ce (ppm) is the metal ion concentration in solution at equilibrium, B which is the constant related to the heat of sorption (J/mol), and K is the Temkin isotherm equilibrium binding constant.

The linear D-R equation can be expressed as follows:

where β is a constant related to the adsorption energy (mol2/kJ2), qm is a constant that indicates the sorption degree characterizing the adsorbent (mg/g), and E is the polanyi potential, which can be obtained by the following equation:

where R is the ideal gas constant (R = 8.314 J/mol K) and T is absolute temperature (K).

2.8 Kinetic studies

The study of the adsorption kinetic behavior of the adsorbents is very important to understand the rate of adsorption of the metals on the surface of chemically treated bone adsorbents. For this purpose, the Pseudo–first order, Pseudo–second order, and Intra–particle diffusion models were used to study the rate of adsorption.

Pseudo- first order kinetic model can be equated as the following:

where qe is the amount of the metal ions adsorbed at equilibrium per unit weight of adsorbent (mg.g−1), qt is the amount of metal ions adsorbed at any time (mg.g−1), and, besides, k1 is the rate coefficient (min−1).

The linearized form of the pseudo–second order kinetic model is evaluated as follows:

where K2 is the rate constant of pseudo–second order adsorption (g/mg/min).

Intra-particle diffusion model is represented as follows:

where Ki (mg g−1 min−1/2) is the rate constant of the intra-particle diffusion model, and C (mg g−1) represents the thickness of the boundary layer.

2.9 Thermodynamic study

Gibbs free energy (ΔGo), enthalpy (ΔHo), and entropy (ΔSo) were calculated from the thermodynamic equation:

where R is the universal gas constant (8.314 J/Mol K), and T is the absolute temperature (K). ΔHo and ΔSo were calculated from the slope and intercept of plots of ln k vs 1/T.

ΔGo value could be calculated from the equation as follows:

where b is the adsorption equilibrium constant of Langmuir isotherm

2.9.1 Desorption test

In order to evaluate the reversibility of metal ion adsorption onto the FB adsorbent, desorption characteristics were also determined. To eliminate the traces of metal ions on the metal laden adsorbent surface, it was cleaned with deionized water after the adsorption process and then dried in an oven at 353 K overnight. Finally, 0.05 g of dried FB adsorbent was agitated with 10 mL of desorption solutions (0.1 M HNO3, 0.1 M NaOH, and deionized water) at the constant optimum conditions (pH 6 ± 0.3, 30 min contact time, 250 rpm at 328 K). After filtration immediately, the concentrations of the Cd2+ and Pb2+ ions were determined by AAS, and the uptake percentages were calculated.

2.9.2 Application of adsorbents in domestic wastewater (real sample test)

Real wastewater sample from Kima fertilizers factory disposal was obtained to investigate the Cd2+ and Pb2+ removal effects of the prepared FB adsorbent. The optimum conditions were used in this study (0.1 g of adsorbent dose, pH 6 ± 0.3, initial metal concentration 10 ppm, solution temperature 328 K and 1 h agitation period, 250 rpm). The concentrations of Pb and Cd ions were measured before adsorption process. After performing the adsorption process under the optimum conditions, the concentrations of Cd2+ and Pb2+ ions were measured, and all results were recorded to calculate the removal percentage of ions from the solution.

3 Results and discussion

3.1 Characterization of the chemically prepared bone adsorbents

3.1.1 XRD analysis

The XRD pattern of the specimens after the chemical treatment with sodium hydroxide solution (NaOH) (Fig. 1) showed that hydroxyapatite appeared at high intensities 2θ at 32.0°, 32.97° for fish bone adsorbent FB. Beside that the FB adsorbent before chemical activation showed a low 2θ at 39.9–49.6° [8, 37]. Same results confirmed the hydroxyapatite characterization of the bone adsorbents which corresponded to the same pattern before treatment [38].

3.1.2 SEM analysis

Scanning electron microscopy (SEM) images of bone adsorbents, which are useful in determining the surface and adsorption details of the bone adsorbents before and after chemical treatment is shown in Fig. 2. The figure shows a variety of cavities and porous morphology with pores of different shapes and sizes. This amorphous, protruding, and rough shape of the surface has a magnificent role in increasing the contact area, enhancing the diffusion of the metal ions on the surface of the adsorbent during the adsorption process. The particles size of the bone adsorbent after the chemical treatment was 2.79 µm for FB. As compared with the results of the raw bone adsorbent (4.96 µm). So, it is noticeable that the chemical treatment with sodium hydroxide (NaOH) encourages the surface activity for uptake more metal ions on its surface.

3.1.3 FTIR analysis

The study of the FTIR of the chemically treated bone FB adsorbent (Fig. 3) showed many functional groups shifted to frequency level or disappeared after the chemical treatment with NaOH solution, indicating the possible involvement of the functional group. The spectra curves of adsorbent after treatment FB showed the same crystallization of water (− OH group) at a range of 3000–3600 cm−1 owing to the chemical treatment with the sodium hydroxide solution (NaOH) [39]. The − OH group was appearing at 3433.2 cm−1 FB adsorbent. PO \(_{4}^{3 - }\) group peaks disappeared after the chemical treatment only in FB-Hy at 1027.8 cm−1 as phosphate group v4 vibrational mode at rage (976–1190 cm−1). This may be because of increased the hydroxyl group in the adsorbent [35]. Alkaline stretching –CH bending group was appeared clearly at 2922.5 cm−1 for FB. Broad C = N, C = O, and C = C stretching groups (1465–1744 cm−1) were appearing at 1648.0 cm−1 [40].

Calcium peak completely disappeared after the chemical treatment in the three types of bone adsorbents. Strong bending peaks of = C-H group (which could be detected in the range 675–1000 cm−1) appeared at 870.4 cm−1 [41]. Carbonate groups (which could be detected at 1414–1500 cm−1 or at 1300–1650 cm−1) were distinguished at 1416.0 cm−1 for FB adsorbent [39]. Similar results were reported by Kizilkaya et al. [35] who also pretreated fish bone by NaOH 0.1 M solution at 60 °C.

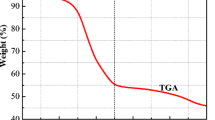

3.1.4 BET surface area

The surface area is a very effective property that describes the adsorbent surface nature, and so it can be clearly distinguished between fish bone sample before and after treatments. The BET method is the most common method for measuring the surface area of adsorbents using nitrogen gas as an adsorbate on the surface of the material. Table 1 results reveal that the measuring surface area of the fish bone before activation was 18.22 m2/g, while after activation (FB), it was raised to 99.8 m2/g, which indicates that the surface area of the fish bone increased after activation. Also, according to the I.U.P.A.C. classification, if the diameter of the particles is less than 2 nm, 2–50 nm and more than 50 nm, they belong to the microporous, mesopore, and macropore groups, respectively [42]. So, as a diameter of the FB particle was in the range 2–50 nm, FB-Hy was a mesoporous materials.

Nahum et al. [34] used synthesized bone char (BC) from pleco fish (Pterygoplichthys spp.) to remove fluoride and cadmium (II) in water. The results showed that the properties of the BCs were independent of the type of bone used and the surface areas were close to 110 m2g−1.

Doostmohammadi et al. [28] reported values of BET specific surface areas of 2.2 and 44 m2/g, respectively, when charring bovine and pig bones under air atmosphere. Hassan et al. [36] achieved 72 m2/g surface area through the pyrolysis of camel bone in an inert atmosphere. Moreno-Piraja´n et al. [43] examined the effect of the atmosphere (either oxidant or inert) in the charring of cow bones and reported that an inert atmosphere allowed larger BET values (223 vs. 178 m2/g). Murillo et al. [29] reported surface area values of chicken pyrolysis in nitrogen atmosphere about 130 m2/g.

3.2 A comparative study of Cd2+ and Pb2+ adsorption on the prepared adsorbents (chemically calcinated FB-Hy and chemically activated raw bone FB)

Table 2 shows the results of the removal percentage of Cd2+ and Pb2+ on the chemically calcinated (FB-Hy) and chemically activated raw bone (FB) adsorbents under the constant conditions(0.1 g adsorbent dose, initial metal concentration 10 ppm, 1-h contact time (250 rpm), pH 6 and solution temperature 328 K). The results reveal that the adsorbent activated with 0.1 M NaOH (FB) exhibited higher removal efficiency of Cd2+ and Pb2+ than the other activators. Chemically activated raw bone (FB) adsorbent shows higher removal of Pb and Cd than with that with the chemical calcinated bone (FB-Hy). So the chemically activated raw bone (FB) adsorbent treated with 0.1 M NaOH was used for the later studies.

Chemical activation was applied to improve the surface properties of bone char. It has been reported as more advantageous than physical activation. Dimovic et al. [44] applied oxidative treatment with H2O2 to raw bones with subsequent calcination, and they concluded that treatment with H2O2 was efficient in removing the organic phase. Recently, it has been reported that NaOH and KOH treatments of bovine bones readily remove organic matter and cause changes in the HAp structure [45]. Kizilkaya et al. [35] used 0.1 M NaOH to prepare fish bone adsorbent. It is also known that thermal treatment at 400–500 °C partially removes the organic components and facilitates the activation effect of the chemical treatment.

3.3 Optimal parameters for the adsorption of Cd2+ and Pb2+ on the chemically activated bone adsorbent (FB)

To evaluate the adsorbent potential of the FB adsorbent, a set of tests were applied to assess the biochar’ potential as an adsorbent of Cd2+ and Pb2+. This includes intial metal concentration, contact time, adsorbent dose, solution pH, and pHpzc.

3.3.1 Effect of initial Cd2+ and Pb2+ concentrations on adsorption process

The metal adsorption mechanism depends mainly on the initial metal concentration. The differential of the Cd2+ and Pb2+ concentration ranged from 10 to 70 ppm under constant conditions (0.1-g adsorbent dose, 1-h contact time (250 rpm), pH 6, and solution temperature 328 K) and reported that the removal percentage of Cd2+ and Pb2+ on FB adsorbent decreased from 99.3 to 97.4% for Cd2+ and from 99.4 to 92.6% for Pb2+ as the metal concentration increased from 10 to 70 ppm (Fig. 4). Also, the results showed higher adsorption of Pb than Cd, this property may be associated with the size of the metal ion and the porosity of the FB adsorbent Lurtwitayapont and Thares [46] reported that the adsorption capacity of Pb on bone char (swine bone) decreased from 1828 to 1225 mg/g as Pb concentration increased from 10 to 30 mg/L, respectively, and could remove Pb more than 99%. Rauf et al. [23] studied the adsorption of Ni ions from aqueous shipbuilding industry wastewater using an adsorbent chicken beak containing hydroxyapatite modified zeolitic imidazolate framework-8 (ZIF-8) compound and found that the maximum adsorption of Ni 63.49 mg.g−1 was at 10 mg/L Ni2+.

3.3.2 Effect of adsorbent dosage on Cd2+ and Pb2+ adsorption

The influence of FB adsorbent dosage on the removal efficiency of Cd2+ and Pb2+ was investigated at different adsorbent dosages (0.01, 0.03, 0.5, and 0.1 g), while keeping all other adsorption conditions constant (initial metal concentration 10 ppm,1-h contact time (250 rpm), pH 6 and solution temperature 328 K). It is clear from Fig. 5 that with the increase of the adsorbent dose, the metal ions (Cd2+ and Pb2+) removal percentage increased till reaching 0.1 g of adsorbent FB. The removal percent of Cd2+ and Pb2+ was 99.9% for both with 0.1 g of the bone adsorbent. This is because of the increase of binding sites for interaction with Cd2+ and Pb2+ at higher adsorbent dosages, which facilitates superior removal performance [47]. So, a dosage of 0.1 g was chosen for the FB adsorption process. This result agrees with the other studies [14, 48].

3.3.3 Effect of contact time on Cd2+ and Pb2+ adsorption

The equilibrium time is one of the important parameters for selecting a wastewater treatment system. The equilibrium time for the adsorption of Cd2+ and Pb2+ ions on FB adsorbent was determined over a period of 30–120 min with constant conditions (0.1-g adsorbent dose, initial metal concentration 10 ppm, pH 6, and solution temperature 328 K). It could be observed that the adsorption of Pb and Cd ions generally decreased with the increase incontact time from 30 to120 min. This decrease is a result of the accessibility of active site and the surface area of the adsorbent which are very high but become exhausted as the adsorption proceeds [32].

The maximum removal of Cd2+ and Pb2+ was almost 99.5% after contact time 30 min, and after that period the removal decreased to 89.8% and 99%, respectively (Fig. 6). Since the equilibrium time 30 min has the highest removal percent, it was used for the further adsorption studies.

3.3.4 Effect of pH on Cd2+ and Pb2+ adsorption

The pH of the solution is largely related to the surface mechanism of the adsorbent. As it can be seen from Fig. 7, the percentage removal of Cd2+ and Pb2+ ions gradually increases from 88.8% to 99.8% and from 99.19 to 99.4% for Cd and Pb, respectively, with an increase in solution pH from 6 to 7, and the highest metal adsorption capacity was at a solution pH 6.0. So, accordingly, the Cd and Pb adsorption should be carried out at pH equal to or greater than 6 at constant conditions (0.1-g adsorbent dose, initial metal concentration 10 ppm, 1-h contact time (250 rpm), and solution temperature 328 K). This result was consistent with most studies [49, 50]. Generally, as the adsorbate pH increases, the deprotonation of of the functional groups on the FB surface adsorbent lead to the formation of negatively charged surface, which favors cation adsorption via electrostatic interaction [49]. These reactions can be expressed as follows:

Kizilkaya et al. [35] reported that the maximum adsorption capacity for Pb (II) using pretreated fish bones was found to be 323 mg/g at optimum conditions. The experiments showed that when pH increased, an increase in the adsorbed amount of metal of the fish bones was observed.

3.3.5 Determination of pHpzc on Cd2+ and Pb2+ adsorption

The range where pH of the solution remains constant is taken as pH at the point of zero charge which was around pH 6. The pH at point of zero charge value was found as 6 (pHpzc) (Fig. 8). This result of pHpzc confirmed the results of studying of the pH effect on the adsorption process.

The cation adsorption (metal ions) is favored at pH > pHPZC, while the adsorption of anions is favored at pH < pHPZC; this is due to electrostatic repulsion [49].

3.3.6 Effect of temperature on Cd2+ and Pb2+ adsorption

The impact of temperature on the uptake of Pb and Cd ions by using FB adsorbent was studied at temperature range from 298 to 328 K at constant conditions (0.1-g adsorbent dose, initial metal concentration 10 ppm,1-h contact time (250 rpm), and pH 6) as shown in Fig. 9. The removal percent of metal ions increases with the increase of solution temperature, and the maximum adsorption was achieved at 328 K. Al-Qadah [51] reported that the increase in the temperature led to an increase the rate of adsorbate molecule diffusion beneath the external boundary layer and also increased the internal pores of the adsorbent particles. Also, many other authors have reported an increase in the metal adsorption by biological materials as the temperature increase. Olaniyi et al. [52] reported that the maximum adsorption capacity of Pb on cow bone charcoal was 1.42 mg/g at 300 °C and 10 min.

3.4 Adsorption isotherm models

The equilibrium adsorption of Cd2+ and Pb2+ ions in their solutions by FB adsorbent was studied as a function of the initial metal concentration. Several isotherm models are available for this study: Linear, Langmuir, Freundlish, Temkin, and Dubinin-Radushkevich isotherm models were chosen for this purpose under constant conditions (0.1-g adsorbent dose, initial metal concentration 10 ppm, 1-h contact time, pH 6, and solution temperature 328 K).

3.4.1 The Linear model

This model recommends that the accumulation of adsorbate by the adsorbent is directly proportional to the solution concentration V.

From Eq. (3), by plotting qe vs Ce, KD can be calculated. The obtained results are presented in Fig. 10 and Table 3.

The results of the slope (KD) for Pb2+ and Cd2+ adsorption are 5.9 and 7.7, respectively. This result confirms that the equilibrium distribution (KD) of Pb2+ on the surface of bone adsorbents was higher than that of Cd2+.

3.4.2 Langmuir adsorption isotherm

The Langmuir model describes the monolayer adsorption coverage of solute particles onto identical sites on the adsorbent surface. This model assumes that adsorbed molecules cannot move across the surface or interact with each other.

From Eq. (4), the parameters b and Qo can be calculated from the intercept and slope plot of Ce/qe against Ce (Fig. 10) of the adsorption of Pb and Cd ions on the surface of the FB adsorbent, also RL which refers to Langmuir equilibrium parameter was calculated from the equation:

The corresponding constants and correlation coefficient (R2) associated with the Langmuir isotherm model for Cd2+ and Pb2+ ions are given in Table 3. The maximum uptake (Qo) of Cd2+ and Pb were 8.43 and 15.75 mg/g, respectively. Langmuir constant of adsorption energy (b) for Cd2+ and Pb were 1.9 and 2.16 L/mg. The results of calculated RL were between 0 and 1, which indicates that the model is favorable to this study. The values of R2 were achieved at 0.98 and 0.991 for Cd2+ and Pb2+, respectively.

As an inorganic material, bone char has high adsorption capacity and can efficiently remove metallic pollutants and other organic/inorganic elements or compounds from water [26, 53] prepared adsorbent from cuttlefish bone waste and used it for adsorption of methylene blue dye and found that the qmax value obtained from the Langmuir isotherm model were calculated as 8.96 mg/g.

3.4.3 Freundlich adsorption isotherm

The Freundlich isotherm model assumes that the uptake of the metal ions occurs on a heterogeneous surface by multilayer adsorption and the amount of adsorbate adsorbed increases infinitely with increasing in initial concentration.

From Eq. (5), the rate constants Kf and n can be evaluated from the slope and intercept results (Fig. 10).

The Freundlich isotherm constants are shown in Table 3.

The obtained Kf and n values for Cd2+ were 9.64, and 4.7 mg−1/n L1/n g−1, respectively, and for Pb2+ 4.7, and 3.29, respectively. Moreover, the correlation coefficient values R2 for Cd2+ and Pb2+ were 0.974, and 0.978, respectively. The high value of Kf indicates a high affinity for Pb adsorption on the FB adsorbent than Cd ions. The value of parameter (n) was determined using the Freundlich isotherm model more than 1, which emphasizes the desirability of the adsorption process of the desired Cd and Pb on the FB adsorbent [54].These results depict that Langmuir model fits the adsorption operation of Cd2+ and Pb2+ by FB adsorbent compared to Freundlich isotherm owing to the high value of correlation coefficient R2.

3.4.4 The Temkin isotherm

Temkin isotherm is used for describe the uniform distribution of binding energy over the adsorption binding surface.

From Eq. (6), B and K constants obtained by plot of qe versus lnCe (Fig. 10). The results (Table 3) showed that B values of Cd2+ and Pb2+ were 3.37 and 1.27 J/mol, and K values were 24.19 and 60.7, respectively. It is obvious from B values that Pb2+ value has lower heat of adsorption than Cd2+.

3.4.5 Dubinin-Radushkevich isotherm model

Dubinin-Radushkevich isotherm is used to describe the adsorption with a Gaussian energy distribution on the nonlinear heterogeneous adsorbent surface.

From Eq. (7), by plotting lnqe vs E2 ( Fig. 10), it is possible to determine the value of β from the slope and the value of qm from the intercept.

The mean free energy E (KJ/mol) of sorption can be calculated by using B values as expressed in the following equation:

E value characterizes the type of the adsorption as chemical ion exchange (when E is between 8 and 16 kJ /mol), or as physical adsorption (when E < 8 kJ/mol).

The results of the mean free energy E of Cd2+ and Pb2+ for FB adsorbent were 3.5 and 5.0 kJ/mol, respectively (Table 3). Since, the obtained results lie in a range < 8, so that the adsorption of Pb and Cd ions are confirmed as physical adsorption.

3.5 Adsorption kinetic studies

The kinetic behavior studies of the adsorption process can provide valuable information about the equilibrium state of the operation.

The rate of the adsorption process could be explained regarding to several parameters such as:

-

1.

Structural properties of the adsorbent (porosity, specific area and particle size)

-

2.

The properties of the metallic ions (ionic radius, number of coordination)

-

3.

The concentration of the metallic ion

-

4.

Chelates which exist between ions and adsorbents.

To understand the adsorption kinetic behavior of Cd 2+ and Pb2+ by FB adsorbent and establish an appropriate contact time to reach the equilibrium stage, changes in adsorption capacity were estimated as a function of contact time at optimum constant (0.1-g adsorbent dose, initial metal concentration 10 ppm,1-h contact time (250 rpm), and pH 6).

First order, second order and intra-particles diffusion models were determined to study the rate of equilibrium time of the adsorption of Pb and Cd ions on the FB adsorbent.

3.5.1 Pseudo–first order model

The pseudo- first order kinetic model or the Lagergren equation assumed that metal adsorption process is first order in nature as it is only dependent on the number of metal ions present at the specific time in solution.

From Eq. (10), straight line could be obtained by plotting log (qe-qt) versus time (min), and from the slope and intercept, we can calculate the values of k1, log qe, respectively.

The calculated parameters (k1, log qe) are listed in Table 4. K1 values for Cd2+and Pb2+ were 0.012 and 0.015 for FB adsorbent, respectively. The correlation coefficients (R2) were 0.89 and 0.997 for Cd2+ and Pb2+, respectively. From the intercept results, the calculated qe could not match with the experimental qe. So that, the first order model could not be used to express the adsorption kinetics of metal ions.

3.5.2 Pseudo–second order model

Pseudo–second order model assumes that the metal biosorption process is dependent on the number of metal ions present in the solution as well as the free biosorption sites on the biosorbent surface [55].

From Eq. (11), a linear curve of t/qt vs t was plotted for adsorption of Cd and Pb ions, and k2 and qe were calculated from the intercept and slope of the plots. The data in Table 4 show that the calculated equilibrium adsorption capacity (q cal) from the curves of Cd and Pb ions were 1.92 and 1.94, 1, respectively. The experimental equilibrium adsorption capacities (experimental) of Cd2+ and Pb2+ ions were 1.93 and 1.95, respectively. Comparing the results of calculated equilibrium capacity(qcal), the capacities of the FB adsorbent almost equal the experimental capacity (qexp) as listed in Table 4. The calculated qe matches the experimental qe, so that the second order model can be used to express the adsorption kinetics of the metal ions. So, the Pb and Cd ions removal using FB adsorbent, strongly followed the pseudo-second-order model. R2 value of the pseudo-second-order model (1 for Pb and Cd) is higher than other models (Table 4), which shows that pseudo-second-order has a more appropriate model to describe the behavior of the adsorption of Cd and Pb on the FB adsorbent. Also, the adopting of the kinetic behavior of the adsorption process from the pseudo-second-order model shows that the adsorption of Cd and Pb on the FB adsorbent is chemical, electrostatic, and chelate surface adsorption, and the reactions on the surface may be limit the speed of the process and govern the adsorption mechanism of the metals [55, 56].

Moreover, K2(g/mg/min) of Cd2+ and Pb2+ were 2.58 and 5.29, respectively. Also, R2 of pseudo second order kinetic is higher than that of the first order kinetics, and so the adsorption of Cd and Pb ions on FB adsorbent follows the pseudo second order kinetic.

3.5.3 Intra-particle diffusion model

The adsorption process can be divided into the boundary layer diffusion, adsorption of the metal ions into sites and intra-particle diffusion, if the movement of the metal ion from the bulk liquid film surrounding the particle is ignored. Boundary layer diffusion is characterized by the initial rate of metal ion adsorption.The intra-particle diffusion relation represents the rate limiting step in many cases.

From Eq. (12), the Ki and C can be determined from the slope and intercept of the linear plot of qt vs t1/2 of the adsorption of Pb and Cd ions as in Fig. 10. The intra-particle diffusion equation revealed that the process has two stages and the speed of the first stage is higher compared to the second one, which is due to unsaturated sites and enough area for Cd and Pb ions.

The values of intra-particle diffusion plots of qt vs t1/2 for the adsorption of Pb and Cd ions on FB adsorbent are shown in Table 4. As shown in Fig. 11, the relationship between qt and t1/2 was not linear over the contact time period. The intra-particle diffusion equation revealed that the process has two stages and the speed of the first stage is higher compared to the second one, which is due to unsaturated sites and enough area for Pb2+ and Cd2+ ions [57].

The correlation coefficient (R2) of Cd and Pb ions are 0.722, and 0.785, respectively. From these data, the intercept value indicates that the lines are not passing through the origin; therefore, some other processes may affect the adsorption. The correlation coefficient (R2) value is less than that of pseudo second order model. The intercept of the plots reflects the boundary layer effect. The larger the intercept, the greater is the contribution of adsorption surface in the rate controlling step. Intraparticle diffusion rates for Pb and Cd adsorption are reported in Table 4. These results suggested that the surface diffusion has a relevant role as the rate-limiting step in the adsorption of metallic ions on FB adsorbent.

3.5.4 Thermodynamics of adsorption

Thermodynamic model is a powerful tool to describe metal sorption processes and to explore governing mechanisms. The thermodynamic behavior of heavy metal adsorption on bone adsorbents can be described as either exothermic (sorption decreases with increasing temperature) or endothermic sorption processes (sorption increases with increasing temperature).

The thermodynamic considerations of the adsorption process are very important to conclude whether the process is spontaneous or not. Gibb’s free energy change (ΔGo) is fundamental criterion of spontaneity. If ΔGo is a negative value, the reaction occurs spontaneously at a given temperature. The thermodynamic other parameters such as enthalpy change (ΔHo) and entropy change (ΔSo), for the adsorption of Pb and Cd ions on FB adsorbent are calculated using Eqs. (13), (14), and (15).

The calculated thermodynamic parameters are listed in Table 5 which confirms that ΔG° values for adsorption Cd2+ and Pb2+ ions were negative for applied temperature range. That negative ΔG° reported the spontaneous and physically nature of adsorption of Pb and Cd ions on FB adsorbent. On the other hand, ΔH° for Cd2+ and Pb2+ ions were positive which confirms the endothermic nature of adsorption process, supported by an increase in qe (mg/g) with increasing temperature. The positive ΔS° reported randomness increase at the solid–solution interface during the adsorption or may reflect an affinity of the carbon sorbent for the metal ions [58].

Kizilkaya et al. [35] found that when Pb adsorped on the pretreated fish bone the enthalpy ΔS of Pb was 46.01 kJ mol−1 and the adsorption mechanism was endothermic. The activation energy, Ea of adsorption of Pb (II), was 7.06 kJ/mol.

3.6 Adsorption mechanism

The adsorption of M2+ (Pb2+ and Cd2+) ions on to the FB adsorbent surfaces can be explained the mechanism happened following an ion exchange reaction between metal ions M2+ (Pb2+ and Cd2+) in solution and Ca2+ ions of HAP on the bone surface. This main removal mechanism is expressed by the reaction [35]:

It was found that ion exchange of lattice Ca with Cd in aqueous solution, surface complexation between oxygen-containing groups and electrostatic interactions between the positively charged Cd2+ and the negatively charged BC surface and oxygen-containing functional groups (e.g., CaOH+2 or POH+2) formed as a result of oxidation of organic matter were responsible for the adsorption and removal of Cd2+ by fishbone bone char [11, 59].

3.7 Desorption study

The desorption efficiency of Cd2+ and Pb2+ ion loaded FB adsorbent was applied by leaching solutions (0.01 M HNO3, 0.01 M NaOH, and deionized water) at the constant optimum conditions(pH 6 ± 0.3, 0.1 g, 1-h contact time at 250 rpm, and 298 ± 3 K). The results reveal that the leaching solution 0.01 M HNO3 has the higher desorption percentage of Cd and Pb (65.9% and 88.2%, respectively) than with the other leaching solutions (Fig. 12).

3.8 Application on the real wastewater

The optimum conditions for the adsorption study of Cd2+ and Pb2+ ions on the FB adsorbent were 10 ppm metal ion solution, 0.1-g adsorbent dose, 30-min shaking time, 250-rpm speed, and temperature 328 K. This condition was applied for removal of Cd2+ and Pb2+ from wastewater sample (Kima factory disposal). The removal percentage of Pb and Cd ions using the fish bone adsorbent reached almost 99%, and this result confirms the high efficiency of the fish bone adsorbent for removal of heavy metals from factories disposal.

4 Conclusion

The investigation of Cd2+ and Pb2+ adsorption on the FB adsorbent, which is a by-product waste from butcher’s shops, represents a suitable reusable material for the production of high removal capacity adsorption. Four different chemical treatments of fish bone adsorbents were used in this study, which were 0.01 M HNO3, 0.1 M NaOH, 0.5% H2O2, and absolute ethanol at room temperature. The chemically activated adsorbent with 0.1 M NaOH (FB) reveals higher Pb and Cd adsorption than that with the other activators.

The adsorption capacity and removal percent of Cd2+ and Pb2+ using FB adsorbent were reported as a function of pH, concentration, adsorbent dosage, pHpzc, contact time and temperature. The highest removal capacity for Cd2+ and Pb2+ ions was obtained at pH 6.0, contact time 30 min, initial metal concentration 10 ppm, adsorbent dosage 0.1 g, and temperature at 328 K. The zero pH value results reported that the optimum pH value lied around pH 6.0.

From the adsorption and kinetic isotherms models of Cd2+ and Pb2+ ion on the surface of the FB adsorbent, it was noted that they fitted well to Langmuir isotherm model and the pseudo-second order kinetic. For real industrial wastewater, Cd2+ and Pb2+ adsorption by the chemically treated adsorbent was 99% at the optimum conditions.

Data availability

Not applicable.

References

Ugochukwu UC, Chukwuone N, Jidere C, Ezeudu B, Ikpo C, Ozor J (2022) Heavy metal contamination of soil, sediment and water due to galena mining in Ebonyi State Nigeria: economic costs of pollution based on exposure health risks. J Environ Manag 321:115864

Mitra S, Chakraborty AJ, Tareq AM, Nainu TBEF, Khusro A, Idris AM, Khandaker MU, Osman H, Alhumaydhi FA, Simal-Gandara J (2022) Impact of heavy metals on the environment and human health: novel therapeutic insights to counter the toxicity. J King Saud Univ - Sci 34(3):101865

Hosseini SS, Hamadi A, Foroutan R, Peighambardoust SJ, Ramavandi B (2022) Decontamination of Cd2+ and Pb2+ from aqueous solution using a magnetic nanocomposite of eggshell/starch/Fe3O4. J Water Process Eng 48:102911

Qasem NAA, Mohammed RH, Lawal DU (2021) Removal of heavy metal ions from wastewater: a comprehensive and critical review. npj Clean Water 4:36

Soliman M, Rashed N, Soltan M (2023) Aeration, alum, and kaolin ore for nutrient and heavy metal removal from urban wastewater for the purpose of reuse and conservation. Pollution 9(3):1162–1173

Elwakee KZ (2020) Magnesium sorption onto titan yellow supported on classic thiourea-formaldehyde resin. Aswan Univ J Environ Stud 1(2):125–136

Goswami L, Pakshirajan K, Pugazhenthi G (2020) Biological treatment of biomass gasification wastewater using hydrocarbonoclastic bacterium Rhodococcus opacus in an up-flow packed bed bioreactor with a novel waste-derived nanobiochar based bio-support material. J Clean Prod 256:120253

Módenes AN, Bazarin G, Borba CE, Locatelli PPP, Borsato FP, Pagno V, Pedrini R, Trigueros DEG, Espinoza-Quiñones FR, Scheufele FB (2021) Tetracycline adsorption by tilapia fish bone-based biochar: mass transfer assessment and fixed-bed data prediction by hybrid statistical-phenomenological modelling. J Clean Prod 279(10):123775

Kizilkaya Bayram A, Tekinay A, Dilgin Y (2010) Adsorption and removal of Cu (II) ions from aqueous solution using pretreated fish bones. Desalination 264:37–47

Hart A, Ebiundu K, Peretomode E, Onyeaka H, Nwabor OF, Obileke KeChrist (2022) Value-added materials recovered from waste bone biomass: technologies and applications. RSC Adv 12:22302–22330

Hart A, Porbeni DW, Omonmhenle S, Peretomode E (2023) Waste bone char-derived adsorbents characteristics adsorption mechanism and model approach. Environ Technol Rev 12(1):175–204

Flores-Cano JV, Leyva-Ramos R, Carrasco-Marin F et al (2016) Adsorption mechanism of Chromium (III) from water solution on bone char: Effect of operating conditions. Adsorption 22:297–308

Patel S, Han J, Qiu W et al (2015) Synthesis and characterisation of mesoporous bone char obtained by pyrolysis of animal bones for environmental application. J Environ Chem Eng 3:2368–2377

Nageeb RM, Abd-Elmenaim Gad A, Fathy NM (2019) Adsorption of Cd (II) and Pb (II) using physically pretreated camel bone biochar. Adv J Chem-Sect A 2(4):347–364

Rojas-Mayorga CK, Silvestre-Albero J, Aguayo-Villarreal IA (2015) A new synthesis route for bone chars using CO2 atmosphere and their application as fluoride adsorbents. MicroporousMesoporous Mater 209:38–44

Mendoza-Castillo DI, Bonilla-Petriciolet A, Ja uregui-Rinco NJ (2015) On the importance of surface chemistry and composition of bone char for the sorption of heavy metals from aqueous solution. Desalin Water Treat 54:1651–1662

Reynel-Avila HE, Mendoza-Castillo DI, Bonilla-Petriciolet A (2015) Assessment of naproxen adsorption on bone char in aqueous solutions using batch and fixed-bed processes. J Mol Liq 209:187–195

Reynel-Avila HE, Mendoza-Castillo DI, Bonilla-Petriciolet A (2016) Relevance of anionic dye properties on water decolorization performance using bone char: adsorption kinetics, isotherms and breakthrough curves. J Mol Liq 219:425–434

Wang SG, Zimmerman A, Li Y, Ma L, Harris W, Migliaccio K (2014) Removal of arsenic by magnetic biochar prepared from pinewood and natural hematite. Bio Resour Technol 2014(10):104

Zheng W, Guo M, Chow T, Bennett DN, Rajagopalan N (2010) Sorption properties of green waste biochar for two triazine pesticides. J Hazard Mater 181:121–126

Dai LC, Lu Q, Zhou HQ, Shen F, Liu ZG, Zhu WK, Huang HG (2021) Tuning oxygenated functional groups on biochar for water pollution control: a critical review. J Hazard Mater 420:26547

Fu Y, Zhang N, Shen Y, Ge X, Chen M (2018) Micro-mesoporous carbons from original and pelletized rice husk via one-step catalytic pyrolysis Bioresour. Technol 269:67–73

Foroutan R, Peighambardoust SJ, Amarzadeh M, Korri AK, Peighambardoust NS, Ahmad A, Ramavandi B (2022) Nickel ions abatement from aqueous solutions and shipbuilding industry wastewater using ZIF-8-chicken beak hydroxyapatite. J Mol Liq 356:119003

Prado Cechinel MA, de Souza SMAGU, de Souza AAU (2014) Study of lead (II) adsorption onto activated carbon originating from cow bone. J Clean Prod 65(15):342–349

Dou S, Ke XX, Shao ZD, Zhong LB, Zhao QB, Zheng YM (2022) Fish scale-basedbiochar with defined pore size and ultrahigh specific surface area for highly efficient adsorption of ciprofloxacin. Chemosphere 287:131962

Çifçi Dİ̇, Aydın N (2023) Exploring the reusability of cuttlefish bones in sustainable waste management by green synthesis method for methylene blue dye removal. Int J Environ Anal Chem. https://doi.org/10.1080/03067319.2023.2174864

Yaning W, Yarui Zhou L, Cai JG, Yong X, Zhang H, Ji L, Song W (2019) Facile preparation of charcoal nanomaterial from fishery waste with remarkable adsorption ability. Materials 12:1318. https://doi.org/10.3390/ma12081318

Doostmohammadi A, Monshi A, Salehi R (2012) Preparation, chemistry and physical properties of bone-derived hydroxyapatite particles having a negative zeta potential, Mater Chem. Phys 132:446–452

Murillo YS, Liliana G, Juan CM (2011) Porous materials obtained from chicken and pork bones for the adsorption of 2,4-dinitrophenol. Afinidad -Barcelona- 68(556):447–452

Rezk RA, Galmed AH, Abdelkreem M, Abdel Ghany NA, Harith MA (2018) Detachment of Cu (II) and Co (II) ions from synthetic wastewater via adsorption on Lates niloticus fish bones using LIBS and XRF. J Adv Res 14:1–9

Lim HK, Teng TT, Ibrahim MH, Ahmad A, Chee HT (2012) Adsorption and removal of zinc (II) from aqueous solution using powdered fish bones. APCBEE Proc 1:96–102

Sabrina M, Jahan SA, Saha B, Sharmin N, Ahmed S (2022) Kinetic and thermodynamic investigation on adsorption of lead onto apatite extracted from mixed fish bone. Environ Nanotechnol Monit Manag 18:100738

Pınar T, Öğüt H, Kalemtaş A (2018) Natural calcium phosphates from fish bones and their potential biomedical. App Mater Sci Eng C, Mater Biol App 91:899–911

Medellín-Castillo NA, Cruz-Briano SA, Leyva-Ramos R, Moreno-Pirajan JC, Torres-Dosal A, Giraldo-Gutiérreze L, Labrada-Delgado FGJ, Pérez RO, Rodriguez-Estupinan JP, Reyes Lopez SY, BerberMendoza MS (2019) Use of bone char prepared from an invasive species, pleco fish (Pterygoplichthys spp), to remove fluoride and Cadmium(II) in water. J Environ Manag 07(256):109956

Bayram K, AdemTekJnay A (2014) Utilization to Remove Pb (II) Ions from aqueous environmentsusing waste fish bones by ion exchange. J Chemsitry 739273:12

Hassan Saad SM, Awwad NS, Aboterika AHA (2008) Removal of mercury(II) from wastewater using camel bone charcoal. J Hazard Mater 154:992–997

Liakos EV, Mone M, Lambropoulou DA, Bikiaris DN, Kyzas GZ (2021) Adsorption evaluation for the removal of nickel, mercury, and barium ions from singlecomponent and mixtures of aqueous solutions by using an optimized biobased chitosan derivative. Polymers 13(2):232

Chakraborty R, RoyChowdhury D (2013) Fish bone derived natural hydroxyapatite-supported copper acid catalyst: taguchi optimization of semibatch oleic acid esterification Chem. Eng J 215–216:491–499. https://doi.org/10.1016/j.cej.2012.11.064

Movasaghi Z, Rehman S, Rehman I (2008) Applied Fourier transform infrared (FTIR) spectroscopy of biological tissues Appl. Spectrosc Rev 43:134–179

Piccirillo C, Moreira IS, Novais RM, Fernandes AJS, Pullar RC, Castro PML (2017) Biphasic apatite-carbon materials derived from pyrolysed fish bones for effective adsorption of persistent pollutants and heavy metals. J Environ Chem Eng 5:4884–4894

Sroka-Bartnicka L, Borkowski G, Ginalska Ślósarczyk A, Kazarian SG (2017) Structural transformation of synthetic hydroxyapatite under simulated in vivo conditions studied by ATR-FTIR spectroscopic imaging Spectroch. Acta A 171:55–161

Arezo S, Hashemi S, Arfaeinia H, Dobaradaran S, Foroutan R, Mahvi AH, Fouladvand M, Sorial GA, Farjadfard S, Ramavandi B (2020) Physicochemical characteristics and mechanism of fluoride removal using powdered zeolite-zirconium in modes of pulsed & continuous sonication and stirring. Adv Powder Technol 31(8):3521–3532

Moreno-Pirajan JC, Gomez-Cruz R, Garcıa-Cuello VS et al (2010) Binary system Cu(II)/Pb(II) adsorption on activated carbon obtained by pyrolysis of cow bone study. J Anal Appl Pyrolysis 89:122–128

Dimovic S, Smiciklas I, Plecas I et al (2009) Comparative studyof differently treated animal bones for CO2? removal. J Hazard Mater 164:279–287

Brzezinska-Miecznik J, Haberko K, Sitarz M et al (2015) Hydroxyapatite from animal bones—extraction and properties. Ceram Int 41:4841–4846

Sudaratn L, Srisatit T (2010) Comparison of lead removal by various types of swine bone adsorbents. Environment Asia 3(1):32–38

Hokkanen S, Bhatnagar A, Repo E, Lou S, Sillanpää M (2016) Calcium hydroxyapatite microfibrillated cellulose composite as a potential adsorbent for the removal of Cr (VI) from aqueous solution. Chem Eng J 283:445–452

Kyung-Won J, Leeb SY, Choia J-W, Leeb YJ (2019) A facile one-pot hydrothermal synthesis of hydroxyapatite/biochar Nanocomposites : Adsorption behavior and mechanisms for the removal of copper(II) from aqueous media. Chem Eng J 369:29–541

Kyung-Won J, Leeb SY, Choia J-W, Leeb YJ (2019) A facile one-pot hydrothermal synthesis of hydroxyapatite/biochar nanocomposites: adsorption behavior and mechanisms for the removal of copper (II) from aqueous media. Chem Eng J 369:529–541

Cechinel MAP, Selene MAGU, Antônio AUS (2014) Study of lead (II) adsorption onto activated carbon originating from cow bone. J Clean Prod 65:342–349

Al-Qadah Z (2000) Adsorption of dyes using shale oil ash’’. Water Res 34:4295–4303

Ibrahim O, Sunday M, Odoh R (2012) Adsorption study of Cr (VI) and Pb (II) from aqueous solution using animal charcoal derived from cow bone. Der Chemica Sinica 3(3):648–657

Wang M, Liu Y, Yao Y, Han L, Liu X (2019) Comparative evaluation of bone chars derived from bovine parts physicochemical properties and copper sorption behavior. Sci Total Environ 2020(700):134470. https://doi.org/10.1016/j.scitotenv.2019.134470

Hassan W, Noureen S, Mustaqeem M, Saleh TA, Zafar S (2020) Efficient adsorbent derived from haloxylon recurvum plant for the adsorption of acid brown dye: kinetics, isotherm and thermodynamic optimization. Surf Interfaces 20:100510

Alizadeh M, Peighambardoust SJ, Foroutan R, Azimi H, Ramavandi B (2022) Surface magnetization of hydrolyzed Luffa Cylindrica biowaste with cobalt ferrite nanoparticles for facile Ni2+ removal from wastewater. Environ Res 212:113242

Foroutan R, Mohammadi A, Ahmadi G, Bikhabar F, Babaei BR (2022) Impactof ZnO and Fe3O4 magnetic nanoscale on the methyl violet 2B removal efficiency of the activated carbon oak wood. Chemosphere 286:131632

Foroutan R, Peighambardoust SJ, Latifi P, Ahmadi A, Alizadeh M, Ramavandi B (2021) Carbon nanotubes/b-cyclodextrin/MnFe2O4 as a magnetic nanocomposite powder for tetracycline antibiotic decontamination from different aqueous environments. J Environ Chem Eng 9(6):106344

Lu CY, Liu CT, Su FS (2009) Sorption kinetics, thermodynamics and competition of Ni2+ from aqueous solutions onto surface oxidized carbon nanotubes. Desalination 249:18–23

Guo Q, Tang H, Jiang L (2022) Meiqing Chen, Nengwu Zhu and Pingxiao Wu (2020) Sorption of Cd2+ on bone chars with or without hydrogen peroxide treatment under various pyrolysis temperatures: comparison of mechanisms and performance. Processes 10(4):618. https://doi.org/10.3390/pr100406

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Material preparation, data collection and analysis were performed by Nada M.Fathy. The first draft of the manuscript was written by M.Nageeb Rashed and A.A.E. Gad, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

No ethical issues

Consent to participate

Consent

Consent for publication

Consent.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rashed, M.N., Gad, A.A.E. & Fathy, N.M. Efficiency of chemically activated raw and calcined waste fish bone for adsorption of Cd (II) and Pb (II) from polluted water. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04885-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04885-4