Abstract

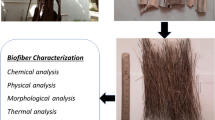

Composite industries focus on utilization of natural resources to imbibe sustainability in their products. This investigation details the segregation and characterization of Licuala grandis leaf sheath fibers (LGLSFs) extracted from leaf sheath of Licuala grandis tree an agro-waste for utilization as raw material in composite industries. The characteristics of LGLSF were compared with other competitive natural fibers to ensure its suitability for reinforcement in composite industry. The characterizations include chemical, mechanical, morphological, and thermal methods. The Fourier transform infrared spectroscopy (FTIR) spectrum revealed the existence of functional groups in LGLSF. The surface texture of LGLSF observed through a scanning electron microscope (SEM) ensures its possibility of making better interfacial bonding characteristics with the matrix when reinforced in polymer composites. To support the industry on decision making process, the quantitative metrics such as cellulose content (49.13 wt.%), minimum wax (0.31 wt.%), lesser density (1.24 g/cm3), higher crystallinity index (48%), tensile strength (102–179 MPa), and Young’s modulus (1.3–5.4 GPa) of LGLSF were appraised. The thermal stability up to 223 °C and exothermic and endothermic behavior of LGLSF at higher temperatures were ensured through thermogravimetric (TGA/DTG) and differential scanning calorimetry (DSC) analysis, respectively. The appraised quantitative values, the thermal behavior, and chemical functionality of LGLSF ensure its use as reinforcement in polymer composites employed for low density structural applications.

Graphical abstract

Similar content being viewed by others

Data availability

This is an ongoing research work, and hence, the data cannot be shared at this moment.

References

Arul Marcel Moshi A, Ravindran D, SundaraBharathi SR, Padma SR, Indran S, Divya D (2020) Characterization of natural cellulosic fiber extracted from Grewia damine flowering plant’s stem. Int J Biol Macromol 154(1246):1255. https://doi.org/10.1016/j.ijbiomac.2020.07.225

Chakravarthy S, Madhu K, Raju JSN, Md JS (2020) Characterization of novel natural cellulosic fiber extracted from the stem of Cissus vitiginea plant. Int J Biol Macromol 161:1358–1370. https://doi.org/10.1016/j.ijbiomac.2020.07.230

Chakkour M, Ould Moussa M, Khay I, Balli M, Ben Zineb T (2023) Towards widespread properties of cellulosic fibers composites: a comprehensive review. J Reinf Plast Compos 42(5–6):222–263. https://doi.org/10.1177/07316844221112974

Shi Y, Jiang J, Ye H, Sheng Y, Zhou Y, Foong SY, Sonne C, Chong WWF, Lam SS, Xie Y, Li J, Ge S (2023) Transforming municipal cotton waste into a multilayer fibre biocomposite with high strength. Environ Res 218:114967. https://doi.org/10.1016/j.envres.2022.114967

Rajkumar R, Manikandan A, Saravankumar SS (2016) Physicochemical properties of alkali-treated new cellulosic fiber from cotton shell. Int J Polym Anal Charact 21:359–364. https://doi.org/10.1080/1023666X.2016.1160509

Sanjay MR, Madhu P, Jawaid M, Senthamaraikannan P, Senthil S, Pradeep S (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Siva R, Valarmathi TN, Palanikumar K, Antony VS (2020) Study on a Novel natural cellulosic fiber from Kigelia africana fruit: characterization and analysis. Carbohydr Polym 244:116494. https://doi.org/10.1016/j.carbpol.2020.116494

Madhu P, Sanjay MR, Senthamaraikannan P, Pradeep S, Saravanakumar SS, Yogesha B (2019) A review on synthesis and characterization of commercially available natural fibers: part II. J Nat Fibers 16:25–36. https://doi.org/10.1080/15440478.2017.1379045

Sathishkumar TP, Navaneethakrishnan P, Shankar S, Rajasekar R (2013) Characterization of new cellulose Sansevieria ehrenbergii fibers for polymer Composites. Comp Inter 20:575–593. https://doi.org/10.1080/15685543.2013.816652

Msahli S, Jaouadi M, Sakli F, Drean JY (2015) Study of the mechanical properties of fibers extracted from Tunisian Agave Americana L. J Nat Fibers 12:552–560. https://doi.org/10.1080/15440478.2014.984046

Boopathi L, Sampath PS, Mylsamy K (2012) Investigation of physical, chemical and mechanical properties of raw and alkali treated Borassus fruit fiber. Compos B Eng 43:3044–3052. https://doi.org/10.1016/j.compositesb.2012.05.002

Raju JSN, Depoures MV, Kumaran P (2021) Comprehensive characterization of raw and alkali (NaOH) treated natural fibers from Symphirema involucratum stem. Int J Biol Macromol 186:886–896. https://doi.org/10.1016/j.ijbiomac.2021.07.061

Mohan Prasad M, Sutharsan SM, Ganesan K, Ramesh Babu N, Maridurai T (2022) Role of sugarcane bagasse biogenic silica on cellulosic Opuntia dillenii fibre-reinforced epoxy resin biocomposite: mechanical, thermal and laminar shear strength properties. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-02154-w

Li T, Zhang Y, Jin Y, Bao L, Dong L, Zheng Y, Xia J, Jiang L, Kang Y, Wang J (2023) Thermoplastic and biodegradable sugarcane lignin-based biocomposites prepared via a wholly solvent-free method. J Clean Prod 386:135834. https://doi.org/10.1016/j.jclepro.2022.135834

Zhou S, Xia L, Zhang K, Zhuan F, Wang Y, Zhang Q, Zhai L, Mao Y, Weilin X (2021) Titanium dioxide decorated natural cellulosic Juncus effusus fiber for highly efficient photo-degradation towards dyes. Carbohydr Polym 232:115830. https://doi.org/10.1016/j.carbpol.2020.115830

Khan A, Vijay R, Lenin Singaravelu D, Sanjay MR, Siengchin S, Jawaid M, Alamry KA, Asiri AM (2022) Extraction and characterization of natural fibers from Citrullus lanatus climber. J Nat Fibers 19:621–629. https://doi.org/10.1080/15440478.2020.1758281

Ding L, Han X, Cao L, Chen Y, Ling Z, Han J, He S, Jiang S (2022) Characterization of natural fiber from manau rattan (Calamus manan) as a potential reinforcement for polymer-based composites. J Bioresour Bioprod 7:190–200. https://doi.org/10.1016/j.jobab.2021.11.002

Amutha K, Sudha A, Saravanan D (2022) Characterization of natural fibers extracted from banana inflorescence Bracts. J Nat Fibers 19:872–881. https://doi.org/10.1080/15440478.2020.1764437

Njoku CE, Omotoyinbo JA, Alaneme KK, Daramola MO (2022) Characterization of Urena lobata fibers after alkaline treatment for use in polymer composites. J Nat Fibers 19(2):485–496. https://doi.org/10.1080/15440478.2020.1745127

Cheng D, Weng B, Chen Y, Zhai S, Wang C, Xua R, Guo J, Lv Y, Shi L, Guo Y (2020) Characterization of potential cellulose fiber from Luffa vine: a study on physicochemical and structural properties. Int J Biol Macromol 164:2247–2257. https://doi.org/10.1016/j.ijbiomac.2020.08.098

Poomathi S, Roji SSS (2022) Experimental investigations on Palmyra sprout fiber and biosilica-toughened epoxy bio composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02867-6

Sanjay MR, Siengchin S, Parameswaranpillai J, Jawaid M, Pruncu CI, Khan A (2019) A comprehensive review of techniques for natural fibers as reinforcement in composites: preparation, processing and characterization. Carbohydr Polym 207:108–121. https://doi.org/10.1016/j.carbpol.2018.11.083

Aziz K, El Achaby M, Mamouni R, Saffaj N, Aziz F (2023) A novel hydrogel beads based copper-doped Cerastoderma edule shells@Alginate biocomposite for highly fungicide sorption from aqueous medium. Chemosphere 311(1):136932. https://doi.org/10.1016/j.chemosphere.2022.136932

Moshi AAM, Ravindran D, Bharathi SRSRS, Indran S, Saravanakumar SS, Liu Y (2020) Characterization of a new cellulosic natural fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 142:212–221. https://doi.org/10.1016/j.ijbiomac.2019.09.094

László Lendvai, Maria Omastova, Amar Patnaik, Gábor Dogossy, Tej Singh (2023) Valorization of waste wood flour and rice husk in poly(lactic acid)-based hybrid biocomposites. J Polym Environ. 31:541–551. https://link.springer.com/article/10.1007/s10924-022-02633-9.

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Binoj JS, Edwin Raj R, Sreenivasan VS, Rexin Thusnavis G (2016) Morphological, physical, mechanical, chemical and thermal characterization of sustainable indian areca fruit husk fibers (Areca Catechu L.) as potential alternate for hazardous synthetic fibers. J Bionic Eng 13:156–165. https://doi.org/10.1016/S1672-6529(14)60170-0

Brailson Mansingh B, Binoj JS, Hassan SA, Mariatti M, Siengchin S, Sanjay MR, Bharath KN (2022) Characterization of natural cellulosic fiber from Cocos nucifera peduncle for sustainable biocomposites. J Nat Fibers 19:9373–9383. https://doi.org/10.1080/15440478.2021.1982827

Binoj JS, Jaafar M, Mansingh BB, Bharathiraja G (2023) Extraction and characterization of novel cellulosic biofiber from peduncle of Areca catechu L. biowaste for sustainable biocomposites. Biomass Conv Bioref. https://doi.org/10.1007/s13399-023-04081-4

PalaniyappanSabarinathan VE, Annamalai K, Rajkumar KV, Dhinakaran V (2022) Synthesis and characterization of randomly oriented silane-grafted novel bio-cellulosic fish tail palm fiber–reinforced vinyl ester composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02459-4

French AD (2020) Increment in evolution of cellulose crystallinity analysis. Cellulose 27:5445–5448. https://doi.org/10.1007/s10570-020-03172-z

Anand PB, Lakshmikanthan A, Chandrashekarappa MPG, Selvan CP, Pimenov DY, Giasin K (2022) Experimental investigation of effect of fiber length on mechanical, wear, and morphological behavior of silane-treated pineapple leaf fiber reinforced polymer composites. Fibers 10(7):56–69. https://doi.org/10.3390/fib10070056

Ilaiya Perumal C, Sarala R (2020) Characterization of a new natural cellulosic fiber extracted from Derris scandens stem. Int J Biol Macromol 165:2303–2313. https://doi.org/10.1016/j.ijbiomac.2020.10.086

Segal L, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Saravanakumar SS, Kumaravel A, Nagarajan T, Sudhakar P, Baskaran R (2013) Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr Polym 92:1928–1933. https://doi.org/10.1016/j.carbpol.2012.11.064

Prabhu P, Jayabalakrishnan D, Balaji V, Bhaskar K, Maridurai T, Arun Prakash VR (2022) Mechanical, tribology, dielectric, thermal conductivity, and water absorption behaviour of Caryota urens woven fibre-reinforced coconut husk biochar toughened wood-plastic composite. Biomass Conv Bioref. https://doi.org/10.1007/s13399-021-02177-3

Thooyavan Y, Kumaraswamidhas LA, Edwin Raj R, Binoj JS, BrailsonMansingh B (2022) Failure analysis of basalt bidirectional mat reinforced micro/nano SiC particle filled vinyl ester polymer composites. Eng Fail Anal 136:e106227. https://doi.org/10.1016/j.engfailanal.2022.106227

Khalili H, Bahloul A, Ablouh E-H, Sehaqui H, Kassab Z, Hassani F-Z, El Achaby M (2023) Starch biocomposites based on cellulose microfibers and nanocrystals extracted from alfa fibers (Stipa tenacissima). Int J Biol Macromol 226:345–356. https://doi.org/10.1016/j.ijbiomac.2022.11.313

Arthanarieswaran VP, Kumaravel A, Saravanakumar SS (2015) Physico-chemical properties of alkali treated Acacia leucophloea fibers. Int J Polym Anal Charact 20:704–713. https://doi.org/10.1080/1023666X.2015.1081133

Jayaraj M, Thirumurugan R, Shanmugam D (2022) Investigation of static and dynamic mechanical properties of CPFLSF and PPLSFreinforced polyester hybrid composites. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-03391-3

Mahalingam J (2022) Mechanical, thermal, and water absorption properties of hybrid short coconut tree primary flower leaf stalk fiber/glass fiber-reinforced unsaturated polyester composites for biomedical applications. Biomass Conv Bioref. https://doi.org/10.1007/s13399-022-02958-4

Ramkumar T, Hariharan K, Selvakumar M, Jayaraj M (2022) Effect of various surface modifications on characterization of new natural cellulosic fiber from coconut tree secondary flower leaf stalk fiber (CSF). J Nat Fibers 19:13362–13375. https://doi.org/10.1080/15440478.2022.2091715

Author information

Authors and Affiliations

Contributions

Antony Sagai Francis Britto: investigation (lead), resources and supporting. Joseph Selvi Binoj: investigation; writing, original draft; reviewing. Bright Brailson Mansingh: writing — original draft. Paulvin Navin Jass: investigation (support), resources and supporting.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

All the authors demonstrate that they have adhered to the accepted ethical standards of a genuine research study. Also, individual consent from all the authors was undertaken to publish the data prior submitting to journal.

Consent for publication

Written formal consent ensures that the publisher has the author’s permission to publish research findings.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Biowaste Licuala grandis leaf sheath fibers (LGLSFs) characterized for reinforcement.

• Little wax (0.31 wt.%) and density (1.24 g/cm3) of LGLSFs ensures better bonding.

• Thermal studies (TGA and DSC) confirm thermal stability of LGLSFs to 223°C.

• Uneven and rough surface texture of LGLSFs approves good interfacial bonding features.

• Specific assets attained favors LGLSFs reinforcement for bio-composite applications.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Britto, A.S.F., Binoj, J.S., Mansingh, B.B. et al. Extensive characterization of novel cellulosic biofiber from leaf sheath of Licuala grandis for biocomposite applications. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04598-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04598-8