Abstract

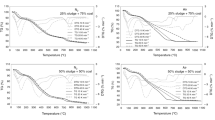

Combustion characteristics and kinetics of camellia seed shell (CS) with additions of sludge ash (SA) and its active species of CaO, Fe2O3, and SiO2 were analyzed by thermogravimetry. The combustion paths of CS with the additives fell between “in situ combustion of carbon-containing components” and “complete volatiles release + char combustion.” In the view of heat release, the additions of SA active species increased the combustion performance of CS. A higher heating rate greatly increased the combustion performance, but the addition of CaO decreased the combustion performance. The combustion kinetic parameters of CS with the 10% additions of SA, CaO, Fe2O3, and SiO2 were analyzed by combining Coats-Redfern and Malek methods. The distributions of the activation energies of the second combustion zone with certain additives were more centralized. It was found that the second combustion zones all followed f(x) = (1 − x)2 at varied heating rates, while those of the third zone were not identical, and those of the fourth zone of CS + 10%CaO followed f(x) = (1 − x)2/3.

Graphical Abstract

Similar content being viewed by others

Data availability

All required/mentioned data are available in the manuscript.

References

Siddiqi H, Mishra A, Maiti P, Behera ID, Meikap BC (2022) In-situ and ex-situ co-pyrolysis studies of waste biomass with spent motor oil: elucidating the role of physical inhibition and mixing ratio to enhance fuel quality. Bioresour Technol 358:127364

Siddiqi H, Bal M, Kumari U, Meikap BC (2020) In-depth physiochemical characterization and detailed thermo-kinetic study of biomass wastes to analyze its energy potential. Renew Energy 148:756–771

Mishra A, Siddiqi H, Kumari U, Behera ID, Mukherjee S, Meikap BC (2021) Pyrolysis of waste lubricating oil/waste motor oil to generate high-grade fuel oil: a comprehensive review. Renew Sustain Energy Rev 150:111446

Siddiqi H, Mishra A, Kumari U, Maiti P, Meikap BC (2021) Utilizing agricultural residue for the cleaner biofuel production and simultaneous air pollution mitigation due to stubble burning: a net energy balance and total emission assessment. ACS Sustain Chem Eng 9:15963–15972

Ong HC, Chen WH, Singh Y, Gan YY, Chen CY, Show PL (2020) A state–of–the–art review on thermochemical conversion of biomass for biofuel production: a TG–FTIR approach. Energy Convers Manag 209:112634

Sharma A, Pareek V, Zhang D (2015) Biomass pyrolysis—a review of modelling, process parameters and catalytic studies. Renew Sustain Energy Rev 47(9):1081–1096

Neha S, Remya N (2023) Optimization of biochar production from microwave co-pyrolysis of food waste and low-density polyethylene. Biomass Convers Bioresour. https://doi.org/10.1007/s13399-023-03948-w

Mu L, Li T, Wang Z, Shang Y, Yin H (2021) Influence of water/acid washing pretreatment of aquatic biomass on ash transformation and slagging behavior during co-firing with bituminous coal. Energy 234:121286

Adanez J, Abad A, Garcia-Labiano F, Gayan P, Diego LF (2012) Progress in chemical–looping combustion and reforming technologies. Prog Energy Combust 38(2):215–282

Gao N, Sipra AT, Quan C (2020) Thermogravimetric analysis and pyrolysis product characterization of municipal solid waste using sludge fly ash as additive. Fuel 281:118572

Gao N, Milandile MH, Sipra AT, Su S, Miskolczi N, Quan C (2022) Co-pyrolysis of municipal solid waste (MSW) and biomass with Co/sludge fly ash catalyst. Fuel 322:124127

Wu X, Liu J, Wei Z, Chen Z, Evrendilek F, Huang W (2022) Oxy-fuel co-combustion dynamics of phytoremediation biomass and textile dyeing sludge: gas-to-ash pollution abatement. Sci Total Environ 825:153656

Huang H, Liu J, Evrendilek F, Zhang G, Sun S, He Y (2022) Bottom slag-to-flue gas controls on S and Cl from co-combustion of textile dyeing sludge and waste biochar: their interactions with temperature, atmosphere, and blend ratio. J Hazard Mater 435:129007

Hu J, Song Y, Liu J, Evrendilek F, Zhang G, Ren M, Xie W, Sun S (2022) Torrefaction-assisted oxy-fuel co-combustion of textile dyeing sludge and bamboo residues toward enhancing emission-to-ash desulfurization in full waste circularity. Fuel 318:123603

Idris SS, Rahman NA, Ismail K (2012) Combustion characteristics of Malaysian oil palm biomass, sub-bituminous coal and their respective blends via thermogravimetric analysis (TGA). Bioresour Technol 123:581–591

Chen J, Wang Y, Lang X, Ren X, Fan S (2017) Comparative evaluation of thermal oxidative decomposition for oil-plant residues via thermogravimetric analysis: thermal conversion characteristics, kinetics, and thermodynamics. Bioresour Technol 243:37–46

Wang SJ, Wu F, Zhang G, Zhu P, Wang ZY, Huang CJ, Chen ST (2014) Research on the combustion characteristics of anthracite and blended coal with composite catalysts. J Energy Inst 87:96–101

Liu Z, Wang G, Li P, Li C (2019) Investigation on combustion of high-sulfur coal catalyzed with industrial waste slags. J Energy Inst 92:621–629

Xu F, Xing X, Gao S, Zhang W, Zhu L, Wang Y, Chen J, Chen H, Zhu Y (2021) Direct chemical looping gasification of pine sawdust using Fe2O3–rich sludge ash as an oxygen carrier: thermal conversion characteristics, product distributions, and gasification performances. Fuel 304:121499

Zou C, Zhao J (2017) Investigation of iron-containing powder on coal combustion behavior. J Energy Inst 90:797–805

Gong Z, Wu W, Zhao Z, Li B (2018) Combination of catalytic combustion and catalytic denitration on semi–coke with Fe2O3 and CeO2. Catal Today 318:59–65

Zhang H, Dou B, Li J, Zhao L, Wu K (2020) Thermogravimetric kinetics on catalytic combustion of bituminous coal. J Energy Inst 93:2526–2535

Cai J, Wang S, Kuang C, Tang X (2017) Insight into the kinetic analysis of catalytic combustion for biomass after alkaline metals loaded pretreatment. Fuel 203:501–513

Cheng J, Zhou F, Xuan X, Liu J, Zhou J, Cen K (2017) Comparison of the catalytic effects of eight industrial wastes rich in Na, Fe, Ca and Al on anthracite coal combustion. Fuel 187(1):398–402

Song Y, Hu J, Liu J, Evrendilek F, Buyukada M (2020) Catalytic effects of CaO, Al2O3, Fe2O3, and red mud on Pteris vittata combustion: emission, kinetic and ash conversion patterns. J Clean Prod 252:119646

Hu J, Yan Y, Song Y, Liu J, Evrendilek F, Buyukada M (2020) Catalytic combustions of two bamboo residues with sludge ash, CaO, and Fe2O3: bioenergy, emission and ash deposition improvements. J Clean Prod 270:122418

Huang Z, Deng Z, Chen D, He F, Liu S, Zhao K, Wei G, Zheng A, Zhao Z, Li H (2017) Thermodynamic analysis and kinetic investigations on biomass char chemical looping gasification using Fe–Ni bimetallic oxygen carrier. Energy 141:1836–1844

Yan X, Hu J, Zhang Q, Zhao S, Dang J, Wang W (2020) Chemical–looping gasification of corn straw with Fe-based oxygen carrier: thermogravimetric analysis. Bioresour Technol 303:122904

Xu X, Li Z, Jiang E (2019) Torrefaction performance of camellia shell under pyrolysis gas atmosphere. Bioresour Technol 284:178–187

Zhang C, Li S, Ouyang S, Tsang CW, Xiong D, Yang K, Zhou Y, Xiao Y (2021) Co-pyrolysis characteristics of camellia oleifera shell and coal in a TGA and a fixed-bed reactor. J Anal Appl Pyrol 155:105035

Deng T, Yu Z, Zhang X, Zhang Y, Chen L, Ma X (2020) Catalytic co-pyrolysis behaviors and kinetics of camellia shell and take-out solid waste using pyrolyzer - gas chromatography/mass spectrometry and thermogravimetric analyzer. Bioresour Technol 297:122419

Meng F, Yu J, Tahmasebi A, Han Y (2013) Pyrolysis and combustion behavior of coal gangue in O2/CO2 and O2/N2 mixtures using thermogravimetric analysis and a drop tube furnace. Energy Fuels 27:2923–2932

Gai C, Dong Y, Zhang T (2013) The kinetic analysis of the pyrolysis of agricultural residue under non-isothermal conditions. Bioresour Technol 127:298–305

Mishra RK, Mohanty K (2018) Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour Technol 251:63–74

Mu L, Wang R, Zhai Z, Zhang B, Shang Y, Yin H (2021) Evaluation of thermokinetics methodology, parameters, and coke characterization of co-pyrolysis of bituminous coal with herbaceous and agricultural biomass. Biomass Convers Bioresour. https://doi.org/10.1007/s13399-021-01502-0

Siddiqi H, Biswas S, Kumari U, Bindu VNVH, Mukherjee S, Meikap BC (2021) A comprehensive insight into devolatilization thermo-kinetics for an agricultural residue: towards a cleaner and sustainable energy. J Clean Prod 310:127365

Siddiqi H, Kumari U, Biswas S, Mishra A, Meikap BC (2020) A synergistic study of reaction kinetics and heat transfer with multi-component modelling approach for the pyrolysis of biomass waste. Energy 204:117933

Chen B, Yao Z, Zhang C, Cheng S, Zhu M, Wang Y, Wu Y, Cao H, Watson I, Cai D (2023) Catalytic co-pyrolysis of cellulosic ethanol-processing residue with high-density polyethylene over biomass bottom ash catalyst. Biomass Convers Bioresour. https://doi.org/10.1007/s13399-023-03915-5

Vlaev L, Nedelchev N, Gyurova K, Zagorcheva M (2008) A comparative study of non-isothermal kinetics of decomposition of calcium oxalate monohydrate. J Anal Appl Pyrol 81:253–262

Singh RK, Patil T, Sawarkar AN (2020) Pyrolysis of garlic husk biomass: physico–chemical characterization, thermodynamic and kinetic analyses. Bioresour Technol Rep 12:100558

Luo L, Zhang Z, Li C, Shu N, He F, Zhang X, Cai J (2021) Insight into master plots method for kinetic analysis of lignocellulosic biomass pyrolysis. Energy 233:121194

Malek J (1992) The kinetic analysis of nonisothermal data. Thermochim Acta 200:257–269

Chen J, Xu W, Zhu L, Xu F, Mu L, Wang Y, Zhu Y (2021) Thermal conversion behaviors, kinetics, and thermodynamics of wastewater sludge via thermogravimetric analysis, and emission characteristics from a large–scale incinerator. J Mater Cycles Waste 23:1466–1478

Xie Z, Ma X (2013) The thermal behaviour of the co–combustion between paper sludge and rice straw. Bioresour Technol 146:611–618

Li J, Dou B, Zhang H, Zhang H, Chen H, Xu Y (2021) Thermochemical characteristics and non-isothermal kinetics of camphor biomass waste. J Environ Chem Eng 9:105311

Song Y, Liu J, Evrendilek F, Kuo J, Buyukada M (2019) Combustion behaviors of Pteris vittata using thermogravimetric, kinetic, emission and optimization analyses. J Clean Prod 237:117772

Fang S, Yu Z, Lin Y, Lin Y, Fan Y, Liao Y, Ma X (2016) Effects of additives on the co-pyrolysis of municipal solid waste and paper sludge by using thermogravimetric analysis. Bioresour Technol 209:265–272

Fang S, Yu Z, Lin Y, Lin Y, Fan Y, Liao Y, Ma X (2017) A study on experimental characteristic of co-pyrolysis of municipal solid waste and paper mill sludge with additives. Appl Therm Eng 111:292–300

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Zhang X, Li J, Yang W, Blasiak W (2011) Formation mechanism of levoglucosan and formaldehyde during cellulose pyrolysis. Energy Fuel 25(8):3739–3746

Huang S, Qin J, Chen T, Yi C, Zhang S, Zhou Z, Zhou N (2022) Co–pyrolysis of different torrefied Chinese herb residues and low–density polyethylene: kinetic and products distribution. Sci Total Environ 802:149752

Funding

Financial supports for this work that have been provided by the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (21KJB470004).

Author information

Authors and Affiliations

Contributions

Xingui Mo: investigation, writing and draft preparation;

Jianqiang Ren: investigation, and data analysis;

Yaoyu Zhou: original draft preparation, and data analysis;

Wenhan Jiang: writing, software, and data analysis;

Jianbiao Chen: conceptualization, writing, editing, funding acquisition, supervision;

Jinjiao Zhu: data analysis, software, and editing;

Chao Wu: original draft preparation, and revision;

Yuezhao Zhu: supervision.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The effects of SA, CaO, Fe2O3, and SiO2 on combustion of camellia seed shell were studied.

• Catalytic combustion performances were influenced by the additives and heating rates.

• Additions of SA active species were conducive to CS combustion in view of heat release.

• Catalytic combustion kinetics were gotten by Coats-Redfern combined with Malek method.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mo, X., Ren, J., Zhou, Y. et al. The influence of sludge ash and its active species on the combustion characteristics and kinetics of biomass: application of model-fitting method combined with master-plots method. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04308-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04308-4