Abstract

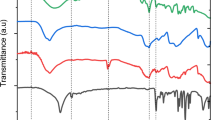

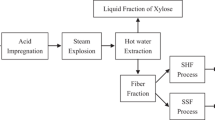

Pretreatment is an important step in lignocellulosic bioethanol production which aims to reduce lignin content and break down lignocellulosic structure thereby increasing the accessibility of enzymes in hydrolysis. Therefore, this research explored the pretreatment process on oil palm empty fruit bunch (EFB) with CO2 impregnation followed by alkali explosion. EFB was impregnated with CO2 at 5 °C for 12 h. After impregnation, EFB was mixed with 2.5 M of NaOH solution (1:5 of S/L ratio) in an alkali explosion reactor. Alkali explosion was conducted at 150 °C, 4 kg/cm2 of pressure with the variation of reaction time for 15, 30, and 45 min. The parameters analyzed in this study include EFB recovery, EFB composition and characteristics, glucose yields, and ethanol yields. EFB composition was analyzed as cellulose, hemicellulose, and lignin while the characteristics of the EFB were examined in functional groups. The results indicated that combined pretreatment using CO2 impregnation followed by 15 min of alkali explosion obtained higher delignification of EFB, glucose, and ethanol yield than only alkali explosion for 30 min. The highest glucose and ethanol yields were 99.33 and 83.80 w/w% of glucose mass in EFB, respectively. These results prove that CO2 can be used as an impregnation agent in lignocellulosic pretreatment and could be combined with alkali explosion.

Similar content being viewed by others

Data availability

Not applicable.

References

Perera F (2018) Pollution from fossil-fuel combustion is the leading environmental threat to global pediatric health and equity: solutions exist. Int J Environ Res Public Health 15(1), 16:1–17. https://doi.org/10.3390/ijerph15010016

Perea-Moreno MA, Samerón-Manzano E, Perea-Moreno AJ (2019) Biomass as renewable energy: worldwide research trends. Sustain 11(3), 863:2–19. https://doi.org/10.3390/su11030863

Bušić A, Marđetko N, Kundas S, Morzak G, Belskaya H, Šantek MI, Komes D, Novak S, Šantek B (2018) Bioethanol production from renewable raw materials and its separation and purification: a review. Food Technol. Biotechnol. 56:289–311. https://doi.org/10.17113/ftb.56.03.18.5546

Bibi R, Ahmad Z, Imran M, Hussain S, Ditta A, Mahmood S, Khalid A (2017) Algal bioethanol production technology: a trend towards sustainable development. Renew Sustain Energy Rev 71:976–985. https://doi.org/10.1016/j.rser.2016.12.126

Lamichhane G, Acharya A, Poudel DK, Aryal B, Gyawali N, Niraula P, Phuyal SR, Budhathoki P, Bk G, Parajuli N (2021) Recent advances in bioethanol production from Lignocellulosic biomass. Int J Green Energy 18:731–744. https://doi.org/10.1080/15435075.2021.1880910

Ling JH, Lim YT, Leong WK, Sia HT (2021) Utilization of oil palm empty fruit bunch in cement bricks. J Adv Civ Environ Eng 4(1):1–10. https://doi.org/10.30659/jacee.4.1.1-10

Sukiran MA, Abnisa F, Wan Daud WMA, Abu Bakar N, Loh SK (2017) A review of torrefaction of oil palm solid wastes for biofuel production. Energy Convers Manag 149:101–120. https://doi.org/10.1016/j.enconman.2017.07.011

Mohammad IN, Ongkudon CM, Misson M (2020) Physicochemical properties and lignin degradation of thermal-pretreated oil palm empty fruit bunch. Energies 13(22):5966. 1–12. https://doi.org/10.3390/en13225966

Elgharbawy AA, Alam MZ, Moniruzzaman M, Kabbashi NA, Jamal P (2018) Chemical and structural changes of pretreated empty fruit bunch (EFB) in ionic liquid-cellulase compatible system for fermentability to bioethanol. 3 Biotech 8:236. https://doi.org/10.1007/s13205-018-1253-8

Windiastuti E, Suprihatin, Bindar Y, Hasanudin U (2022) Identification of potential application of oil palm empty fruit bunches (EFB): a review. IOP Conf Ser Earth Environ Sci 1063:012024–012024-11. https://doi.org/10.1088/1755-1315/1063/1/012024

Dey P, Pal P, Kevin JD, Das DB (2020) Lignocellulosic bioethanol production: prospects of emerging membrane technologies to improve the process—a critical review. Rev Chem Eng 36:333–367. https://doi.org/10.1515/revce-2018-0014

Robak K, Balcerek M (2018) Review of second-generation bioethanol production from residual biomass. Food Technol Biotechnol 56(2):174–187. https://doi.org/10.17113/ftb.56.02.18.5428

Ladeira Ázar RIS, Bordignon-Junior SE, Laufer C, Specht J, Ferrier D, Kim D (2020) Effect of lignin content on cellulolytic saccharification of liquid hot water pretreated sugarcane bagasse. Molecules 25(3), 623:1–12. https://doi.org/10.3390/molecules25030623

Djajadi DT, Jensen MM, Oliveira M, Jensen A, Thygesen LG, Pinelo M, Glasius M, Jørgensen H, Meyer AS (2018) Lignin from hydrothermally pretreated grass biomass retards enzymatic cellulose degradation by acting as a physical barrier rather than by inducing nonproductive adsorption of enzymes. Biotechnol Biofuels 11:1–13. https://doi.org/10.1186/s13068-018-1085-0

Muryanto TE, Abimanyu H, Cahyono A, Cahyono ET, Sudiyani Y (2015) Alkaline delignification of oil palm empty fruit bunch using black liquor from pretreatment. Procedia Chemistry 16:99–105. https://doi.org/10.1016/j.proche.2015.12.032

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83:1–11. https://doi.org/10.1016/S0960-8524(01)00212-7

Weidner E (2018) Impregnation via supercritical CO2–What we know and what we need to know. J Supercrit Fluids 134:220–227. https://doi.org/10.1016/j.supflu.2017.12.024

Morais ARC, Da Costa Lopes AM, Bogel-Łukasik R (2015) Carbon dioxide in biomass processing: contributions to the green biorefinery concept. Chem Rev 115:3–27. https://doi.org/10.1021/cr500330z

Ferreira-Leitão V, Perrone CC, Rodrigues J, Franke APMH, MacRelli S, Zacchi G (2010) An approach to the utilization of CO2 as impregnation agent in steam pretreatment of sugar cane bagasse and leaves for ethanol production. Biotechnol Biofuels 3:1–8. https://doi.org/10.1186/1754-6834-3-7

Rezakazemi M, Darabi M, Soroush E, Mesbah M (2019) CO2 absorption enhancement by water-based nanofluids of CNT and SiO2 using hollow-fiber membrane contactor. Sep Purif Technol 210:920–926. https://doi.org/10.1016/j.seppur.2018.09.005

Triwahyuni E, Miftah AK, Muryanto Maryana R, Sudiyani Y (2021) Effect of CO2-added steam explosion on oil palm empty fruit bunch for bioethanol production. Cellul Chem Technol 55:839–847. https://doi.org/10.35812/CelluloseChemTechnol.2021.55.71

Han M, Kim Y, Kim SW, Choi GW (2011) High efficiency bioethanol production from OPEFB using pilot pretreatment reactor. J Chem Technol Biotechnol 86:1527–1534. https://doi.org/10.1002/jctb.2668

Duangwang S, Sangwichien C (2013) Optimizing alkali pretreatment of oil palm empty fruit bunch for ethanol production by application of response surface methodology. Adv Mater Res 622:117–121. https://doi.org/10.4028/www.scientific.net/AMR.622-623.117

Sudiyani Y, Triwahyuni E, Muryanto Burhani D, Waluyo J, Sulaswaty A, Abimanyu H (2016) Alkaline pretreatment of sweet sorghum bagasse for bioethanol production. Int J Renew Energy Dev 5:113–118. https://doi.org/10.14710/ijred.5.2.113-118

Muryanto Sudiyani Y, Abimanyu H (2016) Optimization of NaOH alkali pretreatment of oil palm empty fruit bunch for bioethanol. Indones J Appl Chem 18:27–35. https://doi.org/10.14203/jkti.v18i01.37

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2012) Determination of structural carbohydrates and lignin in biomass determination of structural carbohydrates and lignin in biomass. Technical Report. NREL/TP-510–42618:1–15. https://www.nrel.gov/docs/gen/fy13/42618.pdf

Hazwan M, Bowra S, Cox P (2020) Purity and structural composition of lignin isolated from Miscanthus x giganteus by sub-critical water extraction with associated modifiers. J Agric Food Eng 1:1–12. https://doi.org/10.37865/jafe.2020.0010

Bahrin EK, Ibrahim MF, Abdul Razak MN, Abd-Aziz S, Hassan MA, Baharuddin AS, Sulaiman A, Shirai Y, Nishida H (2012) Physicochemical property changes and enzymatic hydrolysis enhancement of oil palm empty fruit bunches treated with superheated steam. BioResources 7:1784–1801. https://doi.org/10.15376/biores.7.2.1784-1801

Baruah J, Nath BK, Sharma R, Kumar S, Deka RC, Baruah DC, Kalita E (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6:1–19. https://doi.org/10.3389/fenrg.2018.00141

Monte LS, Escócio VA, de Sousa AMF, Furtado CRG, Leite MCAM, Visconte LLY, Pacheco EBAV (2018) Study of time reaction on alkaline pretreatment applied to rice husk on biomass component extraction. Biomass Conv Bioref 8:189–197. https://doi.org/10.1007/s13399-017-0271-9

Sudiyani Y, Triwahyuni E, Muryanto, Marno S, Putri N (2020) Bioethanol production from alkali steam explosion of oil palm of empty fruit bunch fiber. IOP Conf Ser Mater Sci Eng 854:012030–1-012030-7. https://doi.org/10.1088/1757-899X/854/1/012030

Tan J, Li Y, Tan X, Wu H, Li H, Yang S (2021) Advances in pretreatment of straw biomass for sugar production. Front Chem 9:1–28. https://doi.org/10.3389/fchem.2021.696030

Dewi RK, Zuhroh ST, Zulaikha S (2018) Delignification of chandlenut shell waste with alkali pretreatment method as an alternative fuel feedstock. Int J Mech Eng Technol 9(10):271–278. https://iaeme.com/MasterAdmin/Journal_uploads/IJMET/VOLUME_9_ISSUE_10/IJMET_09_10_027.pdf. Accessed 10 Oct 2022

Rezania S, Oryani B, Cho J, Talaiekhozani A, Sabbagh F, Hashemi B, Rupani PF, Mohammadi AA (2020) Different pretreatment technologies of lignocellulosic biomass for bioethanol production: an overview. Energy. 199:117457. https://doi.org/10.1016/j.energy.2020.117457

Waluyo J, Anggraini RIF, Kurniawan, HH, Sudiyani Y (2018) Physical chemical characterization of alkali pretreatment for oil palm empty fruit bunch. AIP Conf Proc 2024:020072-1-020072-11. https://doi.org/10.1063/1.5064358

Isroi IMM, Millati R, Syamsiah S, Cahyanto MN, Niklasson C, Taherzadeh MJ (2012) Structural changes of oil palm empty fruit bunch (OPEFB) after fungal and phosphoric acid pretreatment. Molecules 17:14995–15012. https://doi.org/10.3390/molecules171214995

Putri AMH, Triwahyuni E, Sudiyani Y (2016) Statistical analysis of NaOH pretreatment effects on sweet sorghum bagasse characteristics. AIP Conf Proceeding 1803:020008-1-020008–7. https://doi.org/10.1063/1.4973135

Cha YL, Yang J, Park Y, An GH, Ahn JW, Moon YH, Yoon YM, Yu GD, Choi IH (2015) Continuous alkaline pretreatment of Miscanthus sachhariflorus using a bench-scale single screw reactor. Bioresour Technol 181:338–344. https://doi.org/10.1016/j.biortech.2015.01.079

Baig KS (2020) Interaction of enzymes with lignocellulosic materials: causes, mechanism and influencing factors. Bioresour Bioprocess 7(21):1–19. https://doi.org/10.1186/s40643-020-00310-0

Thamsee T, Choojit S, Cheirsilp B, Yamseangsung R, Ruengpeerakul T, Sangwichien C (2019) Combination of superheated steam explosion and alkaline autoclaving pretreatment for improvement of enzymatic digestibility of the oil palm tree residues as alternative sugar sources. Waste Biomass Valorization 10:3009–3023. https://doi.org/10.1007/s12649-018-0292-z

Cha YL, Yang J, Ahn JW, Moon YH, Yoon YM, Yu GD, An GH, Choi IH (2014) The optimized CO2-added ammonia explosion pretreatment for bioethanol production from rice straw. Bioprocess Biosyst Eng 37:1907–1915. https://doi.org/10.1007/s00449-014-1165-x

Gao M, Xu F, Li S, Ji X, Chen S, Zhang D (2010) Effect of SC-CO2 pretreatment in increasing rice straw biomass conversion. Biosyst Eng 106:470–475. https://doi.org/10.1016/j.biosystemseng.2010.05.011

de CarvalhoSilvello MA, Martínez J, Goldbeck R (2020) Application of supercritical CO2 treatment enhances enzymatic hydrolysis of sugarcane bagasse. Bioenergy Res 13:786–796. https://doi.org/10.1007/s12155-020-10130-x

Yin J, Hao L, Yu W, Wang E, Zhao M, Xu Q, Liu Y (2014) Enzymatic hydrolysis enhancement of corn lignocellulose by supercritical CO 2 combined with ultrasound pretreatment. Chinese J Catal 35:763–769. https://doi.org/10.1016/S1872-2067(14)60040-1

Funding

This work was supported by Research Center for Chemistry, National Research and Innovation Agency (BRIN).

Author information

Authors and Affiliations

Contributions

ET is the main contributor who conceptualized the study and methodology, collected and analyzed the data, and wrote the original paper. Meanwhile, AKM conducted pretreatment experiments and data collection. MM and RM performed hydrolysis and fermentation processes and analyzed data. YS supervised the study and also the review and editing of the paper.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human or animal participants.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Statement of novelty

Indonesia as one of the largest oil palm producers in the world not only produces oil palm but also generates huge amounts of lignocellulosic biomass such as empty fruit bunch (EFB). This biomass can be converted into energy, for example, bioethanol. Pretreatment is an important stage in lignocellulosic bioethanol production. This study inquires about the application of CO2 as an impregnating agent in the alkali explosion of EFB for bioethanol production. This research reports for the first time that adding CO2 as an impregnating agent before alkali explosion could enhance the percentage of delignification, hydrolysis, and fermentation yield in bioethanol production from EFB. This report was assessed in terms of the percentage of EFB solid recovery after pretreatment, the percentage of the chemical composition of EFB, the characteristics of EFB, the yield of glucose, and ethanol yield after separate hydrolysis and fermentation (SHF).

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Triwahyuni, E., Miftah, A.K., Muryanto, M. et al. Conversion of oil palm empty fruit bunch into bioethanol through pretreatment with CO2 as impregnating agent in alkali explosion. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04102-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04102-2