Abstract

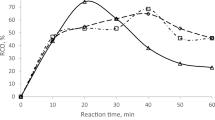

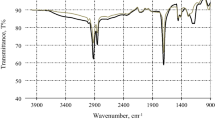

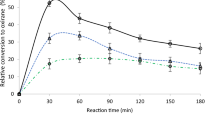

Over the last decade, there has been growing interest/global concern in synthesizing products from renewable energy sources. Epoxides are intermediate products that can be used to produce other materials such as polyols through the epoxidation of vegetable oils. In this study, expired palm oil was used to synthesize epoxides via in situ peracid mechanism utilizing an ion exchange resin catalyst. Based on the results, the relative conversion to oxirane (RCO) is 63%. The following optimum process parameters were used for the epoxidation process: (1) stirring speed: 600 rpm, (2) reaction temperature: 90 °C, and (3) formic acid/unsaturated fatty acid molar ratio: 1:1. Besides that, a mathematical model was developed by using the numerical integration Runge Kutta 4th Order method using MATLAB software. Based on the results of the kinetic study, the summation of error is smaller, and therefore, the kinetic model is validated.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Jalil MJ, Azmi IS, Hadi A (2021) Highly production of dihydroxystrearic acid from catalytic epoxidation process by in situ peracid mechanism. Environ Prog Sustain Energy :1–7. https://doi.org/10.1002/ep.13764

Janković MR, Govedarica OM, Sinadinović-Fišer SV (2019) The epoxidation of linseed oil with in situ formed peracetic acid: a model with included influence of the oil fatty acid composition. Ind Crops Prod 143(June):2020. https://doi.org/10.1016/j.indcrop.2019.111881

Azeman NH, Yusof NA, Othman AI (2015) Detection of free fatty acid in crude palm oil. Asian J Chem 27(5):1569–1573. https://doi.org/10.14233/ajchem.2015.17810

Sardon H, Mecerreyes D, Basterretxea A, Avérous L, Jehanno C (2021) From lab to market: current strategies for the production of biobased polyols. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.1c02361

Tesser R, Russo V, Turco R, Vitiello R, Di M (2020) Bio-lubricants synthesis from the epoxidized oil promoted by clays : kinetic modelling. Chem Eng Sci 214:115445. https://doi.org/10.1016/j.ces.2019.115445

Freites Aguilera A, Hämäläinen R, Eränen K, Tolvanen P, Salmi T (2021) Salmi, Prilezhaev epoxidation of oleic acid in the presence and absence of ultrasound irradiation. J. Chem. Technol. Biotechnol. 96(7):1874–1881. https://doi.org/10.1002/jctb.6706

Jalil MJ, Farhan A, Yamin M, Saufi M (2019) Synthesis of epoxidized oleic acid- based palm oil by peracid mechanism. https://doi.org/10.1088/1757-899X/551/1/012120

de Haro JC, Izarra I, Rodríguez JF, Pérez Á, Carmona M (2016) Modelling the epoxidation reaction of grape seed oil by peracetic acid. J Clean Prod 138:70–76. https://doi.org/10.1016/j.jclepro.2016.05.015

Beltrán Osuna AA, Boyacá Mendivelso LA (2010) Two-phase kinetic model for epoxidation of soybean oil. Ing Investig 30(2):188–196

Farhan A, Yamin M, Jalil MJ, Adnan I, Vsiduru VG (2018) Numerical modeling of epoxidation palm kernel oil based oleic acid 7:123–126

Badri KH, Ngah MS (2015) A mini scale batch reactor for the production of palm-based polyol. Sains Malaysiana 44(6):861–867. https://doi.org/10.17576/jsm-2015-4406-12

Fernandes FC, Kirwan K, Lehane D, Coles SR (2017) Epoxy resin blends and composites from waste vegetable oil. Eur Polym J 89(February):449–460. https://doi.org/10.1016/j.eurpolymj.2017.02.005

Xie WQ, Chai XS (2017) Determination of epoxy groups in epoxy resins by reaction-based headspace gas chromatography. Polym Test 59:113–117. https://doi.org/10.1016/j.polymertesting.2017.01.020

Azmi IS, Bakar MHA, Raofuddin DNA, Habri HH, Azmi MHM, Jalil MJ (2022) Synthesis and kinetic model of oleic acid-based epoxides by in situ peracid mechanism 71:209–214

Zych A et al (2021) Biobased, biodegradable, self-healing boronic ester vitrimers from epoxidized soybean oil acrylate. ACS Appl Polym Mater 3(2):1135–1144. https://doi.org/10.1021/acsapm.0c01335

Montoya C et al (2014) Genetic architecture of palm oil fatty acid composition in cultivated oil palm ( Elaeis guineensis Jacq .) compared ´ s to its wild relative E . oleifera ( H . B . K ) Cortes. Plos One 9(5). https://doi.org/10.1371/journal.pone.0095412

Biermann U et al (2000) {N}ew {s}yntheses with {o}ils and {f}ats as {r}enewable {r}aw {m}aterials for the {c}hemical {i}ndustry. Angew Chemie Int Ed 39(13):2206–2224. https://doi.org/10.1002/1521-3773(20000703)39:13%3c2206::AID-ANIE2206%3e3.0.CO;2-P

Ismail KN et al (2021) High yield dihydroxystearic acid (DHSA) based on kinetic model from epoxidized palm oil. Kem u Ind 70(1–2):23–28. https://doi.org/10.15255/kui.2020.016

Coman AE et al (2021) Synthesis and characterization of renewable polyurethane foams using different biobased polyols from olive oil. Eur Polym J 149(February):110363. https://doi.org/10.1016/j.eurpolymj.2021.110363

Azmi IS, Jalil MJ, Hadi A (2022) Epoxidation of unsaturated fatty acid–based palm oil via peracid mechanism as an intermediate product. Biomass Convers Biorefinery 1. https://doi.org/10.1007/s13399-022-02862-x

Kurańska M et al (2019) Evaluation of application potential of used cooking oils in the synthesis of polyol compounds. J Environ Chem Eng 7(6). https://doi.org/10.1016/j.jece.2019.103506

Yeoh FH, Lee CS, Kang YB, Wong SF, Cheng SF (2018) One-pot synthesis of palm oil-based polyester polyol for production of biodegradable and biocompatible polyurethane. J Appl Polym Sci 135(44):1–16. https://doi.org/10.1002/app.46861

Alsofiany AA, Faiz Mukhtar Gunam Resul M (2021) Epoxidation of waste cooking palm oil with peracetic acid catalyzed by sulfuric acid. Int Congr Adv Technol Eng 2021:4–8. https://doi.org/10.1109/ICOTEN52080.2021.9493511

Hadi A, Jumain M, Aliff J, Mohd F, Intan Y, Azmi S (2022) Single step synthesis of dihydroxystearic acid ( DHSA ) from Epoxidized Palm Oil

Zaimahwati, Agusnar H, Rihayat T, Reflianto D, Gea S (2015) The manufacture of palm oil-based polyurethane nanocomposite with organic montmorillonite nanoparticle as paint coatings. Int J Chem Tech Res 7(5):2537–2544

Tee YB, Talib RA, Abdan K, Chin NL, Basha RK, Md Yunos KF (2016) Comparative study of chemical, mechanical, thermal, and barrier properties of poly(lactic acid) plasticized with epoxidized soybean oil and epoxidized palm oil. BioResources 11(1):1518–1540. https://doi.org/10.15376/biores.11.1.1518-1540

Sun X, Zhao X, Du W, Liu D (2011) Kinetics of formic acid-autocatalyzed preparation of performic acid in aqueous phase. Chinese J Chem Eng 19(6):964–971. https://doi.org/10.1016/S1004-9541(11)60078-5

Ifa L, Syarif T, Sabara Z, Nurjannah N, Munira M, Aryani F (2018) Study on the kinetics of epoxidation reaction of RBD palm olein. IOP Conf Ser Earth Environ Sci 175(1). https://doi.org/10.1088/1755-1315/175/1/012035

Rangarajan B, Havey A, Grulke EA, Culnan PD (1995) Kinetic parameters of a two-phase model for in situ epoxidation of soybean oil 72(10):1161–1169

Campanella A, Baltan MA (2006) Degradation of the oxirane ring of epoxidized vegetable oils in liquid – liquid heterogeneous reaction systems. Chem Eng J 118:141–152. https://doi.org/10.1016/j.cej.2006.01.010

Jalil MJ et al (2022) Optimization of epoxidation palm-based oleic acid to produce polyols. Chem Chem Technol 16(1):66–73. https://doi.org/10.23939/chcht16.01.066

Jumain M, Intan J, Azmi S, Hadi A, Farhan A, Yamin M (2022) In situ hydrolysis of epoxidized oleic acid by catalytic epoxidation ‑ peracids mechanism. J Polym Res :1–12. https://doi.org/10.1007/s10965-022-02944-4

Santacesaria E, Turco R, Russo V, Di Serio M, Tesser R (2020) Kinetics of soybean oil epoxidation in a semibatch reactor. Ind Eng Chem Res 59(50):21700–21711. https://doi.org/10.1021/acs.iecr.0c04530

Funding

Universiti Teknologi MARA and Comgreat Solution Sdn. Bhd, provided support with RMI file no: 100-RMC 5/3/SRP PRI (022/2022).

Author information

Authors and Affiliations

Contributions

Mahazmi Burhanuddin Mahadi: writing and experiment work.

Intan Suhada Azmi: data curation.

Mohd Zulkipli Ab Kadir: methodology.

Mariam A. Rahman: experiment work.

Noorfazlida Mohamed: editing.

Mohd Jumain Jalil: conceptualization and methodology.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mahadi, M.B., Azmi, I.S., Kadir, M.Z.A. et al. Sustainable epoxidation of expired palm oil–derived oleic acid via in situ peracid mechanism with applied ion resin Amberlite IR-120H: from waste to wealth. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-04019-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-04019-w