Abstract

Harnessing of second-generation feedstocks via circular economy approaches is generally considered as environmentally friendly. Nonetheless, different potential impacts can be caused during collection and transformation of such feedstocks, affecting overall sustainability. Assessment of such impacts is of particular importance when producing waste-based biofuels. In this regard, this work’s aim was to carry out a sustainability assessment of the existing reclaiming and exploitation strategy of used cooking oil (UCO) in Bogota, Colombia. Currently, UCO is collected, pretreated, and mostly exported to Europe for biodiesel production. Based upon literature data and a life cycle assessment (LCA), several sustainability criteria were derived, measured, and interpreted within the framework of the integrative concept of sustainability (ICoS). As a reference system, results were compared with those obtained from assessing current production of first-generation palm-oil-based biodiesel. Results from LCA indicate that, per ton of UCO-based biodiesel, emissions of 1.06 kg PM2.5-eq, 2.54 kg NOx-eq, 607.6 kg CO2-eq, 2.81 kg SO2-eq, and 0.09 kg P-eq are generated and that there is use of 9.1 m3 water, and 259 kg oil-eq. UCO transportation and biodiesel production stages were the larger contributors to such impacts, and surprisingly, equivalent emissions of CO2 and fossil fuel consumption were higher than those of first-generation biodiesel. Nevertheless, UCO valorization displayed a better overall performance with respect to the reference system in terms of health, safety, environmental, economic, and social indicators. All impacts were reduced by 30 to 50% under a scenario of local production and consumption of biodiesel.

Similar content being viewed by others

1 Introduction

Used cooking oil (UCO) is a major global food waste mainly generated in highly populated urban areas, specifically at households, hospitality sites, and food processing facilities. Edible oils and fats that are used for food preparation cannot be reused indefinitely as a result of the degradation caused by oxidation, hydrolysis, and thermal processes occurring during cooking and frying [1]. Eventually, the concentration of degradation products increases up to a certain level that turns the cooking oil into a noxious material that can cause a variety of illnesses and health problems, so it has to be discarded [2, 3]. Given the steady increase in the consumption of cooking oils and fats worldwide, the generation of UCO is rapidly rising. This represents a major waste management challenge in megacities such as Bogota (i.e., capital of Colombia), which has nearly 10 million inhabitants within the metropolitan area. Frequently, and due to improper behaviors, absence of regulations, and/or lack of law enforcement, UCO is inadequately disposed. In Bogota, UCOs are generally poured through sinks and siphons, or disposed within the solid waste that are sent to sanitary landfills. They can also be illegally collected and filtered for redistribution as new oil with large impacts in public health. Nonetheless, UCOs can be recovered and exploited as a raw material for biofuels such as biodiesel and hydrogenated vegetable oil (HVO) [2]. Besides fuels, UCOs can also be used as feedstock for a large variety of high value-added chemicals, such as plasticizers, lubricants, polymers, resins, and biomaterials [4]. Considering that the potential global supply of UCO is almost equivalent to the global amount of vegetable oils currently used by the oleochemical industry [2], UCO is considered a promising second-generation feedstock for the oleochemical industry. This is of particular importance nowadays when market imbalances due to political and health situations worldwide have reduced availability of traditional oleochemical feedstocks.

In the particular case of Colombia, it was recently reported that UCO generation was estimated in-between 225–330 kt/year, but only about 5% is currently collected for reuse [2, 3]. Moreover, it has been stated that under suitable promotion policies, potential collection of UCOs could increase up to 50% [5]. Now, considering that the average prices of UCOs and UCO-based biodiesel during 2021–2022 were 1190 US$/ton and 1476 US$/ton, respectively [6], collectable UCOs in Colombia could be worth up to 196 US$ million. Then, taking into account that UCO’s collection costs in Colombia were estimated in about 370 USD/ton [7], collection and exporting of UCOs might generate up to 135 US$ million net annual revenue. This is certainly attractive, but there is need to assess not only the economic dimension but also the potential social and environmental impacts of UCOs exploitation to ensure its sustainability. This has not been done previously, and this information is paramount to develop policies for collection and valorization of UCOs in Colombia. Also, here obtained data can be used as input for trading purposes considering that final users are becoming increasingly aware of sustainability and traceability of waste feedstocks within existing supply chains.

Despite the potential benefits of UCO harnessing, it is imperative to understand the entire life cycle of the proposed valorization approaches and to inquire about the associated impacts with respect to those generated by using first-generation raw materials or even fossil resources. In this regard, sustainability of UCO-based products has been an ongoing subject of study, and a result, it is generally assumed that UCO is a greener oleochemical feedstock over edible oils because it does not compete with food use, it reduces pressure on water, and avoids land-use changes [8, 9]. This has led to the deployment of policies to encourage UCO exploitation such as double-counting mechanisms, favorable prices, capital investment subsidies, and tax reduction or exemptions [2, 4]. Nonetheless, special attention must be put on the sourcing of the feedstock and the complexity of the supply chain, i.e., the degree of centralization of the waste valorization system [10, 11]. Within this context, numerous life cycle assessment (LCA) studies on different UCO exploitation schemes have been reported in the literature, and they have been mainly focused on the production of UCO-based biodiesel. As life cycle impacts are highly dependent on geographic location, studies have been reported for different countries worldwide including Brazil [12,13,14], Cameroon [15], China [16], Colombia [17], Greece [18], Iran [19], Italy [20,21,22], Japan [23, 24], Malaysia [25], Portugal [26,27,28,29], Singapore [30], Spain [11, 31, 32], Thailand [33], UK [8], USA [34], and Vietnam [35]. Most studies have used first-generation-based biodiesel as a reference system, and in overall terms, they agree that UCO-based biodiesel exhibits a better environmental performance than the reference biodiesel or the fossil diesel.

Despite the large number of LCA studies, a small number have included other criteria beyond the environmental one; some have incorporated economic analyses mainly represented by a cost evaluation [13, 30, 35, 36], and few have addressed social aspects [30, 34]. In particular, only two of the identified studies are based on an overall assessment of sustainability. The first one, performed by Vinyes et al. in Spain [31], consists of a life cycle sustainability assessment (LCSA) of different alternatives for domestic UCO collection within the context of some Mediterranean countries. The second one, performed by Mendecka et al. [22], consisted of a multicriteria analysis of a UCO valorization scheme to biodiesel, and the study focused on a comparison between different manufacturing technologies. Besides the different criteria to be included in the analysis, another important factor to be considered in the LCA is the uncertainty of data during the inventory stage. From the revised literature, only one study presented an uncertainty assessment of data included in the LCA for UCO-based biodiesel production in Portugal [29]. According to this study, despite the parametric variability and the uncertainty arising from modelling options, the main source of variation when assessing the life cycle of UCO-based biodiesel systems lies on the features of UCO collection systems.

In addition to the abovementioned investigations, LCA studies on UCO valorization have also been performed for its use as drop-in fuel [19, 21, 37, 38], as well as on its conversion into HVO [36, 39], pyrolyzed oil [40], biogas [41], and most recently polypropylene [42]. Disregarding the final harnessing route, and similarly to the biodiesel case, most studies overlook the role of the UCO collection schemes and the overall impacts of UCO supply chains that could be large [43]. Besides, while it is possible to identify the triple-bottom-line (TBL) theory as a common base element among most studies, the use of this theory has been characterized by a segmented management of the proposed dimensions (i.e., social, environmental, or economic) [44], without deepening the analysis of potential interconnections, and sometimes legitimating trade-offs between them [35]. In contrast, assessment by using the integrative concept of sustainability (ICoS) might offer a more comprehensive approach to sustainability [45], enabling to determine if a technology, a system, an organization, or even a policy effectively contributes to sustainability.

In this context, this work aims to adopt the conceptual framework of the ICoS to perform a sustainability assessment of the current UCO valorization scheme in the city of Bogota. The main goals to be assessed were the potential of the valorization scheme on securing human existence, maintaining society’s productive potential and keeping options for development and action open. The goals, principles, and indicators of the ICoS are summarized in Tables S1 and S2 in the Supplementary Material. These were evaluated by mean of the following criteria: human health, labor conditions, work safety, water use, demand for fossil resources, climate change, water quality, soil quality, waste management, economic performance, social acceptance, governmental framework, and land-use change. Such criteria were evaluated by mean of a LCA of studied collection and exploitation scheme and by revising reports on social, economic, and environmental impacts. The assessed scheme in Bogota consisted of UCO’s collection, pretreatment, transport to seaports, exportation to Europe, and production of UCO-based biodiesel. The reference system for comparison was the production of palm oil-based biodiesel with a comparable transformation process. In addition, two further scenarios were analyzed, namely, local production of UCO-based and palm oil-based biodiesel. Results from this study are fundamental to determine the sustainable nature of the current UCOs harnessing schemes in the city, to identify the hot spots to be improved, and to propose alternatives to enhance sustainability of circular economy models around UCO exploitation in the country.

2 Methodology

The proposed methodology comprises three main phases focused on stablishing the fundamentals of the assessment, its execution, and a final interpretation within the ICoS framework. It is important to highlight that the assessment is not merely sequential but rather iterative, which means that the outcome from the third phase provides a feedback to refine the activities in the second phase.

2.1 First phase — foundations of the assessment

This stage comprised three parallel activities, namely, characterization of the system of interest, definition of the sustainability approach and the conceptual framework, and finally the literature review on related sustainability assessments

2.1.1 Characterization of the system of interest

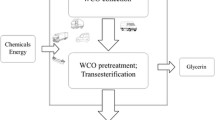

The system under study corresponds to the operation of one of the registered and authorized UCO management companies in Bogota, Colombia. The operation is conceptually described in Fig. 1, and comprises four main stages: UCO collection, pretreatment, transport to Europe, and biodiesel production in Spain. Collection of UCOs is performed under a decentralized system; the company establishes agreements with different hospitality sites and defines a logistic scheme for the collection of the oil using light commercial vehicles. As presented in Table S3 in the Supplementary Material, the average commuting distance between UCO generation points to collection depot was around 50 km, in the 1-ton-capacity vehicles. Fuel consumption and other supply chain characteristics used in this work were also reported in previous studies [7, 46].

In the subsequent stage, pretreatment of UCO is carried out through heating, decantation, and mechanical filtration [46]. Then, when UCO meets certain quality specifications, it is sent overseas to be used as oleochemical feedstock. Initially, UCO is transported about 1000 km in heavy trucks from the pretreatment facilities to a seaport located on the Caribbean coast of Colombia. From this point, UCO is sent to the biodiesel production facilities in Spain. The transportation stage involves 7440 km in a transoceanic ship to the port in Europe, and about 324 km in heavy trucks to the biodiesel plant in central-western Spain (i.e., Extremadura). For clarity, the location of the abovementioned nodes is described in Fig. 2, and the associated inventory data of pretreatment and distribution stages are summarized in Tables S4 and S5 in the Supplementary Material.

Geographic location of nodes for UCO collection, transformation, transport, and exploitation. a Collection points in Bogota [7]. b Pretreatment facility in Bogota. c Exporting seaport in the Caribbean coast of Colombia. d Reception port and biodiesel production facilities in Spain

Biodiesel production in Spain is carried out using the Westfalia technology that is suitable for high acidity feedstocks. This technology consists of a continuous single- or multi-step acid-catalyzed esterification of FFA followed by a continuous two-step base-catalyzed transesterification of triglycerides with methanol, under atmospheric pressure and at temperatures of at least 60 °C [47]. The reaction stages are followed by separation of glycerol, catalyst removal, methanol stripping, and a washing purification of the methyl esters. This technology includes a closed-loop for methanol recovery and recirculation [47]. The parameters for the modeling of this last stage and the corresponding inventory data were obtained from literature reports, and they are summarized in Table S6 of the Supplementary Material.

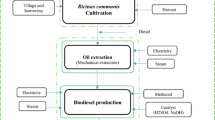

At this point, it is important to define a reference point for a comparative assessment of the studied system. Since the aim of recycling UCO is to discourage the demand for virgin vegetable oil as oleochemical feedstock, palm oil-based biodiesel was chosen as the reference system. This was done considering that Spain’s biodiesel sector mainly relies on imported vegetable oils, and about 62% corresponded to palm oil from Indonesia, Malaysia, and Colombia [48, 49]. Within this context and for a suitable comparison, palm oil from Colombia was chosen as feedstock for the reference system. The main stages of palm oil-based biodiesel production are schematically presented in Fig. 3, and the corresponding Ecoinvent® datasets used to assess the life cycle inventory impacts are reported in Table S7 in the Supplementary Material. After cultivation and harvesting, palm fruits are processed at oil mills that are usually located near the cropping area. Processing consists of sterilizing, shedding, and macerating the fruits to extract the palm oil; afterwards, palm oil is filtered, bleached, and deodorized. For the reference system, it was assumed that crude palm oil is exported from a specific location in Colombia corresponding to that of the companies with the highest exporting volumes of crude palm oil to Spain [50]. It is also assumed that the destination in Spain and the technology for biodiesel production are the same to those used in the UCO-based case.

2.1.2 Definition of the sustainability approach and the conceptual framework

As above mentioned, the sustainability assessment was carried out by mean of the integrative concept of sustainability (ICoS) which employs a life cycle thinking (LCT) approach [51,52,53]. The ICoS framework recognizes the central elements of global perspective, mutual interdependence of intra- and inter-generational justice, and anthropocentric point of departure. As previously mentioned, ICoS goals and principles are presented in Table S1 in the Supplementary Material. The choice of this conceptual framework lies on the fact that it upholds the notion of critical sustainability and avoids the conventional association of the concept of development with economic growth [52].

2.2 Second phase — preparation of the assessment

For this study, specific assessment criteria were selected upon relevance regarding the features of the study system and the sustainability approach. Then, suitable indicators were assigned to each criterion upon representativeness and practicality, keeping in mind that a proper selection of indicators contributes to building an understandable representation of reality [54, 55]. Finally, ICoS goals and rules were aligned to each pairing of criterion-indicator, and the outcome of these steps was summarized in Table S2 in the Supplementary Material.

2.2.1 Life cycle assessment

Quantitative indicators were obtained based upon a LCA, and it was performed using OpenLCA V.1.10.2, and the Ecoinvent 3.5 database. The required inventory data and parameters for the LCA of the study system (UCO-based biodiesel) were obtained from recent investigations on the supply chain and UCO valorization scheme in Bogota [7, 46], as well as from direct inspection of the collection routes and pretreatment facilities of the authorized UCO collector. As previously mentioned, the corresponding input and output data of the different stages are summarized in Tables S3 to S6 in the Supplementary Material.

For the last stage, corresponding to biodiesel production via Westphalia technology, inventory data were also based upon the Ecoinvent dataset. Nonetheless, providers of the dataset were modified to fit the geographical location of the biodiesel facility in Europe (Spain). The resulting data were verified and resulted consistent with those reported in similar LCA studies [21, 46]. Regarding the reference system (i.e., palm oil-based biodiesel), Ecoinvent datasets were also used for oil palm cultivation, oil extraction, and biodiesel production stages, as presented in Table S7 in the Supplementary Material. In the case of the palm oil distribution stage, transportation distances were the same as for the study system, except for the first segment to the exportation port. It was assumed that crude palm oil was exported from a specific location in the northern zone of Colombia, considering that the companies with the highest volume of crude palm oil exported to Spain are located 80 km away from the port [49, 50].

The functional unit of the LCA for the assessment was set to 1 ton of biodiesel, and the selected impact assessment methodology was ReCiPe 2016 (i.e., midpoint level and from a hierarchic cultural perspective). This was selected among the available methodologies because this has been recommended for LCA in biofuel applications [56], and because there is no consensus on a standardized impact assessment methodology for LCA of biofuels [57]. As presented in Table S8 in the Supplementary Material, the provided midpoint impact categories were coupled with the established criteria and respective indicators. The criterion of water use was the only one that was assessed through a different impact assessment methodology, namely, the water scarcity methodology, which uses the water stress index (WSI, m3) as indicator. Considering the informative character of this LCA study, attributional modeling was applied. Consistently, UCO was taken as a burden-free feedstock, which was accepted in similar studies [22, 26, 27]. Thus, UCO-based biodiesel only bears the burden of the valorization process.

2.2.2 Qualitative assessment

For the criteria that were qualitatively evaluated, namely, labor conditions, work safety, social acceptance, governmental framework, and land-use change, the assessment was based on the available information and analogous studies found in the literature. For comparison purposes, results of the qualitative assessment were categorized and graded using a similar approach to that used in matrix-based methods [58, 59]. Table S9 in the Supplementary Material describes how such grades were assigned according to the overall performance or the magnitude of the negative impact of each criterion. It is important to underline that this categorization aimed at a visual comparison of the assessment and that it was not intended to reduce the whole analysis to a numerical value.

2.3 Third phase — analysis and interpretation

Once the results from the LCA were obtained and the qualitative criteria were evaluated, they were interpreted within the ICoS framework. A contribution analysis by life cycle stage or hotspot analysis was carried out. This enabled to identify the key stages that generate the greatest impact on each of the sustainability criteria, and allowed to select the key parameters for a sensitivity analysis, as well as to formulate possible improvement scenarios. In the first case, a sensitivity analysis was conducted by varying the parameter of transportation distance per unit of collected UCO, which is an indicator of the collection scheme’s efficiency. The choice of this parameter responds to the need to better understand the role of the UCO collection stage in the overall results, as previous LCA studies on UCO valorization reveal contradictory results: whereas some conclude that the contribution share from this stage is small [12, 25, 30, 33, 42], others argue that the collection impacts are usually overlooked and can be large [14, 28, 29, 43]. Also, in this study, other transportation distances were fixed (i.e., Bogota to port, transoceanic, port to biodiesel facility in Spain) and the inventory data associated to the transformation into biodiesel were as obtained from the Ecoinvent database. As for possible improvement scenarios, the local transformation of UCOs into biodiesel was considered as an alternative to improve the performance of the current circular economy model around UCOs exploitation in Colombia.

3 Results and discussion

3.1 Assessed life cycle impacts

The following criteria of the ICoS framework were assessed through LCA: human health, water use, demand for fossil resources, climate change, water quality, soil quality, and waste management. In order to compare the study and the reference systems, the stages were designated a common identity, as indicated in Table 1.

According to the characterized UCO supply chain in Bogota, the commuted distances among the different collection routes ranged from 10 to 1200 km/ton UCO, with an average of 50 km/ton UCO and with a standard deviation of 220 km/ton UCO [7]. Considering this high dispersion in the commuting distances, a sensitivity analysis was carried out as described in section S1 of the Supplementary Material. In this case, the collection distance was varied from best- to worst-case scenario as presented in Tables S10 in the Supplementary Material, and the corresponding results are graphically presented in Figures S1 and S2 of the Supplementary Material. The overall life cycle impacts of the different categories could be up to 1.5–1.8 larger under the worst-case scenario, and the contribution of the collection stage to the overall impacts can be up to 40–55%. This verifies that the collection stage is indeed a major contributor to the life cycle impacts under current UCO harnessing approach and that it is crucial to design strategies to optimize the collection scheme.

The complete set of results used for the sustainability assessment under the ICoS framework are summarized in Table 2, and those obtained from the LCA are graphically presented in Fig. 4. These correspond to the study system, the reference system, and both of the proposed improvement scenarios. The last two correspond to local production and consumption of UCO-based biodiesel and of first-generation biodiesel.

Environmental life cycle impacts of studied scenarios. Functional unit: 1 t of biodiesel. Scenarios: UCO collection in Colombia and transformation into biodiesel in Spain or in Colombia. Reference system: Colombian crude palm oil transformed into biodiesel in Spain or in Colombia. Stages: (light green) feed sourcing, (blue) oil pretreatment/extraction, (yellow) exportation, (green) biodiesel production. (dash) Uncertainty. a Particulate matter emissions. b Photochemical oxidants emissions. c Water stress index. d Fossil resources use. e Greenhouse gases emissions. f Eutrophication. g Acidification

From a general perspective, and despite the expected differences due to specific geographical locations and variable databases, all the obtained results were similar to those reported in previous studies that included UCO collection stage [18, 20, 29, 31]. Clearly, the main differences are related with the impacts of the local collection and exportation stages. In particular, and with respect to the first-generation biodiesel reference, it was observed that current UCO collection and valorization scheme mitigates local and regional life cycle impacts such as emission of particular mater (PM2.5-eq), photochemical oxidation (i.e., NOx-eq), eutrophication (i.e., P-eq), acidification (SO2-eq), and water stressing (WSI). Surprisingly, global impacts such as greenhouse gases (GHG) emissions and fossil fuel consumption are larger than the reference system; here is evident the large impact of the exportation to Europe and the collection stages. When local production and consumption of UCO-based biodiesel is accomplished, all impacts are lower compared to those of the first-generation biofuel. Also, it is particularly troublesome the large water consumption per ton of UCO (9.1 m3), which occurs during biodiesel production. This stage is common to all scenarios and might indicate that there is need to improve current processing technologies to minimize water intensity, or to better identify other potential oleochemical derivatives different from biodiesel with lower associated impacts. Nonetheless, there are water savings compared with those associated to the cropping stage required to obtain palm-based biodiesel.

Now, from the hotspot analysis, considering the obtained indicators of Fig. 4, and the assessment criteria of the ICoS that are summarized in Table S2 in the Supplementary Material, it was verified that in the case of UCO-based biodiesel, the exportation stage is a major contributor to many impact categories. In particular, large impacts were observed on human health, climate change, and soil quality. These results make evident that non-necessarily any circular economy scheme for UCO harnessing is truly sustainable and that there is need to promote public policies for local valorization and use.

The following sections describe the assessed impacts considering those indirectly measured from the life cycle assessment or the qualitatively ones obtained from the literature revision (i.e., labor conditions, work safety, social acceptance, governmental framework, and land-use change).

3.1.1 Human health

For the study system, the greatest contribution for the emissions of both fine particulate matter (kg PM2.5-eq) and photochemical oxidants (kg NOx-eq) per ton of biodiesel comes from the stage of UCO distribution. In particular, transoceanic transport accounts for ~40% of impacts, followed by the freight transport with vehicles meeting the Euro IV standards (i.e., the distribution segment in Colombia). The latter process accounts for 20% of the particulate matter emissions and more than 27% of photochemical oxidants. When the exportation is eliminated and biodiesel is produced locally, the magnitude of the impact is reduced by 65% and 71%, respectively. In this case, the hotspots shift to the collection stage and the process of methanol production, as part of the biodiesel production. Regarding the reference system, the emissions from the palm oil distribution stage are also significant, but not to the same extent as in the study system. When palm oil is destined for local production of biodiesel, a reduction of 22% in particulate matter formation and 33% in photochemical formation is achieved. As expected, major hotspots in the reference system are in the stages of palm tree cultivation and oil palm extraction.

3.1.2 Water use

By avoiding water consumption from crop cultivation, the study system’s WSI is less than a third of that of the reference system. This is highly meaningful considering the current debate on using resources for bioenergy crops, and the demonstrated water-food-energy security nexus. For the study system, the main contribution comes from the stage of biodiesel production, particularly from the process of methanol production. When excluding the UCO distribution stage and considering local production, the magnitude of the indicator decreases by 23%, which is not outstandingly high, but neither negligible. It is important to point out that benefits from avoiding water pollution by harnessing UCOs are not accounted for and that those could be large considering current UCO mismanagement in Bogota. Nonetheless, the large WSI of all scenarios (i.e., 7–29 m3) indicate that probably biodiesel might not be the best end application for the collected UCOs, at least under current industrial technologies.

3.1.3 Demand for fossil resources

Despite being conceived to replace fossil fuels, biofuels highly depend on fossil resources to be produced, mainly the agrochemicals. In this sense, without the cultivation stage, second-generation biofuels could be far less dependent on fossil fuels. However, recycling of waste can neither be carried out without energy inputs, which mainly come from fossil fuels since their share in the global energy matrix is still very high (i.e., ~84%) [60]. Overall, the main hotspot comes from the process of methanol production for the transesterification stage in both systems. Yet, the exportation stage is clearly a major contributor to this indicator, especially for the study system and in relation to land transport. When this stage is avoided in the local production of biodiesel, the magnitude of the indicator is reduced by 40%, becoming slightly less dependent on fossil resources than the reference system. The observed fossil fuel use for the current UCO’s valorization scheme (i.e., 259.22 kg oil-eq) corresponds to nearly 10,800 MJ per ton of UCO-based biodiesel. This value is consistent with the reported range of energy intensity in previous LCA studies on waste-based biodiesel (i.e., 6,800-17,400 kg oil-eq/ton) [61].

3.1.4 Climate change

According to the European renewable energy directive (RED II), typical life cycle GHG emissions of UCO-based biodiesel are about 400 kg CO2-eq/ton (excluding the stage of transportation and distribution of the final fuel), which represent savings of 88% with respect to fossil diesel [62]. For the study system, this value goes up to 607.6 kg CO2-eq/ton, which is 50% higher than the typical value, but still represents GHG emission savings of 82% with respect to fossil diesel. This value is in the range (i.e., 130–1383 kg CO2-eq/ton) of previous reports on environmental life cycle assessments of UCO-based biodiesel including the transportation stage [61]. Although this value is acceptable within the RED II standards, the fact that the stage of exportation accounts for almost 50% of the GHG emissions cannot be ignored. When this stage is eliminated and biodiesel is produced locally, GHG emission savings rise to 91%. In this scenario, the major contribution comes from the collection stage.

As for the reference system, it seems to perform better than UCO-based biodiesel, but land-use change effects (LUC) must be considered. However, oil palm crops in Colombia differ substantially from those in Asian countries, since about 80% of these have been planted in pastures and croplands, which have a lower carbon stock than an oil palm crop. Thus, LUC from pastures and croplands to oil palm actually increases carbon stocks per unit of area and thereby reduces the GHG intensity of palm oil-derived products. For the reference system, these GHG emissions savings can range from 93 to 9254 kg CO2-eq per ton of biodiesel [62]. Consequently, the net GHG intensity of the reference system would be better than that of the study system for any type of direct land-use transition. Nevertheless, indirect LUC remains unexamined due to the high degree of uncertainty posed by its prediction and modeling.

3.1.5 Water quality

As observed, the life cycle eutrophication potential of UCO-based biodiesel is about 11% of that of palm oil-based biodiesel. By avoiding the stage of oil palm cultivation, a substantial contribution to mitigating water pollution can be achieved. As for the improvement scenario for the study system, the eutrophication potential is reduced by a third when UCO-based biodiesel is produced locally. It is important to point out that following the attributional approach of the LCA, the mitigation of the eutrophication potential due to avoided UCO pollution was not accounted for. However, this is certainly a non-negligible contribution of UCO reclaiming and exploitation, and must be further assessed.

3.1.6 Soil quality

The stage of oil palm cultivation is highly responsible for the soil pollution effects linked to palm oil-based biodiesel. Therefore, the acidification potential of UCO-based biodiesel is significantly lower (about one-third) than that of palm-based biodiesel. However, in this case, the exportation stage is by far the main contributor to the acidification potential of the study system, specifically, transoceanic transport (44% share). Thus, when eliminated, the value of this indicator is reduced to a third and the hotspots shift to the collection stage (35% share), the methanol production (20% share), and to the heat generation for the pretreatment stage (14% share).

3.2 Assessment of other quantitative criteria

3.2.1 Waste management

UCO valorization prevents the environmental effects of inadequate disposal practices. According to recent studies [3, 46], 90% of the generated UCO in Colombia is mainly disposed through the sewage (~70%) and also within solid waste (~20%). In this sense, the recovery of 1 ton of UCO would avoid the corresponding GHG emissions from the degradation of solid waste in a sanitary landfill (~ 200 kg), and the treatment of wastewater polluted by 700 kg of UCO. The study system could therefore be credited with about 145 kg CO2-eq per ton of biodiesel for the avoided degradation of solid waste, and at least 418 kg CO2-eq per ton of biodiesel for the avoided treatment of wastewater. The latter value is highly uncertain, since it has been reported that one liter of cooking oil has the potential to contaminate at least 1,000 liters of clean water. Then, if the total value of 563 kg CO2-eq is credited to the study system, the GHG intensity of UCO-based biodiesel would be reduced to about 45 kg CO2-eq.

Nevertheless, it is important to recall that Colombia does not count with full coverage of wastewater treatment. By 2018, the proportion of treated urban wastewater was 42% for the whole country and 32% for Bogota [63]. Thus, it is possible to assert that almost 50% of generated UCO in Bogota eventually reaches water bodies. In this case, an increase in GHG emissions is not the main concern, but rather water eutrophication, soil pollution, and toxicity effects on flora and fauna. Regarding toxicity, recent studies have found that a very low concentration of vegetable oils in water generates lower growth rate and higher mortality of seawater mussels and toxicity to benthic organisms [64, 65]. As for soil pollution, UCO produces a remarkable inhibition in plant growth among a wide range of dosages, as well as toxic effects for terrestrial organisms such as earthworms [66]. These impacts can be prevented if UCO is not discarded as waste.

3.2.2 Economic performance

This criterion was assessed by estimating the operating production costs of the feedstock for biodiesel production before exportation, i.e., the cost of producing 1 ton of pretreated UCO and 1 ton of crude palm oil. Far for comprehensive, this assessment intends to be preliminary to obtain approximate values based upon operating costs considering that existing processing facilities have existed for more than a decade, and capital costs were already paid back. In the case of UCO, costs related to the collection stage comprise the purchase of the UCO, fuel consumption in collection vehicles, and the employee salaries. Regarding the stage of UCO pretreatment, the related operating costs comprise the consumption of utilities (electricity, heating fuel, water, and spent filtering earths), as well as the employee salaries. Then, the total production cost of 1 ton of pretreated UCO was estimated in about 370 USD [7, 46].

Regarding palm oil, for the chosen geographical zone of the reference system, official reports indicate a production costs of approximately 430 US$ [67]. A difference of ~60 US$ is significant considering that biodiesel feedstock is a commodity, and a potential reduction in the production costs of biofuel has a paramount impact on its economic viability. Also, and due to the attributional approach of the LCA, there are economic benefits that are not accounted for by avoiding the mismanagement of UCO. These include reduction of costs for wastewater treatment, avoiding sewage systems repairment, mitigation of public health problems, and reduced cleanup of polluted areas. Therefore, it could be expected that the economic performance of UCO-based biodiesel would be much better than estimated.

3.3 Assessment of qualitative criteria

The general categorization and grading for each of the criteria that were qualitative assessed is presented in Table 3. Quantitative characterization of each criterion was defined according to a revision of recent social studies on biodiesel industry, with some focusing in Colombia case [67,68,69,70,71,72,73]. A more detailed discussion is presented in the following sections.

3.3.1 Labor conditions

For this criterion, the main differences between both systems lie in the first two life cycle stages. For UCO-based biodiesel, operations of UCO collection and pretreatment are carried out by registered recycling agents, i.e., formally established companies that are compelled to legally hire their employees [7, 46]. However, there is a risk of labor informality due to the presence of an illegal market that collect UCO and conduct a rudimentary treatment to sell it as new oil for food/feed purposes. As for the reference system, the panorama is more complex; according to official reports, the percentage of job formality in the Colombian oil palm sector is 82.4%, which strongly contrasts with a low 15% of labor formality in the rural area of the country. Nonetheless, according to a recent study, 83.6% of the oil palm sector employment is outsourced through associated work cooperatives and private companies [68]. This presents certain disadvantages in terms of labor association and the assurance of suitable labor conditions.

3.3.2 Work safety

Biodiesel production involves the storage and handling of several hazardous substances, which poses significant risks if appropriate precautions are not taken. In terms of labor incidents, fires and explosions are reported to be the most common in the industry. Also, it has been demonstrated that the growth of biodiesel production has been accompanied by an increase in incident rates, mainly due to the lack of expert operators and safe technologies [69, 70]. Regarding UCO-based biodiesel, the main potential labor incident associated with the first two life cycle stages is the event of a car accident in a UCO collection journey, which could result in a fire event due to the loaded flammable oil.

As for palm oil-based biodiesel, the Colombian Council on Safety reported that during the first half of 2020, production of palm oil displayed the third-highest rate of labor incidents among the different economic activities of the country [71]. This can be partially explained by the fact that the Colombian palm oil sector is not highly automated nor technified. In general, workers must perform tasks of heavy loads lifting and carrying, agrochemicals handling, tilling, and plowing, as well as other manual harvesting-related activities, which have a high inherent risk of labor incidents. Furthermore, biological risks are very significant, since workers are exposed to different species that can wound them and cause allergies or transmit zoonoses. Finally, it is also important to mention the risks that arise from the Colombian internal conflict, even though these are not inherent to the nature of the work. There is the presence of illegal armed groups in oil palm regions which represents a fundamental safety risk for the workers of the sector [72].

3.3.3 Social acceptance

In general, attitudes towards UCO valorization are positive, considering that the ecological pressure of waste is reduced by transforming it into useful products within the framework of circular economy. Nonetheless, it is important to point out that in Colombia, the level of involvement from citizens is still low, so when it comes to the collection, storage, and transport to a proper disposal point, there is not enough public engagement. Regarding palm oil–based biodiesel, the use of palm oil as oleochemical feedstock around the world is highly rejected due to deforestation and impacts on biodiversity. Even though oil palm crops are proven not to be major contributors to deforestation in Colombia, it is hard to break the stereotype given the global circulation of negative publicity. Besides, despite the strong institutional and policy framework that has fostered the acceptance of oil palm by a discourse of “green” economic development in the regions, conflict victims and academics reject the implementation of oil palm monoculture. Nowadays, local social organizations are more aware of the ecological, social, and cultural impacts that have come along with industrial energetic crops [73].

3.3.4 Governmental framework

Even though there is a legal framework that allows valorization of UCO to produce biodiesel, and a national public policy on sustainable production and consumption to promote integrated management of the edible vegetable oils value chain, efforts to promote adequate and effective UCO management strategies are still missing. Comparatively, in the case of palm oil-based biodiesel, different laws, resolutions, and decrees have been stablished to regulate the production of palm oil and its derivatives since the early 2000s. Since then, several incentives for the oil palm sector have been designed and granted through different political and legal tools, particularly to foster the large-scale expansion of oil palm crops. Nonetheless, it has been pointed out that this framework has been shaped by political and economic elites, who have intervened with specific and direct interests in agribusiness [68].

3.3.5 Land-use change

Although LUC is not attributed to UCO valorization, this criterion was analyzed to underline the avoided effects in this matter. As described before, direct LUC to oil palm crops in Colombia has a positive impact in terms of GHG emissions and climate change mitigation. However, LUC goes beyond the ecological effects and transcends to a socio-cultural dimension. Within this context, support for biofuels in Colombia has contributed to land concentration, a phenomenon that has historically sustained the internal conflict. Besides, oil palm crops throughout the country have been directly linked to forced displacement and violation of human rights [73]. Some oil palm companies could be accomplices of this situation, either by commission or omission, if there is no rigorous control over the operations of the main suppliers, the contractors, active partners, and other major stakeholders [68].

3.4 Overall results

Global results of the sustainability assessment for the study are presented in Fig. 5. The labels in the assessed criteria indicate the aligned ICoS rules and goals according to Tables S1 and S2 of the Supplementary Material. The bars represent the magnitude of the life cycle impacts or the performance of UCO-based biodiesel relative to palm oil-based biodiesel. In this plot, the values < 100% indicate UCO-based biodiesel has a lower life cycle impact or a better performance, and vice versa. In the case of quantitative criteria, the comparison of the respective indicators was straightforward in terms of obtained indicators. In the case of qualitative criteria, relative values were obtained from categories and grades presented in Table 3.

Looking at the different goals, the one of securing human existence shows an unambiguous result favoring UCO as a feedstock. For the assessed criteria, the indicators display a better performance or a lower negative impact, and the comparative advantage ranges from 28% (particulate matter formation, contributing to human health) to 55% (photochemical oxidants formation, also contributing to human health). As for the goal of maintaining society’s productive potential, noteworthy improvements of using UCO can be identified for most of the criteria, the largest correspond to waste management and water quality. Only for the criteria of demand for fossil resources and climate change, the indicators reveal a relative disadvantage of 20% and 9%, respectively. Nonetheless, it is important to recall the potential CO2-emission savings of avoiding UCOs into sewage systems, waste treatment plants, and landfills and that they were not credited in this assessment.

Regarding ICoS’ third goal, contrasting results can be observed for the goal of keeping options for development and action open. On the one hand, the criterion of governmental framework exposes a disadvantage of UCO as a feedstock. However, the use of UCO leads to a significantly higher degree of social acceptance and to a large improvement in terms of land-use change. This indicates the need for governmental regulations for the correct management of UCOs and for policies to promote their local transformation into biofuels or preferably into high value-added oleochemicals. In this last case, it would be necessary to assess the sustainability performance for the different oleochemical derivatives considering that collection and pretreatment stages were already evaluated. As the purpose of UCO exploitation is the use of second-generation feedstock within a circular economy model, in the future, it would be necessary to analyze if demand for virgin vegetable oil is actually decreasing, thus contributing to dematerialization of the oleochemical sector. Additionally, further dimensions could be included within future sustainability assessments, for instance, considering maximum thermodynamic efficiencies via exergetic analysis [74]. This would enable to identify key stages to improve to energy use within the different stages of the life cycle.

4 Conclusions and prospects

Based upon a sustainability assessment, it was verified that current UCO exploitation scheme in Bogotá-Colombia via collection and exportation for biodiesel production represents an improvement compared to palm oil-based biodiesel. Results showed that UCO harnessing scheme contributes to the protection of human health, the securing of an autonomous existence, the sustainable use of renewable resources, the sustainable use of the environment as a sink for waste and emissions, the sustainable development of human and knowledge capital, and the conservation of the cultural function of nature. However, current UCO-based biodiesel valorization must be improved regarding the sustainable use of non-renewable resources (specifically the demand for fossil resources), the role in climate change mitigation, and the robustness of the governmental framework. In particular, in terms of climate change mitigation and despite UCO-based biodiesel still represents important GHG emissions savings with respect to fossil diesel, it underperforms with respect to palm oil-based biodiesel. Besides large emissions during the supply chain, this was because CO2 savings from avoiding UCOs into sewage systems, waste treatment plants, and landfills, and the corresponding mitigative actions were not credited due to lack of information and high uncertainty. This indicates that future studies must be conducted to understand and quantify the effects of current UCO’s misdisposing practices. This includes assessing water-soil environmental partitioning, biodegradability rates, ecosystems toxicity, and emissions from the biodegradation processes. Also, it is important to estimate the associated direct and indirect environmental costs.

In addition to the above, it is important to point out that large GHG emission savings could be achieved if UCO is not exported and biodiesel is produced locally. In fact, since the UCO distribution stage is a major contributor to many of the life cycle impacts (i.e., use of fossil resources, emissions of particulate matter and photochemical oxidants, and acidification potential), it is worth fostering local production and consumption of biodiesel. This can be done by promoting local policies to harness UCO as second-generation oleochemical feedstock. Nonetheless, despite the benefits of UCO-based biodiesel, it is necessary to further assess other valorization models as some current impacts are highly negative. For instance, it was verified that water intensity of biodiesel production is large under the different assessed scenarios (> 7 m3/ton). Then, it would be valuable to explore other valorization alternatives and to select among them based upon their sustainability performance. Also, as the purpose of UCO exploitation is the use of second-generation feedstock within a circular economy model, it is fundamental to assess if the recirculation of waste flows is indeed contributing to decreasing extraction and use of virgin resources in the oleochemical sector.

Data Availability

All data are presented in the manuscript and in the Supplementary Material. Any missing data will be provided upon request.

Abbreviations

- GHG:

-

greenhouse gases

- CO2-eq:

-

equivalent emissions of CO2

- COP:

-

Colombian currency (Pesos)

- HVO:

-

hydrotreated vegetable oil

- ICoS:

-

Integrative Concept of Sustainability

- LCA:

-

life cycle assessment

- LCSA:

-

Life Cycle Sustainability Assessment

- LCT:

-

life cycle thinking

- LUC:

-

land-use change effects

- NOx-eq:

-

equivalent emissions of NOx

- Oil-eq:

-

equivalent consumption of fossil fuels

- PM2.5-eq:

-

equivalent particular matter 2.5 μm

- P-eq:

-

equivalent emissions of phosphorous (eutrophication)

- RED:

-

renewable energy directive

- SD:

-

standard deviation

- SO2-eq:

-

equivalent emissions of SO2 (acidification)

- TBL:

-

triple-bottom-line

- UCO:

-

used cooking oil

- WSI:

-

water stress index

References

Loizides MI, Loizidou XI, Orthodoxou DL, Petsa D (2019) Circular bioeconomy in action: collection and recycling of domestic used cooking oil through a social, reverse logistics system. Recycling 4(2):16. https://doi.org/10.3390/recycling4020016

Orjuela A (2019) Industrial oleochemicals from used cooking oils (UCOs) — sustainability benefits and challenges. In: Sikdar SK, Princiotta F (eds) Advances in carbon management technologies. CRC Press. https://doi.org/10.1201/9781003056157-6

Rincón LA, Cadavid JG, Orjuela A (2019) Used cooking oils as potential oleochemical feedstock for urban biorefineries — study case in Bogota, Colombia. Waste Manag 88:200–210. https://doi.org/10.1016/j.wasman.2019.03.042

Orjuela A, Clark J (2020) Green chemicals from used cooking oils: trends, challenges and opportunities. Curr Opin Green Sustain Chem 26:100369. https://doi.org/10.1016/j.cogsc.2020.100369

Greenea. 2016. Analysis of the current development of household UCO collection systems in the EU. [Online]. Available: https://theicct.org/wp-content/uploads/2021/06/Greenea-Report-Household-UCO-Collection-in-the-EU_ICCT_20160629.pdf (Accessed Dec 22, 2022).

Ramírez LM, Cadavid JG, Orjuela A, Gutiérrez MF, Bohórquez WF (2022) Epoxidation of used cooking oils: Kinetic modeling and reaction optimization. Chem Eng Process Process Intensif 176:108963. https://doi.org/10.1016/j.cep.2022.108963

Rodríguez JS, Orjuela A, Cadavid JG (2022) Characterization and optimization of a used cooking oils collection chain — study case Bogotá, Colombia. Chem Eng Res Des 184:59–71. https://doi.org/10.1016/j.cherd.2022.05.049

Acquaye AA, Sherwen T, Genovese A, Kuylenstierna J, Lenny Koh S, McQueen-Mason S (2012) Biofuels and their potential to aid the UK towards achieving emissions reduction policy targets. Renew Sustain Energy Rev 16(7):5414–5422. https://doi.org/10.1016/j.rser.2012.04.046

Upham P, Smith B (2014) Using the rapid impact assessment matrix to synthesize biofuel and bioenergy impact assessment results: the example of medium scale bioenergy heat options. J Clean Prod 65:261–269. https://doi.org/10.1016/j.jclepro.2013.09.041

Chong YT, Teo KM, Tang LC (2016) A life cycle-based sustainability indicator framework for waste-to-energy systems and a proposed metric of sustainability. Renew Sustain Energy Rev 56:797–809. https://doi.org/10.1016/j.rser.2015.11.036

Iglesias L, Laca A, Herrero M, Díaz M (2012) A life cycle assessment comparison between centralized and decentralized biodiesel production from raw sunflower oil and waste cooking oils. J Clean Prod 37:162–171. https://doi.org/10.1016/j.jclepro.2012.07.002

De Pontes Souza D, Mendonça FM, Alves Nunes KR, Valle R (2012) Environmental and socioeconomic analysis of producing biodiesel from used cooking oil in Rio de Janeiro: The case of the Copacabana district. J Ind Ecol 16(4):655–664. https://doi.org/10.1111/j.1530-9290.2012.00517.x

Moecke EHS, Feller R, dos Santos HA, de Medeiros Machado M, Vieira AL, De Aguiar AR, Vieira LL, Soares SR (2016) Biodiesel production from waste cooking oil for use as fuel in artisanal fishing boats: Integrating environmental, economic and social aspects. J Clean Prod 135:679–688. https://doi.org/10.1016/j.jclepro.2016.05.167

Peñarrubia Fernandez IA, Liu DH, Zhao J (2017) LCA studies comparing alkaline and immobilized enzyme catalyst processes for biodiesel production under Brazilian conditions. Resour Conserv Recycl 119:117–127. https://doi.org/10.1016/j.resconrec.2016.05.009

Achten WMJ, Vandenbempt P, Almeida J, Mathijs E, Muys B (2010) Life cycle assessment of a palm oil system with simultaneous production of biodiesel and cooking oil in Cameroon. Environ Sci Technol 44(12):4809–4815. https://doi.org/10.1021/es100067p

Liang S, Xu M, Zhang T (2013) Life cycle assessment of biodiesel production in China. Bioresour Technol 129:72–77. https://doi.org/10.1016/j.biortech.2012.11.037

Vidal-Benavides AI, Quintero-Díaz JC, Herrera-Orozco I (2017) Life cycle analysis of biodiesel production from used vegetal oil. DYNA 84(201):155–162. https://doi.org/10.15446/dyna.v84n201.54469

Foteinis S, Chatzisymeon E, Litinas A, Tsoutsos T (2020) Used-cooking-oil biodiesel: Life cycle assessment and comparison with first- and third-generation biofuel. Renew Energy 153:588–600. https://doi.org/10.1016/j.renene.2020.02.022

Rajaeifar M, Tabatabaei M, Abdi R, Latifi AM, Saberi F, Askari M, Zenouzi A, Ghorbani M (2017) Attributional and consequential environmental assessment of using waste cooking oil- and poultry fat-based biodiesel blends in urban buses: a real-world operation condition study. Biofuel Res J 4(3):638–653. https://doi.org/10.18331/BRJ2017.4.3.3

Ripa M, Buonaurio C, Mellino S, Fiorentino G, Ulgiati S (2014) Recycling waste cooking oil into biodiesel: A life cycle assessment. Int J Performability Eng 10(4):347–356 http://www.ijpe-online.com/EN/10.23940/ijpe.14.4.p347.mag

Lombardi L, Mendecka B, Carnevale E (2018) Comparative life cycle assessment of alternative strategies for energy recovery from used cooking oil. J Environ Manage 216:235–245. https://doi.org/10.1016/j.jenvman.2017.05.016

Mendecka B, Lombardi L, Kozioł J (2020) Probabilistic multi-criteria analysis for evaluation of biodiesel production technologies from used cooking oil. Renew Energy 147:2542–2553. https://doi.org/10.1016/j.renene.2017.05.037

Eguchi S, Kagawa S, Okamoto S (2015) Environmental and economic performance of a biodiesel plant using waste cooking oil. J Clean Prod 101:245–250. https://doi.org/10.1016/j.jclepro.2015.04.008

Yano J, Aoki T, Nakamura K, Yamada K, Ichi Sakai S (2015) Life cycle assessment of hydrogenated biodiesel production from waste cooking oil using the catalytic cracking and hydrogenation method. Waste Manag 38(1):409–423. https://doi.org/10.1016/j.wasman.2015.01.014

Chung ZL, Tan YH, Chan YS, Kansedo J, Mubarak NM, Ghasemi M, Abdullah MO (2019) Life cycle assessment of waste cooking oil for biodiesel production using waste chicken eggshell derived CaO as catalyst via transesterification. Biocatal Agric Biotechnol 21:101317. https://doi.org/10.1016/j.bcab.2019.101317

Morais S, Mata TM, Martins AA, Pinto GA, Costa CAV (2010) Simulation and life cycle assessment of process design alternatives for biodiesel production from waste vegetable oils. J Clean Prod 18(13):1251–1259. https://doi.org/10.1016/j.jclepro.2010.04.014

Varanda MG, Pinto G, Martins F (2011) Life cycle analysis of biodiesel production. Fuel Process Technol 92(5):1087–1094. https://doi.org/10.1016/j.fuproc.2011.01.003

Caldeira C, Freire F, Queiro J (2015) Biodiesel from waste cooking oils in Portugal: alternative collection systems. Waste Biomass Valor 6(5):771–779. https://doi.org/10.1007/s12649-015-9386-z

Caldeira C, Queirós J, Noshadravan A, Freire F (2016) Incorporating uncertainty in the life cycle assessment of biodiesel from waste cooking oil addressing different collection systems Resour. Conserv Recycl 112:83–92. https://doi.org/10.1016/j.resconrec.2016.05.005

Chua CBH, Lee HM, Low JSC (2010) Life cycle emissions and energy study of biodiesel derived from waste cooking oil and diesel in Singapore. Int J Life Cycle Assess 15(4):417–423. https://doi.org/10.1007/s11367-010-0166-5

Vinyes E, Oliver-Solà J, Ugaya C, Rieradevall J, Gasol CM (2013) Application of LCSA to used cooking oil waste management. Int J Life Cycle Assess 18(2):445–455. https://doi.org/10.1007/s11367-012-0482-z

Escobar N, Ribal J, Clemente G, Sanjuán N (2014) Consequential LCA of two alternative systems for biodiesel consumption in Spain, considering uncertainty. J Clean Prod 79:61–73. https://doi.org/10.1016/j.jclepro.2014.05.065

Khoo HH, Tan RBH, Tan Z (2009) GHG intensities from the life cycle of conventional fuel and biofuels. WIT Trans Ecol Environ 123:329–340. https://doi.org/10.2495/AIR090301

Khang DS, Tan RR, Uy OM, Promentilla MA, Tuan PD, Abe N, Razon LF (2019) Design of experiments for global sensitivity analysis in life cycle assessment: the case of biodiesel in Vietnam. Resour Conserv Recycl 119:12–23. https://doi.org/10.1016/j.resconrec.2016.08.016

Sala S, Ciuffo B, Nijkamp P (2015) A systemic framework for sustainability assessment. Ecol Econ 119:314–325. https://doi.org/10.1016/j.ecolecon.2015.09.015

Seber G, Malina R, Pearlson MN, Olcay H, Hileman JI, Barrett SRH (2014) Environmental and economic assessment of producing hydroprocessed jet and diesel fuel from waste oils and tallow. Biomass Bioenergy 67:108–118. https://doi.org/10.1016/j.biombioe.2014.04.024

Spencer S, Scott M, Macken N (2018) A life cycle assessment of biofuel produced from waste cooking oil. ASME Int Mech Eng Congr Expo Proc 6A-144113:1–8. https://doi.org/10.1115/IMECE2018-86301

Li H, Ebner J, Ren P, Campbell L, Dizayi B, Hadavi S (2014) Determination of carbon footprint using LCA method for straight used cooking oil as a fuel in HGVs. SAE Int J Fuels Lubr 7(2):623–630. https://doi.org/10.4271/2014-01-1948

Bezergianni S, Dimitriadis A, Chrysikou LP (2014) Quality and sustainability comparison of one- vs. two-step catalytic hydroprocessing of waste cooking oil. Fuel 118:300–307. https://doi.org/10.1016/j.fuel.2013.10.078

Intarapong P, Papong S, Malakul P (2016) Comparative life cycle assessment of diesel production from crude palm oil and waste cooking oil via pyrolysis. Int J Energy Res 40(5):702–713. https://doi.org/10.1002/er.3433

Ortner ME, Müller W, Schneider I, Bockreis A (2016) Environmental assessment of three different utilization paths of waste cooking oil from households. Resour Conserv Recycl 106:59–67. https://doi.org/10.1016/j.resconrec.2015.11.007

Moretti C, Junginger M, Shen L (2020) Environmental life cycle assessment of polypropylene made from used cooking oil. Resour Conserv Recycl 157:104750. https://doi.org/10.1016/j.resconrec.2020.104750

Behrends FJF (2018) Greenhouse gas footprint of biodiesel production from used cooking oils. Doctoral dissertation. Utrecht University, Utrecht, The Netherlands

Giovannoni E, Fabietti G (2013) What is sustainability? A review of the concept and its applications. In: Busco C, Frigo ML, Riccaboni A, Quattrone P (eds) Integrated reporting: concepts and cases that redefine corporate accountability. Springer, pp 21–40. https://doi.org/10.1007/978-3-319-02168-3_2

Kopfmüller J, Brandl V, Jörissen J, Paetau M, Banse G, Coenen R, Grunwald A (2001) Nachhaltige Entwicklung integrativ betrachtet - Konstitutive Elemente, Regeln, Indikatoren. Ed. Sigma, Berlin

Torres PA (2019) Life Cycle Analysis of the harnessing and valorization of used cooking oils in Bogota as oleochemical feedstock. (In Spanish) Master’s Dissertation,. National University of Colombia, Bogota, Colombia

Bart JCJ, Palmeri N, Cavallaro S (2010) Biodiesel science and technology. From Soil to Oil. Woodhead Publishing, Sawston, UK

Escobar N (2015) Contribution to the environmental impact assessment of biodiesel in the context of Spain. Doctoral dissertation. Polytechnical University of Valencia, Valencia, Spain

Soley, R. 2019. Bioenergy in Spain: ¿Is really an alternative? (In Spanish). Ecologistas en Acción Ed. Madrid, Spain.

TREID. 2020. This is the commercial relationship of Colombia and Spain in first quarter 2019 and 2020. (In Spanish) [Online]. Available: https://www.treid.co/post/asi-es-la-relacion-comercial-de-colombia-y-espana-en-el-primer-semestre-de-2019-y-2020. (Accessed march 1, 2022).

Grunwald A (2012) Sustainability assessment of technologies — an integrative approach. In: Ghenai C (ed) Rijeka sustainable development — energy, engineering and technologies — manufacturing and environment. InTech, London, UK, pp 35–62

Ott K (2006) Friendly Fire Bemerkungen zum integrativen Konzept nachhaltiger Entwicklung. In: Kopfmüller J (ed) Ein Konzept auf dem Prüfstand Das integrative Nachhaltigkeitskonzept in der Forschungspraxis. Edition Sigma, Berlin, pp 63–82. https://doi.org/10.5771/9783845267685-63

Andes L, Lützkendorf T, Ströbele B, Kopfmüller J, Rösch C (2019) Methodensammlung zur Nachhaltigkeitsbewertung - Grundlagen, Indikatoren, Hilfsmittel. Karlsruher Institut für Technologie KIT, Karlsruhe

Hacking T, Guthrie P (2008) A framework for clarifying the meaning of triple bottom-line, integrated, and sustainability assessment. Environ Impact Assess Rev 28(2–3):73–89. https://doi.org/10.1016/j.eiar.2007.03.002

Grunwald A, Kopfmüller J (2012) Nachhaltigkeit, 2nd edn. Campus Verlag. Frankfurt, Germany, Frankfurt am Main

Ren J, Scipioni A, Manzardo A, Liang H (2020) Biofuels for a more sustainable future: life cycle sustainability assessment and multi-criteria decision making. Elsevier, Amsterdam, Netherlands. https://doi.org/10.1016/C2017-0-03041-0

Hjuler SV, Hansen SB (2018) LCA of biofuels and biomaterials. In: Hauschild MZ, Rosenbaum RK, Olsen SI (eds) Life cycle assessment: theory and practice. Springer Nature, Cham, Switzerland. https://doi.org/10.1007/978-3-319-56475-3

Pastakia CMR (1998) The rapid impact assessment matrix (RIAM) — a new tool for environmental impact assessment. In: Jensen K (ed) Environmental impact assessment using the rapid impact assessment matrix (RIAM). Olsen & Olsen, Fredensborg, pp 8–17

Leopold LB, Clarke FE, Hanshaw BB, Balsley JR (1971) A procedure for evaluating environmental impact. Geol Surv Circ 645. https://doi.org/10.3133/cir645

Rapier, R. 2020. Fossil fuels still supply 84 percent of world energy — and other eye openers from BP’s annual review. Forbes, 2020. [Online]. Available: https://www.forbes.com/sites/rrapier/2020/06/20/bp-review-new-highs-in-global-energy-consumption-and-carbon-emissions-in-2019/?sh=71778f9366a1 (Accessed Dec. 22, 2022).

Hosseinzadeh-Bandbafha H, Nizami AS, Kalogirou SA, Gupta VK, Park YK, Fallahi A, Sulaiman A, Ranjbari M, Rahnama H, Aghbashlo M, Peng W, Tabatabaei M (2022) Environmental life cycle assessment of biodiesel production from waste cooking oil: a systematic review. Renew Sustain Energy Rev 161:112411. https://doi.org/10.1016/j.rser.2022.112411

European Parliament. 2018. Directive (EU) 2018/2001 of the European Parliament and of the Council on the promotion of the use of energy from renewable sources. [Online]. Available: http://data.europa.eu/eli/dir/2018/2001/oj (Accessed Dec. 22, 2022).

DNP (2018) National voluntary report - Colombia 2018 (In Spanish). National Planning Department, Colombia

Fingas M (2015) Vegetable oil spills: oil properties and behavior. In: Fingas M (ed) Handbook of oil spill science and technology. John Wiley & Sons, Inc, NY. USA, pp 79–91. https://doi.org/10.1002/9781118989982.ch4

Li Z, Wrenn BA (2004) Effects of ferric hydroxide on the anaerobic biodegradation kinetics and toxicity of vegetable oil in freshwater sediments. Water Res 38(18):3859–3868. https://doi.org/10.1016/j.watres.2004.07.010

Thode Filho S, de Paiva JL, Franco HA, Perez DV, da Costa Marques MR (2017) Environmental impacts caused by residual vegetable oil in the soil-plant system. Ciência e Nat 39(3):748–757. https://doi.org/10.5902/2179460X27645

Mosquera M, Ruiz E, Castro LE, Lopez DF, Munévar DE (2019) Estimation of production costs for Colombian oil palm growers that have adopted good agricultural practices. Palmas 40(2):3–20

Seeboldt S, Abdala YS (2010) Responsibility and sustainability of the palm oil industry: are the principles and criteria of the RSPO feasible in Colombia? OXFAM NOVIB, The Hague, Netherlands

Ηatzisymeon M, Kamenopoulos S, Tsoutsos T (2019) Risk assessment of the life-cycle of the used cooking oil-to-biodiesel supply chain. J Clean Prod 217:836–843. https://doi.org/10.1016/j.jclepro.2019.01.088

Olivares, R. D. C., Rivera, S. S., Núñez, J. E., Leod, M. 2014. Analysis of active failures and latent conditions on biodiesel production facilities. Proceedings of the World Congress on Engineering 2014 Vol II, WCE 2014, July 2 - 4, 2014, London, U.K.

CCS. 2020. The CCS and ILO propose a pact for health and safety in the countryside. [Online]. Available: https://ccs.org.co/el-ccs-y-la-oit-trabajo-proponen-al-gobierno-un-pacto-por-la-seguridad-y-salud-en-el-campo/ (Accessed march 1, 2022).

Gallo O, Hawkins D, Luna-García JE, Torres-Tovar M (2020) Palm oil production in Colombia: decent and healthy work? Rev Cienc Salud 18(2):1–23. https://doi.org/10.12804/revistas.urosario.edu.co/revsalud/a.9260

Castiblanco C, Hortúa S (2012) Biofuels’ energetic paradigm and its implications: a global overview and the Colombian case. Rev Gestión y Ambient 15(3):5–26

Aghbashlo M, Hosseinzadeh-Bandbafha H, Shahbeik H, Tabatabaei M (2022) The role of sustainability assessment tools in realizing bioenergy and bioproduct systems. Biofuel Res J 35:1697–1706. https://doi.org/10.18331/BRJ2022.9.3.5

Acknowledgements

The authors gratefully acknowledge TEAM FOODS for kindly supplying the required information for this work.

Funding

Open Access funding provided by Colombia Consortium This research has been partially funded by the Baden-Württemberg Stiftung; by the Royal Academy of Engineering of the UK under the grant IAPP18-19\65; by the Newton Fund Institutional Links grants — Project 526061819; Minciencias contract 584-2020; and by program ECOSNORD corresponding to Minciencias Contract 487-2021.

Author information

Authors and Affiliations

Contributions

Laura C. Casas was responsible for formal analysis, investigation, methodology, writing — original draft, writing — review and editing. Alvaro Orjuela contributed with conceptualization, formal analysis, investigation, methodology, resources, supervision, writing — original draft, writing — review and editing. Witold-Roger Poganietz contributed with conceptualization, formal analysis, investigation, methodology, supervision, review and editing.

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(PDF 200 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Casas, L.C., Orjuela, A. & Poganietz, WR. Sustainability assessment of the valorization scheme of used cooking oils (UCOs): the case study of Bogotá, Colombia. Biomass Conv. Bioref. (2023). https://doi.org/10.1007/s13399-023-03800-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-023-03800-1