Abstract

The growth and development of biomass-based energy are essential conditions for supplementing the renewable energy sector dominated by solar and wind energy. Conversion of rice straw to biogas by anaerobic digestion can play a vital role in enhancing energy security and the share of bioenergy. The biggest hurdle in the process of digestion of lignocellulosic biomass like rice straw is the prerequisite of its pretreatment. Mostly high-power microwave and high-concentration alkaline pretreatment of lignocellulosic biomass have been studied. In the present study, dilute alkaline and low-power microwave techniques for efficient pretreatment of lignocellulosic materials have been considered. Anaerobic digestion of untreated and pretreated rice straws was performed at mesophilic temperature to compare the effectiveness of pretreatment methods for their biogas yield. Biogas obtained from untreated rice straw was found at 213.7 NmL/gVS. Among alkaline pretreatment with dilute NaOH solution of 0.1 to 0.5% concentrations, the best biogas yield of 418.5 NmL/gVS (96% higher than untreated) was obtained from 0.2% alkaline treated rice straw. Out of different microwave pretreatment from 100 to 500 W, the best biogas yields of 458.8 NmL/gVS (114% higher than untreated) were obtained from 300 W pretreated rice straws. The average biomethane content in the biogas generated after alkaline pretreatment was 52%, and in biogas generated after microwave, pretreatment was found to be 50.7%. Microwave pretreatment was found to be slightly better.

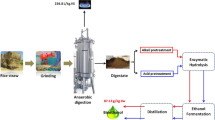

Graphical Abstract

Similar content being viewed by others

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- VS :

-

Volatile solids

- W :

-

Watt

- AD :

-

Anaerobic digestion

- SATAT :

-

Sustainable alternative toward affordable transport

- VFA :

-

Volatile fatty acid

- M :

-

Molar

- N :

-

Normal

- ASTM :

-

American Society for Testing and Material

- ND :

-

Not determined

- C/N :

-

Carbon to nitrogen ratio

- ISR :

-

Inoculums to substrate ratio

- CHNS :

-

Carbon hydrogen nitrogen and sulfur

- TCD :

-

Thermal conductivity detector

- PID :

-

Proportional integral derivative

- SAIF :

-

Sophisticated analytical instrument facility

References

Klare MT (2014) Twenty-first-century energy wars: how oil and gas are fuelling global conflicts. Energy post. EU. https://energypost.eu/twenty-first-century-energy-wars-oil-gas-fuelling-global-conflicts/. Accessed 24 Feb 2022

Nguyen VH, Topno S, Balingbing C et al (2016) Generating a positive energy balance from using rice straw for anaerobic digestion. Energy Rep 2:117–122

Ministry of Petroleum and Natural Gas, Govt. of India (2018) Petroleum Minister to launch SATAT initiative to promote compressed bio-gas as an alternative, green transport fuel. Press Inf Bur 2–3

Kumar Sakhiya A, Anand A, Aier I et al (2020) Sustainable utilization of rice straw to mitigate climate change: a bioenergy approach. Mater Today Proc 46:5366–5371

Ministry of Agriculture and Farmers Welfare, Govt. of India (2021) Third advance estimates of principal crops for 2020–21. https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1826742. Accessed 2 June 2022

Singh RB, Saha RC, Singh M, Chandra D, Shukla SG, Walli TK, Pradhan PK, Kessels HPP (1995) Rice straw, its production, and utilization in India. In: Handbook for straw feeding systems in livestock production. ICAR, pp 325–339. https://edepot.wur.nl/333859

Patel KS, Sahu PK (2015) Combustion characteristics of rice straw calorific valve of rice straw. Int Sci J J Environ Sci: 7–9

Lei Z, Chen J, Zhang Z, Sugiura N (2010) Methane production from rice straw with acclimated anaerobic sludge: effect of phosphate supplementation. Bioresour Technol 101:4343–4348. https://doi.org/10.1016/j.biortech.2010.01.083

Yaru SS, Adigan IK, Akintunde MM (2015) Wobbe index determination of cattle dung biogas. Sci Agric 9:65–71. https://doi.org/10.15192/pscp.sa.2015.9.2.7682

Shajahan MSM, Jamal DN, Mathew J, Akbar AAA, Shiv Kumar A, Hammed MSAS (2022) Improvement in the efficiency of thermal power plant using optimization and robust controller. Case Stud Therm Eng 33:10191

Mirmohamadsadeghi S, Karimi K, Zamani A et al (2014) Enhanced solid-state biogas production from lignocellulosic biomass by organosolv pretreatment. Biomed Res Int 2014. https://doi.org/10.1155/2014/350414

Moodley P, Gueguim Kana EB (2017) Development of steam or microwave-assisted sequential salt-alkali pretreatment for lignocellulosic waste: effect on delignification and enzymatic hydrolysis. Energy Convers Manag 148:801–808. https://doi.org/10.1016/j.enconman.2017.06.056

Xu H, Li Y, Hua D et al (2020) Enhancing the anaerobic digestion of corn stover by chemical pretreatment with the black liquor from the paper industry. Bioresour Technol 306:123090. https://doi.org/10.1016/j.biortech.2020.123090

Yuan H, Guan R, Wachemo AC et al (2020) Improving physicochemical characteristics and anaerobic digestion performance of rice straw via ammonia pretreatment at varying concentrations and moisture levels. Chinese J Chem Eng 28:541–547. https://doi.org/10.1016/j.cjche.2019.07.009

Akyol Ç, Ince O, Bozan M et al (2019) Biological pretreatment with Trametes Versicolor to enhance methane production from lignocellulosic biomass: a metagenomic approach. Ind Crops Prod 140. https://doi.org/10.1016/j.indcrop.2019.111659

Hoang AT, Ong HC, Fattah IMR et al (2021) Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process Technol 223:106997. https://doi.org/10.1016/j.fuproc.2021.106997

Deshmukh A, Nagarnaik PB, Daryapurkar RA (2016) Assessment of biogas generation potential of napier grass. Int Conf Emerg Trends Eng Technol ICETET 2016-March 68–71. https://doi.org/10.1109/ICETET.2015.35

Shetty DJ, Kshirsagar P, Tapadia-Maheshwari S et al (2017) Alkali pretreatment at ambient temperature: a promising method to enhance biomethanation of rice straw. Bioresour Technol 226:80–88. https://doi.org/10.1016/j.biortech.2016.12.003

Kainthola J, Shariq M, Kalamdhad AS, Goud VV (2019) Enhanced methane potential of rice straw with microwave-assisted pretreatment and its kinetic analysis. J Environ Manage 232:188–196. https://doi.org/10.1016/j.jenvman.2018.11.052

Mancini G, Papirio S, Riccardelli G et al (2018) Trace elements dosing and alkaline pretreatment in the anaerobic digestion of rice straw. Bioresour Technol 247:897–903. https://doi.org/10.1016/j.biortech.2017.10.001

Hang Shu C, Jaiswal R, Syong Shih J (2015) Improving biodegradation of rice straw using alkaline and Aspergillus niger pretreatment for methane production by anaerobic co-digestion. J Bioprocess Biotech 5:. https://doi.org/10.4172/2155-9821.1000256

Hoang AT, Nižetić S, Ong HC, et al (2021) Insight into the recent advances of microwave pretreatment technologies for the conversion of lignocellulosic biomass into sustainable biofuel. Chemosphere 281. https://doi.org/10.1016/j.chemosphere.2021.130878

Elalami D, Carrere H, Abdelouahdi K, Garcia-Bernet D, Peydecstaing J, Vaca-Medina G, Jaroul Y, Oukarroum A, Barakat A (2020) Mild microwaves, ultrasonic and alkaline pretreatments for improving methane production: impact on biochemical and structural properties of olive pomace. Bioresour Technol 299:122591

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48. https://doi.org/10.1016/j.biortech.2015.08.085

Khalid MJ, Zeshan WA, Nawaz I (2019) Synergistic effect of alkaline pretreatment and magnetite nanoparticle application on biogas production from rice straw. Bioresour Technol 275:288–296. https://doi.org/10.1016/j.biortech.2018.12.051

Du J, Qian Y, Xi Y, Lü X (2019) Hydrothermal and alkaline thermal pretreatment at a mild temperature in the solid state for physicochemical properties and biogas production from anaerobic digestion of rice straw. Renew Energy 139:261–267. https://doi.org/10.1016/j.renene.2019.01.097

Fernández-Cegrí V, De La Rubia MA, Raposo F, Borja R (2012) Impact of ultrasonic pretreatment under different operational conditions on the mesophilic anaerobic digestion of sunflower oil cake in batch mode. Ultrason Sonochem 19:1003–1010. https://doi.org/10.1016/j.ultsonch.2012.02.001

Holliger C, Alves M, Andrade D et al (2016) Towards a standardization of biomethane potential tests. Water Sci Technol 74:2515–2522. https://doi.org/10.2166/wst.2016.336

Sluiter A, Hames B, Ruiz R et al (2012) Determination of structural carbohydrates and lignin in biomass: TP-510–42618

Naik GP, Poonia AK, Chaudhari PK (2022) Role of extractives in biomethane production : characterization and comparison of different varieties of rice straw. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-022-02375-1

De Vrieze J, Hennebel T, Boon N, Verstraete W (2012) Methanosarcina: The rediscovered methanogen for heavy duty biomethanation. Bioresour Technol 112:1–9

Sabeeh M, Zeshan Liaquat R, Maryam A (2020) Effect of alkaline and alkaline-photocatalytic pretreatment on characteristics and biogas production of rice straw. Bioresour Technol 309:123449

Norazlina I, Dhinashini RS, Nurhafizah I et al (2021) Extraction of xylose from rice straw and lemongrass via microwave-assisted. Mater Today Proc 48:784–789

Haryanto A, Sugar BP, Telaumbanua M, Rosadi RAB (2018) Anaerobic co-digestion of cow dung and rice straw to produce biogas using semi-continuous flow digester: effect of urea addition. IOP Conf Ser Earth Environ Sci 147. https://doi.org/10.1088/1755-1315/147/1/012032

Buswell AM, Mueller HF (1952) Mechanism of methane fermentation. Ind Eng Chem 44:550–552

Achinas S, Euverink GJW (2016) Theoretical analysis of biogas potential prediction from agricultural waste. Resource-Efficient Technol 2(2016):143–147

Naik GP, Poonia AK, Chaudhari PK (2021) Alkaline electro-hydrolysis pretreatment of rice straw for enhanced biogas production under ambient temperature. Int J Chem React Eng 99:1–11

Acknowledgements

We acknowledge the role of SAIF IIT Bombay for their support in getting elemental analysis of rice straw, and Vachan dairy and food products limited Kharora Raipur for providing inoculums for anaerobic digestion. The study was carried out at NIT Raipur by extending laboratory and other infrastructural support and facilities for research work.

Author information

Authors and Affiliations

Contributions

Gopal P. Naik conceived, designed, conducted the study, and drafted the manuscript. Anil K. Poonia supervised, resourced, and validated the work. Parmesh K. Chaudhari was involved in editing drafts and analysis of data. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Naik, G.P., Poonia, A.K. & Chaudhari, P.K. Maximization of biogas by minimal microwave and alkaline pretreatment of rice straw. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03539-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03539-1