Abstract

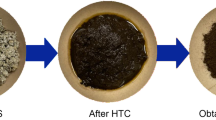

In this study, the energy balance and techno-economic analysis of hydrothermal carbonization (HTC) of avocado stone (AS) were carried out to determine the use of hydrochar as a solid fuel. The experimental data obtained for HTC of AS were used to adjust a simulation model at an industrial scale using Aspen Plus®. The process was simulated, including all required equipment and stages to transform this biomass into dry hydrochar. The simulation result showed that the HTC process is energetically efficient for biomass water ratios above 10 wt.% at different operating temperatures (190–250 °C). The hydrochar obtained at 250 °C has a higher heating value (HHV) of up to 25.81 MJ/kg, and the energy yield of the process can reach 63.45%, while thermal efficiency reached up to 3.56 kWh of hydrochar per kWh of energy used in the process. In addition, the techno-economic analysis of the process showed that the process is economically feasible using hydrochar as pellet which has a competitive price compared to pelletized bulk pine wood, with hydrochar cost 9.64 $/GJHHV. Moreover, under the conditions studied, the initial capital recovery period was 3.7 years. This study could encourage the development of HTC plants and, therefore, the market for hydrochar pellets.

Similar content being viewed by others

References

Missaoui A, Bostyn S, Belandria V, Cagnon B, Sarh B et al (2017) Hydrothermal carbonization of dried olive pomace: energy potential and process performances. J Anal Appl Pyrol 128:281–290

Kumari D, Singh R (2018) Pretreatment of lignocellulosic wastes for biofuel production: a critical review. Renew Sustain Energy Rev 90:877–891

Foust TD, Aden A, Dutta A, Phillips S (2009) An economic and environmental comparison of a biochemical and a thermochemical lignocellulosic ethanol conversion processes. Cellulose 16(4):547–565

Mazumder S, Saha P, McGaughy K, Saba A, Reza MT (2022) Technoeconomic analysis of co-hydrothermal carbonization of coal waste and food waste. Biomass Conversion and Biorefinery 12:39–49

Yang L, Lu C, Gao Y, Lin Y, Xu J et al (2021) Hydrogen-rich gas production from the gasification of biomass and hydrothermal carbonization (HTC) aqueous phase. Biomass Conversion and Biorefinery. https://doi.org/10.1007/s13399-020-01197-9

Naderi M, Vesali-Naseh M (2019) Hydrochar-derived fuels from waste walnut shell through hydrothermal carbonization: characterization and effect of processing parameters. Biomass Conversion and Biorefinery 11:1443–1451

Liu Z, Balasubramanian R (2012) Hydrothermal carbonization of waste biomass for energy generation. Procedia Environ Sci 16:159–166

Heidari M, Salaudeen S, Dutta A, Acharya B (2018) Effects of process water recycling and particle sizes on hydrothermal carbonization of biomass. Energy Fuels 32(11):11576–11586

Hitzl M, Corma A, Pomares F, Renz M (2015) The hydrothermal carbonization (HTC) plant as a decentral biorefinery for wet biomass. Catal Today 257:154–159

Xiao L-P, Shi Z-J, Xu F, Sun R-C (2012) Hydrothermal carbonization of lignocellulosic biomass. Biores Technol 118:619–623

Atallah E, Kwapinski W, Ahmad MN, Leahy J, Alaả H et al (2019) Hydrothermal carbonization of olive mill wastewater: liquid phase product analysis. Journal of Environmental Chemical Engineering 7(1):102833

Islam MA, Akber MA, Limon SH, Akbor MA, Islam MA (2019) Characterization of solid biofuel produced from banana stalk via hydrothermal carbonization. Biomass Convers Biorefinery 9(4):651–658

dos Santos JV, Fregolente LG, Laranja MJ, Moreira AB, Ferreira OP et al (2022) Hydrothermal carbonization of sugarcane industry by-products and process water reuse: structural, morphological, and fuel properties of hydrochars. Biomass Conversion and Biorefinery 12:153–161

Rasam S, Moraveji MK, Soria-Verdugo A, Salimi A (2021) Synthesis, characterization and absorbability of Crocus sativus petals hydrothermal carbonized hydrochar and activated hydrochar. Chem Eng Process-Process Intensif 159:108236

Mahmood R, Parshetti GK, Balasubramanian R (2016) Energy, exergy and techno-economic analyses of hydrothermal oxidation of food waste to produce hydro-char and bio-oil. Energy 102:187–198

Funke A, Ziegler F (2010) Hydrothermal carbonization of biomass: a summary and discussion of chemical mechanisms for process engineering. Biofuels, Bioprod Biorefin 4(2):160–177

Lucian M, Fiori L (2017) Hydrothermal carbonization of waste biomass: process design, modeling, energy efficiency and cost analysis. Energies 10(2):211

Burguete P, Corma A, Hitzl M, Modrego R, Ponce E et al (2016) Fuel and chemicals from wet lignocellulosic biomass waste streams by hydrothermal carbonization. Green Chem 18(4):1051–1060

Stemann J, Erlach B, Ziegler F (2013) Hydrothermal carbonisation of empty palm oil fruit bunches: laboratory trials, plant simulation, carbon avoidance, and economic feasibility. Waste Biomass Valorization 4(3):441–454

Benavente V, Calabuig E, Fullana A (2015) Upgrading of moist agro-industrial wastes by hydrothermal carbonization. J Anal Appl Pyrol 113:89–98

McLeod L, Flores D (2017) Mexico: avocado annual. USDA-Foreing-Agricultural-Service. https://www.fas.usda.gov/data/mexico-avocado-annual-2. Accessed 25 Oct 2020

Ceballos AM, Montoya S (2013) Evaluación química de la fibra en semilla, pulpa y cáscara de tres variedades de aguacate. Biotecnol en el sect agropecuario y agroindustrial 11(1):103–112

Sangare D, Bostyn S, Moscosa-Santillan M, Belandria V, Gökalp I (2021) Quantification and kinetic study of the main compounds in biocrude produced by hydrothermal carbonization of lignocellulosic biomass. Bioresource Technology Reports 15(1):100770

Parshetti GK, Hoekman SK, Balasubramanian R (2013) Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Biores Technol 135:683–689

Khan N, Mohan S, Dinesha P (2021) Regimes of hydrochar yield from hydrothermal degradation of various lignocellulosic biomass: a review. Journal of Cleaner Production 288:125629

Libra JA, Ro KS, Kammann C, Funke A, Berge ND et al (2011) Hydrothermal carbonization of biomass residuals: a comparative review of the chemistry, processes and applications of wet and dry pyrolysis. Biofuels 2(1):71–106

Jain A, Balasubramanian R, Srinivasan M (2016) Hydrothermal conversion of biomass waste to activated carbon with high porosity: a review. Chem Eng J 283:789–805

Pavlovic I, Knez Z, Skerget M (2013) Hydrothermal reactions of agricultural and food processing wastes in sub-and supercritical water: a review of fundamentals, mechanisms, and state of research. J Agric food Chem 61(34):8003–8025

Kambo HS, Dutta A (2015) A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew Sustain Energy Rev 45:359–378

Reza MT, Andert J, Wirth B, Busch D, Pielert J et al (2014) Hydrothermal carbonization of biomass for energy and crop production. Appl Bioenergy 1(1):11–29

Guo S, Dong X, Wu T, Shi F, Zhu C (2015) Characteristic evolution of hydrochar from hydrothermal carbonization of corn stalk. J Anal Appl Pyrol 116:1–9

Lopez-Velazquez M, Santes V, Balmaseda J, Torres-Garcia E (2013) Pyrolysis of orange waste: a thermo-kinetic study. J Anal Appl Pyrol 99:170–177

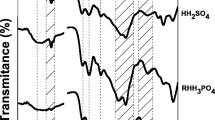

Pandey K, Pitman A (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegradation 52(3):151–160

Himmelsbach DS, Khalili S, Akin DE (2002) The use of FT-IR microspectroscopic mapping to study the effects of enzymatic retting of flax (Linum usitatissimum L) stems. J Sci Food Agric 82(7):685–696

Kubovský I, Kačíková D, Kačík F (2020) Structural changes of oak wood main components caused by thermal modification. Polymers 12(2):485

Charis G, Danha G, Muzenda E (2020) Characterizations of biomasses for subsequent thermochemical conversion: a comparative study of pine sawdust and Acacia Tortilis. Processes 8(5):546

He C, Lin H, Dai L, Qiu R, Tang Y et al (2020) Waste shrimp shell-derived hydrochar as an emergent material for methyl orange removal in aqueous solutions. Environment international 134:105340

Popescu C-M, Singurel G, Popescu M-C, Vasile C, Argyropoulos DS et al (2009) Vibrational spectroscopy and X-ray diffraction methods to establish the differences between hardwood and softwood. Carbohyd Polym 77(4):851–857

Braovac S, Kutzke H (2012) The presence of sulfuric acid in alum-conserved wood–Origin and consequences. J Cult Herit 13(3):S203–S208

Lucian M, Volpe M, Gao L, Piro G, Goldfarb JL et al (2018) Impact of hydrothermal carbonization conditions on the formation of hydrochars and secondary chars from the organic fraction of municipal solid waste. Fuel 233:257–268

Becker R, Dorgerloh U, Paulke E, Mumme J, Nehls I (2014) Hydrothermal carbonization of biomass: major organic components of the aqueous phase. Chem Eng Technol 37(3):511–518

Wirth B, Mumme J, Erlach B (2012) Anaerobic treatment of waste water derived from hydrothermal carbonization. 20th European Biomass Conference and Exhibition. https://doi.org/10.5071/20thEUBCE2012-2AO.4.3

Uddin MH, Reza MT, Lynam JG, Coronella CJ (2014) Effects of water recycling in hydrothermal carbonization of loblolly pine. Environ Prog Sustainable Energy 33(4):1309–1315

Sliz M, Wilk M (2020) A comprehensive investigation of hydrothermal carbonization: energy potential of hydrochar derived from Virginia mallow. Renewable Energy 156:942–950

Stemann J, Putschew A, Ziegler F (2013) Hydrothermal carbonization: process water characterization and effects of water recirculation. Biores Technol 143:139–146

Chae K, Jang A, Yim S, Kim IS (2008) The effects of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Biores Technol 99(1):1–6

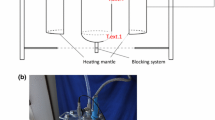

Sangare D, Bostyn S, Moscosa-Santillan M, Gökalp I (2021) Hydrodynamics, heat transfer and kinetics reaction of CFD modeling of a batch stirred reactor under hydrothermal carbonization conditions. Energy 219:119635

Liu Z, Quek A, Hoekman SK, Balasubramanian R (2013) Production of solid biochar fuel from waste biomass by hydrothermal carbonization. Fuel 103:943–949

Yan W, Acharjee TC, Coronella CJ, Vasquez VR (2009) Thermal pretreatment of lignocellulosic biomass. Environ Progress Sustain Energy: Off Publ Am Ins Chem Eng 28(3):435–440

Thomsen MH, Thygesen A, Thomsen AB (2008) Hydrothermal treatment of wheat straw at pilot plant scale using a three-step reactor system aiming at high hemicellulose recovery, high cellulose digestibility and low lignin hydrolysis. Biores Technol 99(10):4221–4228

Turton R, Shaeiwitz JA, Bhattacharyya D, Whiting WB (2018) Analysis, synthesis and design of chemical processes. Pearson, Michigan

Véliz-Jaime MY, González-Diaz Y, Martínez-Despaigne Y (2019) Evaluación técnica y económica del proyecto de obtención de aceites esenciales. Tecnología Química 39(1):207–220

Baasel WD (1989) Preliminary chemical engineering plant design. Springer, New York

Turton R, Bailie RC, Whiting WB, Shaeiwitz JA (2008) Analysis, synthesis and design of chemical processes. Pearson, Michigan

Office of Strategic Iniciatives (2019) Wood pellet prices. New Hampshire government website. https://www.nh.gov/osi/energy/energy-nh/fuel-prices/wood-pellet-prices.htm. Accessed 26 June 2021

Pellet MX (2021) Pellet México.https://pellet.mx/. Accessed 2 July 2021

Trading Economics (2021) Coal markets. https://tradingeconomics.com/commodity/coal. Accessed 4 July 2021

Acknowledgements

The authors would like to thank the Institute of Metallurgy of UASLP for the help and equipment provided.

Funding

Diakaridia Sangaré grateful to CONACYT (Consejo Nacional de Ciencia y Tecnología de México) for granting the scholarship No. 659624. The authors are grateful to ICARE—CNRS- France and the Région Centre-Val de Loire for financial support within the INFLUX project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sangaré, D., Moscosa-Santillan, M., Aragón Piña, A. et al. Hydrothermal carbonization of biomass: experimental study, energy balance, process simulation, design, and techno-economic analysis. Biomass Conv. Bioref. 14, 2561–2576 (2024). https://doi.org/10.1007/s13399-022-02484-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02484-3