Abstract

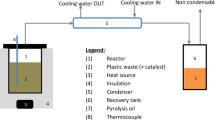

In this study, poplar wood and PET were co-pyrolysed in a fixed-bed reactor in the absence/presence of zeolite (A4 type), aiming to understand the migration pathway of oxygen from both oxygen-containing feedstocks into products. The results indicated that both co-pyrolysis and the zeolite catalyst affected the properties of the products. Comparing to single feedstock, the co-pyrolysis enhanced the yields of tar, while reduced the formation of char, and wax. In addition, the co-pyrolysis decreased the abundance of oxygen-containing and unsaturated species in the tar, and oxygen migrated from feedstock mainly into gas phase in the form of CO and CO2. Zeolite further enhanced the rate of cracking, reducing the yield of char and wax, while increasing the formation of gases. The high rate of cracking/deoxygenation reactions over the zeolite catalyst led to the formation of more light organics, which were mainly saturated aliphatics or aromatics, in the tar. In addition, the zeolite catalyst changed the structure of char, but it did not affect the structure of wax significantly. Little amount of oxygen-containing coke with mainly organized aromatic structure was formed. Zeolite enhanced the migration of oxygen into char and coke. A substantial amount of monoaromatics were formed inside the tar.

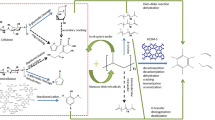

Graphical abstract

Similar content being viewed by others

References

Chamas A, Moon H, Zheng J, Qiu Y, Tabassum T, Jang JH, Abu-Omar M, Scott SL, Suh S (2020) Degradation rates of plastics in the environment. ACS Sustain Chem Eng 8:3494–3511

Panahi L, Gholizadeh M, Hajimohammadi R (2020) Investigating the degradability of polyethylene using starch, oxo-material, and polylactic acid under the different environmental conditions. Asia-Pac J Chem Eng 15:1–12

Li C, Zhang C, Gholizadeh M, Hu X (2020) Different reaction behaviours of light or heavy density polyethylene during the pyrolysis with biochar as the catalyst. J Hazard Mater 339:1–15

Nanda S, Berruti F (2020) Municipal solid waste management and landfilling technologies: a review. Environ Chem Lett 1:1–24

Vaida D, Lelea D (2017) Municipal solid waste incineration: recovery or disposal. Case study of City Timisoara, Romania. Procedia Eng 181:378–384

Rani DA, Boccaccini AR, Deegan D, Cheeseman CR (2008) Air pollution control residues from waste incineration: current UK situation and assessment of alternative technologies. Waste Manage 28:2279–2292

Mor S, Ravindra K, Dahiya RP, Chandra A (2006) Leachate characterization and assessment of groundwater pollution near municipal solid waste landfill site. Environ Monit Assess 118:435–456

Gholizadeh M, Hu X, Liu Q (2019) A mini review of the specialties of the bio-oils produced from pyrolysis of 20 different biomasses. Renew Sustain Energy Rev 114:1–28

Hasan MDM, Wang XS, Mourant D, Gunawan R, Yu C, Hu X, Kadarwati S, Gholizadeh M, Wu H, Li B, Zhang L, Li C-Z (2017) Grinding pyrolysis of Mallee wood: effects of pyrolysis conditions on the yields of bio-oil and biochar. Fuel Process Technol 167:215–220

Mohan D, Pittman CU, Steele PH (2006) Pyrolysis of wood/biomass for bio-oil: a critical review. Energy Fuels 20:848–889

Hu X, Gholizadeh M (2020) Progress of the applications of bio-oil. Renew Sustain Energy Rev 134:1–27

Czernik S, Bridgwater AV (2004) Overview of applications of biomass fast pyrolysis oil. Energy Fuels 18:590–598

Zacher A, Olarte M, Santosa D, Elliot DC, Jones B (2014) A review and perspective of recent bio-oil hydrotreating research. Green Chem 16:491–515

Han Y, Gholizadeh M, Tran C-C, Kaliaguine S, Li C-Z, Olarte M, Garcia-Perez M (2019) Hydrotreatment of pyrolysis bio-oil: a review. Fuel Process Technol 195:106–140

Ryu HW, Kim DH, Jae J, Lam SS, Park ED, Park Y-K (2020) Recent advances in catalytic co-pyrolysis of biomass and plastic waste for the production of petroleum-like hydrocarbons. Biores Technol 310:1–8

Hassan H, Lim JK, Hameed BH (2016) Recent progress on biomass co-pyrolysis conversion into high-quality bio-oil. Biores Technol 221:645–655

Dorado C, Mullen CA, Boateng AA (2014) H-ZSM5 Catalyzed co-pyrolysis of biomass and plastics. ACS Sustain Chem Eng 2:301–311

Chattopadhyay J, Pathak TS, Srivastava R, Singh AC (2016) Catalytic co-pyrolysis of paper biomass and plastic mixtures (HDPE (high density polyethylene), PP (polypropylene) and PET (polyethylene terephthalate)) and product analysis. Energy 103:513–521

Ozsin G, Putun AE (2018) A comparative study on co-pyrolysis of lignocellulosic biomass with polyethylene terephthalate, polystyrene, and polyvinyl chloride: synergistic effects and product characteristics. J Clean Prod 205:1127–1138

Zhao Y, Wang Y, Duan D, Ruan R, Fan L, Zhou Y, Dai L, Lv J, Liu Y (2018) Fast microwave-assisted ex-catalytic co-pyrolysis of bamboo and polypropylene for bio-oil production. Biores Technol 249:69–75

Suriapparao DV, Boruah B, Raja D, Vinu R (2018) Microwave assisted co-pyrolysis of biomasses with polypropylene and polystyrene for high quality bio-oil production. Fuel Process Technol 175:64–75

Ghorbannezhad P, Park S, Onwudili JA (2020) Co-pyrolysis of biomass and plastic waste over zeolite- and sodium-based catalysts for enhanced yields of hydrocarbon products. Waste Manage 102:909–918

Li J, Yu Y, Li X, Wang W, Yu G, Deng S, Huang J, Wang B, Wang Y (2015) Maximizing carbon efficiency of petrochemical production from catalytic co-pyrolysis of biomass and plastics using gallium-containing MFI zeolites. Appl Catal B 172–173:154–164

Wu F, Ben H, Yang Y, Jia H, Wang R, Han G (2020) Effects of different conditions on co-pyrolysis behavior of corn stover and polypropylene. Polymers 12 9 1–47

Wan J, Jiang J, Zhong Z, Wang K, Wang X, Zhang B, Ruan R, Li M, Ragauskas AJ (2019) Catalytic fast co-pyrolysis of bamboo sawdust and waste plastics for enhanced aromatic hydrocarbons production using synthesized CeO2/γ-Al2O3 and HZSM-5. Energy Convers Manage 196:759–767

Iftikhar H, Zeeshan M, Iqbal S, Muneer B, Razzaq M (2019) Co-pyrolysis of sugarcane bagasse and polystyrene with ex-situ catalytic bed of metal oxides/HZSM-5 with focus on liquid yield. Biores Technol 289:1–9

Luo W, Dong H, Wang T, Zhang S, Zhang D, Li B, Huang S, Hu J, Song M, Zhou Z (2021) Co-pyrolysis of Chinese herb residue and polypropylene over Ni, Fe, Co and Cu/AC: co-production and formation mechanism of carbon nanomaterials, liquid oil and pyrolysis gas. Energy 1:1–10

Li C, Zhang C, Zhang L, Gholizadeh M, Hu X (2020) Catalytic pyrolysis of tire waste: impacts of biochar catalyst on product evolution. Waste Manage 116:9–21

Jia H, Ben H, Luo Y, Wang R (2020) Catalytic fast pyrolysis of poly (ethylene terephthalate) (PET) with zeolite and nickel chloride. Polymers 12:1–14

Hu X, Gholizadeh M (2019) Biomass pyrolysis: a review of the process development and challenges from initial researches up to the commercialisation stage, Journal of Energy. Chemistry 39:109–143

Liang C, Zhang L, Zheng Y, Zhang S, Liu Q, Gao G, Dong D, Wang Y, Xu L, Hu X (2020) Methanation of CO2 over nickel catalysts: impacts of acidic/basic sites on formation of the reaction intermediates. Fuel 262:1–10

Nishu R, Liu MM, Rahman M, Sarker M, Chai C, Li J (2020) Cai, A review on the catalytic pyrolysis of biomass for the bio-oil production with ZSM-5: Focus on structure. Fuel Process Technol 199:1–15

Onwudili JA, Muhammad C, Williams PT (2019) Influence of catalyst bed temperature and properties of zeolite catalysts on pyrolysis-catalysis of a simulated mixed plastics sample for the production of upgraded fuels and chemicals. J Energy Inst 92:1337–1347

Salavati S, Zhang CT, Zhang S, Liu Q, Gholizadeh M, Hu X (2019) Cross-interaction during co-gasification of wood, weed, plastic, tire and carton. J Environ Manage 250:1–15

Esmaeili V, Ajalli J, Faramarzi A, Abdi M, Gholizadeh M (2020) Gasification of wastes: the impact of the feedstock type and co-gasification on the formation of volatiles and char. Int J Energy Res 1:1–20

Hu X, Guo H, Gholizadeh M, Sattari B, Liu Q (2019) Pyrolysis of different wood species: impacts of C/H ratio in feedstock on distribution of pyrolysis products. Biomass Bioenerg 120:28–39

Li C, Zhang C, Sun K, Zhang Z, Zhang L, Zhang S, Liu Q, Hu G, Wang S, Hu X (2020) Pyrolysis of saw dust with co-feeding of methanol. Renew Energy 160:1023–1035

Zhang CT, Zhang L, Li Q, Wang Y, Liu Q, Wei T, Dong D, Salavati S, Gholizadeh M, Hu X (2019) Catalytic pyrolysis of poplar wood over transition metal oxides: correlation of catalytic behaviors with physiochemical properties of the oxides. Biomass Bioenergy 124:125–141

Bakatula EN, Mosai AK, Tutu H (2015) Removal of uranium from aqueous solutions using ammonium-modified zeolite, South African. J Chem 68:165–171

Li C, Ataei F, Atashi F, Hu X, Gholizadeh M (2021) Catalytic pyrolysis of polyethylene terephthalate over zeolite catalyst: characteristics of coke and the products. Int J Energy Res 45:19028–19042

Park Y-K, Jung J, Ryu S, Lee HW, Siddiqui MZ, Jae J, Watanabe A, Kim Y-M (2019) Catalytic co-pyrolysis of yellow poplar wood and polyethylene terephthalate over two stage calcium oxide-ZSM-5. Appl Energy 250: 1706–1718

Fan L, Ruan R, Li J, Ma L, Wang C, Zhou W (2020) Aromatics production from fast co-pyrolysis of lignin and waste cooking oil catalyzed by HZSM-5 zeolite. Appl Energy 263:1–11

Funding

This work was supported by University of Tabriz, the National Natural Science Foundation of China (No. 51876080), the Strategic International Scientific and Technological Innovation Cooperation Special Funds of National Key Research and Development Program of China (No. 2016YFE0204000), and the Program for Taishan Scholars of Shandong Province Government.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Co-pyrolysis enhanced yield and improved fuel properties of tar.

• Catalytic co-pyrolysis enhanced transfer of oxygen into gases.

• Zeolite increased the rate of deoxygenation and aromatization reactions.

• Zeolite enhanced formation of graphite structures in char.

• Little coke with mainly aromatic structure formed on zeolites.

Rights and permissions

About this article

Cite this article

Keramatian, Y., Li, C., Hu, X. et al. Co-pyrolysis of polyethylene terephthalate and poplar wood: influence of zeolite catalyst on coke formation. Biomass Conv. Bioref. 13, 16099–16113 (2023). https://doi.org/10.1007/s13399-022-02312-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02312-8