Abstract

The biomass Solanum mauritianum (S. mauritianum) is an invasive weed specie; however, it is a source of medicinally important metabolites, as reported in literature, such as solasonine and solamargine. The study was directed at the optimization of microwave and aqueous two-phase-based extraction techniques which involved microwave-assisted extraction (MAE), aqueous two-phase extraction followed by microwave-assisted extraction (ATPE + MAE), and the “one-pot” microwave-assisted aqueous two-phase extraction (MA-ATPE) for extraction of solasonine and solamargine from leaves of S. mauritianum which was evaluated. The microwave-assisted extraction of solasonine and solamargine yielded optimums at 5.00 min, microwave power of 270 W, and solid/liquid of 0.1 g L−1 at an ethanol concentration of 60%. Application of a two-stage extraction (MAE + ATPE) in CaO-dried alcohol resulted in decreased amounts of solasonine and solamargine extracted. The best yields of solasonine and solamargine were achieved in the MA-ATPE method. Extraction of solamargine and solasonine using Na2CO3 in CaO-dried ethanol during MA-ATPE was approximately threefold and twofold greater than that of MAE + ATPE, respectively. Furthermore, extraction of solamargine and solasonine using NaCl in CaO-dried ethanol during MA-ATPE was approximately twofold greater than that of MAE + ATPE. The synergy of microwaves and salting-out in the “one-pot” MA-ATPE technique was shown to be a contributing factor for enhanced extraction of solamargine and solasonine from leaves of S. mauritianum. Application of this time- and energy-efficient extraction method could potentially be expanded for enrichment of medicinally important compounds from biomass of other medicinal plants.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Plant reaction to damage is an inherent character and occurs through exhibition of defense mechanisms against herbivores and piercing-sucking insects such as whiteflies and bacterial pathogens [1,2,3]. One of the modes of operation of bacterial pathogens involves the release of reactive oxygen species such as singlet oxygen and peroxide radicals which result in oxidative stress leading to cellular damage in the host plants [1]. Other anti-pathogenic modes of plant include inhibition of glioma growth [4] and apoptosis of human chordoma cells [5]. Defense mechanisms against biotic stressors also involve the accumulation of toxic secondary metabolites, such as alkaloids which directly reduce the fitness of the invader [3, 6, 7]. One special class of alkaloids are steroidal glycoalkaloids found in numerous members of the Solanaceae family. They are composed of nitrogen-containing alkaloid groups and carbohydrate sugar side chains [3]. Extraction of toxic phytochemicals from Solanum plants is essential as they are the richest bioresource of drugs for medicinal applications [6]. Glycoalkaloids have been known for their pharmacological effectiveness towards human health such as being antidiabetic [8], antifungal [9], antiparasitic [10], and anticancer [11]. Hence, extraction of these invaluable naturally derived compounds (glycoalkaloids) is worthwhile.

Microwave-assisted extraction (MAE) is a simple environmentally friendly and economical technique for the extraction of biologically active compounds from different plant materials [12, 13]. The advantage of this technique includes shorter extraction time, lesser solvent requirement, improved purity of the extract, low cost, and better extraction yield in comparison to Soxhlet extraction. This extraction method is a quick and highly effective technique for obtaining extracts under mild conditions; therefore, it has been considered a potential alternative to traditional methods [14,15,16]. Aqueous two-phase extraction (ATPE) is desired for its environmental compatibility, low interfacial tension of phases, high yields, and low process time [17, 18]. Recently, researchers have turned their attention to an improved version of ATPE, salting-out assisted liquid–liquid extraction (SALLE) technique, which facilitates extraction of metabolites from complex matrices [19,20,21].

Glycoalkaloids are useful to a certain extent, since they have been shown to possess some bioactive properties which include anti-pesticide or anti-cancer activity [10, 11]. Despite the bioactive properties of glycoalkaloids, they are mainly toxic [3]. This work also aimed to explore conventional extraction methods such as MAE, aqueous two-phase extraction followed by microwave-assisted extraction (MAE + ATPE) and microwave-assisted aqueous two-phase extraction (MA-ATPE) for enrichment of glycoalkaloids from Solanum mauritianum. To the best of our knowledge, S. mauritianum has been underexplored with regard to its metabolites. Though known to be an invasive weed species from the Solanaceae family, the plant has been studied to be an essential ingredient for South African traditional medicine for treatment of menorrhagia [22] dysentery, diarrhea [23], and infertility [24] due to its metabolite composition, which is comprised of a bioactive class of compounds, glycoalkaloids. Hence, the need arises to obtain these medicinally important glycoalkaloid metabolites such as solasonine and solamargine from S. mauritianum using environmentally friendly extraction methods. Ethanol was used as an extractant because it can be regarded as a green solvent [25,26,27,28], because it is a nontoxic solvent. The application of microwaves or aqueous two-phase systems in conjunction with ethanol could potentially pave the way for more reliable means of obtaining these compounds and its sustained use in metabolomics. Furthermore, application of plant-based phytocompounds in medicine could likely eliminate the need for metabolic compounds synthesized in the lab, of which are often laborious and expensive.

2 Materials and methods

2.1 Sample collection

The leaves of S. mauritianum were obtained from Phiphidi, Limpopo, in October 2019, South Africa. The plants were air-dried until a constant weight was obtained, and the leaves were ground with a rotating blade blender into a fine powder with particle sizes ranging from 100 to 300 μm. Thereafter, this powder was stored in glass containers and covered to prevent light penetration.

2.2 Chemicals and materials

Absolute ethanol (99.9% CP), which was used as an extraction solvent, was purchased from Associated Chemical Enterprises (Johannesburg, South Africa). Ultra-pure water (0.005 μs, 18 mΩ) was used for preparation of ethanol solutions. A modified microwave oven (DM 350, Defy, Polokwane, South Africa) of 28 L capacity, working at a frequency of 2450 MHz, was used for microwave-assisted extraction. The salts for ATPE NaCl (anhydrous > 99% purity) and Na2CO3 (anhydrous > 99% purity) and the drying agent CaO (reagent grade > 99% purity) were all purchased from Associated Chemical Enterprises (Johannesburg, South Africa). Whatman grade 1 filter papers were purchased from Sigma-Aldrich (Johannesburg, South Africa).

2.3 Extraction procedure

2.3.1 MAE

Ground leaves of S. mauritianum plant powder (mass: 0.6–1.4 g) was immersed in hydroalcoholic solutions with various concentrations (20–60%) contained in a 1-necked 250-mL round-bottomed flask at irradiation time (1–13 min) with power varied from 90 to 900 W. The method is illustrated in Appendix (Fig. 8a).

2.3.2 MAE + ATPE

The optimized parameters following chromatographic analysis (details are included in Sect. 2.4) for the extraction of solasonine and solamargine during MAE was a 60% ethanol extraction solvent, irradiation time of 5 min at a power of 270 W. A ground S. mauritinum biomass powder with a mass of 1.0 g was immersed in 30% (w/v) of NaCl (chaotrope) or Na2CO3 (kosmotrope). Thereafter, the extract (5 mL) obtained from the optimized conditions during MAE was mixed with either 30% (w/v) of NaCl (5 mL) or 30% (w/v) of Na2CO3 (5 mL) followed by the addition of the extraction solvents—CaO-dried ethanol or 99% ethanol (10 mL)—which resulted in an aqueous two-phase system. The spontaneous formation of ATPE, consisting of a lower aqueous phase and an upper ethanolic phase, under the conditions stated above was also reported by Mokgehle et al. [3]. Hence, this extraction was a sum of two solutions, MAE followed by ATPE. CaO-dried ethanol was prepared by adding 25 g of CaO drying agent to 100 mL of 99% ethanol. The mixture was stirred for 10 min before filtration with a Whatman grade 1 filter paper. The method is illustrated in Appendix (Fig. 8b).

2.3.3 MA-ATPE

In this “one-pot” extraction, the optimized results from MAE were applied on the ATPE solution which consisted of ground plant powder mass: 1 g, saturated salt of 30% (w/v) of NaCl (chaotrope) or Na2CO3 (kosmotrope) which formed the bottom phase while the upper phase extraction solvent consisted of CaO-dried or 99% ethanol (10 mL). In MA-ATPE, both the saturated salt solution 30% (w/v), consisting of either NaCl or Na2CO3, and the ethanol extraction solvent were contained in the round-bottomed flask, all in the microwave oven. The spontaneous formation of ATPE under the conditions stated above was also reported by Mokgehle et al. [3]. In all the three extraction methods conducted, there was no agitation of the sample solution prior to or following extraction. Furthermore, the volumes of the solvents after the extraction period remained unaltered. The setup of the MA-ATPE systems is shown in Appendix (Fig. 8c).

2.4 Analysis on the UHPLC-qTOF-MS

Chromatographic separation of the extracts (upper ethanolic phase) obtained from the ATPE mixture was conducted on a UHPLC-qTOF-MS 9030 mass spectrometer (Shimadzu, Japan). This instrument contained a Shimpack C18, 2.1 × 100 mm, 2.7-μm column from Shimadzu (Honeydew, South Africa) where the mobile phase consisted of formic acid (0.1%) in deionized water (solvent A) and methanol with 0.1% formic acid (solvent B). Chromatographic separation was achieved using a 30-min gradient elution method consisting of the following settings: the initial conditions were 5% solvent B at a flow rate of 0.4 mL min−1 and held constant for 3 min. Conditions were then changed to 45% solvent B at 9 min, increased slightly to 50% solvent A at 21 min, and then quickly ramped up to 90% solvent B at 22 min and kept constant for 3 min. Conditions were changed to 5% solvent B at 27 min and kept for 3 min to allow for re-equilibration before the next run.

For mass spectrometry, the acquisition parameters as discussed by Ramabulana et al. [29] were used. Briefly, MS data were acquired using positive electron spray ionization (ESI) modes. The MS was configured to scan the range of 100–1000 Da with a scan time of 0.2 s. After a series of optimization, the following settings were found to be optimal: capillary voltage of 4.5 eV, sample cone potential of 30 V, source temperature of 120 °C, desolvation temperature of 450 °C, desolvation gas flow of 550 L h−1, and multichannel plate detector potential of 1600 V. In order to achieve efficient fragmentation to aid during identification, the mass spectrometry data were collected using a collision energy ramp of 10–30 eV and, when necessary, a higher collision energy ramp of 60–165 eV was also used. Structural elucidation was done using KNapSAck online metabolite database. Chemical identification was done using KNapSAck Core System online metabolite database (version 1.200.03) [30].

3 Results and discussion

3.1 Chromatographic profile of solasonine and solamargine

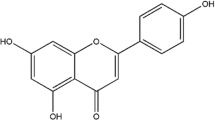

In Fig. 1, the mass spectrometry and elution profile of two glycoalkaloid isomers are shown, where Fig. 1a indicates solasonine m/z 884 and b solamargine m/z 868. Both contain the same aglycone unit solasodine, yet only differ in monosaccharides glycosylated to the aglycone unit. For instance, solamargine contains two rhamnose monosaccharides and glucose while solasonine is composed of glucose, rhamnose, and galactose, which account for the 16 mass unit difference between the two compounds (Fig. 1a and b). Figure 1c shows a 30-min base peak chromatogram of a 60% ethanolic MAE extract from S. mauritianum, which also shows the elution order of two glycoalkaloids with the relatively more polar solasonine eluting at 19.56 min and solamargine at 19.76 min from the reversed phase column. Furthermore, Munari et al. [31] observed a similar trend in the extracts of Solanum lycopersicum on as Zorbax SB-C18 column where solasonine eluted before solamargine which indicated the relatively higher polarity of the former. In another study, Chester et al. [32] quantified solasonine and solamargine obtained from extracts of Solanum nigrum L. based on retention factors (Rf) on the HPTLC chromatogram on the UPLC-ESI–MS/MS. In the same work, solasonine had a lower Rf than solamargine due to its relatively higher polarity. Hence, the presence of galactose is a major contributor to the polarity of solasonine and its relatively higher affinity for the CaO-dried ethanol extraction solvent.

3.1.1 Effect of concentration of ethanol on MAE

A study investigating the effect of ethanol percentage on the extraction of solasonine and solamargine was conducted as shown in Fig. 2. As the concentration of ethanol was increased, the intensities of both solasonine and solamargine also increased. The higher intensities which correlated with the higher yield can be attributed to the higher proportion of ethanol and the lower level of water in the extraction solvent. The ethanol percentage in water was one of the driving factors influencing the MAE of compounds as it affected the solubility of metabolites, penetration of solvent into the cells of plants, interaction of solvent with matrix, and the absorption of microwave energy [33]. Increasing the water concentration in the solvent as highlighted by Veggi et al. [34] and Zhang et al. [35] has been reported to influence selectivity during extraction, which resulted in a greater affinity towards proteins and carbohydrates rather than bioactive plant metabolites. It was also observed that the relative intensities of solamargine to solasonine occurred on a general ratio of 2:1, which probably indicated the greater relative abundance of solamargine compared to solasonine in the leaves of S. mauritianum. Hence, the optimum extraction solvent was 60% ethanol and was then used in the following study.

3.1.2 Effect of solid/liquid ratio on MAE

The effect of solid/liquid ratio was evaluated where 0.6, 1, and 1.4 g were evaluated in 10 mL 60% ethanol and corresponded to solid/liquid ratios of 0.06, 0.1, and 0.14 g L−1, respectively (Fig. 3). The optimal extraction of solasonine and solamargine was observed at 0.1 g L−1. The lower intensities of extracted solamargine and solasonine at 0.06 g L−1 could be due to the relatively lower amount of plant material used. Increased solvent volumes have also been reported to reduce the heating efficiency, limit the breakage of solid cell walls, and inhibit the driving force for the mass transfer of compounds [33]. Similarly, Alara et al. [36] reported that larger volumes of solvent required more energy and time to maximize extraction of analytes from the plant matrix. It was also noted that with larger solid/liquid ratios, reduced extraction of solasonine and solamargine was observed. This could be as a result of lumping of the powdered plant material, limiting access for the extraction solvent to penetrate through the cell walls. Similarly, Sajid et al. [37] reported on clogging during solid-phase micro-extraction. The optimum mass for extraction of solasonine and solamargine was 1 g, with a solid/liquid ratio of 0.1 g L−1.

3.1.3 Effect of irradiation time on MAE

A study evaluating the effect of irradiation time on extraction of solasonine and solamargine was performed as shown in Fig. 4. As time was increased from 1 to 5 min, a gradual increase in the extraction of solasonine and solamargine was noted. In general, higher extraction time tends to increase the yield of extraction. In addition, the dielectric properties of solvents used in MAE may have significant impacts on the extraction time [34, 38]. For instance, at room temperature, water has a dielectric constant of 80; however, the addition of ethanol in the aqueous mixture reduces this constant, greatly allowing it to easily dissolve a wide range of less polar metabolites; hence, in this instance, it only took 5 min to achieve optimal extraction of both solasonine and solamargine, whereas if only water was used as an extractant, optimal extraction of both glycoalkaloids would have most likely taken longer than 5 min [34, 38]. Furthermore, extraction of metabolites from the plant matrix is not an instantaneous process; there are multiple phases occurring which involve removal of compounds from the outer surface of plant matrix, a transition state consisting of intermolecular forces between the metabolites and the plant matrix inhibiting mass transfer brought about by the extraction solvent. After the 5-min irradiation time, a steady decrease in the intensities of both glycoalkaloids was observed (Fig. 4). This steady decrease at longer times was increased which could be associated with the increased degradation of thermolabile metabolites, solasonine and solamargine, during this period. This is in agreement with what was reported by Doulabi et al. [33] and Veggi et al. [34]. The optimal extraction time to be used in the following studies was 5 min.

3.1.4 Effect of power (W) on MAE

Power studies were conducted to examine its effect on the extraction of solasonine and solamargine as shown in Fig. 5. From 90 to 270 W, an increase in extraction of both glycoalkaloids was observed (Fig. 5). Generally, an increase in microwave power can improve the penetration of solvent into plant matrix, resulting in rapid delivery of microwave energy to both solvent and plant matrix [33]. Accordingly, from 90- to 270-W microwave power, dissolution of solasonine and solamargine occurred due to the increased temperature of the extraction solvent. However, from 270 to 900 W, a steady decrease was observed (Fig. 5). This could be because of excessive microwave irradiation energy degrading both solasonine and solamargine [38, 39]. Therefore, the optimal extraction power was observed at 270 W.

3.2 MAE + ATPE

Following the optimized result obtained for MAE (Sect. 3.1) which included 60% ethanol extraction solvent, solid/liquid ratio of 0.1 g L−1, irradiation time of 5 min, and power of 270 W, the obtained conditions were applied for MAE + ATPE to improve the extraction of solasonine and solamargine. Besides the inclusion of ATPE, the 99% ethanol extraction solvent was dried with CaO drying agent with the aim of enhancing the extraction of solasonine and solamargine. Figure 6 shows the extraction profile for solasonine and solamargine using an extraction solvent of 99% ethanol and CaO-dried ethanol when the chaotrope and kosmotrope NaCl and Na2CO3 were used, respectively. In general, no differences were observed in intensities of solasonine and solamargine when CaO-dried ethanol was used as an extraction solvent compared to 99% ethanol for both Na2CO3 and NaCl (Fig. 6). Though CaO was reported as an efficient drying agent by Danish et al. [40] and Jia et al. [41] in sewage sludge and mortar, respectively, its application in drying extraction solvents for the improving extraction of solasonine and solamargine was limited.

3.3 MA-ATPE

With the aim of further improving the extraction of solamargine and solasonine from S. mauritianum, a hyphenated MA-ATPE was applied as shown in Fig. 7. In both instances where the extraction solvents were 99% ethanol and CaO-dried ethanol, Na2CO3 was generally observed to be a better extractant of solasonine and solamargine than NaCl. The opposite effect was observed for the two-stage extraction process MAE + ATPE (Fig. 6), which indicated that the extraction method influenced the salting-out efficiency of solamargine and solasonine from the aqueous solution in the presence of NaCl or Na2CO3. The effect of extraction conditions on salting-out was also reported by Tajeda-Casado et al. [20] and Sazali et al. [21]. The doubly charged carbonate ions from Na2CO3 interacted with the hydration sphere surrounding the solute (solamargine and solasonine) to a greater extent than singly charged chloride ions from NaCl, forming carbonic acid. Thereafter, this led to the precipitation (salting-out) of the solute in the aqueous phase and resultant extraction by ethanol. Salting-out effect has been reported to aid the extraction of vitamin D3 from milk samples [21] and in the determination of 5-nitroimidazolesin in fish [19].

3.4 Comparison of the extraction efficiency of MAE, MAE + ATPE, and MA-ATPE

Enrichment of solasonine and solamargine was considerably greater for MA-ATPE in comparison to MAE + ATPE and MAE. For instance, extraction of solamargine and solasonine using Na2CO3 in CaO-dried ethanol during MA-ATPE (Fig. 7) was approximately threefold and twofold greater than that of MAE + ATPE, respectively (Fig. 6). Similarly, extraction of solamargine and solasonine using NaCl in CaO-dried ethanol during MA-ATPE (Fig. 7) was approximately twofold greater than that of MAE + ATPE (Fig. 6, Table 1). This indicated that in MA-ATPE, the synergistic effect of microwaves and salting-out occurred simultaneously. In this case, extraction was assisted by microwaves which resulted in cell wall rapture and subsequent mass transfer of solasonine and solamargine into the aqueous solution. In addition to microwaves, the salting-out effect prompted the precipitation of solasonine and solamargine from the hydration sphere into the ethanol extraction phase during MA-ATPE. The two-step extraction method MAE + ATPE was observed to have the lowest extraction of metabolites (Fig. 6). This could be attributed to the inter-step loss of metabolites during MAE-ATPE. Furthermore, Gardernar et al. [42] highlighted some disadvantages associated with two-step extractions which involved the requirement for a substantial amount of specimen to prevent analyte loses. It was also observed that MA-ATPE improved extraction of solasonine and solamargine compared to MAE (Table 1). This suggested that the chaotrope and kosmotrope were influential in aiding extraction of solasonine and solamargine in MA-ATPE compared to MAE, from which the extraction did not include salts. Hence, the simultaneous application of microwaves assisted the extraction of solasonine and solamargine in the aqueous two-phase system based on salting-out, as seen with MA-ATPE, and was influential in enhancing the extraction of solasonine and solamargine in comparison to MAE and MAE + ATPE.

4 Conclusions

In this study, the optimization of microwave and aqueous two-phase-based extraction techniques which involved MAE, ATPE + MAE, and MA-ATPE for extraction of solasonine and solamargine from leaves of S. mauritianum was evaluated. The first technique which only involved microwaves, MAE, maximal extraction of solasonine and solamargine was achieved when extraction was conducted for 5 min, microwave power of 270 W, solid/liquid of 0.1 g L−1, and an ethanol concentration of 60%. Efforts were then made to improve extraction of both solasonine and solamargine by applying drying agents such as CaO in the ethanol extraction solvent. Dried ethanol was applied in two-stage extraction (MAE + ATPE). However, the yields of solasonine and solamargine were observed to decrease due to possible analyte loss of metabolites during inter-step transfer between MAE and ATPE. Application of CaO-dried ethanol in conjunction with the “one-pot” MA-ATPE was shown to considerably enhance extraction of both glycoalkaloids relative to MAE and MAE-ATPE. For instance, extraction of solamargine and solasonine using Na2CO3 in CaO-dried ethanol during MA-ATPE was approximately threefold and twofold greater than that of MAE + ATPE, respectively. Furthermore, extraction of solamargine and solasonine using NaCl in CaO-dried ethanol during MA-ATPE was approximately twofold greater than that of MAE + ATPE. Hence, the kosmotrope (Na2CO3) was shown to be a relatively better extractor of solamargine and solasonine in comparison to the chaotrope (NaCl) due to its superior salting-out capacity in MA-ATPE. The results suggested that MA-ATPE, a technique propelled by the synergy of microwaves and salting-out, is a promising time- and energy-efficient method for enrichment of solamargine and solasonine from leaves of S. mauritianum.

Data availability (data transparency)

Not applicable.

Code availability (software application or custom code)

Not applicable.

References

Santamaria ME, Martínez M, Cambra I, Grbic V, Diaz I (2013) Understanding plant defence responses against herbivore attacks: an essential first step towards the development of sustainable resistance against pests. Transgenic Res 22:697–708. https://doi.org/10.1007/s11248-013-9725-4

Montero-Vargus JM, Casarrubias-Castillo K, Martinez-Gallardo N, Ordaz-Ortiz JJ, Delano-Frier JP, Winkle R (2018) Modulation of steroidal glycoalkaloid biosynthesis in (Solanum lycoperium) by jasmonic acid. Plant Sci 277:155–165. https://doi.org/10.1016/j.plantsci.2018.08.020

Mokgehle TM, Madala N, Gitari WM, Tavengwa NT (2021) Advances in the development of biopolymeric adsorbents for the extraction of metabolites from nutraceuticals with emphasis on Solanaceae and subsequent pharmacological applications. Carbohydr Polym 264:1–10. https://doi.org/10.1016/j.carbpol.2021.118049

Wang X, Zou S, Lan YL, Xing JS, Lan XQ, Zhang B (2017) Solasonine inhibits glioma growth through anti-inflammatory pathways. Am J Transl Res 9:3977–3989

Zhao L, Wang L, Di SN, Xu Q, Ren QC, Chen SZ, Huang N, Jia D, Shen XF (2018) Steroidal alkaloid solanine A from Solanum nigrum Linn. exhibits anti-inflammatory activity in lipopolysaccharide/interferon γ-activated murine macrophages and animal models of inflammation. Biomed Pharmacother 105:606–615. https://doi.org/10.1016/j.biopha.2018.06.019

Baldwin IT, Schmelz EA, Ohnmeiss TE (1994) Wound-induced changes in root and shoot jasmonic acid pools correlate with induced nicotine synthesis in Nicotiana sylvestris spegazzini and comes. J Chem Ecol 20:2139–2157. https://doi.org/10.1007/BF02066250

Rodsamran P, Sothornvit R (2019) Microwave heating extraction of pectin from lime peel: characterization and properties compared with the conventional heating method. Food Chem 278:364–372. https://doi.org/10.1016/j.foodchem.2018.11.067

Al-Ashaala HA, Farghaly AA, Abdel-Samee NS (2018) Antidiabetic efficacy of Solanum torvum extract and glycoalkaloids against diabetes induced mutation in experimental animals. Int J Pharm Sci Res 10:1323–1331

Grillo G, Gunjević V, Radošević K, Radojčić Redovniković I, Cravotto G (2020) Deep eutectic solvents and nonconventional technologies for blueberry-peel extraction: kinetics, anthocyanin stability, and antiproliferative activity. Antioxidants 9:1069–1097. https://doi.org/10.3390/antiox9111069

Anwar A, Mungroo MR, Khan S, Fatima I, Rafique R, Khan KM, Siddiqui R, Khan NA (2020) Novel azoles as antiparasitic remedies against brain-eating amoebae. Antibiotics 9:1–13. https://doi.org/10.3390/antibiotics9040188

Albarri R, Toprakçı I, Kurtulbaş E, Şahin S (2021) Estimation of diffusion and mass transfer coefficients for the microwave-assisted extraction of bioactive substances from Moringa oleifera leaves. Biomass Convers Biorefin 221:1–8. https://doi.org/10.1007/s13399-021-01443-8

Li J, Qi H, Wang Y, Su Q, Wu S, Wu L (2016) Hollow fibre-stir bar sorptive extraction and microwave assisted derivatization of amino acids in biological matrices. J Chromatogr A 1474:32–39. https://doi.org/10.1016/j.chroma.2016.10.079

Aeenehvand S, Toudehrousta Z, Kamankesh M, Mashayekh M, Tavakoli HR, Mohammadi A (2016) Evaluation and application of microwave-assisted extraction and dispersive liquid liquid micro-extraction followed by high performance liquid chromatography for the determination of polar heterocyclic aromatic amines in hamburger patties. Food Chem 190:429–435. https://doi.org/10.1016/j.foodchem.2015.05.103

Ahuja S, Diehl D (2006) Sampling and sample preparation. Oxford: Compr Anal Chem 47:15-40. https://doi.org/10.1016/S0166-526X(06)47002-1

Barba FJ, Grimi N, Vorobiev E (2015) New approaches for the use of non-conventional cell-disruption technologies to extract potential food additives and nutraceuticals from microalgae. Food Eng Rev 7:45–62. https://doi.org/10.1007/s12393-014-9095-6

Castejon N, Luna P, Senorans FJ (2018) Alternative oil extraction methods from Echium plantaginium L. seeds using advanced techniques and green solvents. Food Chem 244:75–82. https://doi.org/10.1016/j.foodchem.2017.10.014

Xavier L, Freire MS, Vidal-Tato I, González-Álvarez J (2014) Aqueous two-phase systems for the extraction of phenolic compounds from eucalyptus (Eucalyptus globulus) wood industrial wastes. J Chem Technol Biotechnol 89:1772–1778. https://doi.org/10.1002/jctb.4260

Iqbal M, Tao Y, Xie S, Zhu Y, Chen D, Wang X, Huang L, Peng D, Sattar A, Shabbir MAB, Hussain HF, Ahmed S, Yuan Z (2016) Aqueous two phase system (ATPS): an overview and advances in its applications. Biol Proced Online 18:1–18. https://doi.org/10.1186/s12575-016-0048-8

Hernández-Mesa M, Cruces-Blanco C, García-Campaña AM (2018) Simple and rapid determination of 5-nitroimidazoles and metabolites in fish roe samples by salting-out assisted liquid-liquid extraction and UHPLC-MS/MS. Food Chem 252:294–302. https://doi.org/10.1016/j.foodchem.2018.01.101

Tejada-Casado C, Lara FJ, García-Campaña AM, del Olmo-Iruela M (2018) Ultra-high performance liquid chromatography with fluorescence detection following salting-out assisted liquid–liquid extraction for the analysis of benzimidazole residues in farm fish samples. J Chromatogr A 1543:58–66. https://doi.org/10.1016/j.chroma.2018.02.042

Sazali NH, Alshishani A, Saad B, Chew KY, Chong MM, Miskam M (2019) Salting out assisted liquid liquid extraction coupled with high performance liquid chromatography for the determination of vitamin D3 in milk samples. R Soc Open Sci 6:1–8. https://doi.org/10.1098/rsos.190952

Uche-Okereafor N, Sebola T, Tapfuma K, Mekuto L, Green E, Mavumengwana V (2019) Antibacterial activities of crude secondary metabolite extracts from Pantoea species obtained from the stem of Solanum mauritianum and their effects on two cancer cell lines. Int J Environ Res Public Health 16:1–12. https://doi.org/10.3390/ijerph16040602

Usman H, Victor V, Waziri I (2018) Qualitative phytochemical screening and in vitro antimicrobial activities of Solanum americanum mill. Arid Zone J Eng Technol 14:104–110

Offor SJ, Mbagwu HO, Orisakwe OE (2019) Improvement of lead acetate-induced testicular injury and sperm quality deterioration by Solanum anomalum thonn. ex. schumach fruit extracts in albino rats. J Family Reprod Health 13:98–108

Bermejo DV, Ibáñez E, Reglero G, Fornari T (2016) Effect of cosolvents (ethyl lactate, ethyl acetate and ethanol) on the supercritical CO2 extraction of caffeine from green tea. J Supercrit Fluids 107:507–512. https://doi.org/10.1016/j.supflu.2015.07.008

Carré P, Citeau M, Dauguet S (2018) Hot ethanol extraction: economic feasibility of a new and green process. OCL 25:D206. https://doi.org/10.1051/ocl/2017061

Nutrizio M, Maltar-Strmečki N, Chemat F et al (2021) High-voltage electrical discharges in green extractions of bioactives from oregano leaves (origanum vulgare l.) using water and ethanol as green solvents assessed by theoretical and experimental procedures. Food Eng Rev 13:161–174. https://doi.org/10.1007/s12393-020-09231-2

González-Félix MA, Mejía-Manzano LA, Barba-Dávila BA, Serna-Saldívar SO, González-Valdez J (2021) optimized and scalable green extraction of pristimerin, an anticancerigen from mortonia greggii, by ethanol–phosphate aqueous two-phase systems. Ind Eng Chem Res 60:5403–5410

Ramabulana T, Mavunda RD, Steenkamp PA, Piater LA, Dubery IA, Madala NE (2015) Secondary metabolite perturbations in Phaseolus vulgaris leaves due to gamma radiation. Int J Plant Physiol Biochem 97:287–295. https://doi.org/10.1016/j.plaphy.2015.10.018

Knapsack Core system. Available online http://www.knapsackfamily.com/knapsack_core/top.php (accessed 20 March 2020)

Munari CC, de Oliveira PF, Campos JCL, Martins SPDL, Da Costa JC, Bastos JK, Tavares DC (2014) Antiproliferative activity of Solanum lycocarpum alkaloidic extract and their constituents, solamargine and solasonine, in tumor cell lines. J Nat Med 68:236–241. https://doi.org/10.1007/s11418-013-0757-0

Chester K, Paliwal S, Khan W, Ahmad S (2017) UPLC-ESI-MS/MS and HPTLC method for quantitative estimation of cytotoxic glycosides and aglycone in bioactivity guided fractions of Solanum nigrum L. Front Pharmacol 8:1–15. https://doi.org/10.3389/fphar.2017.00434

Doulabi M, Golmakani MT, Ansari S (2020) Evaluation and optimization of microwave-assisted extraction of bioactive compounds from eggplant peel by-product. J Food Process Preserv 44:1–13. https://doi.org/10.1111/jfpp.14853

Veggi PC, Martinez J, Meireles MAA (2012) Fundamentals of microwave extraction. In Microwave-assisted extraction for bioactive compounds Springer, Boston, MA., 2012:15-22. https://doi.org/10.1007/978-1-4614-4830-3_2

Zhang HF, Yang XH, Wang Y (2011) Microwave assisted extraction of secondary metabolites from plants: current status and future directions. Trends Food Sci Technol 22:672–688. https://doi.org/10.1016/j.tifs.2011.07.003

Alara OR, Abdurahman NH (2019) Microwave-assisted extraction of phenolics from Hibiscus sabdariffa calyces: kinetic modelling and process intensification. Ind Crop Prod 137:528–535. https://doi.org/10.1016/j.indcrop.2019.05.053

Sajid M, Nazal MK, Rutkowska M, Szczepańska N, Namieśnik J, Płotka-Wasylka J (2019) Solid phase micro-extraction: apparatus, sorbent materials, and application. Crit Rev Anal Chem 49:271–288. https://doi.org/10.1080/10408347.2018.1517035

Routray W, Orsat V (2012) Microwave-assisted extraction of flavonoids: a review. Food Bioproc Tech 5:409–424. https://doi.org/10.1007/s11947-011-0573-z

Valdés A, Burgos N, Jiménez A, Garrigós MC (2015) Natural pectin polysaccharides as edible coatings. Coatings 5:865–886. https://doi.org/10.3390/coatings5040865

Danish M, Jing H, Pin Z, Ziyang L, Pansheng Q (2016) A new drying kinetic model for sewage sludge drying in presence of CaO and NaClO. Appl Therm Eng 106:141–152. https://doi.org/10.1016/j.applthermaleng.2016.05.191

Jia Z, Yang Y, Yang L, Zhang Y, Sun Z (2018) Hydration products, internal relative humidity and drying shrinkage of alkali activated slag mortar with expansion agents. Constr Build Mater 158:198–207. https://doi.org/10.1016/j.conbuildmat.2017.09.162

Gardner MS, Kuklenyik Z, Lehtikoski A, Carter KA, McWilliams LG, Kusovschi J, Bierbaum K, Jones JJ, Rees J, Reis G, Pirkle JL, Barr JR (2019) Development and application of a high throughput one-pot extraction protocol for quantitative LC-MS/MS analysis of phospholipids in serum and lipoprotein fractions in normolipidemic and dyslipidemic subjects. J Chromatogr B 1118:137–147. https://doi.org/10.1016/j.jchromb.2019.04.041

Acknowledgements

The authors would like to express their gratitude the University of Venda.

Funding

This study received financial support from the National Research Foundation and Sasol Inzalo.

Author information

Authors and Affiliations

Contributions

TMM, NTT, and NEM conceived the study; TMM and NEM conducted the experiments and data analyses. NTT, NEM, and WMG supervised the project. WMG helped to draft the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mokgehle, T.M., Madala, N.E., Gitari, W.M. et al. Hyphenation of aqueous two-phase and microwave extraction of solasonine and solamargine from leaves of Solanum mauritianum characterized by UHPLC-qTOF-MS. Biomass Conv. Bioref. 13, 12167–12178 (2023). https://doi.org/10.1007/s13399-021-02136-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-02136-y