Abstract

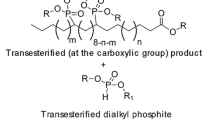

A high yielding, cost-effective, and regioselective methodology for the gram-scale synthesis of 6-O-ascorbyl esters has been developed by the esterification of l-ascorbic acid with a variety of saturated long-chain fatty acids in the presence conc. H2SO4. A renewable food-grade solvent, p-cymene, was efficiently used in the process to affect the product separation from the reaction mixture while the physical methods, e.g., cooling and centrifugation, were applied for product isolation in good yields (70–82%) and purity (> 99%). The methodology was scaled up for the production of 6-O-ascorbyl palmitate (45 g) in 80% yields and > 99% purity. A direct application of the developed method on low-value fats and oils resulted in the synthesis of a mixture of 6-O-ascorbyl esters for use as antioxidants in food products.

Similar content being viewed by others

References

Gao F, Birch J (2015) Oxidative stability, thermal decomposition, and oxidation onset prediction of carrot, flax, hemp, and canola seed oils in relation to oil composition and positional distribution of fatty acids. Eur J Lipid Sci Technol 118:1042–1052. https://doi.org/10.1002/ejlt.201500208

Liu K, Liu Y, Chen F (2019) Effect of storage temperature on lipid oxidation and changes in nutrient contents in peanuts. Food Sci Nutr 7:2280–2290. https://doi.org/10.1002/fsn3.1069

Manzocco L, Romano G, Calligaris S, Nicoli MC (2020) Modeling the effect of the oxidation status of the ingredient oil on stability and shelf life of low-moisture bakery products: The case study of crackers. Foods 9:749. https://doi.org/10.3390/foods9060749 ((1-13))

Zhu T-W, Zhang X, Zong M-H, Linhardt RJ, Li B, Wu H (2019) Interesterified blend-based and physical blend-based special fats: storage stability under fluctuating temperatures. J Sci Food Agric 99:6219–6226. https://doi.org/10.1002/jsfa.9894

Festjens N, Kalai M, Smet J, Meeus A, Coster RV, Saelens X, Vandenabeele P (2006) Butylated hydroxyanisole is more than a reactive oxygen species scavenger. Cell Death Differ 13:166–169. https://doi.org/10.1038/sj.cdd.4401746

Sarafian TA, Kouyoumjian S, Tashkin D, Roth MD (2002) Synergistic cytotoxicity of Delta(9)-tetrahydrocannabinol and butylated hydroxyanisole. Toxicol Lett 133:171–179. https://doi.org/10.1007/s11010-006-2346-y

Taghvaei M, Jafari SM (2015) Application and stability of natural antioxidants in edible oils in order to substitute synthetic additives. J Food Sci Technol 52:1272–1282. https://doi.org/10.1007/s13197-013-1080-1

Shahidi F, Zhong Y (2010) Lipid oxidation and improving the oxidative stability. Chem Soc Rev 39:4067–4079. https://doi.org/10.1039/B922183m

Bera D, Lahiri D, Nag A (2006) Studies on a natural antioxidant for stabilization of edible oil and comparison with synthetic antioxidants. J Food Eng 74:542–545. https://doi.org/10.1016/j.jfoodeng.2005.03.042

Brewer MS (2011) Natural antioxidants: sources, compounds, mechanisms of action, and potential applications. Comp Rev Food Sci Food Safety 10:221–247. https://doi.org/10.1111/j.1541-4337.2011.00156.x

Rege S, Momin S, Bhowmick D (2015) Effect of ascorbic acid on the oxidative stability of water-in-oil emulsion in the presence of lipophilic antioxidants. Int J Food Prop 18:259–265. https://doi.org/10.1080/10942912.2012.675609

Liu Y, Liu C, Li J (2020) Comparison of vitamin C and its derivative antioxidant activity: evaluated by using density functional theory. ACS Omega 5:25467–25475. https://doi.org/10.1021/acsomega.0c04318

Mcmullen LM, Hawrysh ZJ, Lin C, Tokarska B (1991) Ascorbyl palmitate efficacy in enhancing the accelerated storage stability of canola oil. J Food Sci 56:1651–1654. https://doi.org/10.1111/j.1365-2621.1991.tb08663.x

Lerin LA, Richetti A, Dallago R, Treichel H, Mazutti MA, Oliveira JV, Antunes OAC, Oestreicher EG, Oliveira D (2012) Enzymatic synthesis of ascorbyl palmitate in organic solvents: process optimization and kinetic evaluation. Food Bioprocess Technol 5:1068–1076. https://doi.org/10.1007/s11947-010-0398-1

Yadav MG, Kavadia MR, Vadgama RN, Odaneth AA, Lali AM (2018) Production of 6-O-L-ascorbyl palmitate by immobilized Candida antarctica lipase B. Applied Biochem Biotechnol 184:1168–1186. https://doi.org/10.1007/s12010-017-2610-5

Tanini D, Lupori B, Malevolti G, Ambrosi M, Nostro PL, Capperucci A (2019) Direct biocatalysed synthesis of first sulfur-, selenium- and tellurium- containing l-ascorbyl hybrid derivatives with radical trapping and GPx-like properties. Chem Commun 55:5705–5708. https://doi.org/10.1039/C9CC02427A

Zhan SJ, Yalong YL (2011) Preparation method of L-ascorbyl palmitate. CN 106883202. https://patents.google.com/patent/CN102558115A/en

Burham H, Rasheed RAGA, Noor NM, Badruddin S, Sidek H (2009) Enzymatic synthesis of palm-based ascorbyl esters. J Mol Catalysis B Enzymatic 58:153–157. https://doi.org/10.1016/j.molcatb.2008.12.012

Chang SW, Yang CJ, Chen FY, Akoh CC, Shieh CJ (2009) Optimized synthesis of lipase-catalyzed L-ascorbyl laurate by Novozym® 435. J Mol Catalysis B Enzymatic 56:7–12. https://doi.org/10.1016/j.molcatb.2008.04.001

Hsieh H, Nair GR, Wu W (2006) Production of ascorbyl palmitate by surfactant-coated lipase in organic media. J Agric Food Chem 54:5777–5781. https://doi.org/10.1021/jf060089d

Wen B, Eli W, Xue Q, Dong X, Liu W (2007) Ultrasound accelerated esterification of palmitic acid with vitamin C. Ultrason Sonochem 14:213–218. https://doi.org/10.1016/j.ultsonch.2006.02.003

Cui Y-M, Wei D-Z, Yu J-T (1997) Lipase-catalyzed esterification in organic solvent to resolve racemic naproxen. Biotech Lett 19:865–868. https://doi.org/10.1023/A:1018333503317

Ji JM (2011) Chemical synthesis of ascorbyl palmitate in [BMIM]BF4]. Adv Mater Res 236–238:1962–1965. https://doi.org/10.4028/www.scientific.net/AMR.236-238.1962

Dwivedi P, Singh M, Sehra N, Pandey N, Sangwan RS, Mishra BB (2017) Processing of wet Kinnow mandarin (Citrus reticulata) fruit waste into novel Brønsted acidic ionic liquids and their application in hydrolysis of sucrose. Bioresour Technol 250:621–624. https://doi.org/10.1016/j.biortech.2017.11.100

Martineza A, Mijangosa GE, Romero-Ibarraa IC, Altamiranob RH, Cervantes VY (2019) In-situ transesterification of Jatropha curcas L. seeds using homogeneous and heterogeneous basic catalysts. Fuel 235:277–287. https://doi.org/10.1016/j.fuel.2018.07.082

Kumar D, Das T, Giri BS, Verma B (2018) Characterization and compositional analysis of highly acidic Karanja oil and its potential feedstock for enzymatic synthesis of biodiesel. New J Chem 42:15593–15602. https://doi.org/10.1039/C8NJ03084G

Ramadan MF, Mohdaly AAA, Assiri AMA, Tadros M, Niemeyer BC (2016) Functional characteristics, nutritional value and industrial applications of Madhuca longifolia seeds: an overview. J Food Sci Technol 53:2149–2157. https://doi.org/10.1007/s13197-015-2095-6

Atabani AE, Silitonga AS, Ong HC, Mahlia TMI, Masjuki HH, Badruddin IA, Fayaz H (2013) Non-edible vegetable oils: a critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew Sust Energ Rev 18:211–245. https://doi.org/10.1016/j.rser.2012.10.013

Acknowledgements

We thank the DBT-Center of Innovative and Applied Bioprocessing (CIAB) for infrastructure and research facility. SAIF-Panjab University, Chandigarh, is acknowledged for spectroscopic studies.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pandey, N., Singh, M., Dwivedi, P. et al. Synthesis of food-grade 6-O-ascorbyl fatty esters and their semi-synthesis from low-value oils as resources. Biomass Conv. Bioref. 13, 15393–15400 (2023). https://doi.org/10.1007/s13399-021-01682-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01682-9