Abstract

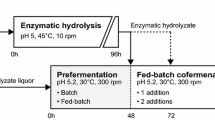

A quick fed-batch saccharification (QFBs) strategy of pretreated wheat straw at high solid loadings (HSL) was developed to achieve high sugar concentrations and increase lignocellulosic ethanol productivities in the fermentation stage. Pretreatment time, number of feedings, and the time between them were evaluated using a Box-Behnken design. A surface response model was employed to maximize sugars released at 20% (w/w) HSL. Total sugar concentrations after 60 h with 20% (w/w), 25% (w/w), and 30% (w/w) HSL were 128.5 g/l, 142.4 g/l, and 163.5 g/l, respectively. These were 14.6–42% higher than their batch saccharification counterparts. The QFBs was implemented as part of sequential (SHF) and simultaneous saccharification-fermentation (SSF) strategies as well as the presaccharification stage of a semi-simultaneous saccharification-fermentation (SSSF) strategy. In the latter strategy, the highest ethanol concentration achieved was 31.7 g/l. The ethanol volumetric productivity was 2.2- and 3-fold their SHF and SSF counterparts.

Similar content being viewed by others

References

Achinas S, Euverink GJW (2016) Consolidated briefing of biochemical ethanol production from lignocellulosic biomass. Electron J Biotechnol 23:44–53. https://doi.org/10.1016/j.ejbt.2016.07.006

Machineni L (2020) Lignocellulosic biofuel production: review of alternatives. Biomass Convers Biorefinery 10:779–791. https://doi.org/10.1007/s13399-019-00445-x

Larsen J, Øtergaard Petersen M, Thirup L et al (2008) The IBUS process - Lignocellulosic bioethanol close to a commercial reality. Chem Eng Technol 31:765–772. https://doi.org/10.1002/ceat.200800048

Xiros C, Janssen M, Byström R, Børresen BT, Cannella D, Jørgensen H, Koppram R, Larsson C, Olsson L, Tillman AM, Wännström S (2017) Toward a sustainable biorefinery using high-gravity technology. Biofuels, Bioprod Biorefining 11:15–27. https://doi.org/10.1002/bbb.1722

Saini JK, Agrawal R, Satlewal A, Saini R, Gupta R, Mathur A, Tuli D (2015) Second generation bioethanol production at high gravity of pilot-scale pretreated wheat straw employing newly isolated thermotolerant yeast Kluyveromyces Marxianus DBTIOC-35. RSC Adv 5:37485–37494. https://doi.org/10.1039/c5ra05792b

Koppram R, Tomás-Pejó E, Xiros C, Olsson L (2014) Lignocellulosic ethanol production at high-gravity: challenges and perspectives. Trends Biotechnol 32:46–53. https://doi.org/10.1016/j.tibtech.2013.10.003

Chen H, Fu X (2016) Industrial technologies for bioethanol production from lignocellulosic biomass. Renew Sustain Energy Rev 57:468–478. https://doi.org/10.1016/j.rser.2015.12.069

Viamajala S, McMillan JD, Schell DJ, Elander RT (2009) Rheology of corn stover slurries at high solids concentrations - effects of saccharification and particle size. Bioresour Technol 100:925–934. https://doi.org/10.1016/j.biortech.2008.06.070

Palonen H, Tjerneld F, Zacchi G, Tenkanen M (2004) Adsorption of Trichoderma reesei CBH I and EG II and their catalytic domains on steam pretreated softwood and isolated lignin. J Biotechnol 107:65–72. https://doi.org/10.1016/j.jbiotec.2003.09.011

Zhang Y, Liu Y-Y, Xu J et al (2012) High solid and low enzyme loading based saccharification of agricultural biomass. 7:345–353

Agrawal R, Bhadana B, Mathur AS, Kumar R, Gupta RP, Satlewal A (2018) Improved enzymatic hydrolysis of pilot scale pretreated rice straw at high total solids loading. Front Energy Res 6:115. https://doi.org/10.3389/fenrg.2018.00115

Pérez Pimienta JA, Papa G, Rodriguez A, Barcelos CA, Liang L, Stavila V, Sanchez A, Gladden JM, Simmons BA (2019) Pilot-scale hydrothermal pretreatment and optimized saccharification enables bisabolene production from multiple feedstocks. Green Chem 21:3152–3164. https://doi.org/10.1039/c9gc00323a

Pérez-Pimienta JA, Papa G, Gladden JM, Simmons BA, Sanchez A (2020) The effect of continuous tubular reactor technologies on the pretreatment of lignocellulosic biomass at pilot-scale for bioethanol production. RSC Adv 10:18147–18159. https://doi.org/10.1039/d0ra04031b

Rodríguez F, Sanchez A, Amaya-Delgado L (2018) Xyloligosaccharides production from lignocellulosic biomass using a pretreatment continuous tubular reactor. Modelling and experimental validation. Ind Crops Prod 134:62–70. https://doi.org/10.1016/j.indcrop.2019.03.058

Sluiter A, Hames B, Ruiz R, et al (2008) Determination of structural carbohydrates and lignin in biomass: laboratory analytical procedure (LAP). https://www.nrel.gov/docs/gen/fy11/42618.pdf

Jaramillo I, Sanchez A (2018) Mass flow dynamic modeling and residence time control of a continuous tubular reactor for biomass pretreatment. ACS Sustain Chem Eng 6:8570–8577. https://doi.org/10.1021/acssuschemeng.8b00882

Adney B, Baker J (2008) Measurement of cellulase activities laboratory. Tech Rep NREL/TP-510-42628 8

Luo P, Liu Z, Yang C, Wang G (2008) Study of simultaneous saccharification and fermentation for steam exploded wheat straw to ethanol. Front Chem Eng China 2:447–451. https://doi.org/10.1007/s11705-008-0069-1

Dowe N, Mcmillan J (2008) SSF experimental protocols -- lignocellulosic biomass hydrolysis and fermentation. Tech Rep NREL/TP-510-42630

Sant’Ana da Silva A, Fernandes de Souza M, Ballesteros I, Manzanares P, Ballesteros M, P. S. Bon E (2016) High-solids content enzymatic hydrolysis of hydrothermally pretreated sugarcane bagasse using a laboratory-made enzyme blend and commercial preparations. Process Biochem 51:1561–1567. https://doi.org/10.1016/j.procbio.2016.07.018

Alvira P, Negro MJ, Ballesteros I, González A, Ballesteros M (2016) Steam explosion for wheat straw pretreatment for sugars production. Bioethanol 2:66–75. https://doi.org/10.1515/bioeth-2016-0003

Mukasekuru MR, Hu J, Zhao X, Sun FF, Pascal K, Ren H, Zhang J (2018) Enhanced high-solids fed-batch enzymatic hydrolysis of sugar cane bagasse with accessory enzymes and additives at low cellulase loading. ACS Sustain Chem Eng 6:12787–12796. https://doi.org/10.1021/acssuschemeng.8b01972

Gao Y, Xu J, Yuan Z, Zhang Y, Liu Y, Liang C (2014) Optimization of fed-batch enzymatic hydrolysis from alkali-pretreated sugarcane bagasse for high-concentration sugar production. Bioresour Technol 167:41–45. https://doi.org/10.1016/j.biortech.2014.05.034

Gladis A, Bondesson PM, Galbe M, Zacchi G (2015) Influence of different SSF conditions on ethanol production from corn stover at high solids loadings. Energy Sci Eng 3:481–489. https://doi.org/10.1002/ese3.83

Du J, Zhang F, Li Y et al (2014) Enzymatic liquefaction and saccharification of pretreated corn stover at high-solids concentrations in a horizontal rotating bioreactor. Bioprocess Biosyst Eng 37:173–181. https://doi.org/10.1007/s00449-013-0983-6

Geng W, Jin Y, Jameel H, Park S (2015) Strategies to achieve high-solids enzymatic hydrolysis of dilute-acid pretreated corn stover. Bioresour Technol 187:43–48. https://doi.org/10.1016/j.biortech.2015.03.067

Du J, Cao Y, Liu G et al (2017) Identifying and overcoming the effect of mass transfer limitation on decreased yield in enzymatic hydrolysis of lignocellulose at high solid concentrations. Bioresour Technol 229:88–95. https://doi.org/10.1016/j.biortech.2017.01.011

Liu Y, Xu J, Zhang Y, Yuan Z, Xie J (2015) Optimization of high solids fed-batch saccharification of sugarcane bagasse based on system viscosity changes. J Biotechnol 211:5–9. https://doi.org/10.1016/j.jbiotec.2015.06.422

Caspeta L, Caro-Bermúdez MA, Ponce-Noyola T, Martinez A (2014) Enzymatic hydrolysis at high-solids loadings for the conversion of agave bagasse to fuel ethanol. Appl Energy 113:277–286. https://doi.org/10.1016/j.apenergy.2013.07.036

Li K, Qin JC, Liu CG, Bai FW (2016) Optimization of pretreatment, enzymatic hydrolysis and fermentation for more efficient ethanol production by Jerusalem artichoke stalk. Bioresour Technol 221:188–194. https://doi.org/10.1016/j.biortech.2016.09.021

Gupta R, Kumar S, Gomes J, Kuhad RC (2012) Kinetic study of batch and fed-batch enzymatic saccharification of pretreated substrate and subsequent fermentation to ethanol. Biotechnol Biofuels 5:16. https://doi.org/10.1186/1754-6834-5-16

Hernández-Beltrán JU, Hernández-Escoto H (2018) Enzymatic hydrolysis of biomass at high-solids loadings through fed-batch operation. Biomass and Bioenergy 119:191–197. https://doi.org/10.1016/j.biombioe.2018.09.020

Sharma S, Kumar R, Gaur R, Agrawal R, Gupta RP, Tuli DK, Das B (2015) Pilot scale study on steam explosion and mass balance for higher sugar recovery from rice straw. Bioresour Technol 175:350–357. https://doi.org/10.1016/j.biortech.2014.10.112

Fockink DH, Urio MB, Chiarello LM, Sánchez JH, Ramos LP (2016) Principles and challenges involved in the enzymatic hydrolysis of cellulosic materials at high total solids. En: Green Fuels and Technology. pp 147–173 Springer, Cham. https://doi.org/10.1007/978-3-319-30205-8_7

Horan E, Zhang J, Viikari L et al (2011) Thermostable endoglucanases in the liquefaction of hydrothermally pretreated wheat straw. Biotechnol Biofuels 4:1–10. https://doi.org/10.1186/1754-6834-4-2

Koppram R, Nielsen F, Albers E et al (2015) Simultaneous saccharification and co-fermentation for bioethanol production using corncobs at lab, PDU and demo scales. Fuel Prod from Non-Food Biomass Corn Stover:155–179. https://doi.org/10.1201/b18437

Gonçalves FA, Ruiz HA, Nogueira CDC et al (2014) Comparison of delignified coconuts waste and cactus for fuel-ethanol production by the simultaneous and semi-simultaneous saccharification and fermentation strategies. Fuel 131:66–76. https://doi.org/10.1016/j.fuel.2014.04.021

Santos JRA, Lucena MS, Gusmão NB, Gouveia ER (2012) Optimization of ethanol production by Saccharomyces cerevisiae UFPEDA 1238 in simultaneous saccharification and fermentation of delignified sugarcane bagasse. Ind Crops Prod 36:584–588. https://doi.org/10.1016/j.indcrop.2011.10.002

Tomás-Pejó E, Oliva JM, Ballesteros M, Olsson L (2008) Comparison of SHF and SSF processes from steam-exploded wheat straw for ethanol production by xylose-fermenting and robust glucose-fermenting Saccharomyces cerevisiae strains. Biotechnol Bioeng 100:1122–1131. https://doi.org/10.1002/bit.21849

Li X, Lu J, Zhao J, Qu Y (2014) Characteristics of corn stover pretreated with liquid hot water and fed-batch semi-simultaneous saccharification and fermentation for bioethanol production. PLoS Oneuiy87:9. https://doi.org/10.1201/b18437

Lu J, Li X, Yang R, Yang L, Zhao J, Liu Y, Qu Y (2013) Fed-batch semi-simultaneous saccharification and fermentation of reed pretreated with liquid hot water for bio-ethanol production using Saccharomyces cerevisiae. Bioresour Technol 144:539–547. https://doi.org/10.1016/j.biortech.2013.07.007

Hiyama RYO, Harada A, Seiki G, Orihashi KEN (2016) Ethanol production from unpretreated waste medium of shiitake mushroom (Lentinula edodes) by semi-simultaneous saccharification and fermentation under high substrate concentration conditions. Cellul Chem Technol 50:771–780

de Oliveira RA, Gottschalk LMF, Freitas SP, Bon EP d S (2018) One-vessel saccharification and fermentation of pretreated sugarcane bagasse using a helical impeller bioreactor. Biomass Conv Bioref 8:1–10. https://doi.org/10.1007/s13399-017-0272-8

Shahsavarani H, Hasegawa D, Yokota D, Sugiyama M, Kaneko Y, Boonchird C, Harashima S (2013) Enhanced bio-ethanol production from cellulosic materials by semi-simultaneous saccharification and fermentation using high temperature resistant Saccharomyces cerevisiae TJ14. Seibutsu-kogaku Kaishi 115:20–23. https://doi.org/10.1016/j.jbiosc.2012.07.018

Sárvári Horváth I, Franzén CJ, Taherzadeh MJ et al (2003) Effects of furfural on the respiratory metabolism of Saccharomyces cerevisiae in glucose-limited chemostats. Appl Environ Microbiol 69:4076–4086. https://doi.org/10.1128/AEM.69.7.4076

Acknowledgements

The authors also acknowledge Dr. J. A. Perez-Pimienta and Dr. F. Rodriguez-Palomera for their assistance in the pretreatment of WS using the CR at the Bioenergy Futures Laboratory.

Funding

Financial support was received from the Energy Sustainability Fund 2014 (CONACYT-SENER, Mexico) Grants 245750 and 249564 (Mexican Bioenergy Innovation Centre, Bio-alcohols Cluster). JG received financial support from CONACYT in the form of Ph.D. scholarships (455101 and 291250).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. The conceptualization of the work was established by Jorge Gonzalez, Arturo Sanchez, and Lorena Amaya. Material preparation, data collection, and analysis were performed by Jorge Gonzalez and Alexander Valle. The first draft of the manuscript was written by all authors who commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gonzalez-Rios, J.A., Valle-Pérez, A.U., Amaya-Delgado, L. et al. A quick fed-batch saccharification strategy of wheat straw at high solid loadings improving lignocellulosic ethanol productivity. Biomass Conv. Bioref. 13, 4991–5003 (2023). https://doi.org/10.1007/s13399-021-01580-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01580-0