Abstract

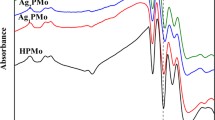

In this work, biomass-based platform molecule lactic acid conversion to acrylic acid has been studied. A series of lanthanum phosphate (LaP) catalysts prepared by varying the lanthanum to phosphorus (La/P) mole ratio (i.e., 0.2, 0.35, 0.5, 1.0, and 2.0) and also prepared at different calcination temperatures (i.e., 400, 500, 600, and 800 °C) were investigated. The catalysts were characterized by using different techniques and tested in the dehydration of lactic acid (LA) to acrylic acid (AA) production. All the synthesized catalysts were characterized to analyze the physicochemical properties such as degree of crystallinity, total surface acidity, specific surface area, and morphology. The La/P mole ratio was found to be significant in designing the optimized catalytic system. The NH3-TPD results imply that all the catalysts exhibited varied amount of total acidity with phosphate loadings, which are mostly weak acid sites. The weak acid sites which are mainly Lewis acidity type played an important role in producing AA selectively and efficiently from the LA conversion. The most optimized reaction conditions were determined to obtain the highest LA conversion, selectivity, and AA yield. The catalyst with an La/P mole ratio of 0.35 and calcined at 500 °C exhibited the best performance with complete LA conversion, AA selectivity of ~ 74%, and a maximum yield of AA of ~ 74%. Furthermore, the LaP(0.35)[500] catalyst was successfully tested at three different time on streams and found to be stable.

Similar content being viewed by others

References

Hengfu S, Chun B, Xu C (2020) Hydrothermal liquefaction of biomass to fuels and value-added chemicals: products applications and challenges to develop large-scale operations. Biomass Bioenergy 135:105510

Climent MJ, Corma A, Iborra S (2014) Conversion of biomass platform molecules into fuel additives and liquid hydrocarbon fuels. Green Chem 16:516–547. https://doi.org/10.1039/C3GC41492B

Xu C, Paone E, Rodrı’guez-Padro’n D, Luque R, Mauriello F (2020) Recent catalytic routes for the preparation and the upgrading of biomass derived furfural and 5-hydroxymethylfurfura. Chem Soc Rev 49:4273–4306

Meng W, Raf D, Kyriakos M, John W, Tianwei T, Jan Baeyens FG, Yunming F (2019) Biomass-derived aviation fuels: challenges and perspective. Progress in Energy and Combustion Science 74:31–49

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “Top 10” revisited. Green Chem 12:539–554. https://doi.org/10.1039/B922014C

Serrano-Ruiz JC, Pineda A, Balu AM, Luque R, Campelo JM, Romero AA, Ramos-Fernández JM (2012) Catalytic transformations of biomass-derived acids into advanced biofuels. Catal Today 195:162–168. https://doi.org/10.1016/j.cattod.2012.01.009

Dusselier M, Wouwe PV, Dewaele A, Makshina E, Sels BF (2013) Lactic acid as a platform chemical in the biobased economy: the role of chemo catalysis. Energy Environ Sci 6:1415–1442. https://doi.org/10.1039/C3EE00069A

Jarvinen M, Myllykoski L, Keiski R, Sohlo J (2000) Separation of lactic acid from fermented broth by reactive extraction. Bioseparation 9:163–166. https://doi.org/10.1023/A:1008183322075

Wang FF, Liu CL, Dong WS (2013) Highly efficient production of lactic acid from cellulose using lanthanide triflate catalysts. Green Chem 15:2091–2095. https://doi.org/10.1039/C3GC40836A

Wang FF, Liu J, Li H, Liu CL, Yang RZ, Dong WS (2015) Conversion of cellulose to lactic acid catalyzed by erbium-exchanged montmorillonite K10. Green Chem 17:2455–2463. https://doi.org/10.1039/C4GC02131B

Yang L, Su J, Carl S, Lynam JG, Yang X, Lin H (2015) Catalytic conversion of hemicellulosic biomass to lactic acid in pH neutral aqueous phase media. Appl Catal B Environ 162:149–157. https://doi.org/10.1016/j.apcatb.2014.06.025

Purushothaman RKP, Haveren JV, Van Es DS, Melian-Cabrera I, Meeldijk JD, Heeres HJ (2014) An efficient one pot conversion of glycerol to lactic acid using bimetallic gold-platinum catalysts on a nanocrystalline CeO2 support. Appl Catal B Environ 147:92–100. https://doi.org/10.1016/j.apcatb.2013.07.068

Sharninghausen LS, Campos J, Manas MG, Crabtree RH (2014) Efficient selective and atom economic catalytic conversion of glycerol to lactic acid. Nature Commun 5:5084. https://doi.org/10.1038/ncomms6084

Marianou AA, Michailof CC, Ipsakis D, Konstantinos Triantafyllidis Angelos A. Lappasa (2019) Cellulose conversion into lactic acid over supported HPA catalysts. Green Chem 21:6161–6178

Xia M, Dong W, Minyan G, Cheng C, Zheng S, Zhang Y (2018) Synergetic effects of bimetals in modified beta zeolite for lactic acid synthesis from biomass derived carbohydrates. RSC Adv 8:8965–8975

Xu X, Lin J, Cen P (2006) Advances in the research and development of acrylic acid production form biomass. Chinese J Chem Eng 14:419–427. https://doi.org/10.1016/S1004-9541(06)60094-3

Lin MM (2001) Selective oxidation of propane to acrylic acid with molecular oxygen. Appl Catal A Gen 207:1–16. https://doi.org/10.1016/S0926-860X(00)00609-8

Fan Y, Zhou C, Zhu X (2009) Selective catalysis of lactic acid to produce commodity chemicals. Catal Rev 51:293–324. https://doi.org/10.1080/01614940903048513

Lyu S, Wang T (2017) Efficient production of acrylic acid by dehydration of lactic acid over BaSO4 with crystal defects. RSC Adv 7:10278–10286

Sawicki RA (1988) Catalyst for dehydration of lactic acid to acrylic acid, U.S. Patent 4729978

Zhang J, Lin J, Cen P (2008) Catalytic dehydration of lactic acid to acrylic acid over sulfate catalysts. Can J Chem Eng 86:1047–1053. https://doi.org/10.1002/cjce.20115

Tang C, Peng J, Fan G, Li X, Pu X, Bai W (2014) Catalytic dehydration of lactic acid to acrylic acid over dibarium pyrophosphate. Catal Commun 43:231–234. https://doi.org/10.1016/j.catcom.2013.10.009

Tang C, Peng J, Li X, Zhai Z, Jiang N, Bai W, Gao H, Liao Y (2014) Strontium pyrophosphate modified by phosphoric acid for the dehydration of lactic acid to acrylic acid. RSC Adv 4:28875–28882. https://doi.org/10.1039/C4RA03398A

Blanco E, Delichere P, Millet JMM, Loridant S (2014) Gas phase dehydration lactic acid to acrylic acid over alkalin-earth phosphate catalysts. Catal Today 226:185–191. https://doi.org/10.1016/j.cattod.2013.09.059

Holmen RE (1958) Production of acrylates by catalytic dehydration of lactic acid and alkyl lactates, US Patent 2859240

Nagaraju N, Kumar VP, Srikanth A, Rajan NP, Chary KVR (2016) Vapor-phase catalytic dehydration of lactic acid to acrylic acid over nano-crystalline cerium phosphate catalysts. Appl Petrochem Res 6:367–377. https://doi.org/10.1007/s13203-016-0150-5

Wang H, Yu D, Sun P, Yan J, Wang Y, Haung H (2008) Rare earth metal modified NaY: structure and catalytic performance for lactic acid dehydration to acrylic acid. Catal Commun 9:1799–1803. https://doi.org/10.1016/j.catcom.2008.01.023

Yan B, Tao LZ, Liang Y, Xu BQ (2014) Sustainable production of acrylic acid: catalytic performance of hydroxyapatites for gas-phase dehydration of lactic acid. ACS Catal 4:1931–1943. https://doi.org/10.1021/cs500388x

Matsura Y, Onda A, Ogo S, Yanagisawa K (2014) Acrylic acid synthesis from lactic acid over hydroxyapatite catalysts with various cations and anions. Catal Today 226:192–197. https://doi.org/10.1016/j.cattod.2013.10.031

Li C, Zhu Q, Cui Z, Wang B, Tan T (2019) Insight into deactivation behavior and determination of generation time over hydroxyapatite catalyst in the dehydration of lactic acid to acrylic acid. Ind Eng Chem Res 58:53–59. https://doi.org/10.1021/acs.iecr.8b04340

Ghantani VC, Lomate S, Dongre MK, Umbarkar SB (2013) Catalytic dehydration of lactic acid to acrylic acid using calcium hydroxyapatite catalysts. Green Chem 15(2013):1211–1217. https://doi.org/10.1039/C3GC40144H

Yan B, Tao LZ, Liang Y, Xu BQ (2014) Sustainable production of acrylic acid: alkali-ion exchanged beta zeolite for gas phase dehydration of lactic acid. Chem Sus Chem 6:1568–1578. https://doi.org/10.1002/cssc.201400134

Zhang L, Theng DS, Du Y, Xi S, Huang L, Gao F, Wang C, Chen L, Borgna A (2017) Selective conversion of lactic acid to acrylic acid over alkali and alkaline-earth metal co-modified NaY zeolites. Catal Sci Technol 7:6101–6111. https://doi.org/10.1039/C7CY02142A

Yan B, Tao L, Mahmood A, Yu L, Xu B-Q (2016, 2016) Potassium-ion exchanged zeolites for sustainable production of acrylic acid by gas-phase dehydration of lactic acid. ACS Catal. https://doi.org/10.1021/acscatal.6b01979

Yan B, Mahamood A, Liang Y, Xu BQ (2016) Sustainable production of acrylic acid: Rb+- and Cs+-exchanged beta zeolite catalysts for catalytic gas-phase dehydration of lactic acid. Catal Today 269:65–73. https://doi.org/10.1016/j.cattod.2015.10.030

Nafe G, Lopez-Martinez MA, Dyballa M, Hunger M, Traa Y, Hirth T, Klemm E (2015) Deactivation behavior of alkali-metal zeolites in the dehydration of lactic acid to acrylic acid. J Catal 329:413–424. https://doi.org/10.1016/j.jcat.2015.05.017

Yuan C, Liu H, Zhang Z, Lu H, Zhu Q, Chen Y (2015) Alkali-metal-modified ZSM-5 zeolites for improvement of catalytic dehydration of lactic acid to acrylic acid. Chinese J. Catal 36:1861–1866. https://doi.org/10.1016/S1872-2067(15)60970-6

Sobuś N, Michorczyk B, Piotrowski M, Kuterasiński Ł, Chlebda DK, Łojewska J, Jędrzejczyk RJ, Jodłowski P, Kuśtrowski P, Czekaj I (2019) Design of Co, Cu and Fe–BEA zeolite catalysts for selective conversion of lactic acid into acrylic acid. Catal Lett 149:3349–3360. https://doi.org/10.1007/s10562-019-02883-8

Liu ZH, Yan B, Liang Y, Xu BQ (2020) Comparative study of gas-phase dehydration of alkyl lactates and lactic acid for acrylic acid production over hydroxyapatite catalysts. Molecular Catalysis 494:111098. https://doi.org/10.1016/j.mcat.2020.111098

Tang C, Peng J, Li X, Zhai Z, Bai W, Jiang N, Gao H, Liao Y (2015) Efficient and selective conversion of lactic acid into acetaldehyde using a mesoporous aluminum phosphate catalyst. Green Chem 17:1159–1166. https://doi.org/10.1039/C4GC01779J

Rajesh K, Mukundan P, Krishna Pillai P, Nair VR, Warrier KGK (2004) High-surface-area nanocrystalline cerium phosphate through aqueous sol−gel route. Chem Mater 16:2700–2705. https://doi.org/10.1021/cm0499139

Guo Z, Theng DS, Tang KY, Zhang L, Huang L, Borgna A, Wang C (2016) Dehydration of lactic acid to acrylic acid over lanthanum phosphate catalysts: the role of Lewis acid sites. Phys Chem Chem Phys 18:23746–23754. https://doi.org/10.1039/C6CP04163A

Onoda H, Nariai H, Moriwaki A, Maki H, Motooka I (2002) Formation and catalytic characterization of various rare earth phosphates. Mater Chem 12:1754–1760. https://doi.org/10.1039/B110121H

Takita Y, Sano K, Muraya T, Nishiguchi H, Kawata N, Ito M, Akbay T, Ishihara T (1998) Oxidative dehydrogenation of iso-butane to iso-butene II. Rare earth phosphate catalysts. Appl Catal A: Gen 170:23–31. https://doi.org/10.1016/S0926-860X(98)00043-X

Ho LN, Nishiguchi H, Nagaoka K, Takita Y (2006) Synthesis and characterization of a series of mesoporous nanocrystalline lanthanides phosphate. J Porous Mater 13:237–244. https://doi.org/10.1007/s10934-006-8010-9

Rajesh K, Shajesh P, Seidel O, Mukundan P, Warrier KGK (2007) A facile sol–gel strategy for the synthesis of rod-shaped nanocrystalline high-surface-area lanthanum phosphate powders and nanocoatings. Adv Funct Mater 17:1682–1690. https://doi.org/10.1002/adfm.200600794

Rajesh K, Sivakumar B, Pillai PK, Mukudhn P, Warrier KGK, Nair VR (2004) Synthesis of nanocrystalline lanthanum phosphate for low temperature densification to monazite ceramics. Mater Lett 58:1687–1691. https://doi.org/10.1016/j.matlet.2003.11.028

Lucas S, Champion E, Bernache-Assollant D, Leroy G (2004) Rare earth phosphate powders RePO4.nH2O (Re = La, Ce or Y)-part-II. Thermal behavior. J Solid State Chem 177:1312–1320. https://doi.org/10.1016/j.jssc.2003.11.004

Chai Z, Suo Q, Wang H, Wang X (2013) Mesoporous lanthanum phosphate nano structures containing H3PO4 as superior electrolyte for PEM fuel cell. RSC Adv 3:21928–21935. https://doi.org/10.1039/C3RA42094A

Yan B, Liu ZH, Liang Y, Xu BQ (2020) Acrylic acid production by gas-phase dehydration of lactic acid over K+-exchanged ZSM-5: reaction variable effects, kinetics and new evidence for cooperative acid-base bifunctional catalysis. Ind Eng Chem Res 59:17417–17428. https://doi.org/10.1021/acs.iecr.0c02148

Huang L, Theng DS, Zhang L, Chen L, Wang C, Borgna A (2019) In situ-generated supported potassium lactate: stable catalysis for vapor-phase dehydration of lactic acid to acrylic acid. ACS Omega 4:8146–8166. https://doi.org/10.1021/acsomega.9b00745

Rajan NP, Rao GS, Kumar VP, Chary KVR (2014) Vapour phase dehydration of glycerol over VPO catalyst supported on zirconium phosphate. Catal Sci Technol 4:81–92. https://doi.org/10.1039/C3CY00430A

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

(DOC 406 kb)

Rights and permissions

About this article

Cite this article

Nekkala, N., Balla, P., Ginjupalli, S.R. et al. Lanthanum phosphate: an efficient catalyst for acrylic acid production through lactic acid dehydration. Biomass Conv. Bioref. 12, 3535–3546 (2022). https://doi.org/10.1007/s13399-020-01148-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01148-4