Abstract

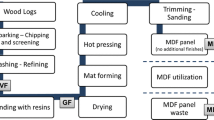

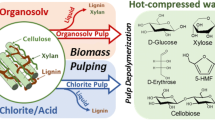

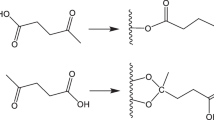

This study investigates the feasibility of acid precipitation for the separation and recovery of lignin and hydrocarbon derivatives from the waste stream of the alkali extraction of recycled cardboard. The recovery of chemicals from this effluent is complex due to their heterogeneity. Apart from the lignin and hydrocarbon derivatives, also, fillers, inks, and polysaccharides are present. A procedure of fractional acid precipitation was designed, reducing the pH from 10.7 to 8.8, 7.2, 5.1, 3.1, and 1.5. Each solid fraction was analyzed by infrared spectroscopy to determine its chemical composition and amount of precipitate. A mixture of lignin and hydrocarbon derivatives was detected in the solids obtained at pH 3.1. A dichloromethane extraction of the hydrocarbon derivatives was performed. Both recovered lignin and hydrocarbon were analyzed by infrared and gel permeation chromatography. The lignin showed similar characteristics (e.g., molecular weight ≈ 10.000 Da) as commercial lignin from virgin softwood. For the hydrocarbon derivatives, a molecular weight range between 10,000 and 150 Da was observed. In conclusion, this paper shows that the recovery of lignin and hydrocarbon derivatives is scientifically and technologically possible from the waste stream of the cardboard recycling processes. Further research is necessary to improve the extraction efficiency that was around 7.9% for the lignin and around 5.5% of the total amount of extractives compared with their amount in cardboard. Despite the low extraction efficiency, the estimated 9.6 million tons of lignin present in cardboard and the lignin price around 300–500 USD/ton make this research of industrial interest.

Graphical abstract

Similar content being viewed by others

References

European Commission. https://ec.europa.eu/clima/policies/strategies/2050_en. Accessed 21/01/2020

Monte MC, Fuente E, Blanco A, Negro C (2009) Waste management from pulp and paper production in the European Union. Waste Manag 29:293–308

CEPI (Confederation of European paper industries) (2018) Key statistics report. http://www.cepi.org/key_statistics_2018 On-line Publication 09/07/2018;

Martin J, Haggith M State of the Global Paper Industry, Environmental Paper Network https://environmentalpaper.org/wp-content/uploads/2018/04/StateOfTheGlobalPaperIndustry2018_FullReport-Final-1.pdf. Accessed 01/01/2020

Holik H (ed) (2013) Handbook of paper and board, vol 1. Wiley-VCH Verlag GmbH & Co, Weinheim

Bajpai P (2015) Management of pulp and paper mill waste. Springer, Switzerland

Ek M, Gellerstedt G, Henriksson G (2009) Wood Chemistry and Wood Biotechnology, vol 1. De Gruyter, Berlin

Adamoupolos S, Oliver JV (2006) Fibre composition of packaging grade papers as determined by the graff “C” staining test. Wood Fibre Sci 38(4):567–575

Eds SH (2006) Handbook of pulp. WILEY-VCH Verlag GmbH &Co, Weinheim

Zanuttini MA, Marzocchi VA, Mocchiutti P (2009) Alkaline peroxide treatment for improving the papermaking properties of recycled unbleached softwood kraft pulps. Cellul Chem Technol 43(1–3):65–69

Cho BU, Ryu JY, Song BK (2012) Improvement of ink and heavy metal removal from old corrugated container stock by alkali kneading. J Ind Eng Chem 18:697–701

Bajpai P (2010) Environmentally friendly production of pulp and paper. Wiley, Hoboken

Cequier E, Aguilera J, Balcells M, Garayoa RC (2019) Extraction and characterization of lignin from olive pomace: a comparison study among ionic liquid, sulfuric acid, and alkaline treatments. Biomass Conv Bioref 9:241–252

Monte LS, Escócio VA, de Sousa AMF, Furtado CRG, Leite MCAM, Visconte LLY, Pacheco EBAV (2018) Study of time reaction on alkaline pretreatment applied to rice husk on biomass component extraction. Biomass Conv Bioref 8:189–197

Tang P, Hassan O, Yue CS, Abdul PM (2020) Lignin extraction from oil palm empty fruit bunch fiber (OPEFBF) via different alkaline treatments. Biomass Conv Bioref 10:125–138

Dohertya WOS, Mousavioun P, Fellows CM (2011) Value-adding to cellulosic ethanol: lignin polymers. Ind Crop Prod 33:259–276

Wendisch VF, Kim Y, Lee J (2018) Chemicals from lignin: recent depolymerization techniques and upgrading extended pathways. Curr Opin Green Sustain Chem 14:33–39

Vishtal AG, Kraslawski A (2011) Challenges in industrial applications of technical lignins. BioResources 6(3):3547–3568

Speight JG (2019) Heavy oil recovery and upgrading. Elsevier, Cambridge, pp 559–614

Stiefel S, Di Marino D, Eggert A, Kühnrich IR, Schmidt M, Grande PM, Leitner W, Jupke A, Wessling M (2017) Liquid/liquid extraction of biomass-derived lignin from lignocellulosic pretreatments. Green Chem 19:93–97

Bokharya A, Leitcha M, Gaob WJ, Fatehi P, Liao BQ (2019) Separation of hemicelluloses and lignins from synthetic hydrolyzate and thermomechanical pulp mill process water via liquid-liquid extraction. Sep Purif Technol 215:508–515

Domínguez-Robles J, Espinosa E, Savy D, Rosal A, Rodriguez A (2016) Biorefinery process combining Specel® process and selective lignin precipitation using mineral acids. BioResources 11(3):7061–7077

Kamble SV, Bhattacharyulu YC (2015) Selective separation of biomass from black liquor waste by inorganic and organic acids. Int J Adv Res 3(1):684–692

da Silva SHF, Gordobil O, Labidi J (2020) Organic acids as a greener alternative for the precipitation of hardwood kraft lignins from the industrial black liquor. Int J Biol Macromol 142:583–591

Jaquess P, Bernard Janse B (2012) Processes and systems for enzymatically isolating lignin and other bioproducts from herbaceous plants. U.S. patent 20120190092

Nong G, Zhou Z, Wang S (2016) Generation of hydrogen, lignin and sodium hydroxide from pulping black liquor by electrolysis. Energies 9:13

Kurple K, Kurple N, Kerman M (2016) Process for the isolation of lignin from black liquor and modification of the lignin for plastic applications. U.S. patent 2016032525

Kouisni L, Holt-Hindle P, Maki K, Paleologou M (2012) The Lignoforce System™: a new process for the production of high-quality lignin from black liquor. J-FOR 2(4):6–10

Tomani P (2010) The Lignoboost process. Cellul Chem Technol 44(1–3):53–58

Bhaskar T, Pandey A, Mohan SV, Lee DJ, Khanal SK (2018) Waste biorefinery: potential and perspectives. Elsevier, Amsterdam

García A, Toledano A, Serrano L, Egüés I, González M, Marín F, Labidi J (2009) Characterization of lignins obtained by selective precipitation. Sep Purif Technol 68:193–198

Wang G, Chen H (2013) Fractionation of alkali-extracted lignin from steam-exploded stalk by gradient acid precipitation. Sep Purif Technol 105:98–105

Lourençon TV, Hansel FA, da Silva TA, Ramos LP, de Muniz GIB, Magalhães WLE (2015) Hardwood and softwood kraft lignins fractionation by simple sequential acid precipitation. Sep Purif Technol 154:82–88

Bajpai P (2015) Pulp and paper industry: chemicals. Elsevier, Waltham

Burkart L (1999) Process for preparation of lignin and microcellulose. U.S. patent 5859236A

Jahan MS, Rahman MM, Sarkar M (2016) Upgrading old corrugated cardboard (OCC) to dissolving pulp. Cellulose 23:2039–2047

Tolbert A, Akinosho H, Khunsupat R, Naskar AK, Ragauskas AJ (2014) Characterization and analysis of the molecular weight of lignin. Biofuels Bioprod Biorefin 8:836–856. https://doi.org/10.1002/bbb

Cao B, Heise O (2005) Analyzing contaminants in OCC: wax or not wax? Pulp Pap. Canada 106(4):41–46

Venditti RA, Gilbert RD, Kadla JF, Bliss TL (2004) Supercritical carbon dioxide extraction of wax treated old corrugated containers: an economic analysis. Prog Pap Recycl 13(2):13–19

Freeland SJ (1999) Method for removing wax from a pulp furnish. WO 99/42651

Zhu W (2013) Equilibrium of lignin precipitation: the effects of pH, temperature, ion strength and wood origins, Thesis for the degree of licentiate of engineering, Chalmers University of Technology, Gothenburg, Sweden

Suess HS (2010) Pulp bleaching today. De Gruyter, Berlin

Socrates G (2001) Infrared and Raman characteristic group frequencies: tables and charts. Wiley, Chichester

Othmer K (1991) Kirk-Othmer encyclopedia of chemical technology, 4th edn. Wiley, New York

Silverstein RM, Webster FX, Kiemle DJ (2005) Spectrometric identification of organic compounds. Wiley, New York

Tipson RS (1968) Infrared spectroscopy of carbohydrates a review of literature. U.S. Government Printing Office, Washington D.C.

Heitner C, Dimmel DR, Schmidt JA (eds) (2010) Lignin and lignans advances in chemistry. Boca Raton, CRC press

Jin S, Fallgren P, Lu A (2011) Calcium carbonate and calcium carbonate-containing materials for removing bioagents from water, US pat. 2011/003118 A1

Moyo F, Tandlich R, Wilhelmi BS, Balaz S (2014) Sorption of hydrophobic organic compounds on natural sorbents and organoclays from aqueous and non-aqueous solutions: a mini-review. Int J Environ Res Public Health 11:5020–5048

Peng X, Nie S, Li X, Huang X, Li Q (2019) Characteristics of the water- and alkali-soluble hemicelluloses fractionated by sequential acidification and graded-ethanol from sweet maize stems. Molecules 24:212

Ragnar M, Lindgren CT, Nilvebrant N (2000) pKa-values of guaiacyl and syringyl phenols related to lignin. J Wood Chem Technol 20(3):277–305

Gominšek T, Lubej A, Pohar C (2005) Continuous precipitation of calcium sulfate dihydrate from waste sulfuric acid and lime. J Chem Technol Biotechnol 80:939–947

Morgan LJ, Ananthapadmanabhan KP, Somasundaran P (1986) Oleate adsorption on hematite: problems and methods. Int J Miner Process 18:139–152

Sharma SK (2015) Green chemistry for dyes removal from waste water. Scrivener Publishing LLC, Salem

Bajwa DS, Pourhashem G, Ullah AH, Bajwa SG (2019) A concise review of current lignin production, applications, products and their environmental impact. Ind Crop Prod 139:111526

Hodásová L, Jablonský M, Škulcová A, Ház A (2015) Lignin, potential products and market value. Wood Res Slovakia 60(6):973–986

Acknowledgments

The authors would like to thank Prof. Dr. Christophe Vande Velde of the iPRACS research group of the University of Antwerp for the help in the spectra interpretation and Prof. Dr. ir. Wim Thielemans of the University of Leuven for the help in the interpretation of GPC chromatograms.

Funding

This study was supported by research funding from Flanders Innovation & Entrepreneurship (VLAIO) (Pr. Nr. IWT.155050) and the University of Antwerp.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 119 kb).

Rights and permissions

About this article

Cite this article

Tofani, G., Cornet, I. & Tavernier, S. Separation and recovery of lignin and hydrocarbon derivatives from cardboard. Biomass Conv. Bioref. 12, 3409–3424 (2022). https://doi.org/10.1007/s13399-020-00931-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00931-7