Abstract

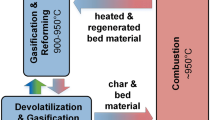

An internal reformer is developed for in situ catalytic reforming of tar and methane (CH4) in allothermal gasifiers. The study has been performed in the 150 kW dual fluidised bed (DFB) biomass gasifier at Mid Sweden University (MIUN). The MIUN gasifier is built for research on synthetic fuel production. Reduction of tars and CH4 (except for methanation application) in the syngas is a major challenge for commercialization of biomass fluidised-bed gasification technology towards automotive fuel production. The MIUN gasifier has a unique design with an internal reformer, where intensive contact of gas and catalytic solids improves the reforming reactions. This paper presents an initial study on the internal reformer operated with and without Ni-catalytic pellets, by evaluation of the syngas composition and tar/CH4 content. A novel application of Ni-catalyst in DFB gasifiers is proposed and studied in this work. It can be concluded that the reformer with Ni-catalytic pellets clearly gives a higher H2 content together with lower CH4 and tar contents in the syngas than the reformer without Ni-catalytic pellets. The gravimetric tar content decreases down to 5 g/m3 and the CH4 content down below 6 % in the syngas. The tar content can be decreased further to lower levels, with increased gas contact to the specific surface area of the catalyst and increased catalyst surface-to-volume ratio. The new design in the MIUN gasifier increases the gasification efficiency, suppresses the tar generation and upgrades the syngas quality.

Similar content being viewed by others

References

Zhang W (2010) Automotive fuels from biomass via gasification. Fuel Process Technol 91(8):866–876

Göransson K, Söderlind U, He J, Zhang W (2011) Review of syngas production via biomass DFBGs. Renew Sust Energ Rev 15:482–92

He J, Zhang W. Techno-economic evaluation of thermo-chemical biomass-to-ethanol. Applied Energy.88:1224–32

Milne T, Evans R, Abatzaglou N. Biomass Gasifier “Tars”: Their Nature, Formation, and Conversion. NREL/TP-570-25357, National Renewable Energy Laboratory, Golden, CO (US); 1998

Dayton D (2002). A review of the literature on catalytic biomass tar destruction. US DOE NREL Report Golden, CO.:510–32815

Pfeifer C, Hofbauer H (2008) Development of catalytic tar decomposition downstream from a dual fluidized bed biomass steam gasifier. Powder Technol 180:9–16

Rabou LPLM, Zwart RWR, Vreugdenhil BJ, Bos L (2009) Tar in biomass producer gas, the energy research centre of the Netherlands (ECN) experience: an enduring challenge. Energy Fuel 23:6189–98

Hofbauer H, Veronik G, Fleck T, Rauch R, Mackinger H, Fercher E (1997) The FICFB gasification process. Dev in thermochemical bio conv 2:1016–25

Belgiorno V, De Feo G, Della Rocca C, Napoli R (2003) Energy from gasification of solid wastes. Waste Manag 23:1–15

Lind F, Berguerand N, Seemann M, Thunman H (2013) Ilmenite and nickel as catalysts for upgrading of raw gas derived from biomass gasification. Energy Fuel 27:997–1007

Lind F, Seemann M, Thunman H (2011) Continuous catalytic tar reforming of biomass derived raw gas with simultaneous catalyst regeneration. Ind Eng Chem Res 50:11553–62

Pfeifer C, Rauch R, Hofbauer H, Swierczynski D, Courson C, Kiennemann A (2004) Hydrogen-rich gas production with a Ni-catalyst in a dual fluidized bed biomass gasifier. Sci in Thermal and Chem Bio Conv, Vic, Canada 30:677–90

Caballero MA, Aznar MP, Gil J, MartÃn JA, Francés E, Corella J (1997) Commercial steam reforming catalysts to improve biomass gasification with steam—oxygen mixtures. 1. Hot gas upgrading by the catalytic reactor. Ind Eng Chem Res 36:5227–39

Aznar MP, Caballero MA, Gil J, Martín JA, Corella J (1998) Commercial steam reforming catalysts to improve biomass gasification with steam—oxygen mixtures. 2. Catalytic tar removal. Ind Eng Chem Res 37:2668–80

Corella J, Orío A, Toledo J-M (1999) Biomass gasification with air in a fluidized bed: exhaustive tar elimination with commercial steam reforming catalysts. Energy Fuel 13:702–9

Corella J, Orío A, Aznar P (1998) Biomass gasification with air in fluidized bed: reforming of the gas composition with commercial steam reforming catalysts. Ind Eng Chem Res 37:4617–24

Narváez I, Corella J, Orío A (1997) Fresh tar (from a biomass gasifier) elimination over a commercial steam-reforming catalyst. Kinetics and effect of different variables of operation. Ind Eng Chem Res 36:317–27

Kirnbauer F, Wilk V, Kitzler H, Kern S, Hofbauer H (2012) The positive effects of bed material coating on tar reduction in a dual fluidized bed gasifier. Fuel 95:553–62

Rauch R, Pfeifer C, Bosch K, Hofbauer H, Swierczynski D, Courson C et al (2004) Comparison of different olivines for biomass steam gasification. Sci Thermal Chem Bio Conv 1:799–809

Göransson K, Söderlind U, Engstrand P, Zhang W (2014). An Experimental Study on Catalytic Bed Materials in a Biomass Dual Fluidised Bed Gasifier. Submitted to Renewable Energy - manuscript in progress

Xu G, Murakami T, Suda T, Matsuzaw Y, Tani H (2009) Two-stage dual fluidized bed gasification: its conception and application to biomass. Fuel Process Technol 90:137–44

Schmid JC, Pröll T, Pfeifer C, Hofbauer H. Improvement of gas-solid interaction in dual circulating fluidized bed systems. Proc 9th European Conference on Industrial Furnaces and Boilers (INFUB), Estoril, Portugal

Göransson K, Söderlind U, Zhang W (2011) Experimental test on a novel dual fluidised bed biomass gasifier for synthetic fuel production. Fuel 90:1340–9

Söderlind U., Zhang W., Göransson K., Engstrand P. “A fluidized bed gasifier system”, EP 14163446.9;. 3 April 2014

Lancee RJ, Dugulan AI, Thüne PC, Veringa HJ, Niemantsverdriet JW, Fredriksson HOA (2014) Chemical looping capabilities of olivine, used as a catalyst in indirect biomass gasification. Appl Catal B Environ 145:216–22

Pecho J, Schildhauer TJ, Sturzenegger M, Biollaz S, Wokaun A (2008) Reactive bed materials for improved biomass gasification in a circulating fluidised bed reactor. Chem Eng Sci 63:2465–76

Wei L, Xu S, Liu J, Lu C, Liu S, Liu C (2006) A novel process of biomass gasification for hydrogen-rich gas with solid heat carrier: preliminary experimental results. Energy Fuel 20:2266–73

Van Paasen SVB, Kiel JHA (2004). Tar formation in a fluidised-bed gasifier - impact of fuel properties and operating conditions. The 2nd World Conference and Technology Exhibition on Biomass for Energy, Industry and Climate Protection. Rome, Italy

Van de Kamp W, De Wild P, Zielke U, Suomalainen M, Knoef H, Good J, et al. (2005). Tar measurement standard for sampling and analysis of tars and particles in biomass gasification product gas. 14th European Biomass Conference Proceedings. Paris, France

Pfeifer C, Rauch R, Hofbauer H (2004) In-bed catalytic tar reduction in a dual fluidized bed biomass steam gasifier. Ind Eng Chem Res 43:1634–40

Corella J, Toledo JM, Padilla R (2004) Catalytic hot gas cleaning with monoliths in biomass gasification in fluidized beds. 1. Their effectiveness for tar elimination. Ind Eng Chem Res 43:2433–45

Swierczynski D, Libs S, Courson C, Kiennemann A (2007) Steam reforming of tar from a biomass gasification process over Ni/olivine catalyst using toluene as a model compound. Appl Catal B Environ 74:211–22

Acknowledgments

The authors would like to acknowledge the project support of EU Regional Development Fund, Toyota, ÅF Foundation for Research and Development, LKAB, Länsstyrelsen Västernorrland, Swedish Gasification Centre (SFC), and SCA BioNorr AB, Härnösand.

Author information

Authors and Affiliations

Corresponding author

Glossary

- BFB

-

Bubbling fluidised bed

- CFB

-

Circulating fluidised bed

- CLC

-

Chemical looping combustion

- DFB

-

Dual fluidised bed

- DFBG

-

Dual fluidised bed gasifier

- GHG

-

Greenhouse gas

- MIUN

-

Mid Sweden University

- WGS

-

Water-gas-shift

Rights and permissions

About this article

Cite this article

Göransson, K., Söderlind, U., Henschel, T. et al. Internal tar/CH4 reforming in a biomass dual fluidised bed gasifier. Biomass Conv. Bioref. 5, 355–366 (2015). https://doi.org/10.1007/s13399-014-0151-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-014-0151-5