Abstract

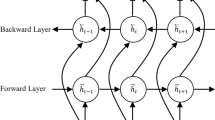

Predictive maintenance in industrial settings, especially tool wear prediction, remains crucial for operational efficiency and cost reduction. This paper proposes BiLPReS, a novel predictive model leveraging a hybrid architecture integrating bidirectional long short-term memory, Performer encoder, and residual-skip connections. Compared to convolutional and recurrent neural networks, the proposed model achieves long-range dependent global sensing and parallel computing. The Performer encoder reduces the computational complexity by the FAVOR + approach compared to the Transformer encoder. Moreover, the proposed model includes residual-skip connections to enhance information flow efficiency and minimize the risk of information loss during training. The final use of the fully connected layer reduces dimensionality and generates the predicted values. Experiments on the PHM2010 dataset involve the analysis of multichannel sensor signals, including force, acceleration, and acoustic emission. The model undergoes training and validation through k-fold cross-validation. Results unequivocally demonstrate the model’s high accuracy. Furthermore, conducting comparative experiments by selectively reducing modules validates the effectiveness of the utilized modules in enhancing the model’s performance. This study provides a viable solution for optimizing maintenance schedules, reducing downtime, and real-time monitoring of tool machining.

Similar content being viewed by others

References

Tao, F.; Qi, Q.; Liu, A.; Kusiak, A.: Data-driven smart manufacturing. J. Manuf. Syst. 48, 157–169 (2018). https://doi.org/10.1016/j.jmsy.2018.01.006

Yan, B.; Zhu, L.; Dun, Y.: Tool wear monitoring of TC4 titanium alloy milling process based on multi-channel signal and time-dependent properties by using deep learning. J. Manuf. Syst. 61, 495–508 (2021). https://doi.org/10.1016/j.jmsy.2021.09.017

Thakre, A.A.; Lad, A.V.; Mala, K.: Measurements of tool wear parameters using machine vision system. Model. Simul. Eng. 2019, 1876489 (2019). https://doi.org/10.1155/2019/1876489

Huang, Z.; Shao, J.; Guo, W.; Li, W.; Zhu, J.; Fang, D.: Hybrid machine learning-enabled multi-information fusion for indirect measurement of tool flank wear in milling. Measurement 206, 112255 (2023). https://doi.org/10.1016/j.measurement.2022.112255

Kuntoğlu, M.; Salur, E.; Gupta, M.K.; Sarıkaya, M.; Pimenov, D.Y.: A state-of-the-art review on sensors and signal processing systems in mechanical machining processes. Int. J. Adv. Manuf. Technol. 116, 2711–2735 (2021). https://doi.org/10.1007/s00170-021-07425-4

Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D.: Deep learning for smart manufacturing: methods and applications. J. Manuf. Syst. 48, 144–156 (2018). https://doi.org/10.1016/j.jmsy.2018.01.003

Zhang, C.; Zhang, H.: Modelling and prediction of tool wear using LS-SVM in milling operation. Int. J. Comput. Integr. Manuf. 29, 76–91 (2016). https://doi.org/10.1080/0951192X.2014.1003408

Wu, D.; Jennings, C.; Terpenny, J.; Gao, R.X.; Kumara, S.: A comparative study on machine learning algorithms for smart manufacturing: tool wear prediction using random forests. J. Manuf. Sci. Eng. (2017). https://doi.org/10.1115/1.4036350

Zhang, X.; Liu, L.; Wan, X.; Feng, B.: Tool wear online monitoring method based on DT and SSAE-PHMM. J. Comput. Inf. Sci. Eng. (2021). https://doi.org/10.1115/1.4050531

Li, Y.; Huang, X.; Tang, J.; Li, S.; Ding, P.: A steps-ahead tool wear prediction method based on support vector regression and particle filtering. Measurement 218, 113237 (2023). https://doi.org/10.1016/j.measurement.2023.113237

Geramifard, O.; Xu, J.X.; Zhou, J.H.; Li, X.: Multimodal hidden markov model-based approach for tool wear monitoring. IEEE Trans. Ind. Electron. 61, 2900–2911 (2014). https://doi.org/10.1109/TIE.2013.2274422

Liang, Y.; Hu, S.; Guo, W.; Tang, H.: Abrasive tool wear prediction based on an improved hybrid difference grey wolf algorithm for optimizing SVM. Measurement 187, 110247 (2022). https://doi.org/10.1016/j.measurement.2021.110247

Cheng, M.; Jiao, L.; Shi, X.; Wang, X.; Yan, P.; Li, Y.: An intelligent prediction model of the tool wear based on machine learning in turning high strength steel. Proc. Inst. Mech. Eng. Part B: J. Eng. Manuf. 234, 1580–1597 (2020). https://doi.org/10.1177/0954405420935787

Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Santamaría, J.; Fadhel, M.A.; Al-Amidie, M.; Farhan, L.: Review of deep learning: concepts CNN architectures, challenges, applications, future directions. J. Big. Data. 8, 53 (2021). https://doi.org/10.1186/s40537-021-00444-8

Zhang, X.; Shi, B.; Feng, B.; Liu, L.; Gao, Z.: A hybrid method for cutting tool RUL prediction based on CNN and multistage Wiener process using small sample data. Measurement 213, 112739 (2023). https://doi.org/10.1016/j.measurement.2023.112739

Li, J.; Lu, J.; Chen, C.; Ma, J.; Liao, X.: Tool wear state prediction based on feature-based transfer learning. Int. J. Adv. Manuf. Technol. 113, 3283–3301 (2021). https://doi.org/10.1007/s00170-021-06780-6

Lee, W.; Abdullah, M.; Ong, P.; Abdullah, H.; Teo, W.: Prediction of flank wear and surface roughness by recurrent neural network in turning process. J. Adv. Manuf. Technol. (JAMT). 15, (2021). https://jamt.utem.edu.my/jamt/article/view/6101

Serin, G.; Sener, B.; Ozbayoglu, A.M.; Unver, H.O.: Review of tool condition monitoring in machining and opportunities for deep learning. Int. J. Adv. Manuf. Technol. 109, 953–974 (2020). https://doi.org/10.1007/s00170-020-05449-w

Marani, M.; Zeinali, M.; Songmene, V.; Mechefske, C.K.: Tool wear prediction in high-speed turning of a steel alloy using long short-term memory modelling. Measurement 177, 109329 (2021). https://doi.org/10.1016/j.measurement.2021.109329

Molitor, D.A.; Kubik, C.; Becker, M.; Hetfleisch, R.H.; Lyu, F.; Groche, P.: Towards high-performance deep learning models in tool wear classification with generative adversarial networks. J. Mater. Process. Technol. 302, 117484 (2022). https://doi.org/10.1016/j.jmatprotec.2021.117484

Terrazas, G.; Martínez-Arellano, G.; Benardos, P.; Ratchev, S.: Online tool wear classification during dry machining using real time cutting force measurements and a CNN approach. J. Manuf. Mater. Process. (2018). https://doi.org/10.3390/jmmp2040072

Zhu, Q.; Sun, B.; Zhou, Y.; Sun, W.; Xiang, J.: Sample augmentation for intelligent milling tool wear condition monitoring using numerical simulation and generative adversarial network. IEEE Trans. Instrum. Meas. 70, 1–10 (2021). https://doi.org/10.1109/TIM.2021.3077995

Ma, J.; Luo, D.; Liao, X.; Zhang, Z.; Huang, Y.; Lu, J.: Tool wear mechanism and prediction in milling TC18 titanium alloy using deep learning. Measurement 173, 108554 (2021). https://doi.org/10.1016/j.measurement.2020.108554

Waheed, A.; Goyal, M.; Gupta, D.; Khanna, A.; Al-Turjman, F.; Pinheiro, P.R.: CovidGAN: data augmentation using auxiliary classifier GAN for improved Covid-19 detection. IEEE Access 8, 91916–91923 (2020). https://doi.org/10.1109/ACCESS.2020.2994762

Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł; Polosukhin, I.: Attention is all you need. Adv. Neural. Inf. Process. Syst. (2017). https://doi.org/10.48550/arXiv.1706.03762

Feng, T.; Guo, L.; Gao, H.; Chen, T.; Yu, Y.; Li, C.: A new time–space attention mechanism driven multi-feature fusion method for tool wear monitoring. Int. J. Adv. Manuf. Technol. 120, 5633–5648 (2022). https://doi.org/10.1007/s00170-022-09032-3

Liu, H.; Liu, Z.; Jia, W.; Lin, X.; Zhang, S.: A novel transformer-based neural network model for tool wear estimation. Meas. Sci. Technol. 31, 065106 (2020). https://doi.org/10.1088/1361-6501/ab7282

Devlin, J.; Chang, M.W.; Lee, K.; Toutanova, K.: Bert: pre-training of deep bidirectional transformers for language understanding. arXiv preprint arXiv:1810.04805. (2018). https://doi.org/10.48550/arXiv.1810.04805

Floridi, L.; Chiriatti, M.: GPT-3: its nature, scope, limits, and consequences. Minds. Mach. 30, 681–694 (2020). https://doi.org/10.1007/s11023-020-09548-1

Yang, Z.; Dai, Z.; Yang, Y.; Carbonell, J.; Salakhutdinov, R.R.; Le, Q.V.: Xlnet: generalized autoregressive pretraining for language understanding. Adv. Neural. Inf. Process. Syst. (2019). https://doi.org/10.48550/arXiv.1906.08237

Dosovitskiy, A.; Beyer, L.; Kolesnikov, A.; Weissenborn, D.; Zhai, X.; Unterthiner, T.; Dehghani, M.; Minderer, M.; Heigold, G.; Gelly, S.: An image is worth 16x16 words: transformers for image recognition at scale. arXiv preprint arXiv:2010.11929. (2020). https://doi.org/10.48550/arXiv.2010.11929

Sun, Q.; Yu, Z.; Li, Y.; Yang, S.; Xu, J.; Yu, H.: Wear status prediction of micro milling tools by transfer learning and ViT model, In: 2021 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), pp. 183–187 (2021). https://doi.org/10.1109/3M-NANO49087.2021.9599807

So, D.R.; Liang, C.; Le, Q.V.: The evolved transformer, In: International conference on machine learning, PMLR, pp. 5877–5886 (2019). https://doi.org/10.1109/IJCNN.1989.118638

Choromanski, K.; Likhosherstov, V.; Dohan, D.; Song, X.; Gane, A.; Sarlos, T.; Hawkins, P.; Davis, J.; Mohiuddin, A.; Kaiser, L.: Rethinking attention with performers. arXiv preprint arXiv:2009.14794. (2020). https://doi.org/10.48550/arXiv.2009.14794

Wang, S.; Li, B.Z.; Khabsa, M.; Fang, H.; Ma, H.: Linformer: self-attention with linear complexity. arXiv preprint arXiv:2006.04768. (2020). https://doi.org/10.48550/arXiv.2006.04768

Ebrahimi, M.S.; Abadi, H.K.: Study of residual networks for image recognition intelligent computing. In: Proceedings of the computing conference, vol. 2, pp. 754–763. Springer,(2021). https://doi.org/10.1007/978-3-030-80126-7_53

He, K.; Zhang, X.; Ren, S.; Sun, J.: Identity mappings in deep residual networks. In: Computer Vision–ECCV 2016: 14th European conference, Amsterdam, The Netherlands, October 11–14, 2016, Proceedings, Part IV 14, pp. 630–645. Springer, (2016). https://doi.org/10.1109/ICSensT.2016.7796266

Shao, J.: Linear model selection by cross-validation. J. Am. Stat. Assoc. 88, 486–494 (1993). https://doi.org/10.1080/01621459.1993.10476299

Hecht-Nielsen, R.: Theory of the backpropagation neural network Neural networks for perception, p. 65–93. Elsevier, Amsterdam (1992) https://doi.org/10.1109/IJCNN.1989.118638

Chen, T.; Liu, X.; Xia, B.; Wang, W.; Lai, Y.: Unsupervised anomaly detection of industrial robots using sliding-window convolutional variational autoencoder. IEEE Access 8, 47072–47081 (2020). https://doi.org/10.1109/ACCESS.2020.2977892

Kingma, D.P.; Ba, J.: Adam: A method for stochastic optimization. arXiv preprint arXiv:1412.6980. (2014). https://doi.org/10.48550/arXiv.1412.6980

Yao, Y.; Rosasco, L.; Caponnetto, A.: On early stopping in gradient descent learning. Constructive Approx 26, 289–315 (2007). https://doi.org/10.1007/s00365-006-0663-2

Xu, X.; Tao, Z.; Ming, W.; An, Q.; Chen, M.: Intelligent monitoring and diagnostics using a novel integrated model based on deep learning and multi-sensor feature fusion. Measurement 165, 108086 (2020). https://doi.org/10.1016/j.measurement.2020.108086

Nagelkerke, N.J.: A note on a general definition of the coefficient of determination. Biometrika 78, 691–692 (1991). https://doi.org/10.2307/2337038

Qiao, H.; Wang, T.; Wang, P.; Qiao, S.; Zhang, L.: A time-distributed spatiotemporal feature learning method for machine health monitoring with multi-sensor time series. Sensors (2018). https://doi.org/10.3390/s18092932

Zhao, R.; Wang, J.; Yan, R.; Mao, K.: Machine health monitoring with LSTM networks, In: 2016 10th international conference on sensing technology (ICST), pp. 1–6. (2016). https://doi.org/10.1109/ICSensT.2016.7796266

Yu, W.; Huang, H.; Guo, R.; Yang, P.: Tool wear prediction based on attention long short-term memory network with small samples. Sens. Mater. (2023). https://doi.org/10.18494/SAM4509

Liu, H.; Liu, Z.; Jia, W.; Zhang, D.; Wang, Q.; Tan, J.: Tool wear estimation using a CNN-transformer model with semi-supervised learning. Meas. Sci. Technol. 32, 125010 (2021). https://doi.org/10.1088/1361-6501/ac22ee

Feng, Y.: Improving tool wear prediction with synthetic features from conditional generative adversarial networks. TechRxiv (2022). https://doi.org/10.36227/techrxiv.21253308.v1

Acknowledgements

This research acknowledges the financial and equipment support partially provided by the Department of Science and Technology of Jilin Province (20210201108GX).

Author information

Authors and Affiliations

Contributions

Zekai Si provided conceptualization, methodology, and software. Sumei Si provided validation, visualization, and data curation. Deqiang Mu approved supervision, and project administration.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Si, Z., Si, S. & Mu, D. Efficient Tool Wear Prediction in Manufacturing: BiLPReS Hybrid Model with Performer Encoder. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-024-08943-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-024-08943-5