Abstract

Silicate-based drilling fluid (SDF) has a strong inhibition effect on shale swelling and provides good wellbore stability. SDF has also been widely used in drilling through the reservoir in recent years. However, SDF has certain damage effects on the reservoir, and its damage mechanism is not well understood. In this work, the damage of the tight sandstone formations induced by SDF was assessed by conducting fluid displacement and filtrate imbibition experiments. In addition, the damage mechanisms were further analyzed based on microscopic experiments. The research results mainly included the following four aspects: First, SDF caused significant reservoir damage by solid-phase particles and filtrate intrusion in tight sandstone reservoirs, and the latter was the main reason. Second, the incompatibility between the filtrate of the SDF and formation led to reservoir damage. This was because the SiO32−, CO32−, and OH− in the SDF reacted with Ca2+, Mg2+, and Al3+ in the formation, resulting in the generation of new minerals such as kaolinite and gibbsite. Third, the filtrate of the SDF increased the hydrophilicity of the rock surface, which induced the aqueous trapping damage. Finally, SDF was strongly alkaline (pH = 13.08), in which OH− produced by sodium metasilicate hydrolysis had alkaline corrosion effect on minerals, enhancing pore permeability. This work provides experimental evidence for the feasibility discussion of the SDF in tight sandstone reservoirs.

Similar content being viewed by others

Abbreviations

- μ a :

-

Apparent viscosity (mPa s)

- μ p :

-

Plastic viscosity (mPa s)

- τ i :

-

Initial shear (Pa)

- τ f :

-

Final shear (Pa)

- τ 0 :

-

Dynamic shear (Pa)

- D k :

-

The permeability damage rate (%)

- K 0 :

-

The initial permeability (mD)

- K 1 :

-

The post-damage permeability (mD)

- m 0 :

-

Initial mass of the rock samples (g)

- m 1 :

-

The mass of the rock samples after self-imbibition (g)

- m 2 :

-

The mass of the rock samples after backflow (g)

- φ :

-

The backflow rate of self-imbibition (%)

- r 1 :

-

Large solid-phase particle radius (μm)

- r 2 :

-

Pore size of the tight sandstone (μm)

- r 3 :

-

Small solid-phase particle radius (μm)

- D 10 :

-

The corresponding particle size when the cumulative particle size distribution reaches 10% (μm)

- D 50 :

-

The median particle size of solid-phase particles (μm)

- D 90 :

-

The corresponding particle size when the cumulative particle size distribution reaches 90% (μm)

- Rc50 :

-

The median pore throat radius (μm)

- P c :

-

Capillary imbibition force (mN/cm2)

- σ :

-

The surface tension of the liquid (mN/cm)

- θ :

-

The contact angle (°)

- r :

-

The capillary radius (cm)

References

Li, Y.; Wang, M.S.; Tan, X.F.; An, Y.H.; Liu, H.A.; Gao, K.; Guo, M.Y.: Application of hybrid silicate as a film-forming agent in high-temperature water-based drilling fluids. ACS Omega 6, 20577–20589 (2021). https://doi.org/10.1021/acsomega.1c02725

Murtaza, M.; Mahmoud, M.; Tariq, Z.: Experimental investigation of a novel, efficient, and sustainable hybrid silicate system in oil and gas well cementing. Energy Fules 34, 7388–7396 (2020). https://doi.org/10.1021/acs.energyfuels.0c01001

Murtaza, M.; Kamal, M.S.; Mahmoud, M.: Application of a novel and sustainable silicate solution as an alternative to sodium silicate for clay swelling inhibition. ACS Omega 5, 17405–17415 (2020). https://doi.org/10.1021/acsomega.0c01777

Fan, J.W.; Ebadati, A.; Metwally, A.S.M.: An experimental study to evaluate the efficiency of silicate drilling fluids on the stabilization of shale layers. Appl Water Sci 12, 1–6 (2022). https://doi.org/10.1007/s13201-022-01726-z

Khodja, M.; Canselier, J.P.; Bergaya, F.; Fourar, K.; Khodja, M.; Cohaut, N.; Benmounah, A.: Shale problems and water-based drilling fluid optimisation in the Hassi Messaoud Algerian oil field. Appl. Clay Sci. 49, 383–393 (2010). https://doi.org/10.1016/j.clay.2010.06.008

McDonald, M.J.: A novel potassium silicate for use in drilling fluids targeting unconventional hydrocarbons. In: Paper presented at the SPE Canadian Unconventional Resources Conference, Calgary, Alberta, Canada (2012). https://doi.org/10.2118/162180-MS

Guo, J.K.; Yan, J.N.; Fan, W.W.; Zhang, H.J.: Applications of strongly inhibitive silicate-based drilling fluids in troublesome shale formations in Sudan. J. Petrol. Sci. Eng. 50, 195–203 (2006). https://doi.org/10.1016/j.petrol.2005.12.006

Sukarasep, W.; Dey, R.S.; Phonpuntin V.: Sodium silicate based drilling fluid application in gulf of Thailand to stabilise wellbore: a case study. In: Paper presented at the IADC/SPE Asia Pacific Drilling Technology Conference, Virtual (2021). https://doi.org/10.2118/200991-MS

Cardno, D.G.; Ripley, D.; Crawford J.W.: The use of silicate-WBM facilitates successful primary cementation operations on the BHP petroleum Liverpool bay development. In: Paper presented at the SPE/IADC Drilling Conference, Amsterdam, Netherlands (1997). https://doi.org/10.2118/37611-MS

Sorić, T.; Marinescu P.; Huelke R.: Silicate-based drilling fluids deliver optimum shale inhibition and wellbore stability. In: Paper presented at the IADC/SPE Drilling Conference, Dallas, Texas (2004). https://doi.org/10.2118/87133-MS

Bryan, S.; Cavett, L.; Dearing, H.: Tailored fluids improve shale drilling efficiency. Hart Energy 80, 69–70 (2007)

Fritz, B.; Jarrett M.: Potassium silicate treated water-based fluid: an effective barrier to instability in the Fayetteville shale. In: Paper Presented at the IADC/SPE Drilling Conference and Exhibition (2012). https://doi.org/10.2118/151491-MS

Van Oort, E.; Ripley, D.; Ward, I.; Chapman, J.W.; Williamson, R.; Aston, M.: Silicate-Based Drilling Fluids: Competent, Cost-effective and Benign Solutions to Wellbore Stability Problems Paper presented at the IADC/SPE Drilling Conference, New Orleans (1996). https://doi.org/10.2523/35059-MS

Alford, S.; Dzialowski, A.; Jiang, P.; Ullmann, H.: Research into lubricity, formation damage promises to expand applications for silicate drilling fluids. In: Paper Presented at the SPE/IADC Drilling Conference, Amsterdam, Netherlands (2001). https://doi.org/10.2118/67737-MS

Ward, I.; Chapman, J.W.: Silicate based muds: chemical optimization based on field experience. SPE Drill. Complet 14, 57–63 (1999). https://doi.org/10.2118/55054-PA

Lakatos, I.; Szentes, G.; Toro, M.; Karaffa, Z.; Vago, A.: Mitigation of formation damage caused by chemical overdosing in water shut-off treatments. In: Paper Presented at the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA (2020). https://doi.org/10.2118/199292-MS

Huang, W.A.; Lan, Q.; Qiu, Z.S.; Zhang, Y.; Zhong, H.Y.; Feng, G.T.: Colloidal properties and clay inhibition of sodium silicate in solution and montmorillonite suspension. SILICON 8, 111–122 (2016). https://doi.org/10.1007/s12633-015-9351-2

Bailey, L.; Craster, B.; Sawdon, C.; Brady, M.; Cliffe, S.: New insight into the mechanisms of shale inhibition using water based silicate drilling fluids. In: Paper presented at the IADC/SPE Drilling Conference, Dallas, Texas (1998). https://doi.org/10.2118/39401-MS

Pilgun, S.; Aramelev, A.: Environmentally compatible drilling fluids. In: Paper Presented at the SPE Arctic and Extreme Environments Technical Conference and Exhibition, Moscow, Russia (2013). https://doi.org/10.2118/166847-RU

Liu, S.X.; Ott, W.K.: Sodium silicate applications in oil, gas & geothermal well operations. J. Petrol. Sci. Eng. 195, 107693 (2020). https://doi.org/10.1016/j.petrol.2020.107693

Kudapa, V.K.; Kumar, S.: Applications of sodium silicate in oil and gas well operations. Mater. Today Proc. (2023). https://doi.org/10.1016/j.matpr.2023.05.086

Hamouda, A.A.; Akhlagh Amiri, H.A.: Factors affecting alkaline sodium silicate gelation for in-depth reservoir profile modification. Energies 7, 568–590 (2014). https://doi.org/10.3390/en7020568

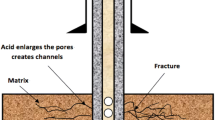

Luo, X.W.; Jiang, G.C.; Yang, L.L.: Experimental investigation of formation damage during drilling of ultradeep fractured carbonate reservoir. Geomech. Energy Environ. 33, 100437 (2023). https://doi.org/10.1016/j.gete.2023.100437

Miller, M.L.; Scorsone, J.T.; Whitfill, D.L.; McDonald, M.; Miller, N.: The development of a geopolymer-based pill as an engineered solution to lost circulation. In: Paper Presented at the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, USA (2013). https://doi.org/10.2118/166123-MS

Pham, L.T.; Hatzignatiou, D.G.: Rheological evaluation of a sodium silicate gel system for water management in mature, naturally-fractured oilfields. J. Petrol. Sci. Eng. 138, 218–233 (2016). https://doi.org/10.1016/j.petrol.2015.11.039

Jafarov, T.; Mahmoud, M. ; Al-Majed, A.; Elkatatny, S.; Bageri, B.: Improving well productivity of tight gas reservoirs by using sodium silicate in water-based drill-in fluid. In: Paper Presented at the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, Louisiana, USA (2018). https://doi.org/10.2118/189535-MS

Kang, Y.L.; She, J.P.; Zhang, H.; You, L.J.; Yu, Y.F.; Song, M.G.: Alkali erosion of shale by high-pH fluid: reaction kinetic behaviors and engineering responses. Nat. Gas Sci. Eng. 29, 201–210 (2016). https://doi.org/10.1016/j.jngse.2016.01.013

Zhao, X.; Qiu, Z.S.; Sun, B.J.; Liu, S.J.; Xing, X.J.; Wang, M.L.: Formation damage mechanisms associated with drilling and completion fluids for deepwater reservoirs. J. Petrol. Sci. Eng. 173, 112–121 (2019). https://doi.org/10.1016/j.petrol.2018.09.098

Larrondo, L.E.: Laboratory evaluation of sodium hydroxide, sodium orthosilicate, and sodium metasilicate as alkaline flooding agents for a western Canada reservoir. In: Paper Presented at the SPE Oilfield and Geothermal Chemistry Symposium, Phoenix, Arizona (1985). https://doi.org/10.2118/13577-MS

Jiang, T.M.; Hirasaki, G.J.; Miller, C.A.; Ng, S.: Wettability alteration of clay in solid-stabilized emulsions. Energy Fuels 25, 2551–2558 (2011). https://doi.org/10.1021/ef2000079

Amiri, H.A.A.: Improvement of water displacement efficiency in sandstone reservoirs using buffered sodium silicate. Porous Media 20, 193–203 (2017). https://doi.org/10.1615/JPorMedia.v20.i3.10

Song, X.J.; Qin, Y.; Ma, H.: Wettability and its influencing factors of tight sandstones in coal measures in Ordos Basin, China. ACS Omega 7, 28503–28515 (2022). https://doi.org/10.1021/acsomega.2c03288

Acknowledgments

This work was supported by the National Natural Science Foundation of China (No. 51704043), the Science and Technology Planning Project of Sichuan Province (No. 2021YJ0359), and the National Natural Science Youth Foundation of China (No. 52104003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Teng, G., She, J., Ma, W. et al. Experimental Investigation of Tight Sandstone Reservoir Damage Induced by Silicate-Based Drilling Fluid. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-024-08857-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-024-08857-2