Abstract

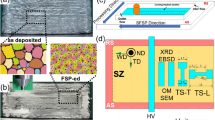

In this study, a bulk-area stirring zone (BSZ) was generated within the Al–Mg–Si alloy using friction stir processing with a combination of pin overlapping and water cooling. Detailed examinations were conducted on various aspects, including microstructural evolution, intermetallic behavior, crystallographic texture, and mechanical properties. The bulk-area stir zone (BSZ) microstructure contains an equiaxed fine-grained structure with more fraction of high-angle grain boundaries due to intense plastic straining and dynamic recrystallization. The grain refinement remained consistent across each overlapping pass, typically within the range of 3 to 4 µm. Notably, the BSZ exhibited the formation of A1-{111}(112) texture components with a maximum intensity of 5.4 owing to the material flow caused by the tool’s revoluting nature around the pin. The hardness distribution across the BSZ was found to be uniform and aligned with the grain size values. The combined effects of material softening and intermetallic dissolution in the BSZ led to a substantial enhancement of 127% in ductility.

Similar content being viewed by others

References

RS Mishra ZY Ma 2005 Friction stir welding and processing Mater. Sci. Eng. Rep. 50 1 78 https://doi.org/10.1016/j.mser.2005.07.001

R Nandan T Debroy HKDH Bhadeshia 2008 Recent advances in friction-stir welding–process Weldment Struct. Propert. 53 980 1023 https://doi.org/10.1016/j.pmatsci.2008.05.001

KN Ramesh S Pradeep V Pancholi 2012 Multipass friction-stir processing and its effect on mechanical properties of aluminum alloy 5086 Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 43 4311 4319 https://doi.org/10.1007/s11661-012-1232-3

J Gandra RM Miranda P Vilaça 2011 Effect of overlapping direction in multipass friction stir processing Mater. Sci. Eng. A 528 5592 5599 https://doi.org/10.1016/j.msea.2011.03.105

BVS Keerthana MVNV Satyanarayana KV Reddy MNS Shankar 2023 Effect of post-process and in-process cooling on wide-area stir zone processed via friction stir processing with pin overlapping Eng. Res. Express. https://doi.org/10.1088/2631-8695/acdb33

MVNV Satyanarayana A Kumar VKS Jain R Kumar S Mishra 2023 Microstructure, mechanical properties and corrosion behavior of friction stir processed AA2014 alloy Arch. Civ. Mech. Eng. 23 1 16 https://doi.org/10.1007/s43452-022-00565-8

LB Johannes RS Mishra 2007 Multiple passes of friction stir processing for the creation of superplastic 7075 aluminum Mater. Sci. Eng. A 464 255 260 https://doi.org/10.1016/j.msea.2007.01.141

YJ Kwon I Shigematsu N Saito 2003 Production of ultra-fine grained aluminum alloy using friction stir process Mater. Trans. 44 1343 1350 https://doi.org/10.2320/matertrans.44.1343

BVS Keerthana MVNV Satyanarayana MNS Shankar 2023 Effect of cooling-assisted friction stir processing on corrosion behavior of AA5083 alloy J. Inst. Eng. Ser. D. https://doi.org/10.1007/s40033-023-00470-1

JQ Su TW Nelson TR McNelley RS Mishra 2011 Development of nanocrystalline structure in Cu during friction stir processing (FSP) Mater. Sci. Eng. A 528 5458 5464 https://doi.org/10.1016/j.msea.2011.03.043

KJ Al-Fadhalah AI Almazrouee AS Aloraier 2014 Microstructure and mechanical properties of multi-pass friction stir processed aluminum alloy 6063 Mater. Deg. 53 550

Z Zhang BL Xiao ZY Ma 2014 Influence of water cooling on microstructure and mechanical properties of friction stir welded 2014Al-T6 joints Mater. Sci. Eng. A 614 6 15 https://doi.org/10.1016/j.msea.2014.06.093

S Sinhmar DK Dwivedi 2017 Enhancement of mechanical properties and corrosion resistance of friction stir welded joint of AA2014 using water cooling Mater. Sci. Eng. A 684 413 422 https://doi.org/10.1016/j.msea.2016.12.087

A Rodríguez A Calleja LN López Lacalle de O Pereira H González G Urbikain J Laye 2019 Burnishing of FSWAluminum Al-Cu-Li components Metals (Basel). 9 1 16 https://doi.org/10.3390/met9020260

O Pereira G Urbikain A Rodríguez A Fernández-Valdivielso A Calleja I Ayesta LNL Lacalle de 2017 Internal cryolubrication approach for Inconel 718 milling Procedia Manuf. 13 89 93 https://doi.org/10.1016/j.promfg.2017.09.013

C Sharma DK Dwivedi P Kumar 2012 Influence of in-process cooling on tensile behaviour of friction stir welded joints of AA7039 Mater. Sci. Eng. A 556 479 487 https://doi.org/10.1016/j.msea.2012.07.016

G Venkateswarlu D Devaraju MJ Davidson B Kotiveerachari GRN Tagore 2013 Effect of overlapping ratio on mechanical properties and formability of friction stir processed Mg AZ31B alloy Mater. Des. 45 480 486 https://doi.org/10.1016/j.matdes.2012.08.031

A Alavi Nia H Omidvar SH Nourbakhsh 2014 Effects of an overlapping multi-pass friction stir process and rapid cooling on the mechanical properties and microstructure of AZ31 magnesium alloy Mater. Des. 58 298 304 https://doi.org/10.1016/j.matdes.2014.01.069

Y Chen H Ding J Li Z Cai J Zhao W Yang 2016 Influence of multi-pass friction stir processing on the microstructure and mechanical properties of Al-5083 alloy Mater. Sci. Eng. A 650 281 289 https://doi.org/10.1016/j.msea.2015.10.057

MVNV Satyanarayana A Kumar 2020 Influence of cooling media in achieving grain refinement of AA2014 alloy using friction stir processing Eng. Part C J. Mech. Eng. Sci. 234 4520 4534 https://doi.org/10.1177/0954406220922858

VKS Jain KU Yazar S Muthukumaran 2019 Development and characterization of Al5083-CNTs/SiC composites via friction stir processing J. Alloys Compd. 798 82 92 https://doi.org/10.1016/j.jallcom.2019.05.232

RW Fonda JF Bingert 2007 Texture variations in an aluminum friction stir weld Scr. Mater. 57 1052 1055 https://doi.org/10.1016/j.scriptamat.2007.06.068

F Nascimento T Santos P Vilaça RM Miranda L Quintino 2009 Microstructural modification and ductility enhancement of surfaces modified by FSP in aluminium alloys Mater. Sci. Eng. A 506 16 22 https://doi.org/10.1016/j.msea.2009.01.008

A Yazdipour MA Shafiei K Dehghani 2009 Modeling the microstructural evolution and effect of cooling rate on the nanograins formed during the friction stir processing of Al5083 Mater. Sci. Eng. A. 527 192 197 https://doi.org/10.1016/j.msea.2009.08.040

MVNV Satyanarayana A Kumar K Kranthi Kumar 2021 Towards finding a novel constant between local and bulk strength of friction stir processed aluminum alloys J. Mater. Des. Appl. 235 2151 https://doi.org/10.1177/14644207211025055

YH Zhao SB Lin L Wu FX Qu 2005 The influence of pin geometry on bonding and mechanical properties in friction stir weld 2014 Al alloy Mater. Lett. 59 2948 2952 https://doi.org/10.1016/j.matlet.2005.04.048

CY Liu B Qu P Xue ZY Ma K Luo MZ Ma RP Liu 2018 Fabrication of large-bulk ultrafine grained 6061 aluminum alloy by rolling and low-heat-input friction stir welding J. Mater. Sci. Technol. 34 112 118 https://doi.org/10.1016/j.jmst.2017.02.008

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Satyanarayana, M.V.N.V., Srinivasnaik, M., Reddy, B.M. et al. Exploring Microstructural, Textural, and Mechanical Properties in Bulk-Area Stir Zone Fabrication Through Overlapping Friction Stir Processing with Water Cooling. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-024-08799-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-024-08799-9