Abstract

The utilization of reclaimed asphalt pavement (RAP) aggregates as an alternative for rigid pavements is limited. The main objective of this study is to explore and improve the utilization of RAP aggregates as an alternative material for rigid pavement. Specifically, this study focuses on addressing a significant challenge associated with RAP aggregates, which is their poor bond with cementitious binders. The poor bonding results in low compressive and tensile strengths of concrete or mortar. The poor bonding is mainly due to the presence of a thin oily layer of asphalt residue. A proposed method was carried out to reduce the negative impact on the bond between the aggregate and mortar by exposing the RAP aggregates to the pyrolysis process. The research focused on the analyses of the physical and chemical behavior of the aggregates, using the SEM, EDX, and FTIR approaches, as well as reviewing the mortar in both compressive and flexural tensile strength. The pyrolysis affected the physical and mechanical properties positively and the chemical composition of the RAP showed significant changes. The chemical constituents of asphalt attached to RAP aggregates are hydrocarbons. The thin layer of RAP asphalt is the cause of weak bonding, but this layer was altered by the pyrolysis procedure. As a result, water absorption decreased, which had a positive impact on the hydraulic synergy of cement. It is shown that the pyrolyzing RAP improves the compressive strength and flexural tensile strength through modification of the asphalt residue covering the aggregates.

Similar content being viewed by others

Data Availability

Data sets generated during the current study are available from the corresponding author upon reasonable request.

Abbreviations

- \(f_{{\text{c}}}^{{\prime }}\) :

-

Compressive strength of mortar (MPa)

- f t :

-

Flexural strength of mortar (MPa)

- P :

-

Load (N)

- A :

-

Cross-sectional area (mm2)

- M :

-

Bending moment (Nmm)

- y :

-

Half height of beam (mm)

- Ix :

-

Beam inertia (mm4)

- RAP:

-

Reclaimed asphalt pavement

- PYRO:

-

Pyrolysis aggregate

- FTIR:

-

Fourier transform infra-red

- EDX:

-

Energy-dispersive X-ray

- SEM:

-

Scanning electron microscope

- ASTM:

-

American standard testing material

- SNI:

-

Standard Nasional Indonesia

- MPa:

-

Mega pascal

- C:

-

Carbon

- Ca:

-

Calcium

- C–H:

-

Hydrocarbon

- O–H:

-

Hydroxide

- C–S:

-

Carbon sulfide

- C–O:

-

Carbon monoxide

- S:

-

Sulfur

- S–S:

-

Disulfide

- Si:

-

Silica

- Fe:

-

Ferrit

References

Sunarjono, S.; Hidayati, N.: Mixture design consideration for foamed asphalt using RAP materials. IOP Conf. Ser. Mater. Sci. Eng. 403, 012027 (2018). https://doi.org/10.1088/1757-899X/403/1/012027

Andrei, D.; Kitch, W.; Ellingsen, E.; Grosz, L.; Longoria, S.; Stoica, D.: Review of High Percentage RAP Usage in Asphalt Concrete, p. 112 (2013). https://www.researchgate.net/publication/271601966_Review_of_High_Percentage_RAP_Usage_in_Asphalt_Concrete

Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H.: Reclaimed Asphalt Pavement—A Literature Review (2014). Civil Engineering Studies Illinois Center for Transportation Series No. 07-001 UILU-ENG-2007-2014

Abdelhak, B.; Abdelmadjid, H.C.; Mohamed, G.; Hamza, G.: Effect of recycled asphalt aggregates on the rutting of bituminous concrete in the presence of additive. Arab. J. Sci. Eng. 41(10), 4139–4145 (2016). https://doi.org/10.1007/s13369-016-2125-3

Al Mamun, A.; Al-Abdul Wahhab, H.I.; Dalhat, M.A.: Comparative evaluation of waste cooking oil and waste engine oil rejuvenated asphalt concrete mixtures. Arab. J. Sci. Eng. 45(10), 7987–7997 (2020). https://doi.org/10.1007/s13369-020-04523-5

Widayanti, A.; Soemitro Ria, A.A.; Ekaputri, J.J.; Suprayitno, H.: Characterization of Reclaimed Asphalt Pavement (RAP) as a Road Pavement Material (National Road Waru, Sidoarjo), MATEC Web Conference, vol. 181 (2018). https://doi.org/10.1051/matecconf/201818105001

Gao, J.; Yang, J.; Yu, D.; Jiang, Y.; Ruan, K.; Tao, W.; Sun, C.; Luo, L.: Reducing the variability of multi-source reclaimed asphalt pavement materials: a practice in China. Constr. Build. Mater. 278, 66 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122389

Copeland, A.: Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice (2011)

Pokorný, J.; Šál, J.; Ševčík, R.: Properties of reclaimed asphalt pavement enriched concrete. AIP Conf. Proc. 2322, 5–10 (2021). https://doi.org/10.1063/5.0042501

Oliveira, J.R.M.; Silva, H.M.R.D.; Jesus, C.M.G.; Abreu, L.P.F.; Fernandes, S.R.M.: Pushing the asphalt recycling technology to the limit. Int. J. Pavem. Res. Technol. 6(2), 109–116 (2013). https://doi.org/10.6135/ijprt.org.tw/2013.6(2).109

Thanya, I.N.A.; Suweda, I.W.; Putra, G.K.: Performance of asphalt concrete wearing course (AC-WC) utilizing reclaimed asphalt pavement from cold milling bound with 80/100 pen asphalt. IOP Conf. Ser. Mater. Sci. Eng. 316(1), 66 (2018). https://doi.org/10.1088/1757-899X/316/1/012037

Nataadmadja, A.D.; Prahara, E.; Sumbung, P.C.: Analysis of the usage of rubberized asphalt in hot mix asphalt using Reclaimed Asphalt Pavement (RAP). IOP Conf. Ser. Earth Environ. Sci. (2018). https://doi.org/10.1088/1755-1315/109/1/012036

Abraham, S.M.; Ransinchung, G.D.R.N.: Influence of RAP aggregates on strength, durability and porosity of cement mortar. Constr. Build. Mater. 189, 1105–1112 (2018). https://doi.org/10.1016/j.conbuildmat.2018.09.069

Hoy, M.; Horpibulsuk, S.; Arulrajah, A.: Strength development of Recycled Asphalt Pavement—fly ash geopolymer as a road construction material. Constr. Build. Mater. 117, 209–219 (2016). https://doi.org/10.1016/j.conbuildmat.2016.04.136

Budianto: Menuju Jalan yang Andal. In: PT. Cakra Daya Sakti, Surabaya (2009)

Dinis-Almeida, M.; Castro-Gomes, J.; Sangiorgi, C.; Zoorob, S.E.; Afonso, M.L.: Performance of warm mix recycled asphalt containing up to 100% RAP. Constr. Build. Mater. 112, 1–6 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.108

Lu, M.; Saleh, D.X.: Laboratory evaluation of warm mix asphalt incorporating high RAP proportion by using evotherm and sylvaroad additives. J. Constr. Build. Mater. 114, 580–587 (2016). https://doi.org/10.1016/j.conbuildmat.2016.03.200

Pradyumna, P.; Mittal, T.; Abhishek, J.: Characterization of reclaimed asphalt pavement (RAP) for use in bituminous road construction. Procedia Soc. Behav. Sci. 66, 1149–1157 (2013)

Widger, A.; Skilnick, F.; Zabolotnii, E.: Utilization of recycled asphalt in cold mixes and cold in–place recycling processes-guidelines. In: Engineering-Training Clifton Associated Ltd. Communities of Tomorrow, Leveraged Municipal Innovation Fund (2012)

Setiadji, B.H., et al.: Pyrolysis of reclaimed asphalt aggregates in mortar. Int. J. Technol. 13(4), 751–763 (2022). https://doi.org/10.14716/ijtech.v13i4.5621

Joice, E.: Perilaku Material Daur Ulang Lapis Pondasi Perkerasan Jalan Yang Distabilisasi Dengan Semen Dan Pozolan Alam. In: Disertation Report University of Diponegoro (2015)

Mary, J.; Sepuri, H.K.; Thejas, H.K.: A review on recycled asphalt pavement in cement concrete. Int. J. Latest Eng. Res. Appl. 3, 9–18 (2019)

Abraham, S.M.; Ransinchung, G.D.: Laboratory research on reclaimed asphalt pavement-inclusive cementitious mixtures. ACI Mater. J. 117(2), 193–204 (2020). https://doi.org/10.14359/51722398

Ransinchung, G.D.; Singh, S.; Abraham, S.M.: Feasibility of reclaimed asphalt pavement in rigid pavement construction. In: Eng. Challenges Sustain. Futur.—Proceedings of the 3rd International. Conference Civil, offshore Environment Engineering (ICCOEE 2016), pp. 401–404 (2016). https://doi.org/10.1201/b21942-81

Abraham, S.M.; Ransinchung, G.D.R.N.: Pore structure characteristics of RAP-inclusive cement mortar and cement concrete using mercury intrusion porosimetry technique. Adv. Civ. Eng. Mater. 8(3), 1–24 (2019). https://doi.org/10.1520/acem20180161

Qiang, W.; Peiyu, Y.; Ruhan, A.; Jinbo, Y.; Xiangming, K.: Strength mechanism of cement-asphalt mortar. J. Mater. Civ. Eng. 23(9), 1353–1359 (2011). https://doi.org/10.1061/(ASCE)MT.1943-5533.0000301

Riyanto, T.; Putri, F.M.Y.; Widayat, W.: Heat integration analysis of preliminary plant design of glycerol conversion into propylene glycol. Int. J. Eng. Appl. 7(6), 204 (2019). https://doi.org/10.15866/irea.v7i6.17879

Basu, P.: Biomass Gasification and Pyrolysis Practical Design and Theory. Elsevier, UK (2010)

Sam, K.D.; Wampler, T.P.: Analytical Pyrolysis Handbook. CRC Press/Taylor & Francis Group, London (2021)

Musta, R.; Ibrahim, M.S.; Nurliana, L.: Identifikasi Senyawa Penyusun Produk Cair Hasil Pirolisis Aspal Alam dari Lawele Kabupaten Buton. Hydrog. Jurnal Kependidikan Kimia 9(1), 1–7. https://doi.org/10.33394/hjkk.v9i1.3568

Khan, M.Z.H.; Sultana, M.; Hasan, M.R.: Pyrolytic waste plastic oil and its diesel blend: fuel characterization. J. Environ. Public Health (2016). https://doi.org/10.1155/2016/7869080

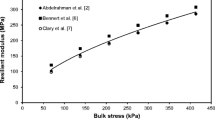

Sihombing, A.V.R.; Subagio, B.S.; Hariyadi, E.S.; Yamin, A.: Development of resilient modulus model proposed for bio-asphalt as modifier in asphalt concrete containing reclaimed asphalt pavement. Int. J. Geomate 19(71), 130–136 (2020). https://doi.org/10.21660/2020.71.68349

Al-Sabaeei, A.M.; Alhussian, H.; Abdulkadir, S.J.; Giustozzi, F.; Napiah, M.; Jagadeesh, A.; Sutanto, M.; Memon, A.M.: Utilization of response surface methodology and machine learning for predicting and optimizing mixing and compaction temperatures of bio-modified asphalt. Case Stud. Constr. Mater. 18, e02073 (2023). https://doi.org/10.1016/j.cscm.2023.e02073

Wang, H.; Ma, Z.; Chen, X.; Mohd Hasan, M.R.: Preparation process of bio-oil and bio-asphalt, their performance, and the application of bio-asphalt: a comprehensive review. J. Traffic Transp. Eng. 7(2), 137–151 (2020). https://doi.org/10.1016/j.jtte.2020.03.002

Kulkarni, P.: Reclaimation of Reclaimed Asphalt Pavement (RAP) by Pyrolysis. A Thesis Environmental Engineering, University Of Cincinnati, India (2003)

Istoto, E.H.; Widayat; Saptadi, S.: Production of fuels from HDPE and LDPE plastic waste via pyrolysis methods. In: ICENIS 2019, vol. 11, pp. 9–12. https://doi.org/10.1051/e3sconf/201912514011

Mohammadafzali, M.; Ali, H.; Sholar, G.A.; Rilko, W.A.; Baqersad, M.: Effects of rejuvenation and aging on binder homogeneity of recycled asphalt mixtures. J. Transp. Eng. Part B Pavem. 145(1), 1–9 (2019). https://doi.org/10.1061/JPEODX.0000089

Dinh, B.H.; Park, D.W.; Le, T.H.M.: Effect of rejuvenators on the crack healing performance of recycled asphalt pavement by induction heating. Constr. Build. Mater. 164, 246–254 (2018). https://doi.org/10.1016/j.conbuildmat.2017.12.193

Sihombing, A.V.R.; Subagio, B.S.; Hariyadi, E.S.; Yamin, A.: Mechanical properties of bio-asphalt on recycled asphalt pavement binder BT. In: Proceedings of the 9th International Conference on Maintenance and Rehabilitation of Pavements—Mairepav9, pp. 529–538 (2020)

Elkashef, M.; Williams, R.C.; Cochran, E.W.: Physical and chemical characterization of rejuvenated reclaimed asphalt pavement (RAP) binders using rheology testing and pyrolysis gas chromatography-mass spectrometry. Mater. Struct. Constr. 51(1), 2018 (2018). https://doi.org/10.1617/s11527-018-1141-z

Zhang, X.; Zhu, J.; Wu, C.; Wu, Q.; Liu, K.; Jiang, K.: Preparation and properties of wood tar-based rejuvenated asphalt. Materials (2020). https://doi.org/10.3390/ma13051123

Susianto, S.; Anindita, Y.D.; Altway, A.; Afuza, A.; Wena, E.N.; Altway, A.: Proses Katalitik Pirolisis Untuk Cracking Bitumen Dari Asbuton dengan Katalis Zeolit Alam. In: The 2nd Conference on Innovation and Industrial Applications (CINIA 2016), 2016, no. 1, pp. 259–264. https://doi.org/10.12962/j23546026.y2018i1.3426

Liu, P.; Zhu, M.; Zhang, Z.; Wan, W.; Yani, S.; Zhang, D.: Thermogravimetric studies of characteristics and kinetics of pyrolysis of buton oil sand. Energy Procedia 61, 2741–2744 (2014). https://doi.org/10.1016/j.egypro.2014.12.294

Ma, Y.; Li, S.: The pyrolysis, extraction and kinetics of Buton oil sand bitumen. Fuel Process. Technol. 100, 11–15 (2012). https://doi.org/10.1016/j.fuproc.2012.03.001

ASTM E986-04: Standard Practice for Scanning Electron Microscope Beam Size Characterization, ASTM Copyright, vol. 3, pp. 1–3 (1997)

Pereira, M.O., et al.: Investigating counterfeiting of an artwork by XRF, SEM-EDS, FTIR and synchrotron radiation induced MA-XRF at LNLS-BRAZIL. Spectrochim Acta Part A Mol. Biomol. Spectrosc. 246, 11895 (2021). https://doi.org/10.1016/j.saa.2020.118925

Kataki, S.; Hazarika, S.; Baruah, D.C.: Investigation on by-products of bioenergy systems (anaerobic digestion and gasification) as potential crop nutrient using FTIR, XRD, SEM analysis and phyto-toxicity test. J. Environ. Manag. 196, 201–216 (2017). https://doi.org/10.1016/j.jenvman.2017.02.058

SNI 1969-2008: Cara Uji Berat Jenis dan Penyerapan Air Agregat Kasar. Badan Standarisasi Nasional Indonesia, p. 20 (2008)

SNI 03-1971: Metode Pengujian Kadar Air Agregat, Badan Standarisasi Nasional Indonesia, pp. 3–6 (1990)

SNI-03-6894: Metode pengujian kadar aspal dari campuran beraspal dengan cara sentrifus 1, Badan Standarisasi Nasional Indonesia, pp. 1–6 (2002)

ASTM C131: C131/C131M-14 Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. Annu. B. Am. Soc. Test. Mater. ASTM Standard, Conshohocken, USA, vol. 4, Note 2, pp. 5–8 (2014)

ASTM-C109: Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens) 1. In: Chemical Analysis, vol. i, no. C109/C109M-11b, pp. 1–9 (2010)

Uddin, M.A.; Bashir, M.T.; Khan, A.M.; Alsharari, F.; Farid, F.R.: Alrowais Effect of silica fume on compressive strength and water absorption of the portland cement–silica fume blended mortar. Arab. J. Sci. Eng. (2023). https://doi.org/10.1007/s13369-023-08204-x

ASTM C348: Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. In: Annual Book of ASTM Standards, vol. 4, pp. 2–7 (1998)

Korouzhdeh, T.; Eskandari-Naddaf, H.: Mechanical properties and microstructure evaluation of cement mortar with different cement strength classes by image analysis. Arab. J. Sci. Eng. 47(4), 4763–4783 (2022). https://doi.org/10.1007/s13369-021-06257-4

Kumar, R.; Roy, M.K.; Mishra, M.K.: Synthesis and characterization of biofuel using waste cooking oil obtained by the college canteen. Int. J. Eng. Appl. 6, 66 (2022). https://doi.org/10.15866/irea.v10i6.22002

Widayat; Satriadi, H.; Wibawa, L.P.; Hanif, G.F.; Qomaruddin, M.: Oil and gas characteristics of coal with pyrolysis process. In: AIP Conference Proceedings, vol. 2453 (2022). https://doi.org/10.1063/5.0094759

Zhu, Z.; Tian, H.; Jiang, G.; Dou, B.: Effects of high temperature on rock bulk density. Geomech. Geoengin. 17(2), 647–657 (2022). https://doi.org/10.1080/17486025.2020.1827169

Deef-Allah, E.; Abdelrahman, M.: Interactions between RAP and virgin asphalt binders in field, plant, and lab mixes. World J. Adv. Res. Rev. 13(1), 231–249 (2022)

Yin, Y.; Chen, H.; Kuang, D.; Song, L.; Wang, L.: Effect of chemical composition of aggregate on interfacial adhesion property between aggregate and asphalt. Constr. Build. Mater. 146, 231–237 (2017). https://doi.org/10.1016/j.conbuildmat.2017.04.061

Udomkan, N.; Limsuwan, P.: Temperature effects on freshwater snail shells: Pomacea canaliculata Lamarck as investigated by XRD, EDX, SEM and FTIR techniques. Mater. Sci. Eng. C 28(2), 316–319 (2008). https://doi.org/10.1016/j.msec.2007.03.001

Maghsoodi, V.: W/C ratio profile in ITZ of mortar. Arab. J. Sci. Eng. 43(4), 1817–1824 (2018). https://doi.org/10.1007/s13369-017-2757-y

Reinhardt, H.W.: 2013 Factors Affecting the Tensile Properties of Concrete. Woodhead Publishing Limited (2013). https://doi.org/10.1533/9780857097538.1.19

SNI 8457: Rancangan tebal jalan beton untuk lalu lintas rendah, Badan Standardisasi Nasional Indonesia (2017)

Ahmed, M.; Mallick, J.; Abul Hasan, M.: A study of factors affecting the flexural tensile strength of concrete. J. King Saud Univ. Eng. Sci. 28(2), 147–156 (2016). https://doi.org/10.1016/j.jksues.2014.04.001

Acknowledgements

This paper was funded by a Domestic Postgraduate Education Scholarship (BPPDN) with Letter Number: B/67/D.D3/KD.02.00/2019 from the Ministry of Education, Culture, Research, Technology, Republic of Indonesia.

Funding

This paper was funded by scholarship from Ministry of Education, Culture, Research, Technology, Republic of Indonesia, which the authors gratefully acknowledge.

Author information

Authors and Affiliations

Contributions

MQ proposing ideas, formal analysis, and writing–review and editing and original draft. HAL contributed to conceptualization, writing, supervising methods, and manuscript checking. Purwanto helped in resources, investigation, and visualization. Widayat contributed to conceptualization, methodology, validation, and manuscript checking. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Qomaruddin, M., Lie, H.A., Purwanto et al. Chemical and Microstructural Changes in Reclaimed Asphalt Pavement Aggregates by Pyrolysis. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-023-08698-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-023-08698-5