Abstract

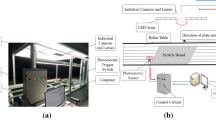

In this study, we propose a random cropping augmentation (RCA) based on an optimized YOLOv8 algorithm by introducing a tiny object detection layer to improve the accuracy of surface defect detection on the inner wall of micro-holes of cylindrical high-precision parts. The inner surfaces of cylindrical high-precision parts possess attributes like high smoothness, elongated channels, limited visibility, minute flaws, and challenges capturing image data. These characters impose significant difficulties in automating defect detection for this part type. Taking the automobile fuel injector valve seat as an example, industrial CCD cameras and lenses are combined with a circular light source to acquire magnified image data. The images are preprocessed using tile and adaptive histogram equalization algorithms. Then, the RCA algorithm expands and randomly combines the image data. We compare the proposed algorithm with the original faster RCNN, YOLOv5 and YOLOv8 algorithm for surface defect detection on the inner wall of the automotive fuel injector valve seat. The experimental results demonstrate that after extending the dataset with the RCA algorithm, there have been significant improvements in the mean average precision (mAP) for the faster RCNN, YOLOv5, and YOLOv8 algorithms. The mAP@0.5 for these algorithms has increased from 37.1%, 48.7%, and 62.2% to 60.9%, 72.6%, and 81.1%, respectively. Furthermore, the improved YOLOv8 algorithm, which incorporates tiny object detection module, achieved an mAP@0.5 of 87% on the dataset extended by the RCA algorithm, with precision and recall reaching 89.7% and 80.6%, respectively. The improved YOLOv8 + RCA algorithm performs better than mainstream algorithms in surface defect detection on the inner wall of the fuel injector valve seat while meeting the requirements of industrial production quality inspection for detection speed.

Similar content being viewed by others

Data Availability

The datasets used and analyzed during the current study are available from the corresponding author upon reasonable request.

References

Peng, Y.; Liu, G.; Quan, Y.; Zeng, Q.: The depth measurement of internal defect based on laser speckle shearing interference. Opt. Laser Technol. 92, 69–73 (2017)

Xiao, X.; Yu, L.; Dong, Z.; Mbelek, R.; Xu, K.; Lei, C.; Zhong, W.; Lu, F.; Xing, M.: Adipose stem cell-laden injectable thermosensitive hydrogel reconstructing depressed defects in rats: filler and scaffold. J. Mater. Chem. B 3, 5635–5644 (2015)

Kong, H.; Yang, J.; Chen, Z.: Accurate and efficient inspection of speckle and scratch defects on surfaces of planar products. IEEE Trans. Industr. Inf. 13, 1855–1865 (2017)

Chen, J.S.; Li, C.S.: Prediction and control of thermal scratch defect on surface of strip in tandem cold rolling. J. Iron. Steel Res. Int. 22, 106–114 (2015)

Rodionova, I.; Zaitsev, A.; Baklanova, O.; Kazankov, A.Y.; Naumenko, V.; Semernin, G.: Effect of carbon steel structural inhomogeneity on corrosion resistance in chlorine-containing media. Metallurgist 59, 774–783 (2016)

Amaya, J.; Lelah, A.; Zwolinski, P.: Design for intensified use in product–service systems using life-cycle analysis. J. Eng. Des. 25, 280–302 (2014)

Park, M.; Jin, J.S.; Au, S.L.; Luo, S.; Cui, Y.: Automated defect inspection systems by pattern recognition. Int. J. Signal Process. Image Process. Pattern Recognit. 2, 31–42 (2009)

Tsai, D.M.; Huang, T.Y.: Automated surface inspection for statistical textures. Image Vis. Comput. 21, 307–323 (2003)

Tsai, D.M.; Wu, S.K.: Automated surface inspection using Gabor filters. Int. J. Adv. Manuf. Technol. 16, 474–482 (2000)

Samarawickrama, Y.C.; Wickramasinghe, C.D.: Matlab based automated surface defect detection system for ceremic tiles using image processing. In: Proceedings of the 2017 6th National Conference on Technology and Management (NCTM). IEEE, pp. 34–39 (2017)

Jie, L.; Siwei, L.; Qingyong, L.; Hanqing, Z.; Shengwei, R.: Real-time rail head surface defect detection: a geometrical approach. In: Proceedings of the 2009 IEEE International Symposium on Industrial Electronics. IEEE, pp. 769–774 (2009)

Iivarinen, J.: Surface defect detection with histogram-based texture features. In: Proceedings of the Intelligent Robots and Computer Vision xix: Algorithms, Techniques, and Active Vision. SPIE, vol. 4197, pp. 140–145 (2000)

Elbehiery, H.; Hefnawy, A.; Elewa, M.: Surface defects detection for ceramic tiles using image processing and morphological techniques (2005)

Jia, H.; Murphey, Y.L.; Shi, J.; Chang, T.S.: An intelligent real-time vision system for surface defect detection. In: Proceedings of the Proceedings of the 17th International Conference on Pattern Recognition, 2004. ICPR 2004. IEEE, vol. 3, pp. 239–242 (2004)

Xue-Wu, Z.; Yan-Qiong, D.; Yan-Yun, L.; Ai-Ye, S.; Rui-Yu, L.: A vision inspection system for the surface defects of strongly reflected metal based on multi-class SVM. Expert Syst. Appl. 38, 5930–5939 (2011)

Shanmugamani, R.; Sadique, M.; Ramamoorthy, B.: Detection and classification of surface defects of gun barrels using computer vision and machine learning. Measurement 60, 222–230 (2015)

Li, Q.; Wang, M.; Gu, W.: Computer vision based system for apple surface defect detection. Comput. Electron. Agric. 36, 215–223 (2002)

Pastor-López, I.; Santos, I.; Santamaría-Ibirika, A.; Salazar, M.; De-la Peña-Sordo, J.; Bringas, P.G.: Machine-learning-based surface defect detection and categorisation in high-precision foundry. In: Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA). IEEE, pp. 1359–1364 (2012)

Gauen, K.; Dailey, R.; Laiman, J.; Zi, Y.; Asokan, N.; Lu, Y.H.; Thiruvathukal, G.K.; Shyu, M.L.; Chen, S.C.: Comparison of visual datasets for machine learning. In: Proceedings of the 2017 IEEE International Conference on Information Reuse and Integration (IRI). IEEE, pp. 346–355 (2017)

Zhiqiang, W.; Jun, L.; A review of object detection based on convolutional neural network. In: Proceedings of the 2017 36th Chinese Control Conference (CCC). IEEE, pp. 11104–11109 (2017)

Huang, J.; Rathod, V.; Sun, C.; Zhu, M.; Korattikara, A.; Fathi, A.; Fischer, I.; Wojna, Z.; Song, Y.; Guadarrama, S.; et al.: Speed/accuracy trade-offs for modern convolutional object detectors. In: Proceedings of the Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 7310–7311 (2017)

Yadav, N.; Binay, U.: Comparative study of object detection algorithms. Int. Res. J. Eng. Technol. (IRJET) 4, 586–591 (2017)

He, K.; Zhang, X.; Ren, S.; Sun, J.: Spatial pyramid pooling in deep convolutional networks for visual recognition. IEEE Trans. Pattern Anal. Mach. Intell. 37(9), 1904–1916 (2015)

Girshick, R.: Fast r-cnn. In: Proceedings of the IEEE International Conference on Computer Vision, pp. 1440–1448 (2015)

Ren, S.; He, K.; Girshick, R.; Sun, J.: Faster r-cnn: towards real-time object detection with region proposal networks. Adv. Neural Inf. Process. Syst. 28 (2015)

Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A.: You only look once: unified, real-time object detection. In: Proceedings of the Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 779–788 (2016)

Jocher, G.; et al.: ultralytics/yolov5: v7.0-YOLOv5 SOTA realtime instance segmentation, pp. 7347926 (2022). https://doi.org/10.5281/zenodo

Thuan, D.: Evolution of Yolo algorithm and Yolov5: the state-of-the-art object detention algorithm (2021).

Nelson, J.; Solawetz, J.: YOLOv5 is here: state-of-the-art object detection at 140 FPS (2020). https://blog.roboflow.com/yolov5-is-here/

Jocher, G.; Chaurasia, A.; Qiu, J.: YOLO by Ultralytics (2023). https://github.com/ultralytics/ultralytics

Carion, N.; Massa, F.; Synnaeve, G.; Usunier, N.; Kirillov, A.; Zagoruyko, S.: End-to-end object detection with transformers. In: European Conference on Computer Vision, pp. 213–229. Springer (2020)

Alrifaey, M.; Lim, W.H.; Ang, C.K.; Natarajan, E.; Solihin, M.I.; Juhari, M.R.M.; Tiang, S.S.: Hybrid deep learning model for fault detection and classification of grid-connected photovoltaic system. IEEE Access 10, 13852–13869 (2022)

Okada, S.; Nakamura, O.; Esaki, Y.: Development and commercialization of laser inspection system to detect surface flaws of machined holes. Synthesiol. Engl. Edit. 11, 133–145 (2019)

Yuan, S.; Yan, N.; Zhu, L.; Hu, J.; Li, Z.; Liu, H.; Zhang, X.: High dynamic online detection method for surface defects of small diameter reflective inner wall. Measurement 195, 111138 (2022)

Peiner, E.; Balke, M.; Doering, L.: Slender tactile sensor for contour and roughness measurements within deep and narrow holes. IEEE Sens. J. 8, 1960–1967 (2008)

Dong, Y.; Li, J.; Ren, Y.; Fan, S.; Zhao, S.: Laser-assisted cyclic chipless splitting for hard-to-cut thick wall tubes and fatigue fracture mechanism analysis. Int. J. Mech. Sci. 168, 105308 (2020)

Wang, C.Y.; Liao, H.Y.M.; Wu, Y.H.; Chen, P.Y.; Hsieh, J.W.; Yeh, I.H.: CSPNet: a new backbone that can enhance learning capability of CNN. In: Proceedings of the Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops, pp. 390–391 (2020)

Zhang, H.; Wang, Y.; Dayoub, F.; Sunderhauf, N.: Varifocalnet: an iou-aware dense object detector. In: Proceedings of the Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, pp. 8514–8523 (2021)

Lin, T.Y.; Goyal, P.; Girshick, R.; He, K.; Dollár, P.: Focal loss for dense object detection. In: Proceedings of the Proceedings of the IEEE International Conference on Computer Vision, pp. 2980–2988 (2017)

Li, X.; Wang, W.; Wu, L.; Chen, S.; Hu, X.; Li, J.; Tang, J.; Yang, J.: Generalized focal loss: learning qualified and distributed bounding boxes for dense object detection. Adv. Neural. Inf. Process. Syst. 33, 21002–21012 (2020)

Liu, M.; Wang, X.; Zhou, A.; Fu, X.; Ma, Y.; Piao, C.: Uav-yolo: small object detection on unmanned aerial vehicle perspective. Sensors 20, 2238 (2020)

Maragatham, G.; Roomi, S.M.M.: A review of image contrast enhancement methods and techniques. Res. J. Appl. Sci. Eng. Technol. 9, 309–326 (2015)

Zhang, H.; Cisse, M.; Dauphin, Y.N.; Lopez-Paz, D.: mixup: beyond empirical risk minimization. arXiv e-prints, pp. 1710 (2017)

Yun, S.; Han, D.; Oh, S. J.; Chun, S.; Choe, J.; Yoo, Y.: CutMix: regularization strategy to train strong classifiers with localizable features (2019). Available: http://arxiv.org/abs/1905.04899.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that there is no conflict of interest regarding the publication of this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Solihin, M.I. & Nugroho, H.A. RCA: YOLOv8-Based Surface Defects Detection on the Inner Wall of Cylindrical High-Precision Parts. Arab J Sci Eng (2024). https://doi.org/10.1007/s13369-023-08483-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-023-08483-4