Abstract

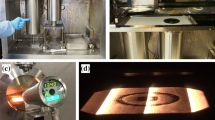

Blended powder semisolid forming (BPSF) includes powders uniform distribution, mechanical alloying, cold compaction, and semisolid heating. Homogenization of nanoparticles within matrix phase is a crucial step in production of BPSFed parts. In this research, with the aim of providing uniform distribution and dispersion, two sets of experiments were done. Firstly, 316L matrix particles (66–83 μm) and 1 wt% \({\mathrm{Al}}_{2}{\mathrm{O}}_{3\mathrm{np}}\) nanoparticles (50 nm) were mechanically milled at rotational speed of 200 rpm in a planetary ball mill at different mixing times (0.5, 1, 2, and 4 h). Secondly, ultrasonic treatment was added before mechanical alloying to deagglomerate nanoparticles. Subsequently, powders were blended using a planetary ball mill. 316L/1 wt% \({\mathrm{Al}}_{2}{\mathrm{O}}_{3\mathrm{np}}\) blended powders were cold compacted under a pressure of 700 MPa. The semisolid heating process was conducted in a liquid fraction of 30%. Blended powder morphology, microstructure, mechanical properties, and phase formation of the samples were investigated. The obtained results indicate that low mechanical mixing times can only improve distribution. Using ultrasonic before ball milling guaranties uniform distribution and dispersion in BPSF. Ultrasonic treatment significantly deagglomerates clusters of nanoparticles and sticks them to the matrix particle surfaces. BPSFed 316L/1 wt % \({\mathrm{Al}}_{2}{\mathrm{O}}_{3\mathrm{np}}\) composite indicated porosity, hardness, and compressive strength of 7.45%, 267 HV10, and 951 MPa, respectively. Obtained physical and mechanical properties of the sample are superior compared to the properties of parts obtained from casting and powder metallurgy routes.

Similar content being viewed by others

References

Moreira, A.B., et al.: Production and characterization of austenitic stainless steel cast parts reinforced with wc particles fabricated by ex situ technique. Materials (Basel) 14(24), 7855 (2021)

McGuire, M.F.: Stainless steels for design engineers. ASM International, Netherlands (2008)

Kandala, S.R.; Balani, K.; Upadhyaya, A.: Mechanical and electrochemical characterization of supersolidus sintered austenitic stainless steel (316 L). High Temp. Mater. Processes (London) 2019(38), 792–805 (2019)

Lo, K.H.; Shek, C.H.; Lai, J.K.L.: Recent developments in stainless steels. Mater. Sci. Eng. R. Rep. 65(4), 39–104 (2009)

de Lima, M.S.F.; Sankaré, S.: Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers. Mater. Des. 55, 526–532 (2014)

Jamaati, R.; Toroghinejad, M.R.: High-strength and highly-uniform composite produced by anodizing and accumulative roll bonding processes. Mater. Des. 31(10), 4816–4822 (2010)

Ibrahim, I.A.; Mohamed, F.A.; Lavernia, E.J.: Particulate reinforced metal matrix composites—a review. J. Mater. Sci. 26(5), 1137–1156 (1991)

Miracle, D.B.: Metal matrix composites—From science to technological significance. Compos. Sci. Technol. 65(15), 2526–2540 (2005)

Moya, J.S.; Lopez-Esteban, S.; Pecharromán, C.: The challenge of ceramic/metal microcomposites and nanocomposites. Prog. Mater. Sci. 52(7), 1017–1090 (2007)

Tjong, S.C.: Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 9(8), 639–652 (2007)

Ajayan, P.M.: Bulk metal and ceramics nanocomposites, In: Nanocomposite Sci. Technol. 1–7 (2003)

Oxana Vasilievna Kharissova, L.; Myriam Torres-MartínezKharisov, B.I.: Handbook of nanomaterials and nanocomposites for energy and environmental applications. Springer, Berlin (2021)

Suryanarayana, C.: Mechanical alloying and milling. Prog. Mater. Sci. 46(1), 1–184 (2001)

Javdani, A.; Daei-Sorkhabi, A.H.: Microstructural and mechanical behavior of blended powder semisolid formed Al7075/B4C composites under different experimental conditions. Trans Nonferrous Metals Soc. China 28(7), 1298–1310 (2018)

Mussatto, A., et al.: Advanced production routes for metal matrix composites. Eng. Rep. 3(5), e12330 (2021)

Javdani, A., et al.: Blended powder semisolid forming of Al7075/Al2O3 composites: investigation of microstructure and mechanical properties. Mater. Des. 109, 57–67 (2016)

Sajjadi, S.A.; Ezatpour, H.R.; Beygi, H.: Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater. Sci. Eng. A 528(29), 8765–8771 (2011)

Lloyd, D.J.: Particle reinforced aluminium and magnesium matrix composites. Int. Mater. Rev. 39(1), 1–23 (1994)

Zebarjad, S.M.; Sajjadi, S.A.: Microstructure evaluation of Al–Al2O3 composite produced by mechanical alloying method. Mater. Des. 27(8), 684–688 (2006)

Wu, Y.: Development of novel semisolid powder processing for micromanufacturing, in department of mechanical engineering. IOWA State University, Ames (2009)

Suryanarayana, C.: Mechanical Alloying: A Novel Technique to Synthesize Advanced Materials. Research (2019). https://doi.org/10.34133/2019/4219812

Gao, M.C.; Yeh, J.W.; Liaw, P.K.; Zhang, Y.: High-entropy alloys: fundamentals and applications. Springer, Berlin (2016)

Li, G., et al.: Current progress in rheoforming of wrought aluminum alloys: a review. Metals (2020). https://doi.org/10.3390/met10020238

Jiang, J., et al.: Microstructure, mechanical properties and wear behavior of the rheoformed 2024 aluminum matrix composite component reinforced by Al2O3 nanoparticles. Metals (2018). https://doi.org/10.3390/met8060460

Luo, X., et al.: The current status and development of semi-solid powder forming (SPF). JOM 71(12), 4349–4361 (2019)

Young, R.M.K.; Clyne, T.W.: A powder-based approach to semisolid processing of metals for fabrication of die-castings and composites. J. Mater. Sci. 21(3), 1057–1069 (1986)

Morooka, T., et al.: fundamental study on semi-solid diecasting by using powder influence of stirring in semi-solid state of mixed Al-Si powder. J. Jpn. Soc. Powder Powder Metall. 42(3), 336–340 (1995)

Luo, S.J.: Semi-solid extrusion of TiCp/2024Al composites prepared by contact reaction method. Trans. Nonferrous Met. Soc. China 10, 304–308 (2000)

Cheng, Y.; L, S.J.; Du M, Z.: Thixoforming of SiC ceramic matrix composites in pseudo-semi-solid state. Trans. Nonferrous Metals Soc. China 15(5), 1062–1066 (2005)

Luo, S.-J.; Cheng, Y.-S.; Wang, P.-X.: Pseudo-semi-solid thixoforging of cup shell with Al/Al2O3. Trans. Nonferrous Metals Soc. China 16(4), 772–775 (2006)

Hamilton, R.W., et al.: Direct semi-solid forming of a powder SiC–Al PMMC: flow analysis. Compos. A Appl. Sci. Manuf. 34(4), 333–339 (2003)

Yasue, K., et al.: Elemental blended powders semisolid forming of Ti-Al based alloys. J. Mater. Sci. 35(23), 5927–5932 (2000)

Wen, C.E.; Yasue, K.; Yamada, Y.: Fabrication of TiAl by blended elemental powder semisolid forming. J. Mater. Sci. 36(7), 1741–1745 (2001)

Wu, Y.: Fabrication of metal matrix composite by semi-solid powder processing, in mechanical engineering department. IOWA State University, Ames (2011)

Bastwros, M., et al.: Effect of ball milling on graphene reinforced Al6061 composite fabricated by semi-solid sintering. Compos. B Eng. 60, 111–118 (2014)

Liu, Y.; Luo, X.; Li, Z.: Microstructure evolution during semi-solid powder rolling and post-treatment of 7050 aluminum alloy strips. J. Mater. Process. Technol. 214(2), 165–174 (2014)

Luo, X., et al.: Semi-solid powder rolling of AA7050 alloy strips: densification and deformation behaviors. Metall. and Mater. Trans. A. 46, 2185–2193 (2015)

Wu, M., et al.: Deformation behavior and forming process simulation of semi-solid powder rolling based on the combined constitutive model. Mater. Res. Express 9(12), 126510 (2022)

Plata, G., et al.: Semisolid forging of steels: readiness from an industrial point of view. AIP Conf. Proc. 2113(1), 140001 (2019)

Dudek, A.; Włodarczyk, R.: Composite 316L+Al2O3 for application in medicine. Mater. Sci. Forum 706–709, 643–648 (2012)

Ben Zine, H.R., et al.: Novel alumina dispersion-strengthened 316l steel produced by attrition milling and spark plasma sintering. Coatings (2023). https://doi.org/10.3390/coatings13020322

Roohi, A.H.; Mirsadeghi, A.; Sadooghi, A.: Investigation of structural, mechanical, and corrosion properties of steel 316L reinforcement by hBN and TiC particles. Mater. Res. Express 9(6), 065006 (2022)

Shin, S., et al.: Dispersion mechanism and mechanical properties of sic reinforcement in aluminum matrix composite through stir- and die-casting processes. Appl. Sci. (2021). https://doi.org/10.3390/app11030952

Suryanarayana, C.: Mechanical alloying: a critical review. Mater. Res. Lett. 10(10), 619–647 (2022)

Zhao, Z., et al.: Microstructure and mechanical properties of tic-reinforced 316l stainless steel composites fabricated using selective laser melting. Metals (2019). https://doi.org/10.3390/met9020267

Salman, O.O., et al.: Additive manufacturing of a 316l steel matrix composite reinforced with CeO2 particles: process optimization by adjusting the laser scanning speed. Technologies (2018). https://doi.org/10.3390/technologies6010025

Behera, B.P.: Synthesis of nano-structured stainless steel powder by mechanical alloying and characterization. In: Jena, S.K. (Ed.) Metallurgical and materials engineering. National Institute of Technology, Rourkela (2013)

Safia, A.; Saida, S.; Joan Joseph, S.O.: Thermal stability of the nanostructured powder mixtures prepared by mechanical alloying. In: Amal Ali, E. (Ed.) Applications of calorimetry in a wide context. IntechOpen, Rijeka (2013)

AlMangour, B.; Grzesiak, D.; Yang, J.-M.: Rapid fabrication of bulk-form TiB2/316L stainless steel nanocomposites with novel reinforcement architecture and improved performance by selective laser melting. J. Alloy. Compd. 680, 480–493 (2016)

Sumanth Kumar, D.; Jai Kumar, B.; Mahesh, H.M.: Chapter 3 Quantum nanostructures (QDs): an overview. In: Mohan Bhagyaraj, S., et al. (Eds.) Synthesis of inorganic nanomaterials. Woodhead Publishing, Cambridge (2018)

Ghayour, H.; Abdellahi, M.; Bahmanpour, M.: Optimization of the high energy ball-milling: modeling and parametric study. Powder Technol. 291, 7–13 (2016)

Li, X., et al.: Selective laser melting of stainless steel and alumina composite: experimental and simulation studies on processing parameters, microstructure and mechanical properties. Mater. Des. 145, 1–10 (2018)

Gülsoy, H.Ö.; Baykara, T.; Özbek, S.: Injection moulding of 316L stainless steels reinforced with nanosize alumina particles. Powder Metall. 54(3), 360–365 (2011)

Mahathanabodee, S.; T.P.; Raadnui, S.; Tongsri, R.; Sombatsompop, N.: Microstructure, physical properties and wear behavior of ss316l/h-bn composites, In: 8th Asian-Australasian Conference on Composites Materials, Kuala Lumpur, Malaysia (2012)

Imbaby, M.F.; Jiang, K.: Fabrication of free standing 316-L stainless steel–Al2O3 composite micro machine parts by soft moulding. Acta Mater. 57(16), 4751–4757 (2009)

Khakbiz, M.; Simchi, A.; Bagheri, R.: Investigation of rheological behaviour of 316L stainless steel–3 wt-%TiC powder injection moulding feedstock. Powder Metall. 48(2), 144–150 (2005)

Li, B., et al.: Additive manufacturing of ultrafine-grained austenitic stainless steel matrix composite via vanadium carbide reinforcement addition and selective laser melting: formation mechanism and strengthening effect. Mater. Sci. Eng. A 745, 495–508 (2019)

Park, K., et al.: Semisolid state sintering behavior of aluminum-stainless steel 316l composite materials by powder metallurgy. Materials (Basel) 12(9), 1473 (2019)

Tanprayoon, D., et al.: Microstructure and hardness response of novel 316L stainless steel composite with TiN addition fabricated by SLM. Opt. Laser Technol. 129, 106238 (2020)

Zhai, W., et al.: Characterization of nanoparticle mixed 316 L powder for additive manufacturing. J. Mater. Sci. Technol. 47, 162–168 (2020)

Zhao, S., et al.: Densification behavior and mechanical properties of nanocrystalline TiC reinforced 316L stainless steel composite parts fabricated by selective laser melting. Opt. Laser Technol. 103, 239–250 (2018)

Radhamani, A.V., et al.: Structural, mechanical and tribological investigations of CNT-316 stainless steel nanocomposites processed via spark plasma sintering. Tribol. Int. 152, 106524 (2020)

Ansell, T.Y., et al.: Effect of high energy ball milling on spherical metallic powder particulates for additive manufacturing. Part. Sci. Technol. 39(8), 981–989 (2021)

Malaki, M., et al.: Advanced Metal Matrix Nanocomposites. Metals (2019). https://doi.org/10.3390/met9030330

Mao, Y., et al.: Effect of sintering temperature on binder jetting additively manufactured stainless steel 316L: densification, microstructure evolution and mechanical properties. J. Market. Res. 22, 2720–2735 (2023)

ASTM: ASTM B311–17 Standard test method for density of powder metallurgy (PM) material containing less than two percent porosity. ASTM International, West Conshohocken (2017)

Nanda, B.P.; Satapathy, A.: Processing and characterization of epoxy composites reinforced with short human hair. IOP Conf. Ser. Mater. Sci. Eng. 178(1), 012012 (2017)

ASTM: ASTM E92–17. Standard test methods for Vickers hardness and Knoop hardness of metallic materials. ASTM International, West Conshohocken (2009)

ASTM: ASTM E9–19: standard test methods of compression testing of metallic materials at room temperature. ASTM International, West Conshohocken (2019)

Malaki, M., et al.: Wettability in metal matrix composites. Metals (2021). https://doi.org/10.3390/met11071034

Prabu, S.B., et al.: Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite. J. Mater. Process. Technol. 171(2), 268–273 (2006)

Vaghari, M.; Khayati, G.R.; Jenabali Jahromi, S.A.: Studying on the fatigue behavior of Al- Al2O3 metal matrix nano composites processed through powder metallurgy. J Ultrafine Grained Nanostn. Mater. 52(2), 210–217 (2019)

Razavi Hesabi, Z.; Hafizpour, H.R.; Simchi, A.: An investigation on the compressibility of aluminum/nano-alumina composite powder prepared by blending and mechanical milling. Mater. Sci. Eng. A 454–455, 89–98 (2007)

Bevan, M.A.; et al.: Mechanical properties and behavior of additive manufactured stainless steel 316L. In: Characterization of minerals, metals, and materials 2017. (2017) Springer

Balázsi, C., et al.: Microstructural and magnetic characteristics of ceramic dispersion strengthened sintered stainless steels after thermal ageing. Fusion Eng. Des. 145, 46–53 (2019)

Albahlol, O.A., et al.: Investigation of microstructure and mechanical properties of layered material produced by adding Al2O3 to 316L stainless steel. Metals (2023). https://doi.org/10.3390/met13071226

Dandekar, C.R.; Shin, Y.C.: Effect of porosity on the interface behavior of an Al2O3–aluminum composite: a molecular dynamics study. Compos. Sci. Technol. 71(3), 350–356 (2011)

Chen, C., et al.: Aluminum powder size and microstructure effects on properties of boron nitride reinforced aluminum matrix composites fabricated by semi-solid powder metallurgy. Mater. Sci. Eng. A 646, 306–314 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Javdani, A., Ahmadi Najafabadi, M. Achieving Homogeneous Distribution and Dispersion of \({\mathrm{Al}}_{2}{\mathrm{O}}_{3\mathrm{np}}\) Nanoparticles within 316L Matrix for Production of Metal Matrix Nanocomposites via Blended Powder Semisolid Forming. Arab J Sci Eng (2023). https://doi.org/10.1007/s13369-023-08437-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13369-023-08437-w